To my other TR6 pages

April 13, 2014

Flywheel and Clutch

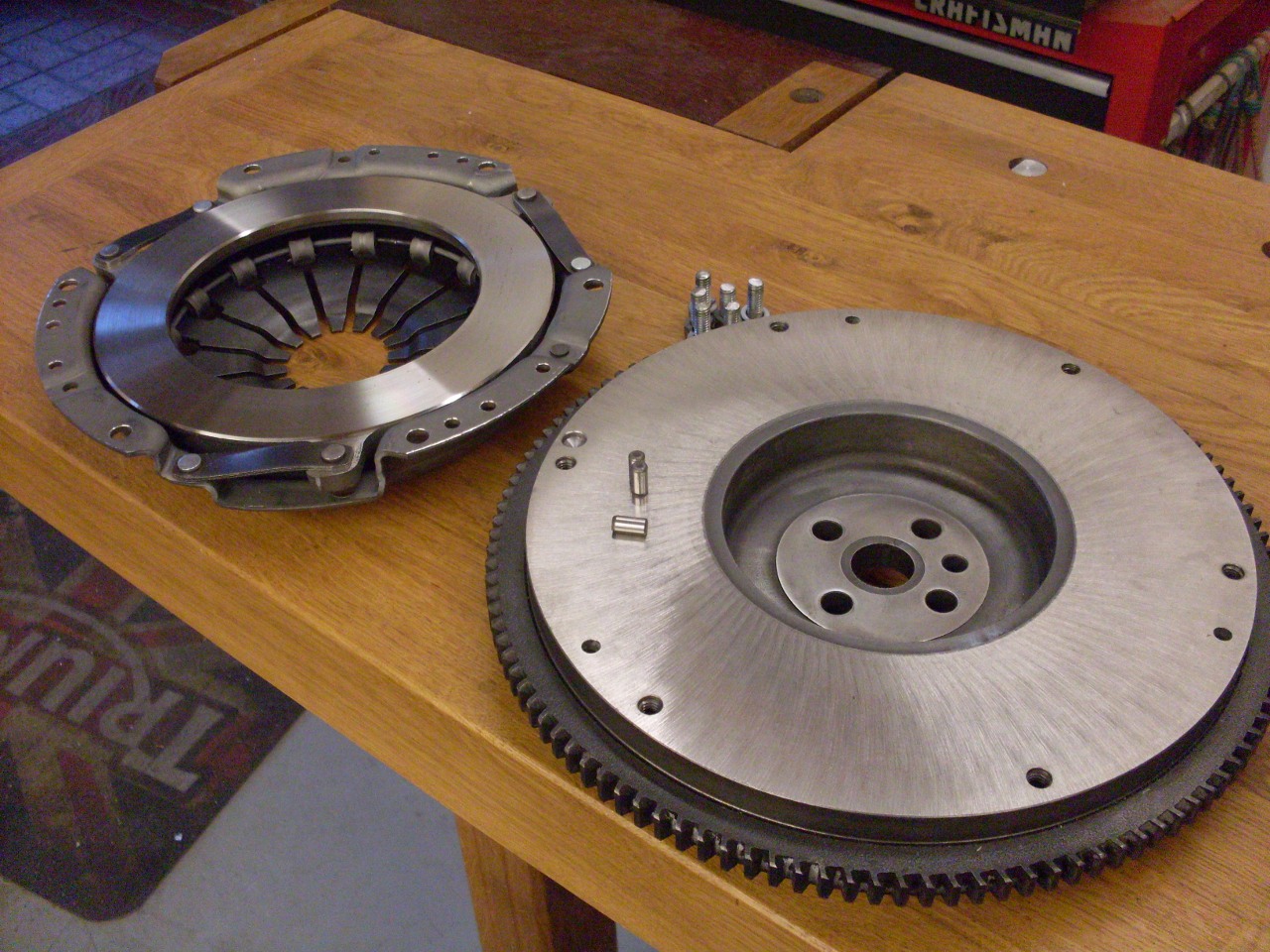

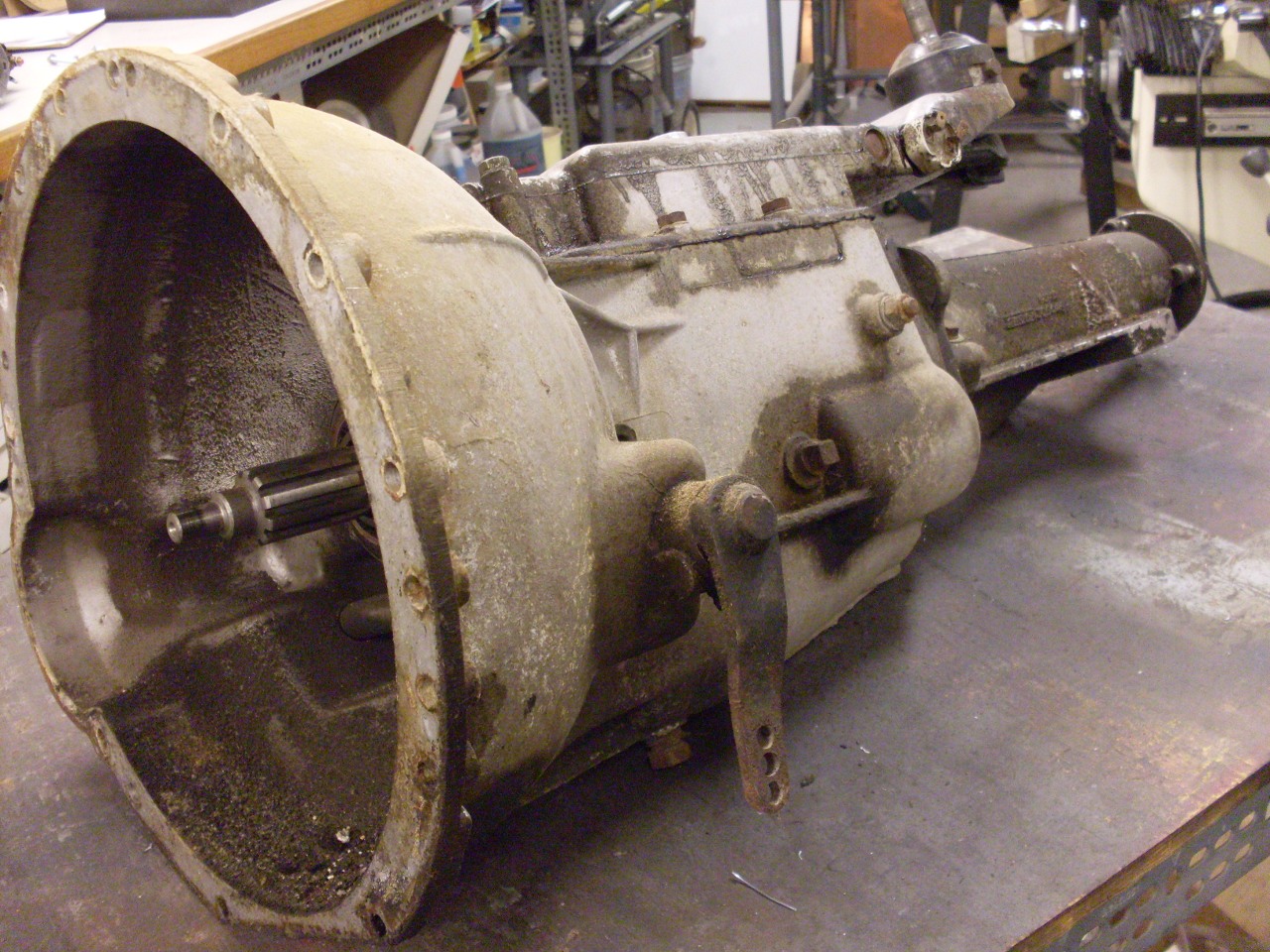

With the engine and transmission finished, the only remaining pieces between them are the flywheel and clutch.

The flywheel is a massive piece of iron that rotates on the rear

end of the crankshaft. It serves to damp the torque pulses from

the individual cylinders, smoothing out the delivery of energy to

the drive train. However, one of the downsides of a heavy flywheel is

that it takes significant energy to increase its rotational velocity.

This can take away from the linear acceleration the car is

capable of.

One popular performance modification for these and

many other engines is to lighten the flywheel by an amount that will

allow better acceleration, but not impair the smoothing action.

Unfortunately, while simple in principle, it's a little more

complicated than just hacking pieces of the flywheel off. First,

the flywheel must maintain sufficient strength to withstand the very

large forces generated at high RPMs. Second, the flywheel has to

remain balanced so that it doesn't contribute vibrations of its own.

Beyond these things, it turns out that it is very important where the weight is removed. A flywheel resists acceleration by its moment of inertia

(MI). The total MI of a flywheel depends not only on the mass of

the wheel, but how the mass is distributed. Mass near the

periphery of the wheel contributes much more to the total MI than mass

nearer the spin axis. So to be most effective, flywheel material

has to be removed as far from the spin axis as possible, consistent

with strength and balance.

One

interesting way to look at the

effect of lightening a flywheel is to calculate the equivalent weight

that would have to be removed from the car to give the same increase in

acceleration. The basis for this comparison goes something like

this: When accelerating, some of the energy developed by the

engine must be used to accelerate the flywheel. This energy is

not available to drive the wheels. If we lighten the flywheel so

that it takes less energy to accelerate it, the more the drive train

will see. There's more, and here is where it gets interesting.

Since there is a gear reduction between the engine and the drive

wheels, there is a torque multiplication. This means that any

increase in torque into the drive train will be multiplied by the gear

ratio before it gets to the wheels. This increased torque at the

wheels translates into a larger linear force on the pavement, which

means a higher acceleration for the car. One other way to get

higher acceleration for a car for a given linear force on the pavement

is to lighten the car. Given these two ways to get a car to

accelerate faster, we can compute the weight reduction of the car that

would give the same acceleration increase as a certain flywheel weight

reduction. Depending on where the weight is removed from the

flywheel, the exact drive train gear ratios, and the size of the drive

wheel, the multiplier can

easily be more than 10--that is, a pound of well placed metal removed

from the flywheel will give the same acceleration increase as

lightening the car by 10 pounds or more. Those afflicted with a

knack for math can see more detail on this here.

My flywheel as removed was dirty and rusty.

First

task was to clean it up to see if there were any obvious problems.

After this, I thought the flywheel was in pretty decent shape.

The friction surface still showed some evidence of the last grind

marks.

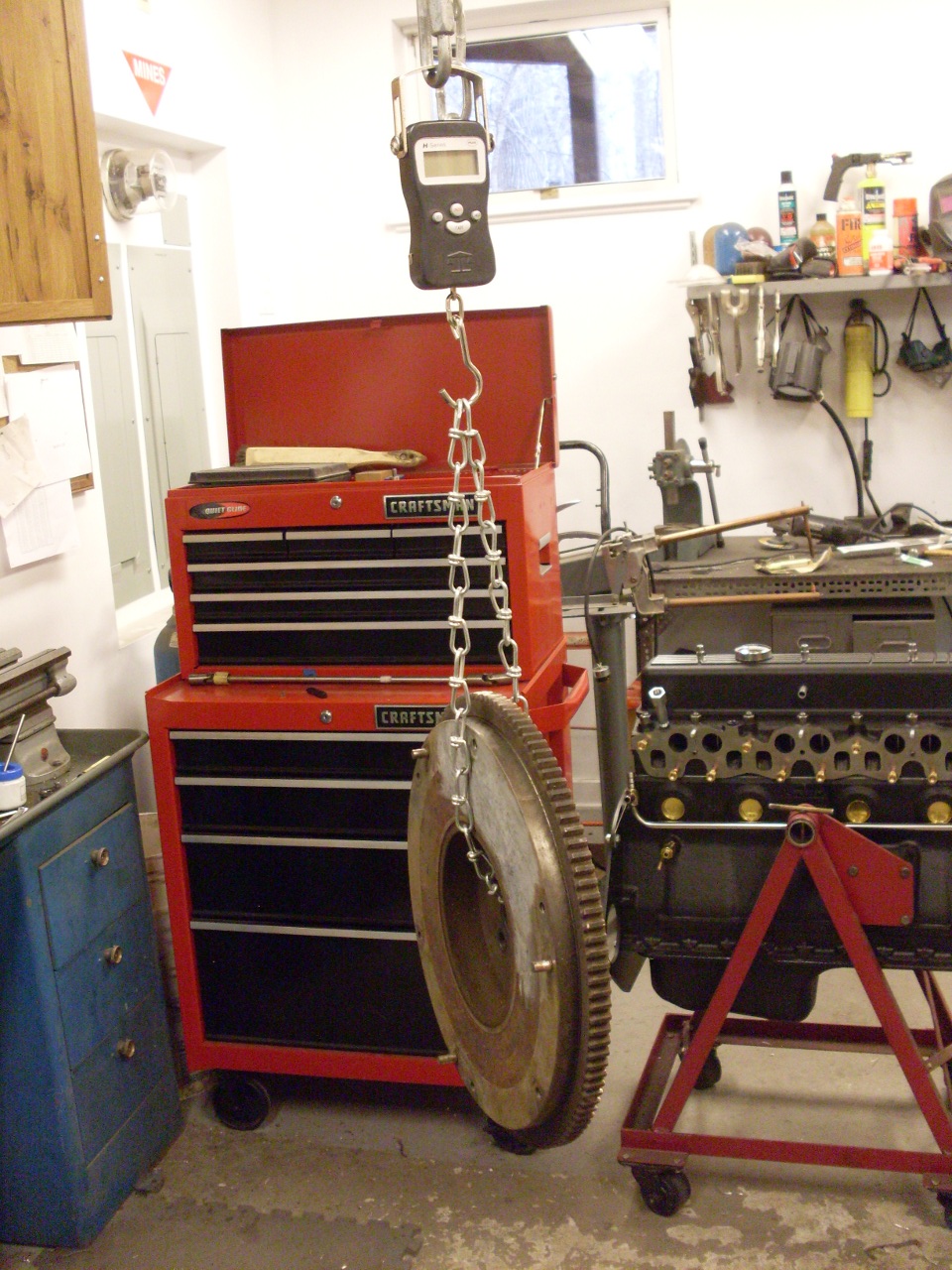

Then

I weighed the wheel so I'd know the starting point. It came in at

27.24 pounds. Many consider this to be a little heavy for these

cars anyway.

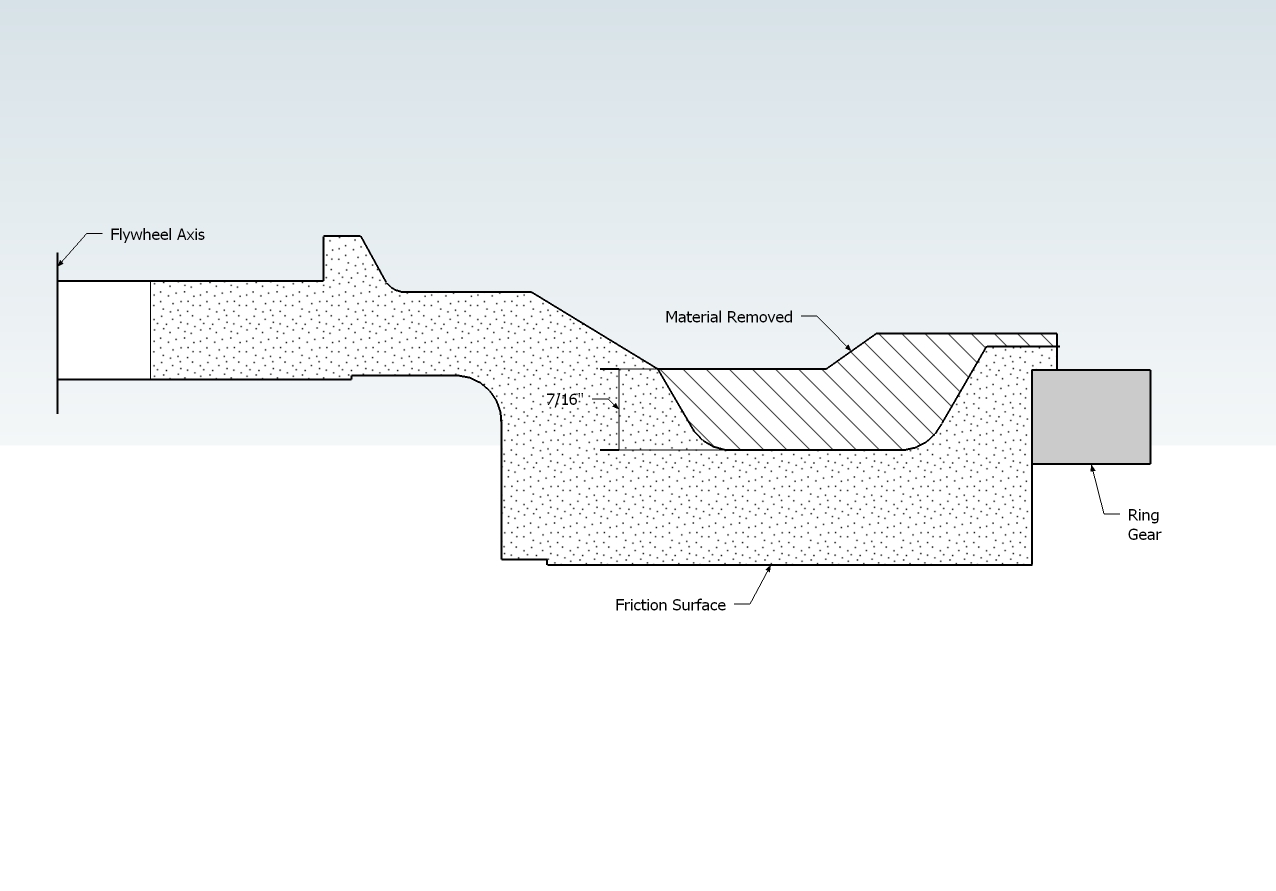

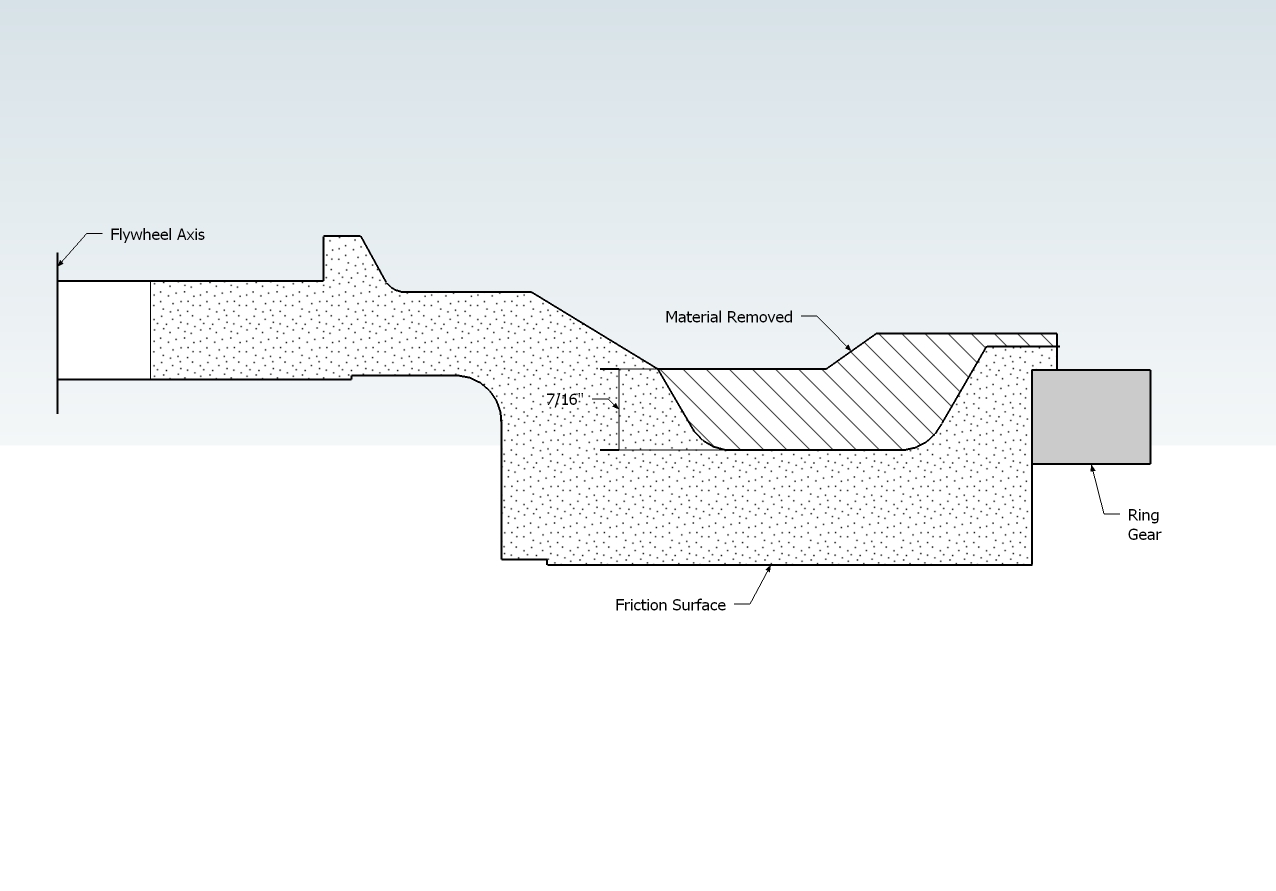

After

some careful measuring, I came up with a plan for material removal.

I calculated that this should remove around five pounds, but

being mostly towards the periphery, the effect should be maximized.

**DISCLAIMER**Please note that this plan for material removal is not

a recommendation. It is a description of what I did. Please don't

adopt what I have done here without a full understanding of the

principles involved, or professional advice.

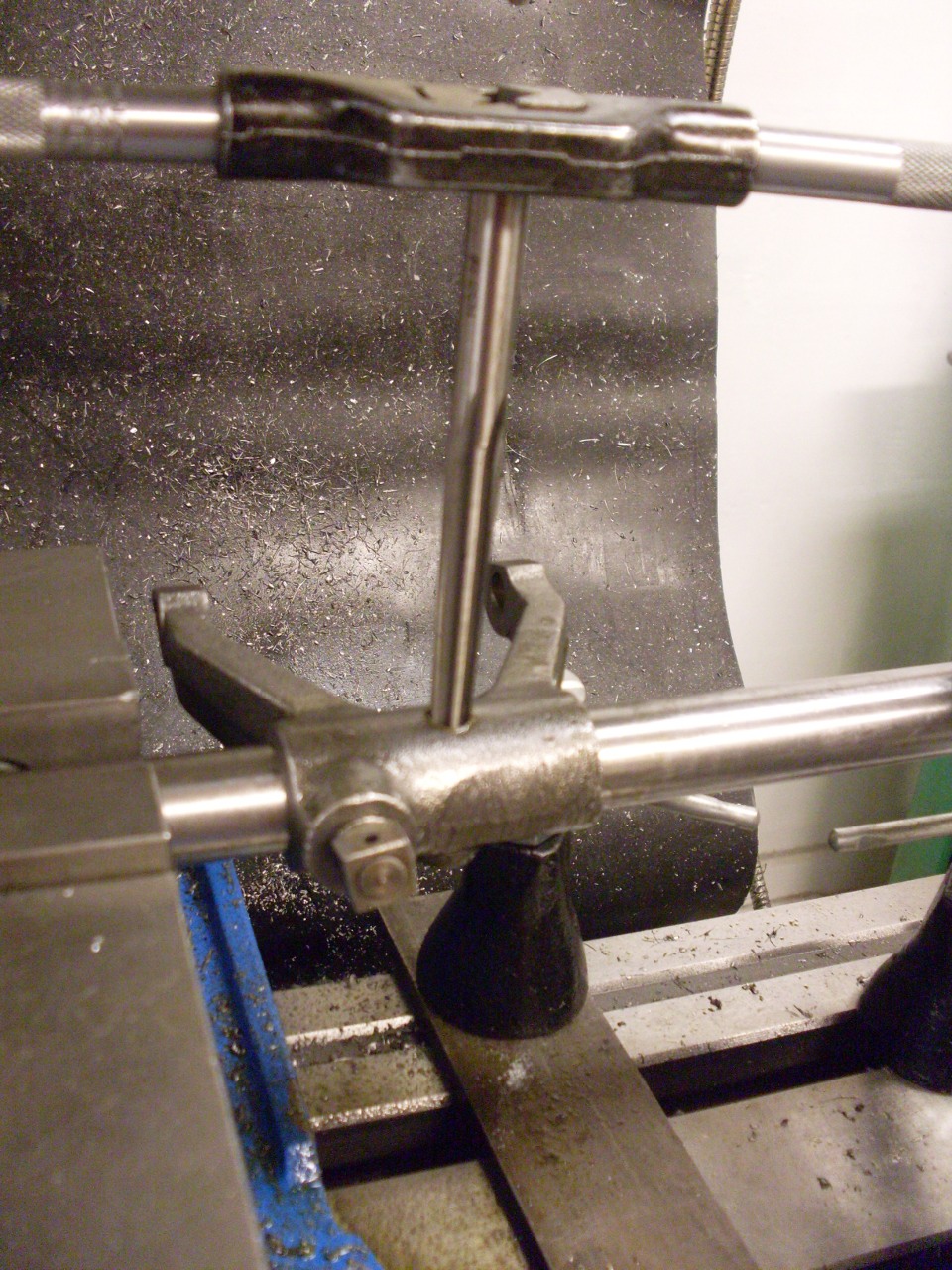

This

would normally be done on a lathe, but the flywheel is just a little

too big for mine, so the material was removed on a mill, as evidenced

by the tooling marks.

The

final weigh-in showed a new weight of 22.44 pounds--a loss of 4.8

pounds, pretty close to my estimate. I know my vacuum got a lot

heavier.

Then

it was off to a shop to have the flywheel surfaced and balanced.

Unexpectedly, I found that most shops, at least in my

area, did't have the small arbors necessary to balance TR6

flywheels. Finally found one, but it was 30 miles away.

One

other mod for a flywheel that is sometimes considered is

stepping. Stepping a flywheel consists of machining away a little

material on the part of the flywheel where the clutch mounts.

This in effect moves the pressure plate a little closer to the

flywheel. The motivation for doing this is often stated as

increased pressure on the clutch disc. This sounds intuitive, but

in reality, the result may be just the opposite. The problem is

that the belleville type springs used in diaphragm clutches have a very

non-linear rate curve. In fact, it is so non-linear that it often

has a region where the rate is actually negative. In this region,

increased displacement actually results in less

force. You can sometimes actually feel this in pushing the clutch

pedal--the required effort peaks early in the travel, then gets

smaller. It is in this negative rate region that a new clutch

operates. As the clutch disc wears thinner, there is less

displacement of the pressure plate, and the operating point moves up

the curve to higher pressure until it finally passes "over the hump" to

a region of positive rate where further wear reduces the pressure,

eventually to the point of slipping.

It

could be that the idea of stepping a flywheel is something left over

from the days of coil spring clutches with their simple linear rate

springs. Also, it is true that some stock flywheels are stepped,

but in these cases, the step was presumably a design parameter used to

get the desired operating point for the clutch. On the other

hand, stepping a flywheel as a modification has to be undertaken with a

good understanding of the spring rate curve for the particular clutch. I

didn't have any good reason for wanting to change the disc pressure,

let alone reducing it, so I didn't consider stepping any further.

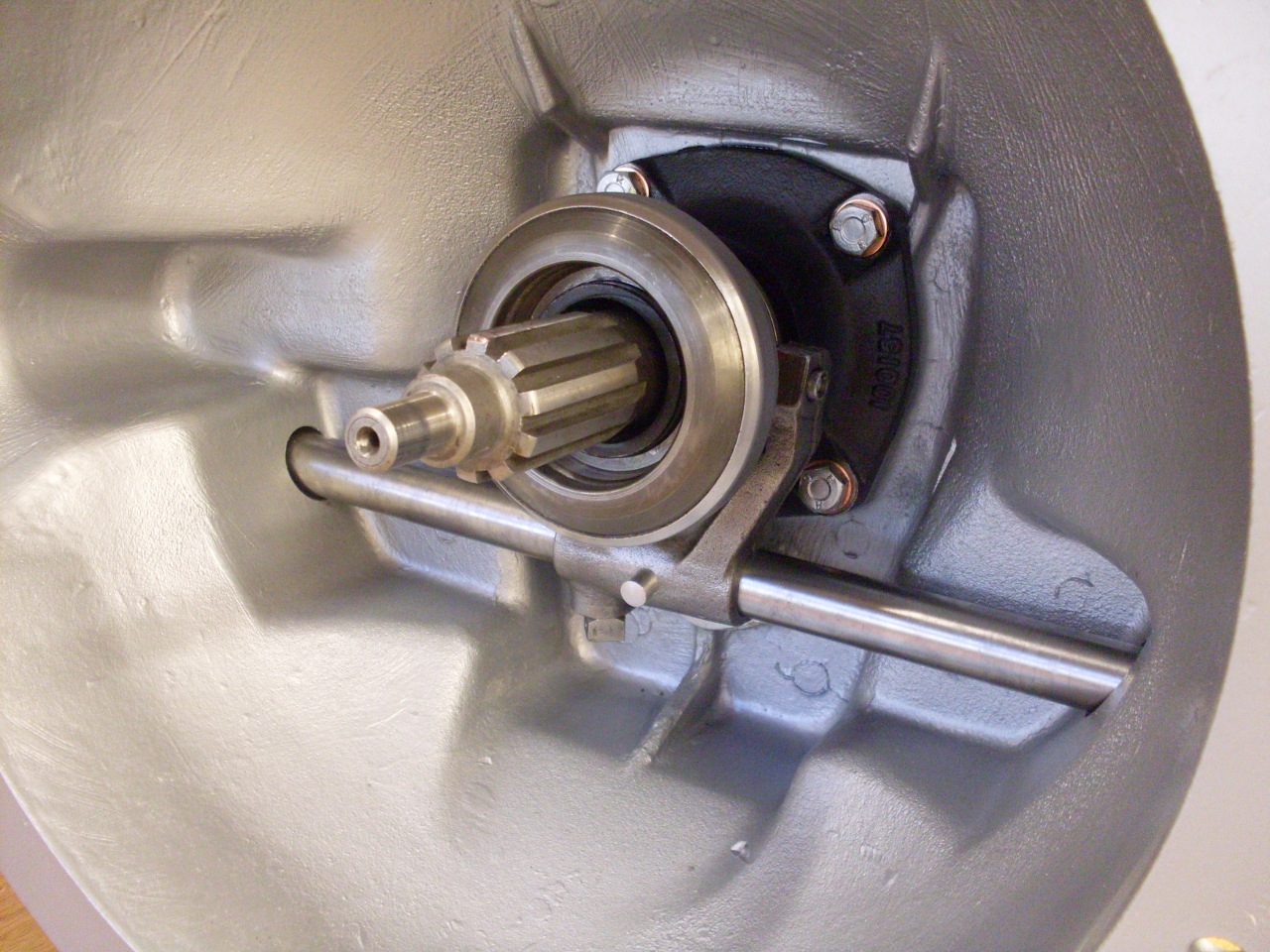

Clutch Linkage

The

TR6 uses a standard diaphragm clutch. The release (throwout)

bearing rides on a carrier that is moved by a fork. The fork is

fixed to a cross shaft that runs horizontally through the bell housing

and carries an arm on its drivers side end. The arm is actuated

by a hydraulic slave cylinder. There are a number of joints in

the overall mechanism, and each can contribute a little slop.

Most of the parts in this chain of

linkages needed some kind of attention.

Back in the early 80s

when I had the transmission out to fix the third gear synch ring, I

also modified the bushes for the clutch cross shaft where it runs

through he bell housing. I took out the short steel bushes and

installed full length bronze bushes, and then drilled and tapped the

bottom side of the bush bosses for grease zerts. This seemed to

work really well for maybe a year until the clutch started getting

stiff and sticky. It would release OK, but was slow to engage.

It appeared that the cross shaft was binding in the bushes.

It finally got so bad that one day I pushed in the clutch and it

stuck there. I didn't have time to fix it, so in the garage it

went. My theory at the time was that clutch dust mixed with the

grease and hardened. Fast forward 30+years, and it was still

stuck when I parted the transmission from the engine a few months ago.

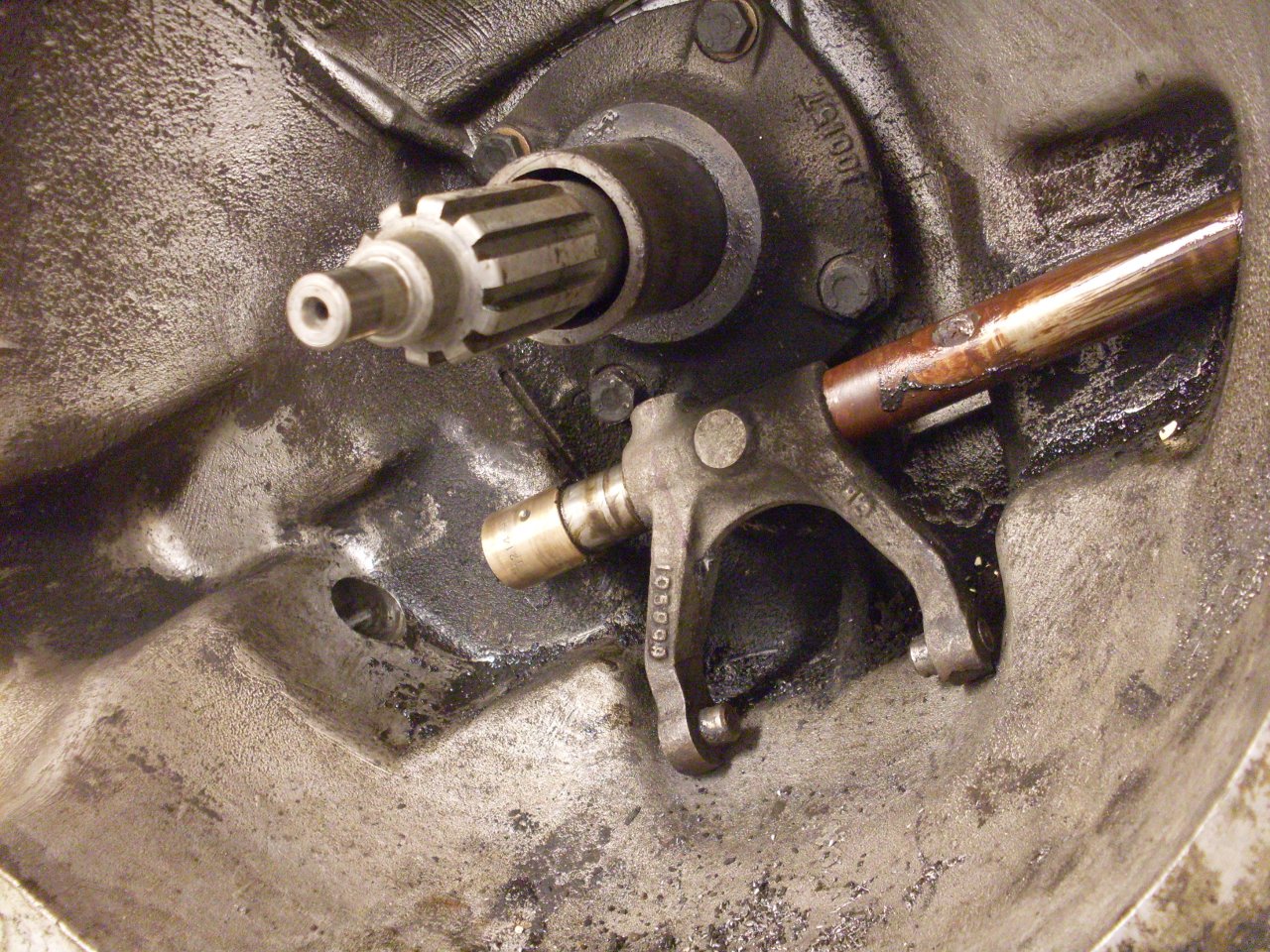

When I started working on the transmission a few weeks ago, the shaft would not

budge. I had to put a 3 foot cheater on the cross shaft arm to

get it to move. one bush was seized to the shaft and I had to cut

it off. This is still a bit of a mystery to me since I know that

earlier TRs had zerts for their bushes.

On

the way to removing the cross shaft, I encountered a heartache that

many TR owners know all too well. When I unscrewed the tapered

pin holding the fork to the shaft, only part of it came out. The

pin had broken in its bore and the lower part was keeping the fork from

coming off. This well known problem is caused by a bad design of the

bore for the pin. The bore in the shaft is tapered, but the bore

in the fork is not. This leaves the bottom end of the pin not

registered to anything on the fork so all the shear force is

concentrated at the upper intersection of the shaft and fork. The

pin can't take it, so it breaks.

The most immediate problem was

to get the remains of the pin out so the fork could be separated form

the shaft. Since the shaft won't come out of the bell housing

with the fork on it, all operations to remove the pin had to be done in

the housing.

The solution, not original to me, was to drill a

small hole in the fork such that it would open into the bottom of the

tapered pin bore. This would allow a small drift to be inserted

to drive the pin fragment out.

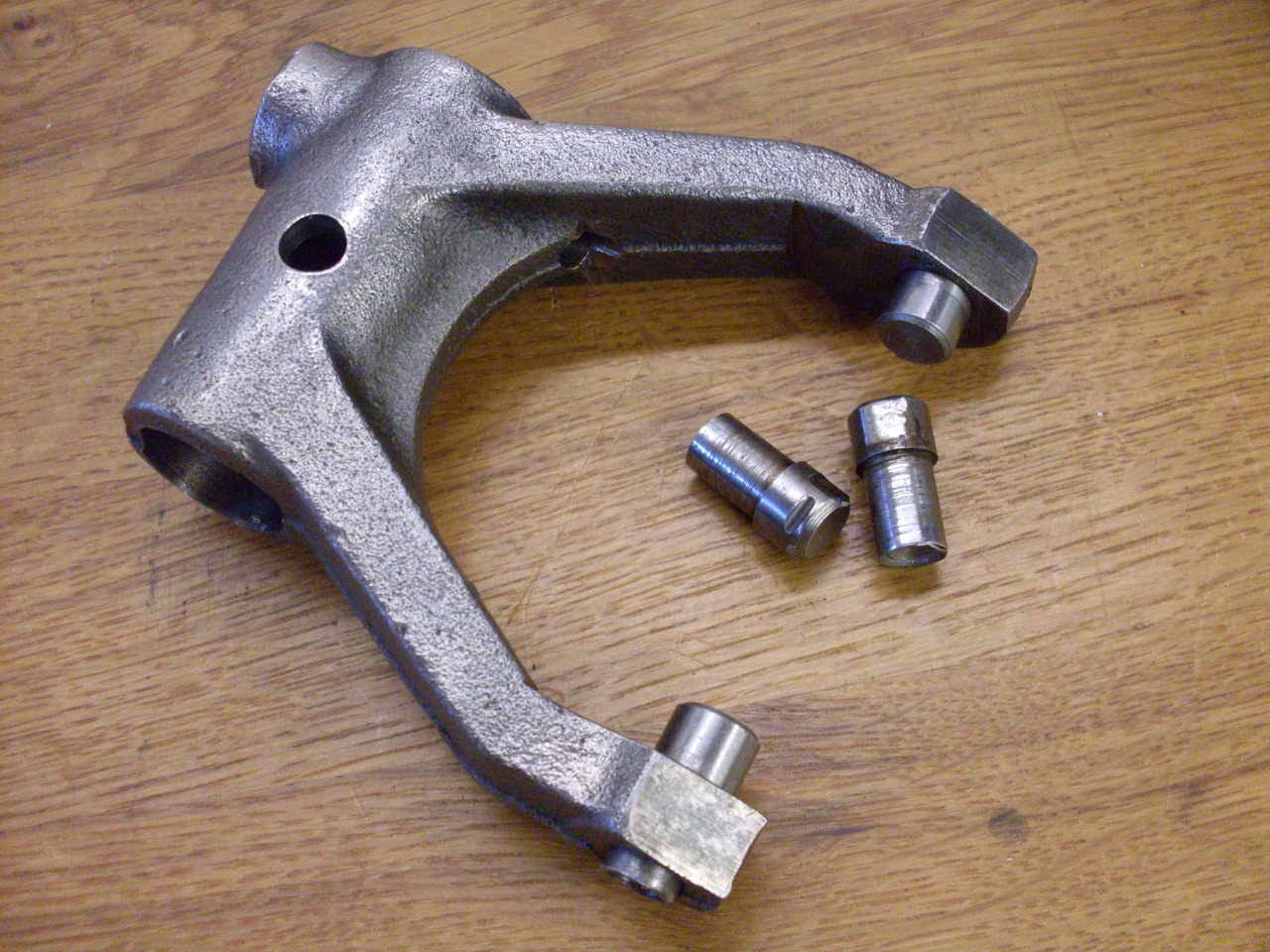

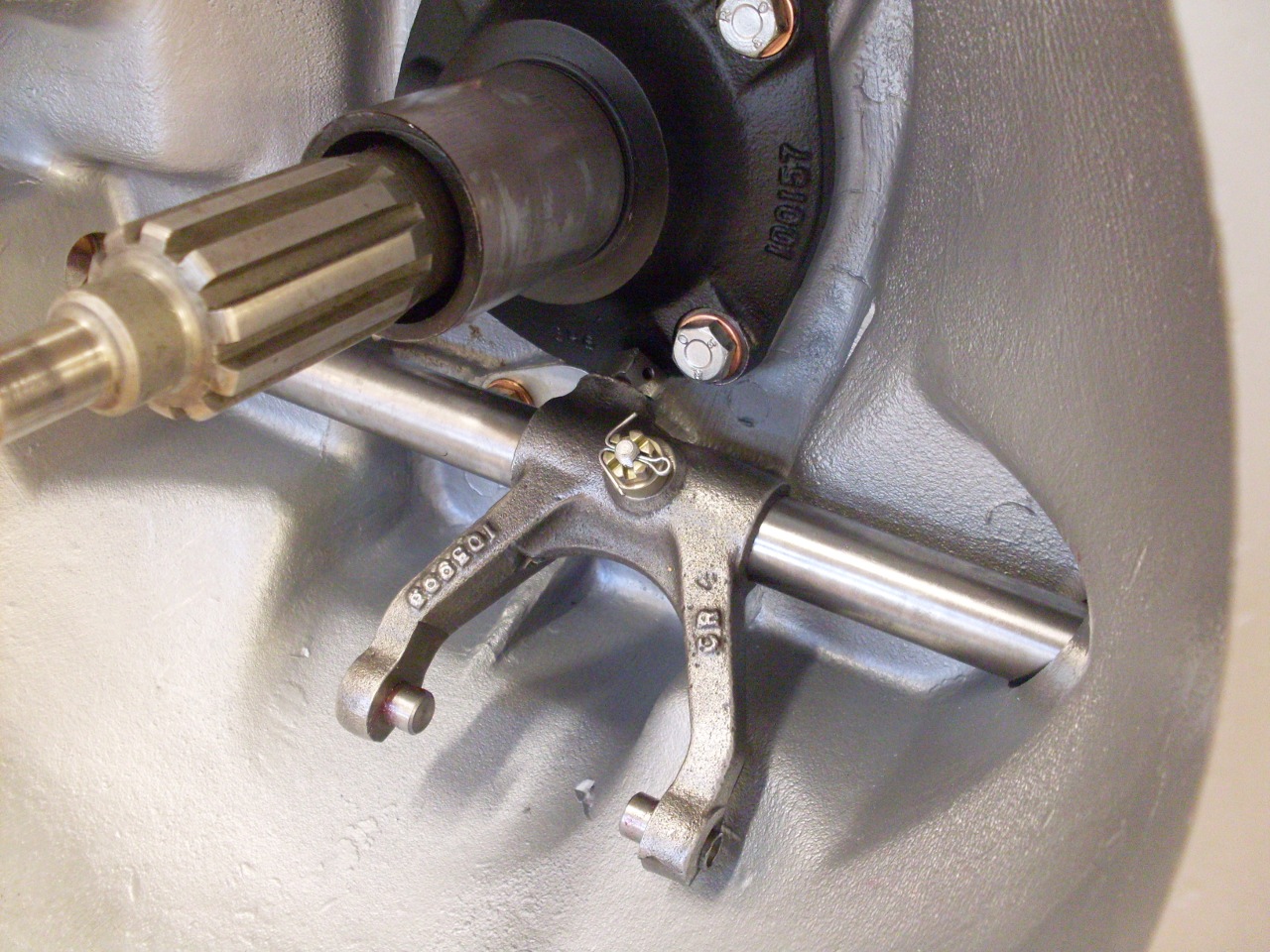

While

on the subject of the fork, it has two pins which engage a groove in

the release bearing carrier. These pins were pretty worn,

especially where one of them rests against the anti-rotation pin in the

carrier. These pins are replaceable, and are just driven

out, and new ones pressed in.

The

wear on the fork pins was matched by wear in the release bearing

carrier groove. There is a pin in the groove that prevents the

carrier and the inner race of the bearing from turning. Torque

transmitted by the bearing keeps the carrier up against the pin most of

the time, so the carrier wears in the areas where the fork pins rest.

The

wear bothers me, and if there were no alternative, I'd replace the

carrier. However, my mistrust of most aftermarket parts led me to

another option. Since the areas of wear are determined by the

position of the anti-rotation pin, it seemed simplest to just move the

pin. I drilled another pin hole 90 degrees from the original.

This renewal could actually be repeated quite a few times.

Another

area that was asking for attention was the arm on the cross shaft.

There are three holes in the arm to connect to a pushrod from the

slave cylinder, presumably to allow a little adjustment of the lever

ratio between the slave cylinder and the release bearing fork.

It's the middle hole that's nearly always used, and mine was

elongated. To fix this, I welded up all the holes, and just

redrilled the middle one. I've never even been tempted to use

either of the other holes, so they seemed superfluous.

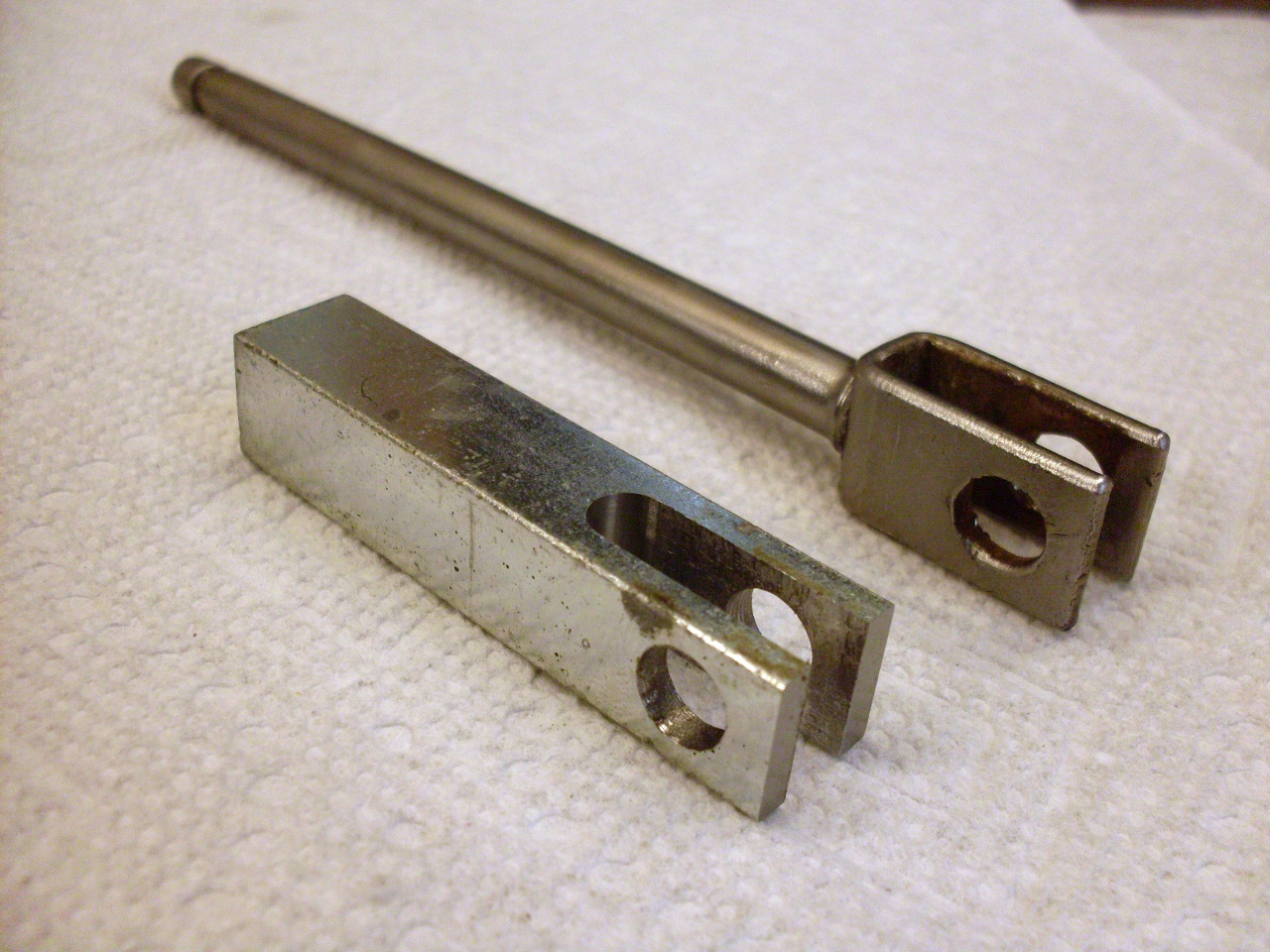

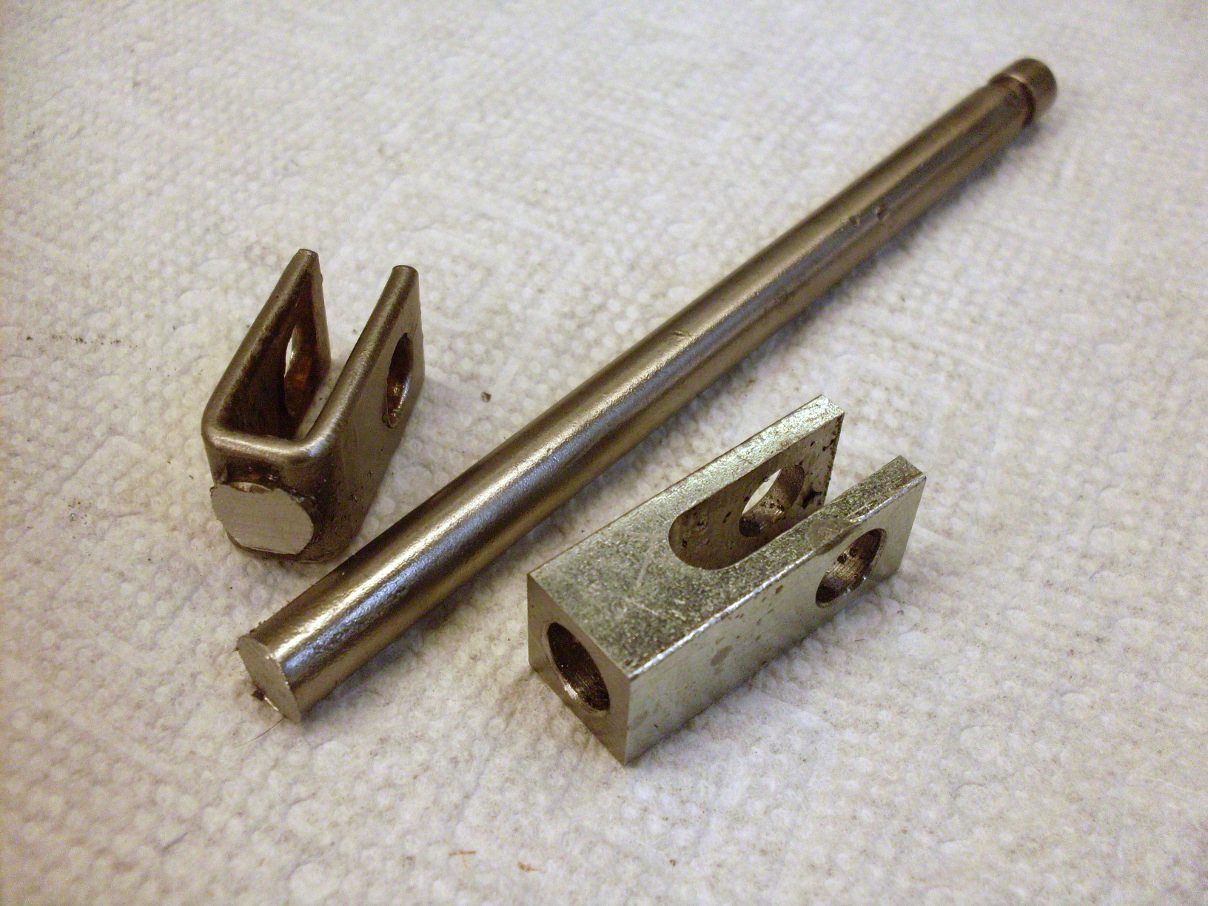

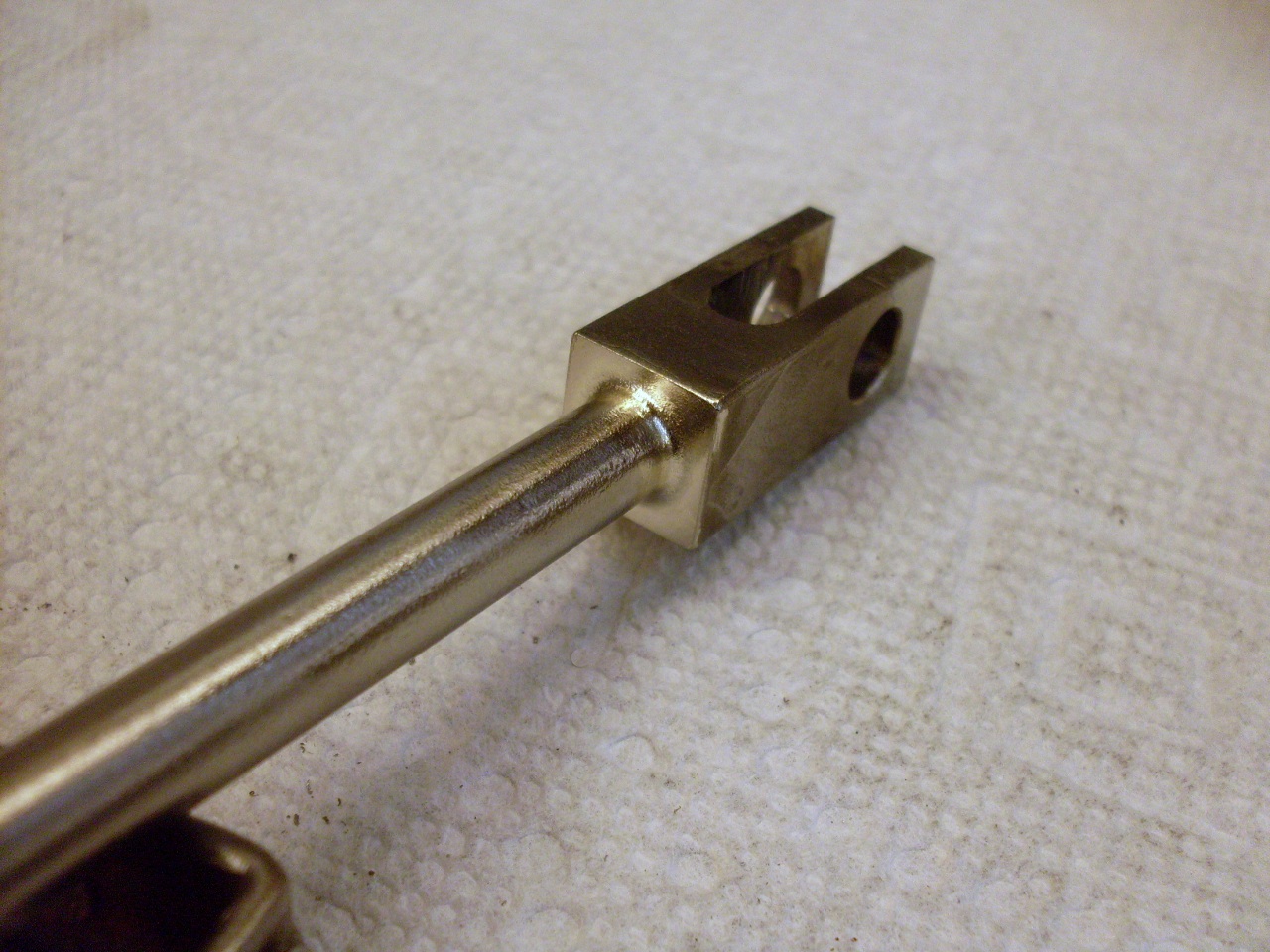

Next up was the slave cylinder pushrod. Like the cross shaft arm. its clevis holes were distorted.

Rather than trying to weld up the rather thin arms on the pushrod, I

decided to just make a new, slightly beefier clevis end for the rod.

I'm particularly proud of that silver solder job. I don't think I've

ever had one come out that nice before. The last pic is after zinc plating the rod and making a new stainless clevis pin.

My

slave cylinder was toast. I think I took it apart back in the 80s

when I made a feeble attempt to diagnose the clutch problem, and it was

sitting under one of the seats for 30 years. It's bore was rusted

and some of the parts were missing.

I

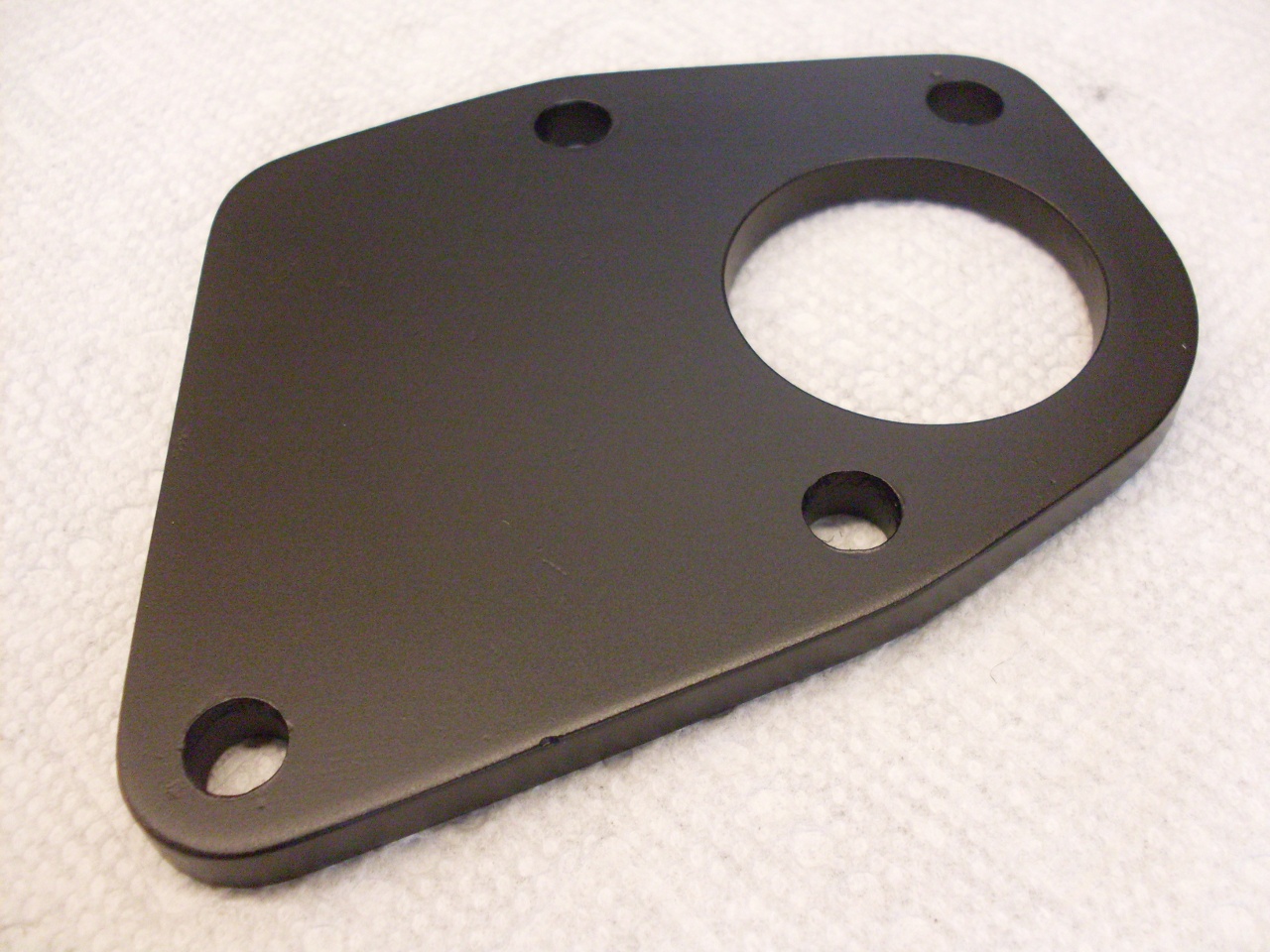

got a new slave cylinder. It has a smaller body diameter than the

original, but the one inch bore is the same. It had a pretty

lousy paint job, so I repainted it and the original mounting plate.

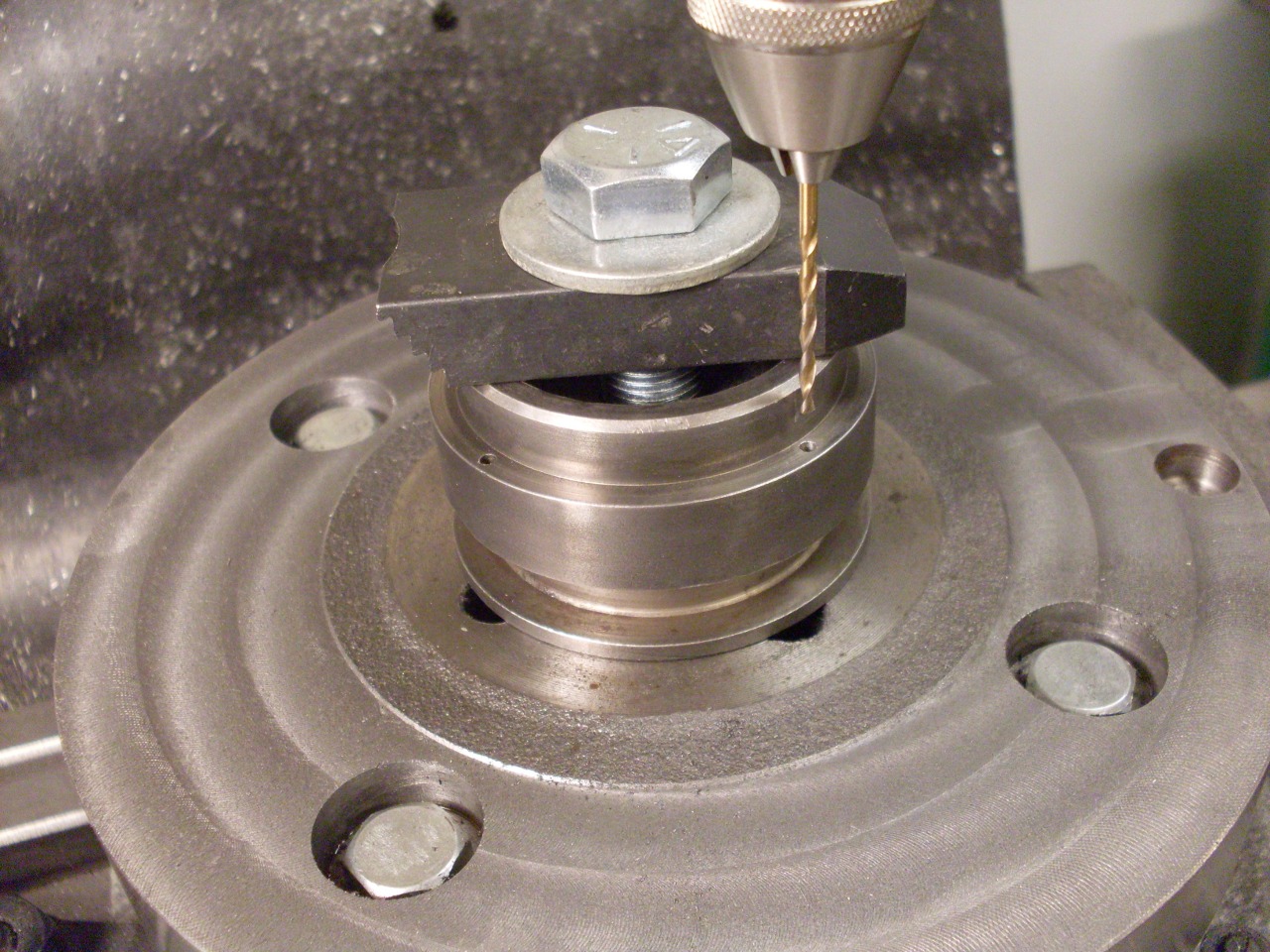

The

last job was to fix the design flaw that causes the taper pin on the

fork to break. There are a number of decent solution that have

been applied here. Some involve giving some support to the small

end of the stock pin, while others provide a second pin or bolt to take

some of the shear stress off the original pin. I found a nice

writeup on one of the TR6 forums that describes what I consider to be

an ideal solution. It consists of installing a new taper pin in a

fully tapered hole. There is even a boss on the fork that looks

like it was created for just this kind of solution. The thing

that makes this approach so sweet is the unique taper pin used.

The pin has a threaded section on its small end which allows a nut to

draw the pin in and keep it from backing out. Known as an "AN386"

type pin, it is most often used in aircraft applications (I believe the

"AN" identifies it as a military specification).

The

pin has a 1/2" per foot taper, and is compatible with a Brown &

Sharp (B&S) #2 taper. After screwing in the top remnant of

the original pin to locate the fork, I drilled through the boss on the

part so that the hole would be centered in the shaft. I then

followed with a slightly larger drill from the other side to rough out

the taper. The final taper was accomplished with a B&S #2

hand reamer. There isn't a much more accurate way to make a taper

pinned joint than this "in situ" process.

The

pin can be pushed in by hand, but the nut draws it in another 1/8" or

so. To guarantee that the pin is in full double shear, the bore

is usually sized so that some of the small end of the pin sticks out a

little when the pin is fully seated. That's why the special

recessed washer is used under the nut.

I

had ordered a new stock pin, and though I think the new pin makes it

redundant and unnecessary, I didn't see any reason not to install it

anyway. The tapered

spring goes on the shaft between the lever arm and the bell

housing. It is apparently no longer available, and mine was torn

up during the violence in removing my shaft. The one in the

picture was donated by a generous member of one of the popular TR6

forums.

Comments to: elhollin1@yahoo.com

To my other TR6 pages