To my other TR6 pages

November 10, 2015

Installing the Drive Train

My

whole summer and fall was occupied with getting the tub under paint.

That done, I could finally return to the rolling frame and start

bolting on some of the big heavy lumps that have been cluttering every

horizontal surface in my shop for a year or more.

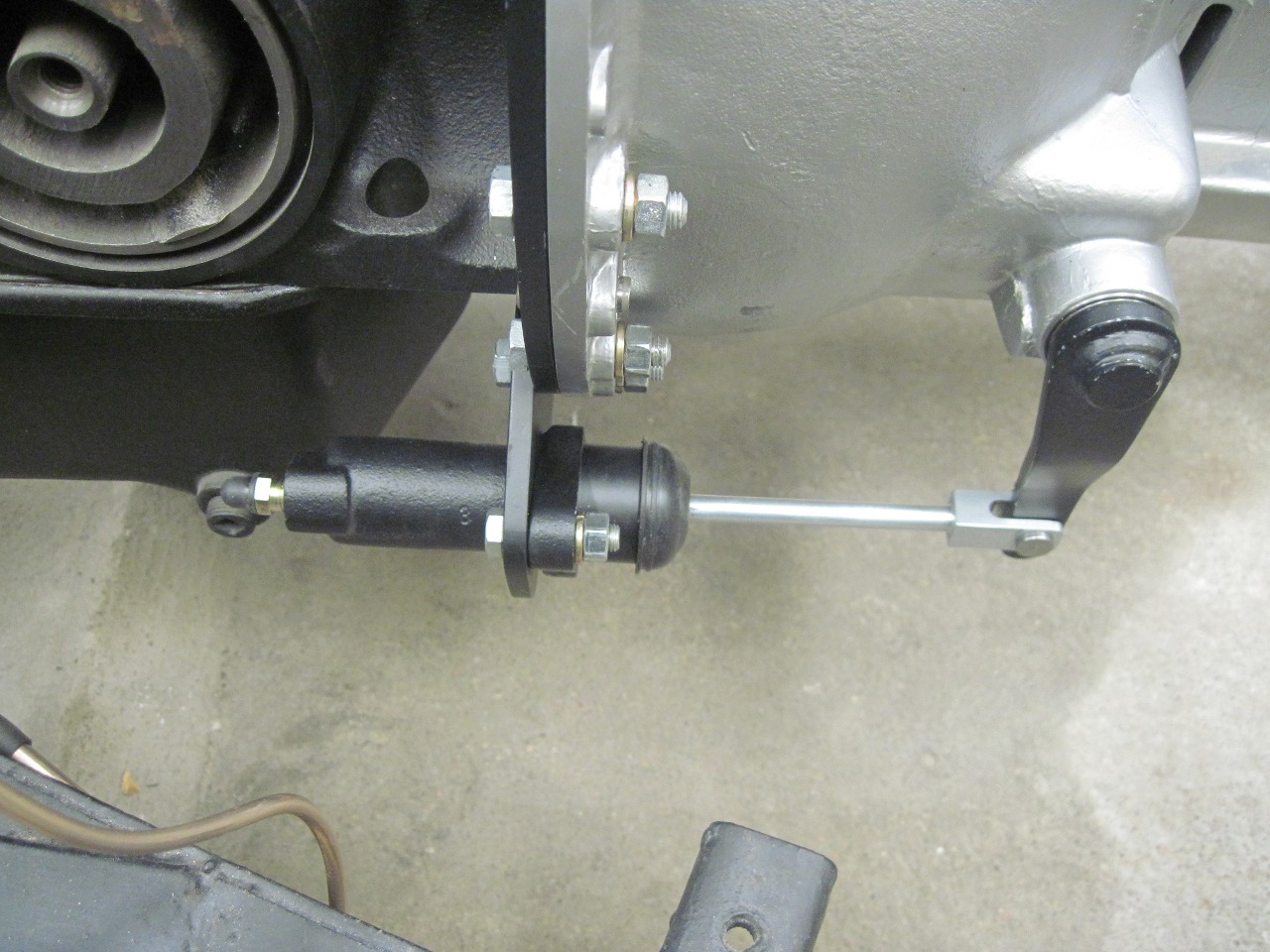

First up was

this rather ungainly contraption. It's the rear transmission

mount. It's been powder coated and fitted with new rubber parts

and original hardware.

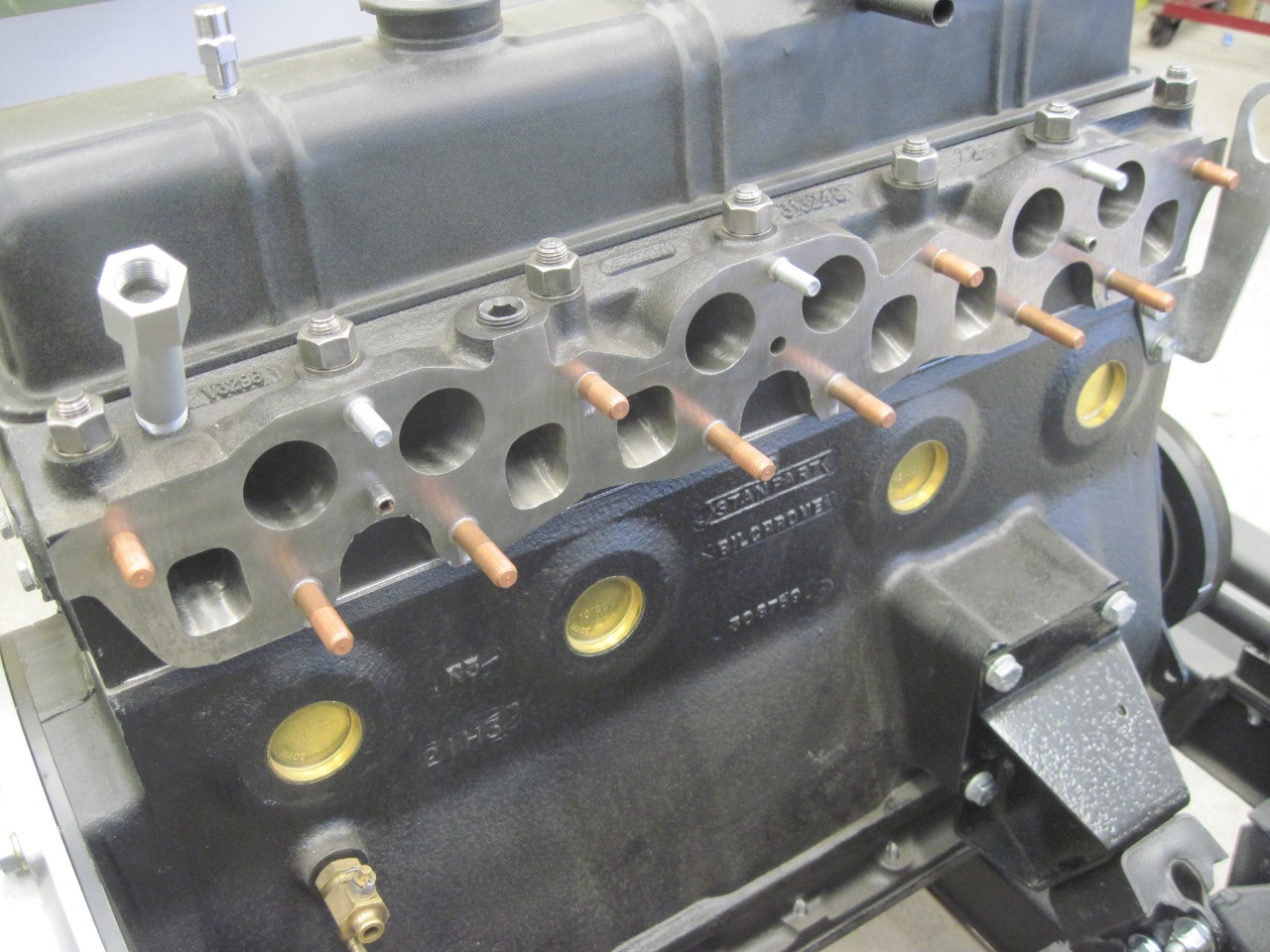

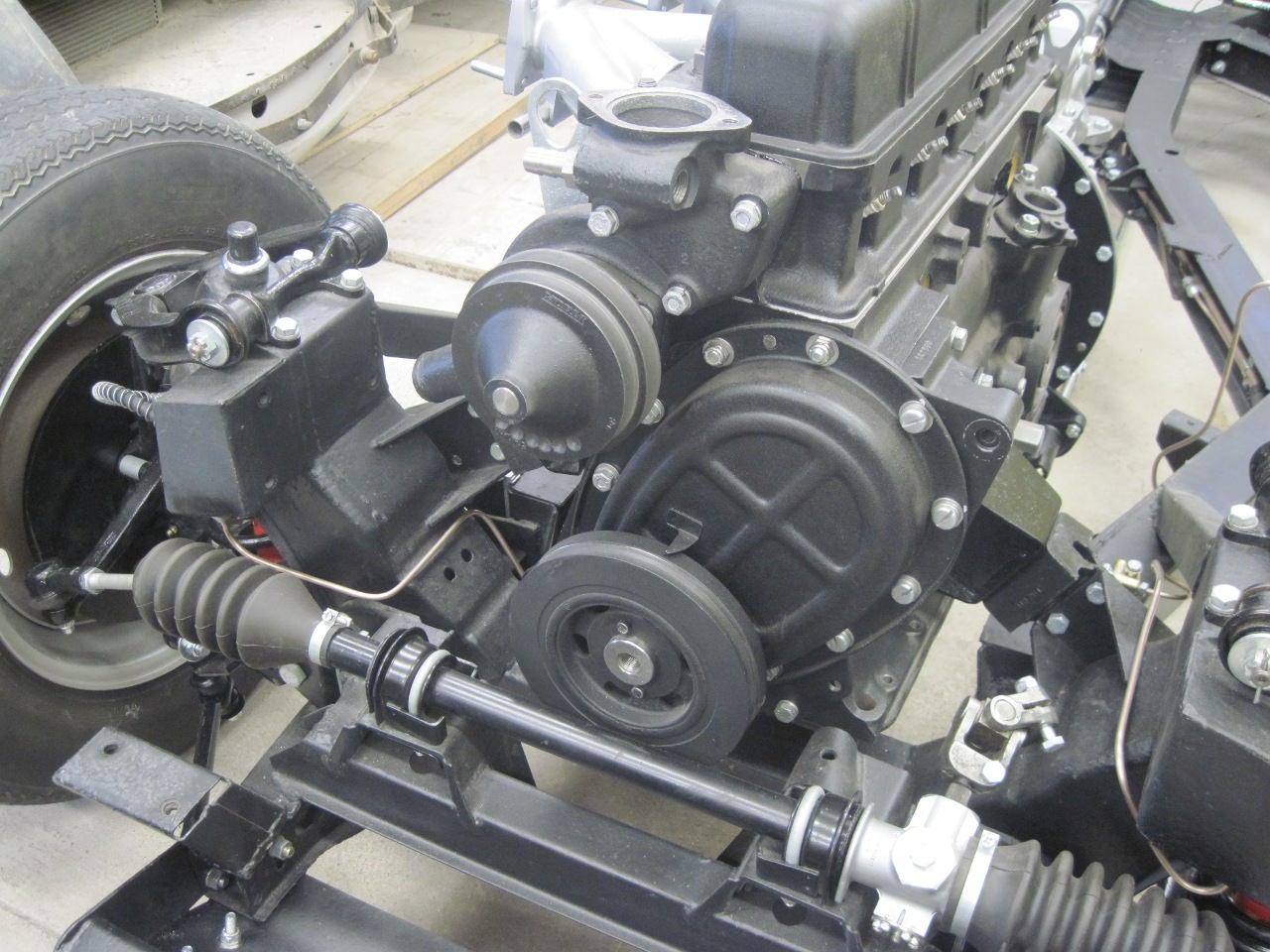

I

brought the rebuilt engine up from the shop, and started prepping it to

go into the frame. It has to be married to the gear box, and both

installed as a unit. First, the flywheel and clutch

had to be mounted. The pilot bearing for the gearbox input shaft

goes in the flywheel. It's captive, so has to go in before the

flywheel is mounted.

Flywheel

is held on by four beefy hex screws. Torquing them just tends to

turn the crankshaft, so I had to install the exclusive ACME 1000B

flywheel stopper.

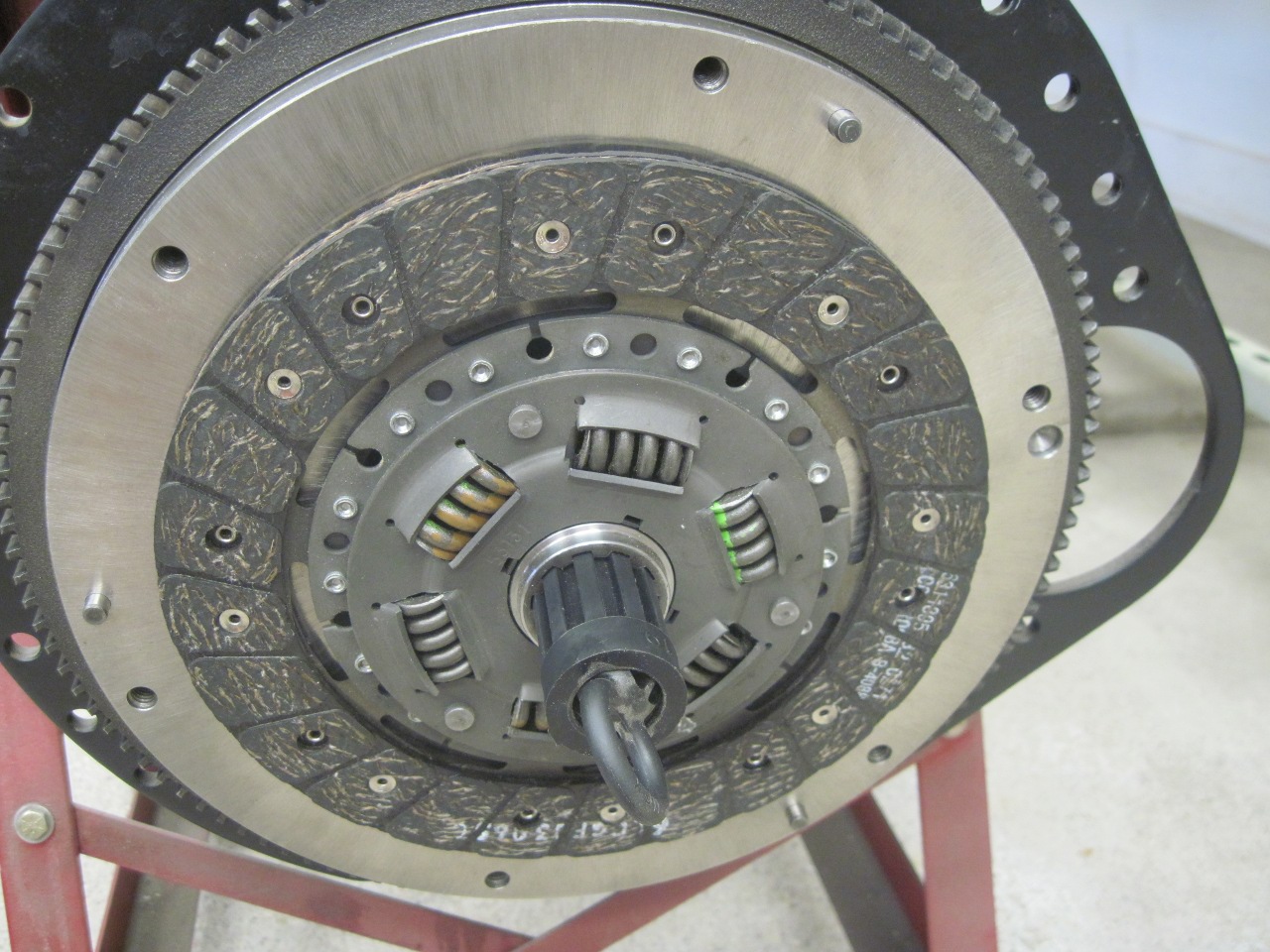

Next

is the clutch disc, which has to be aligned precisely with the pilot

bearing, or the gearbox input shaft will never mate properly.

Luckily, there is an alignment tool for this.

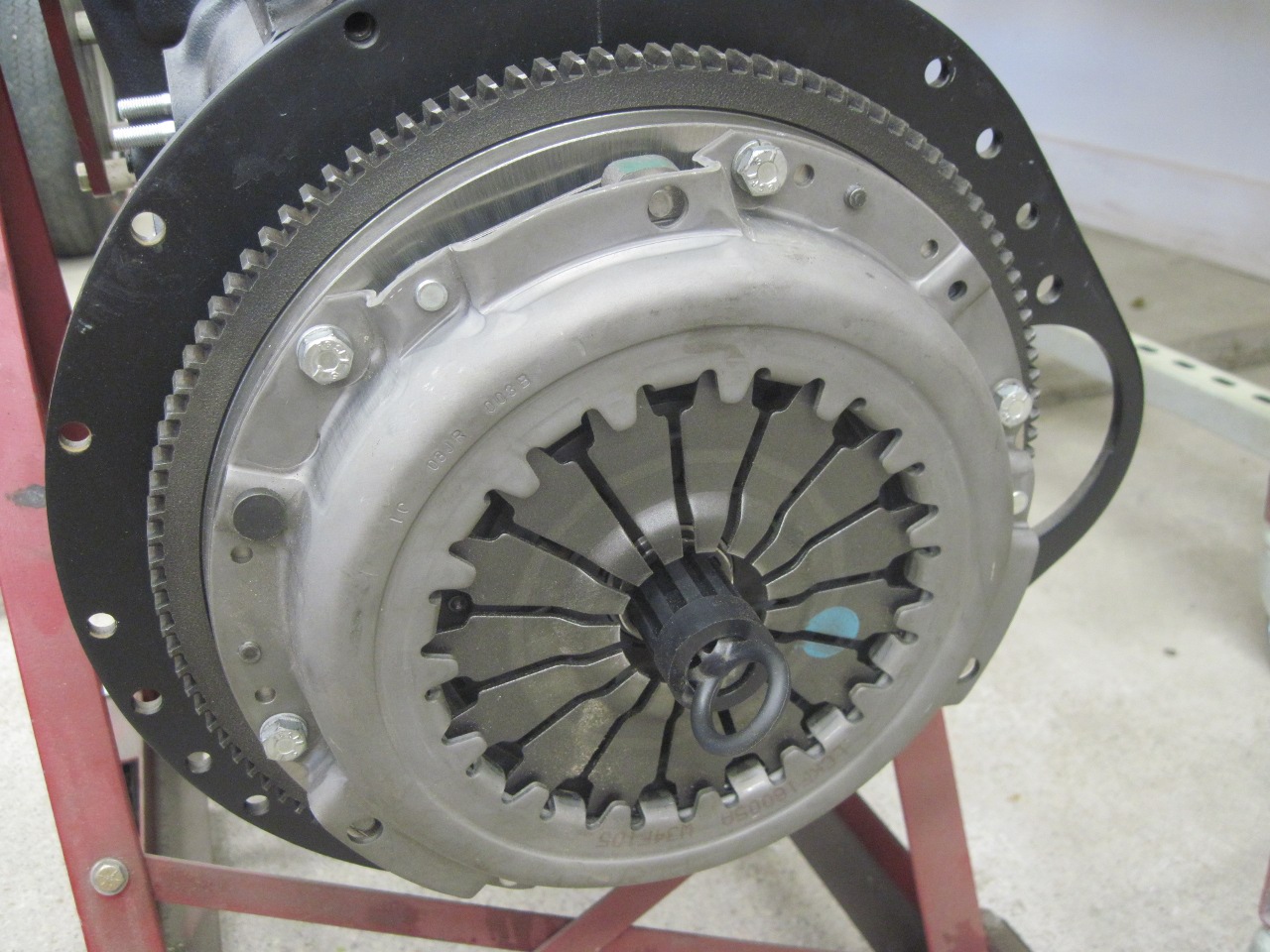

The rest of the clutch assembly is then fastened into place.

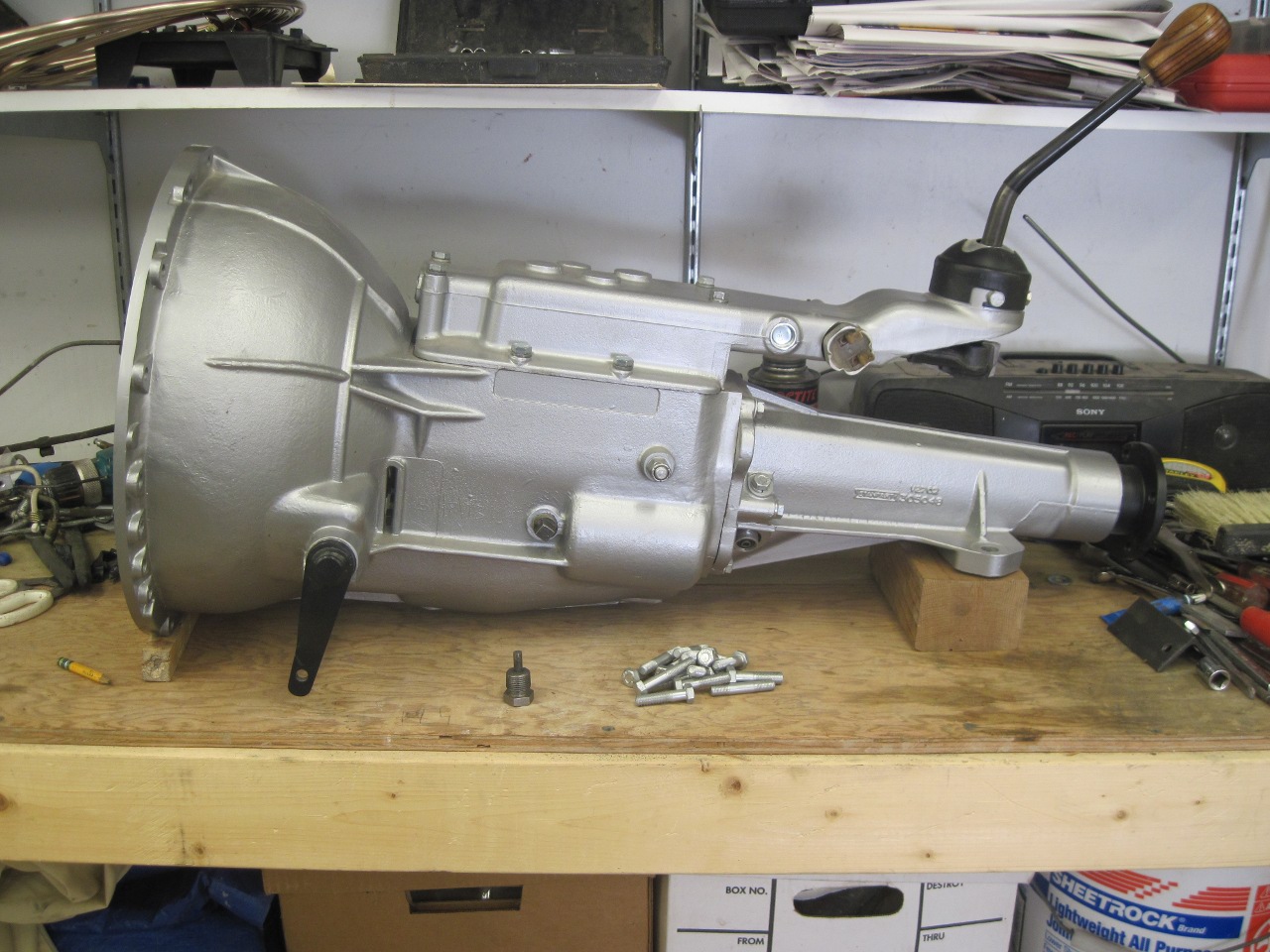

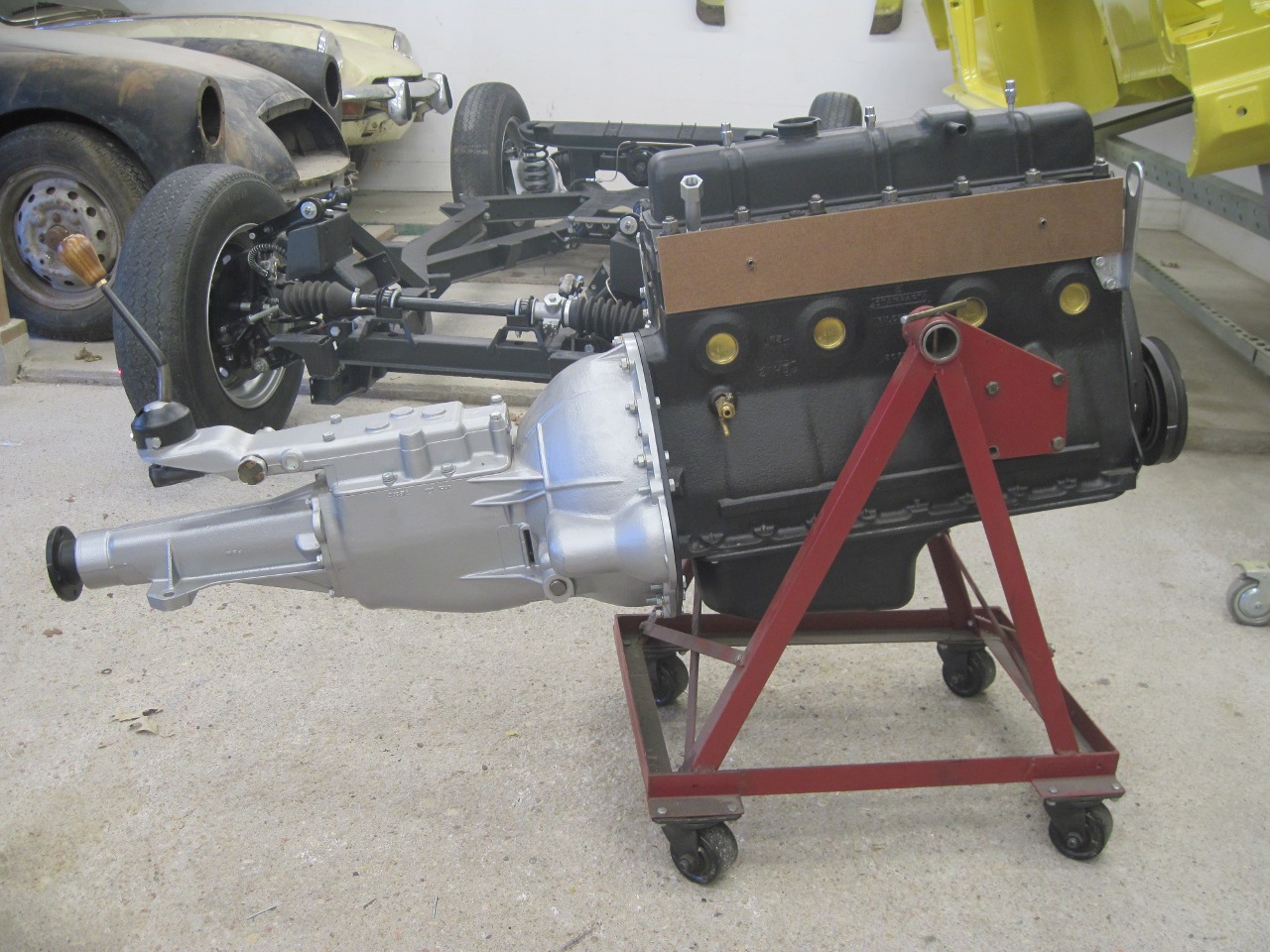

I hauled up the rebuilt gearbox, and checked the clutch actuating components in the bell housing. I still had the original bell housing bolts.

I was doing this solo, so my recruited my shyhook to help with the mating ceremony.

Attached

the skyhook to the engine/gearbox, and lifted it out of the

cradle the engine has been in for nearly two years.

Bolted the front motor mounts to the engine, and took it on

home. Finally--body and soul together again!

To finish off the drive train, I dug out the rebuilt drive shaft. It was pretty satisfying to slide it into place.

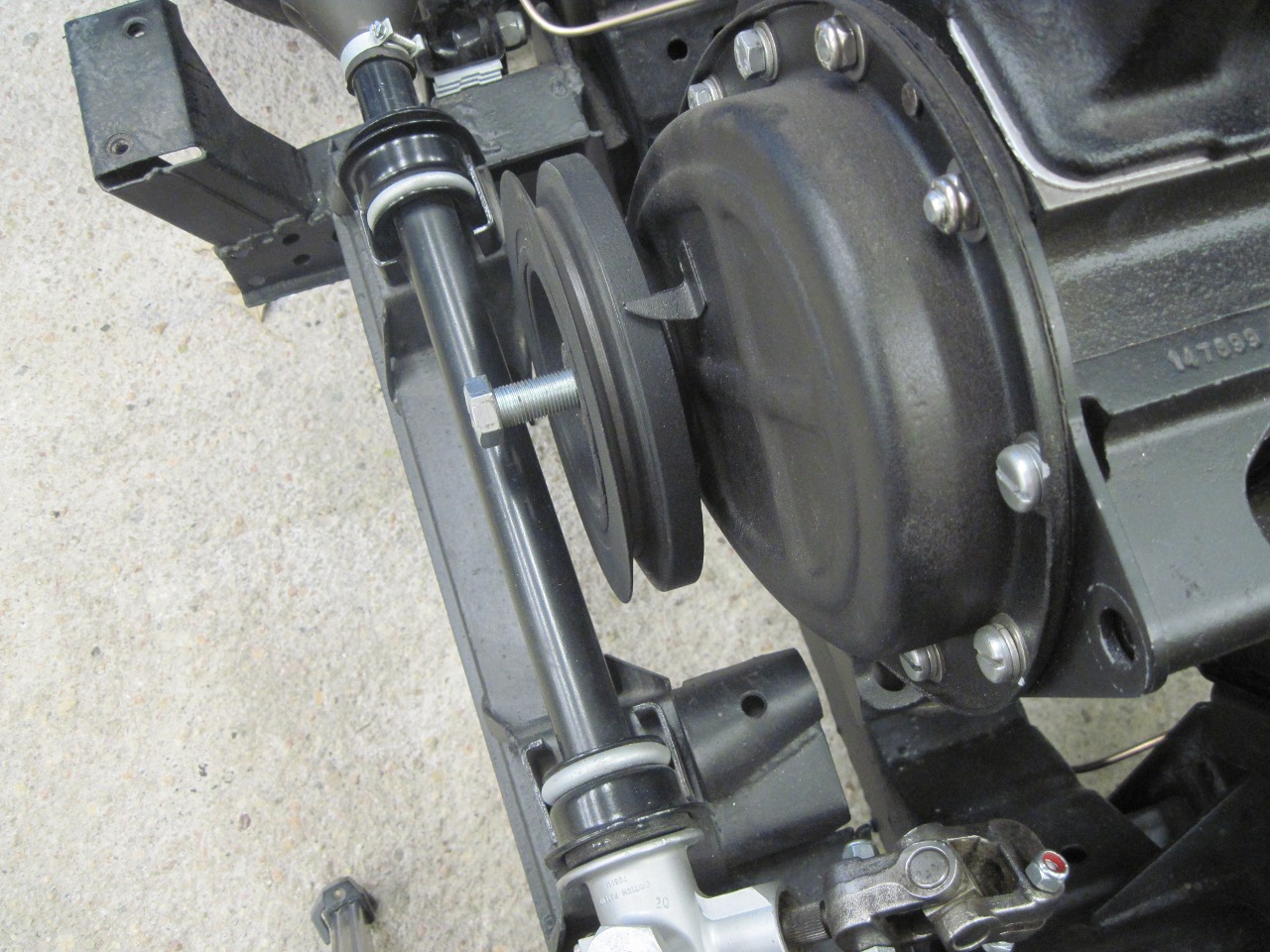

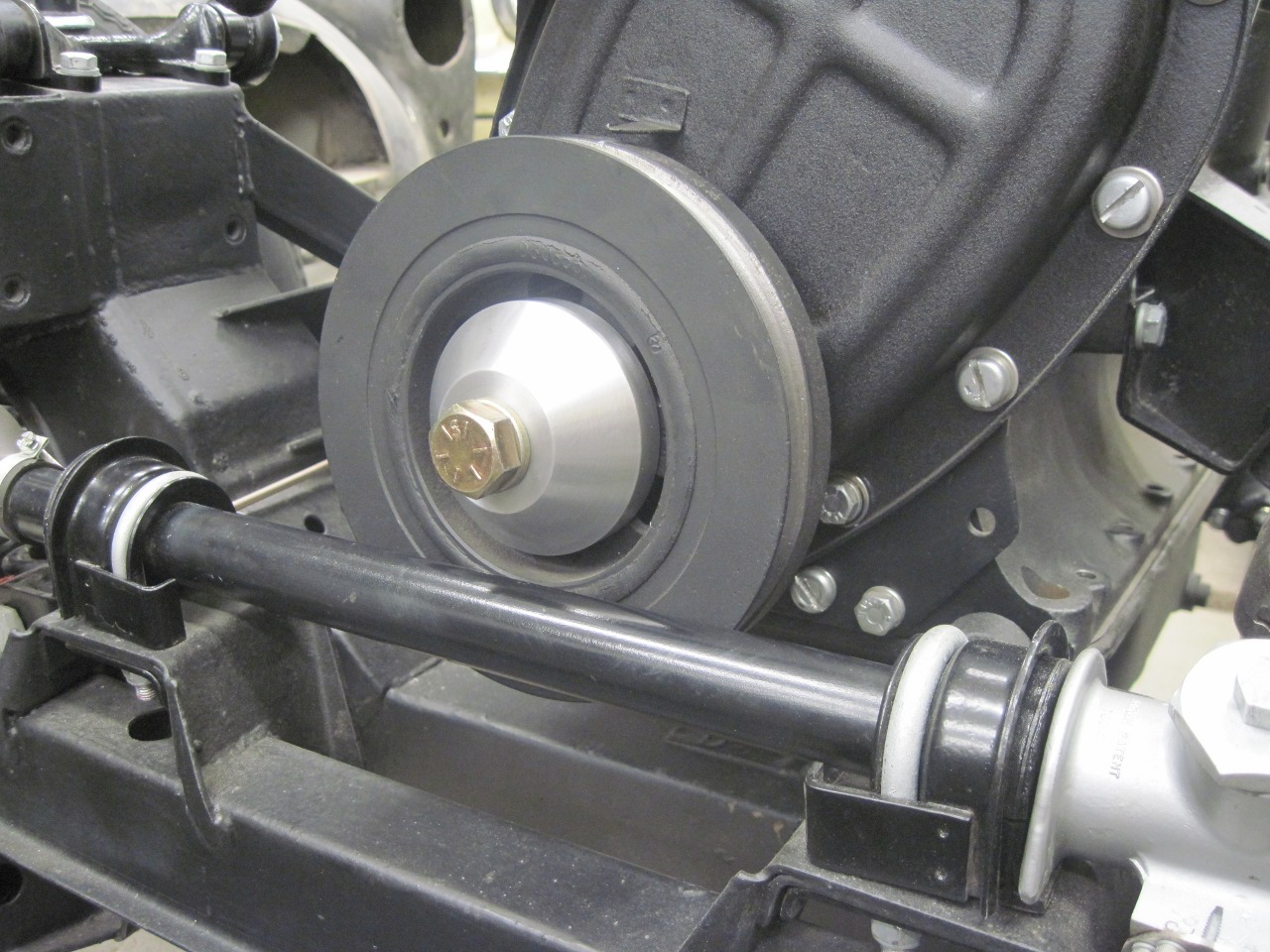

There

is a common complaint among TR6 owners that the damper wheel at the

front of the engine is so close to the steering rack that a fanbelt

can't be squeezed through. Well, I found that by keeping all of

the motor and gearbox mount bolts loose and pushing back on the engine,

there was enough leeway in the slotted mount holes to get 1/2 inch of

clearance. That should be enough to sneak a fanbelt through.

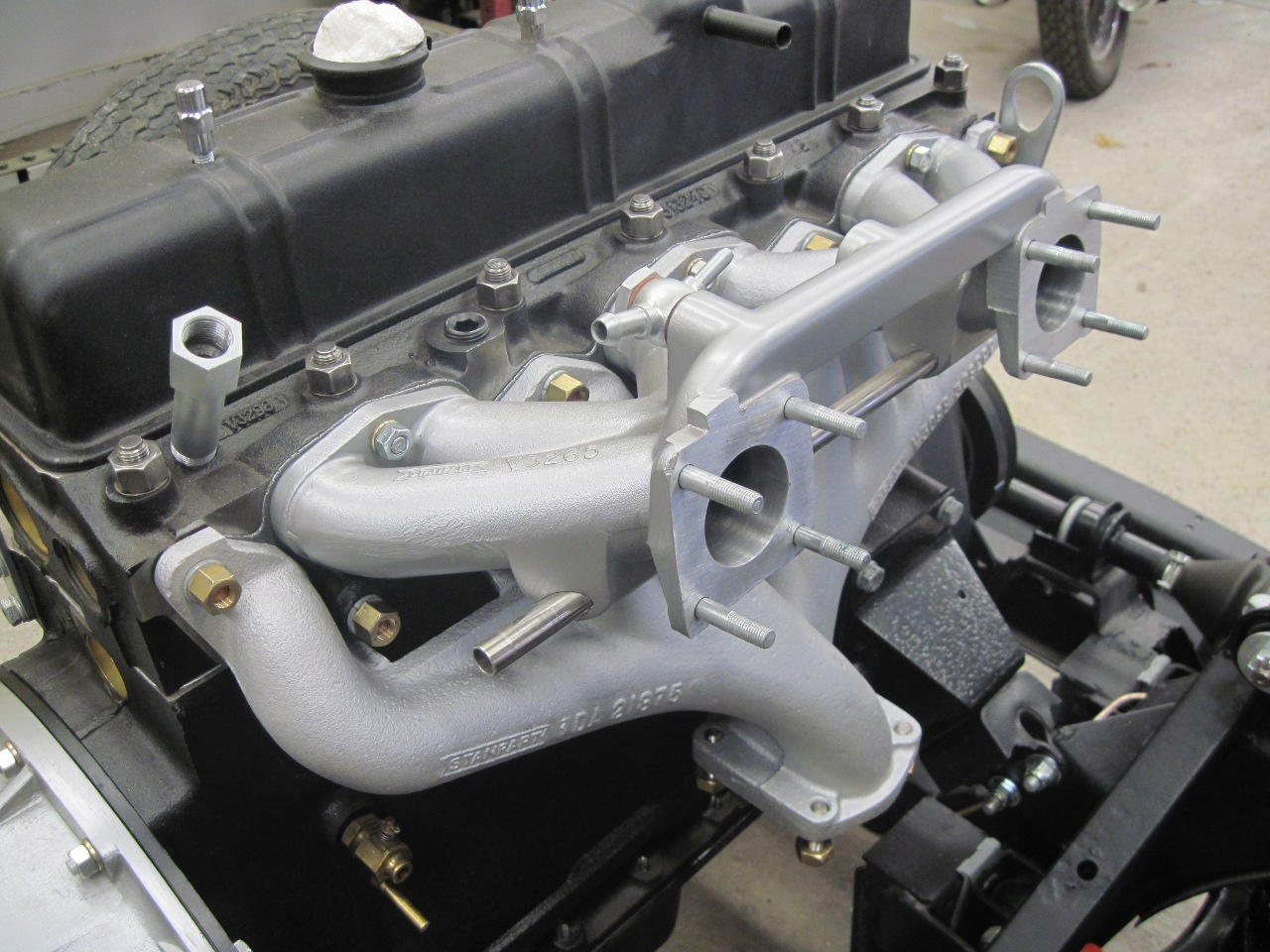

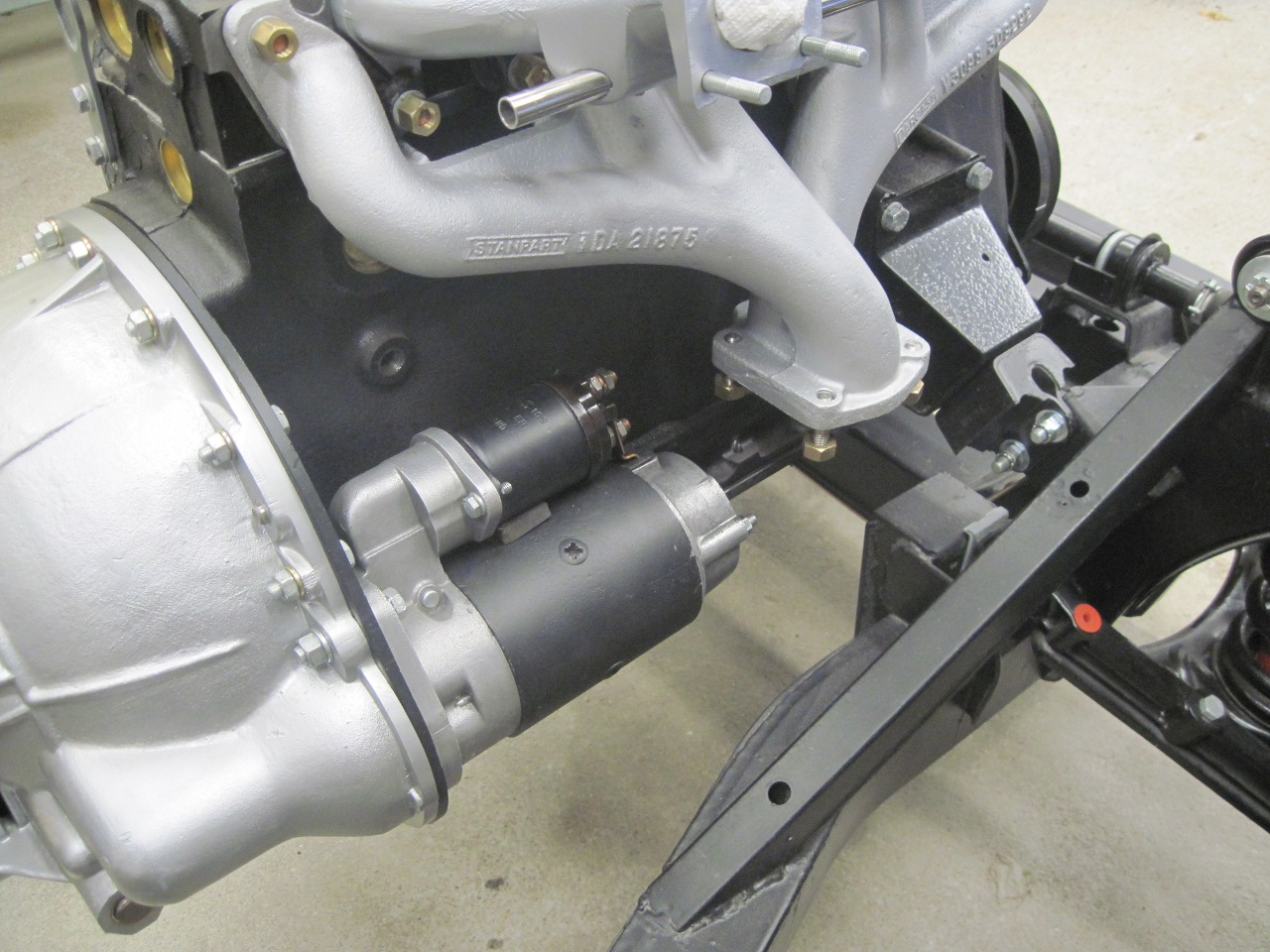

I'm

going to install the exhaust system before the tub goes on the frame,

and also want to investigate some carburettor heat shielding, so I went

ahead and installed the exhaust and intake manifolds.

And the starter.

And the clutch slave.

And the water pump.

I can never seem to remember to order gaskets, so that's a

home-made one. It takes a little time, but they always fit.

And lastly, my home made fan eliminator.

I'm getting dangerously close to getting the tub back on the frame!

Comments to Ed at: elhollin1@yahoo.com

To my other TR6 pages