To other TR6 pages.

December 6th, 2013

Water Pump

[Click pics for a larger view]

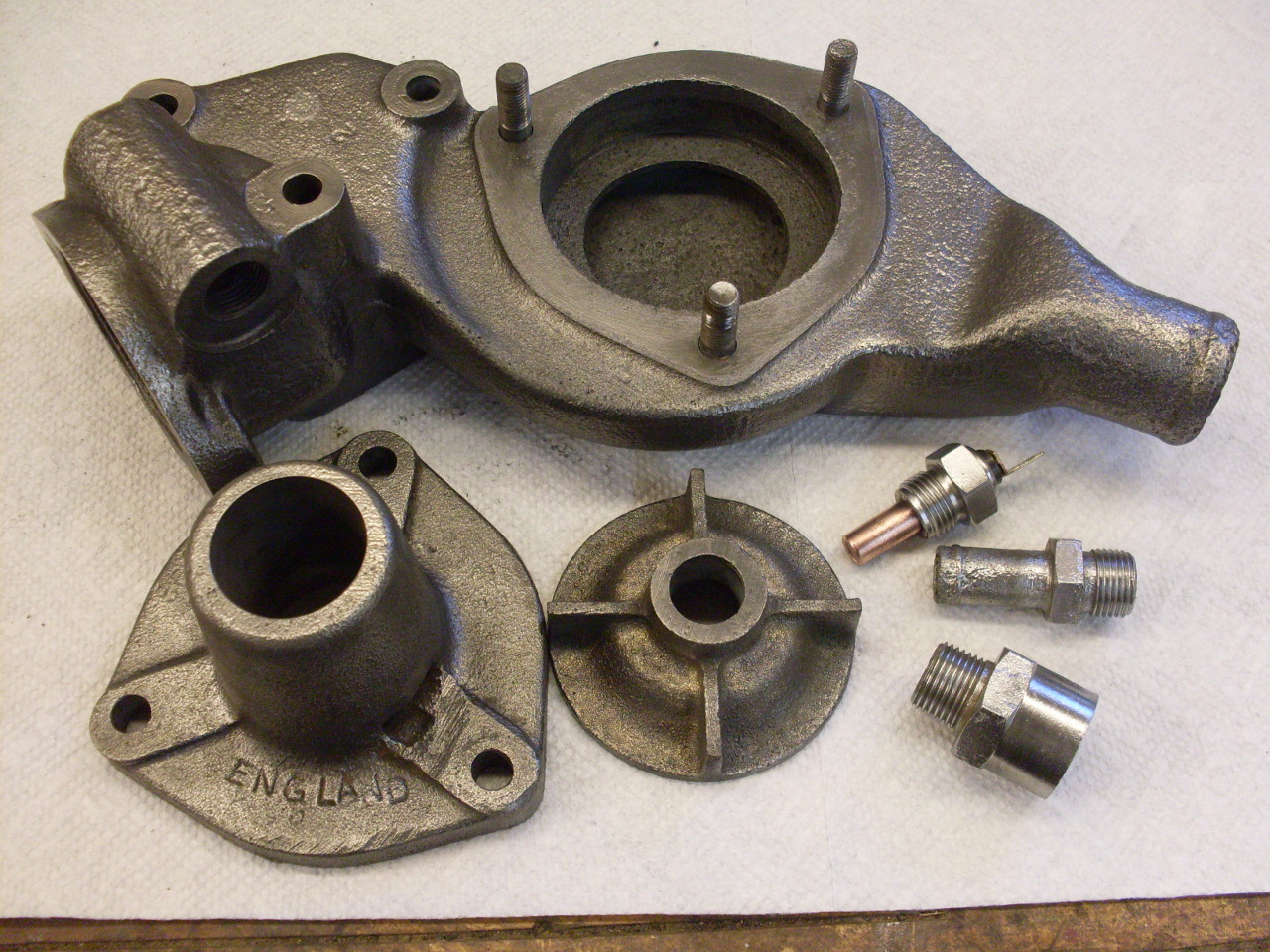

The

cooling system on the TR6 is a pretty ordinary pump assisted

thermosiphon arrangement. The pump assembly is an odd-shaped

iron casting with various inlets and outlets that bolts to the

cylinder head.

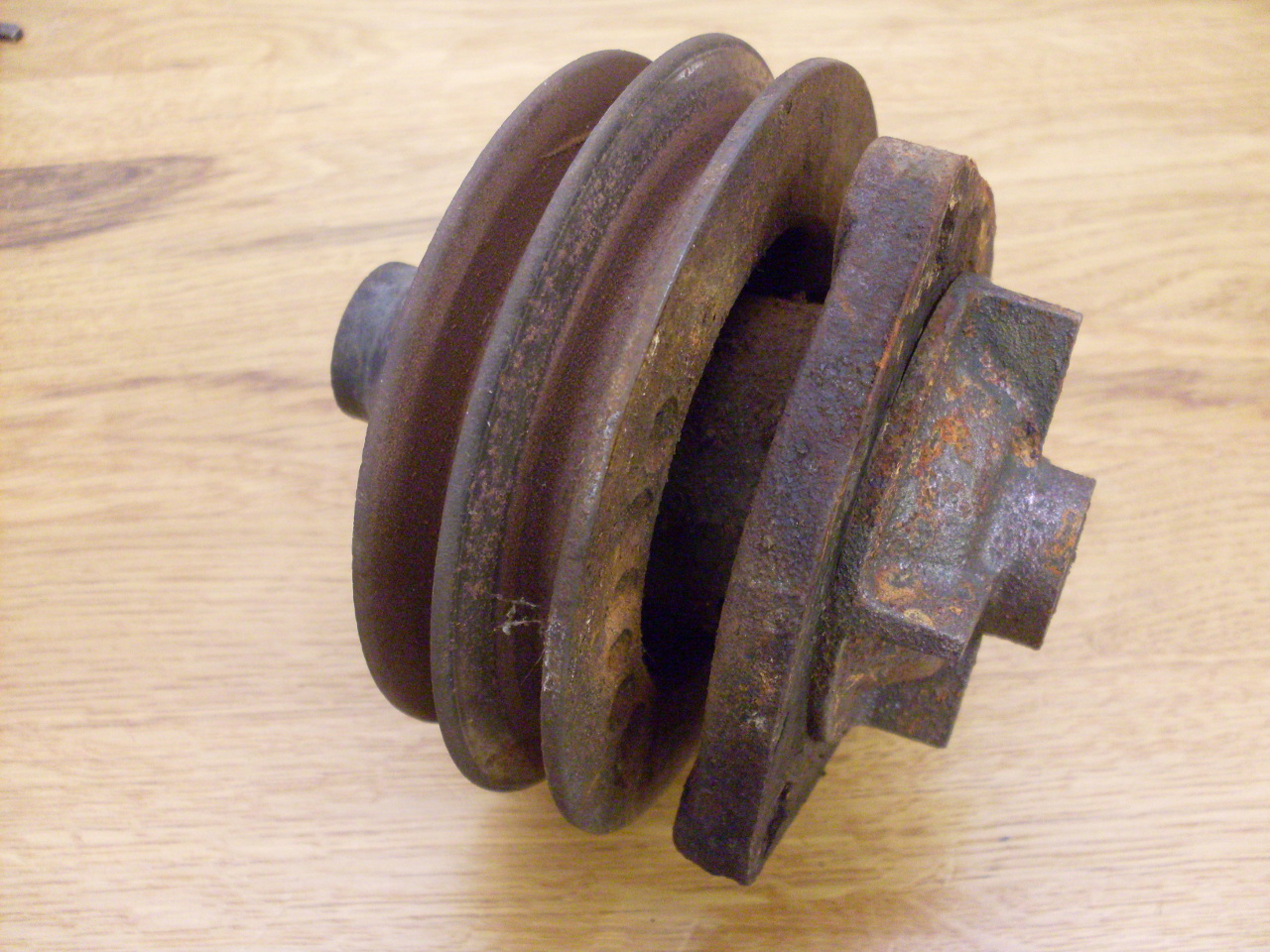

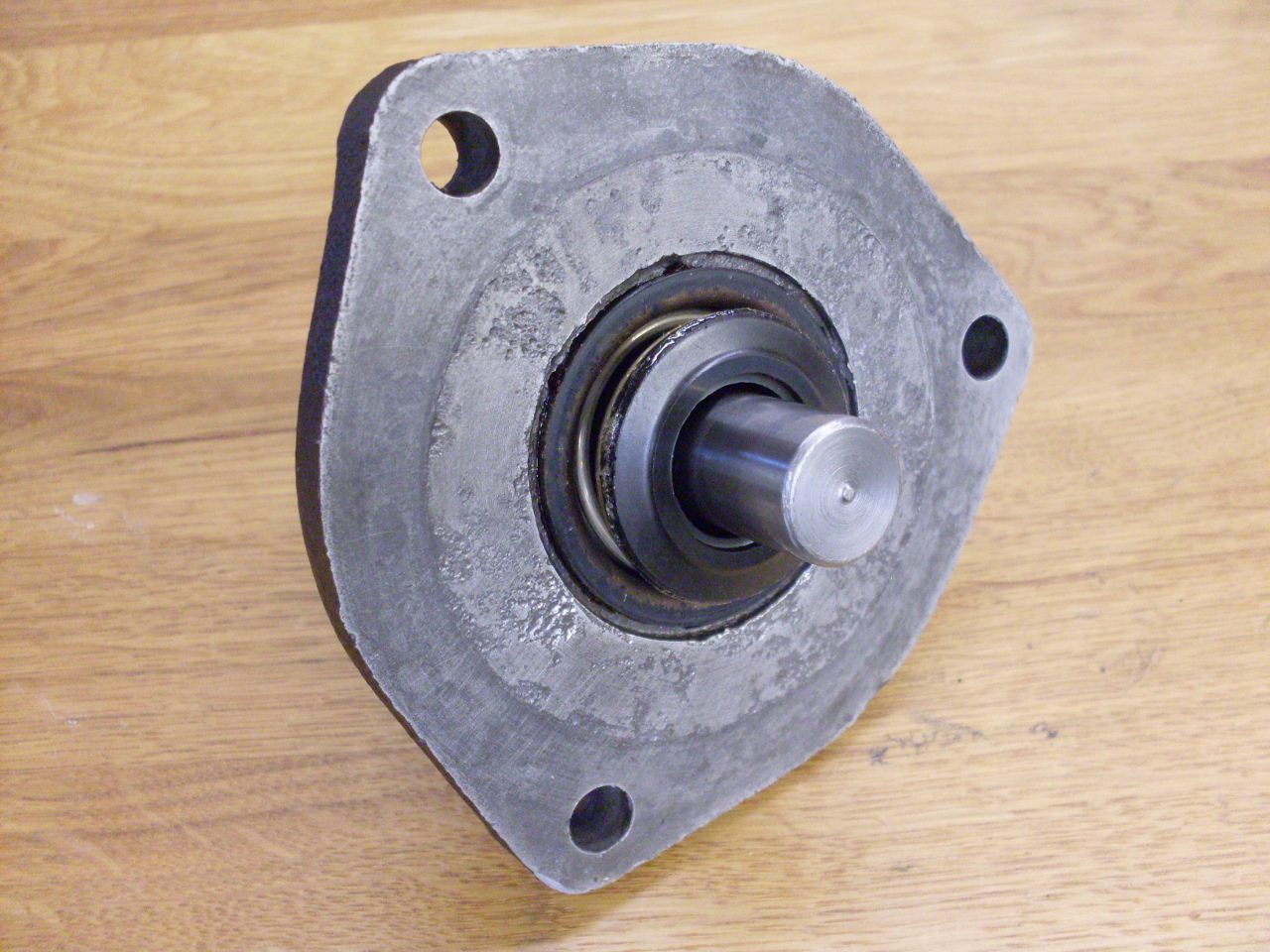

The pumping

is done by the impeller assembly, which is actually called the water

pump in most parts listings. This is the assembly that is

replaced when you "replace the water pump". The shell that it

bolts to is called the water pump housing.

The

impeller assembly (water pump), while normally replaced as a unit, is

rebuildable, though parts are not found at most auto parts stores.

First step is to push off the pulley, then push the bearing out

of its housing, then push the impeller off the shaft. What's left

is the replaceable items: the bearing and the seal. It was

obvious from the rust patterns on the shaft and the bearing housing

that the seal had been leaking. The bearing, while still smooth

in turning did have a slight side-to-side play.

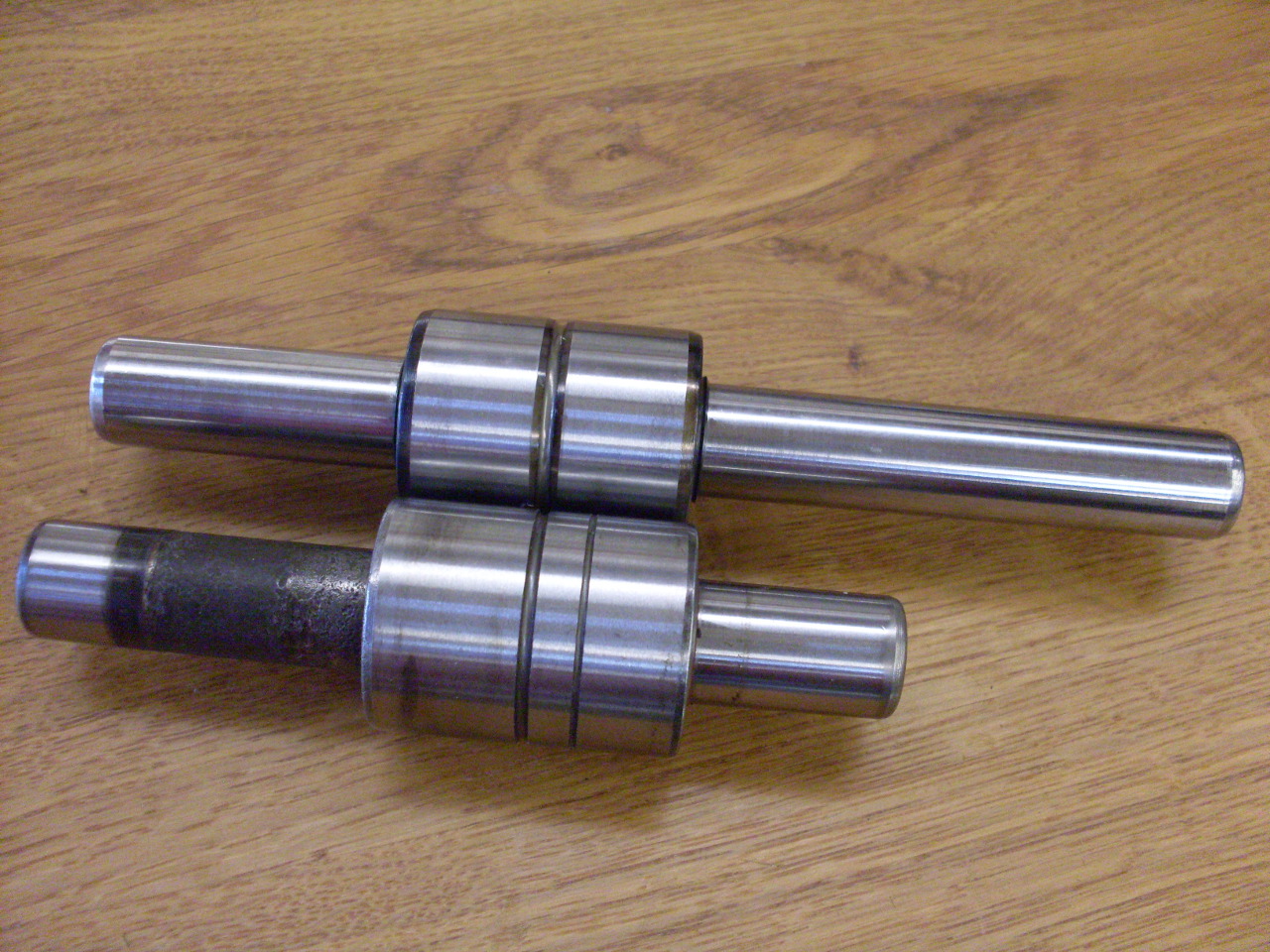

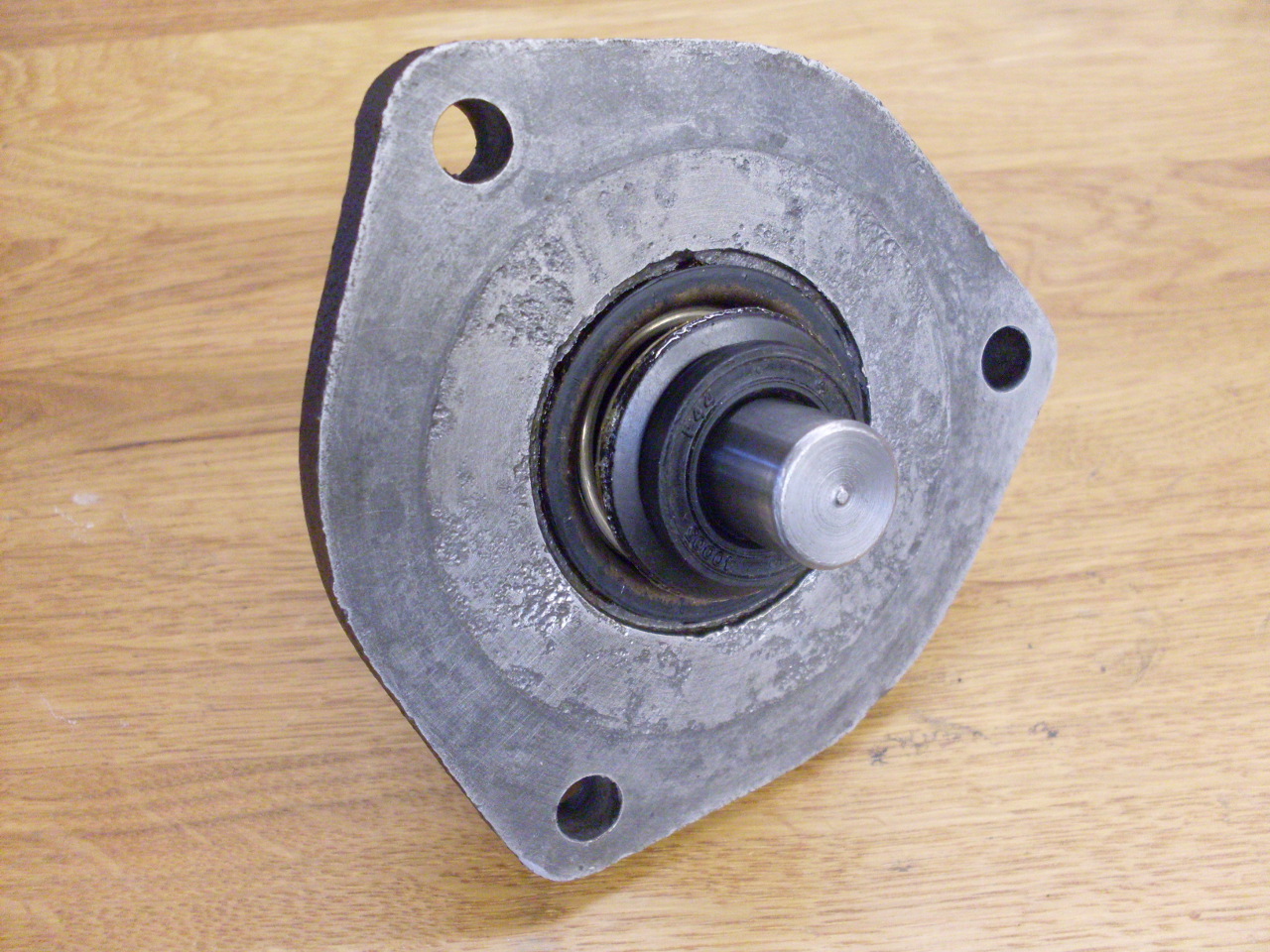

This

is what's called a water pump bearing. It is an outer race that

carries two ball cages, forming a "ball bearing" at each end.

There is no inner race--the balls run directly on the shaft.

It is a sealed unit with no external provision for lubrication.

The

30 mm outer race diamater, 40 mm barrel length, and 16 mm shaft

diameter are apparently pretty common for these bearings, but the shaft

lengths are all over the map. Also, since these bearings are

typically used in automotive applications, many industrial suppliers

don't carry them (neither do most auto parts stores, for that matter).

I did find a bearing supplier that had a unit with longer shafts,

but since the shafts are not hardened, at least on the parts that

protrude, it was easy to cut them.

The

seal is a "mechanical seal" commonly used on wet pump shafts.

There are two hard graphite or ceramic discs--one stationary, and

the other spinning with the shaft--that form the primary seal.

The discs are in contact face to face under spring pressure.

There is a huge variety of these, and finding a replacement from

industrial sources was just too confusing. I ended up

finding a british-made NOS unit from an antique car parts outfit.

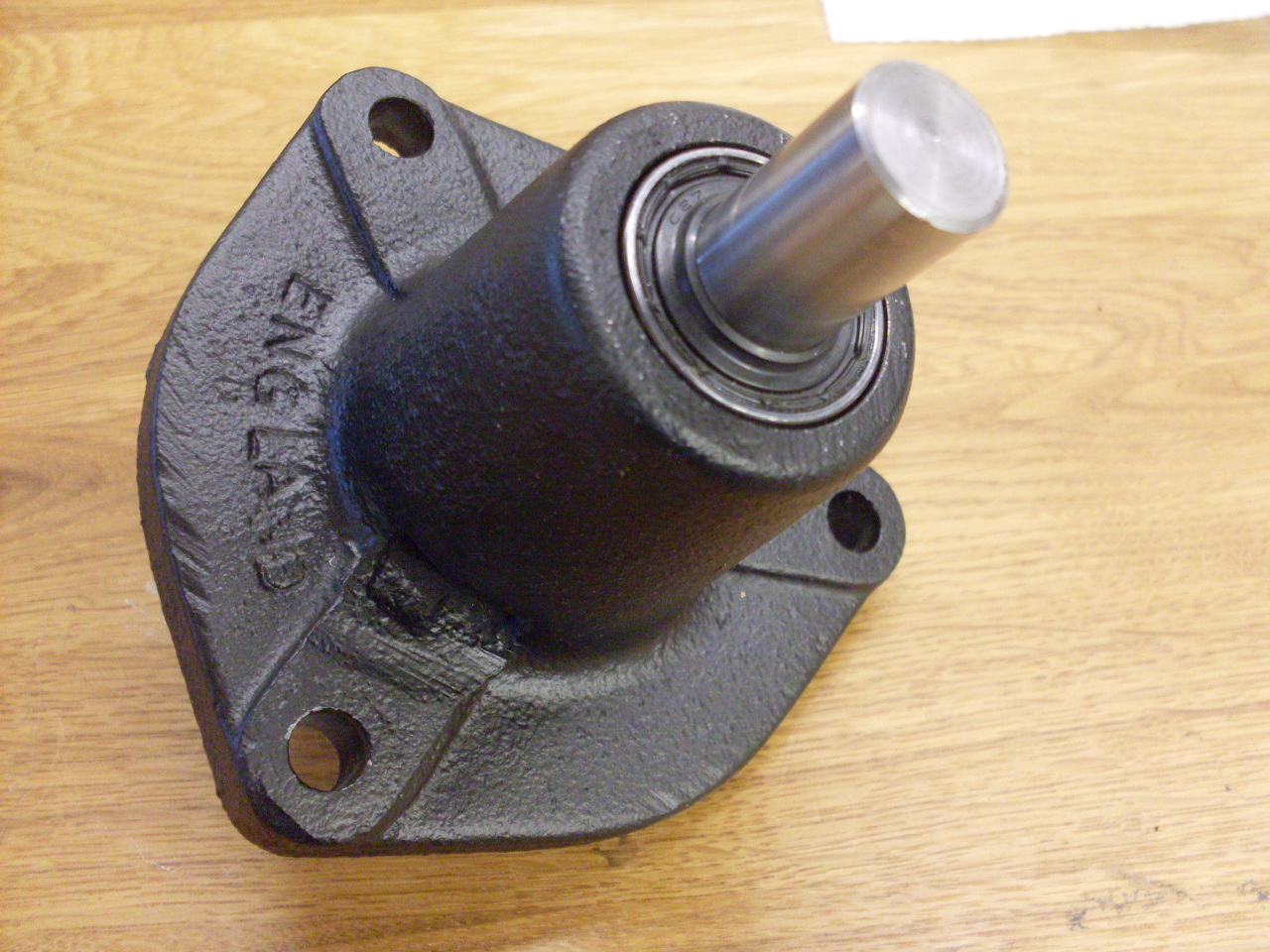

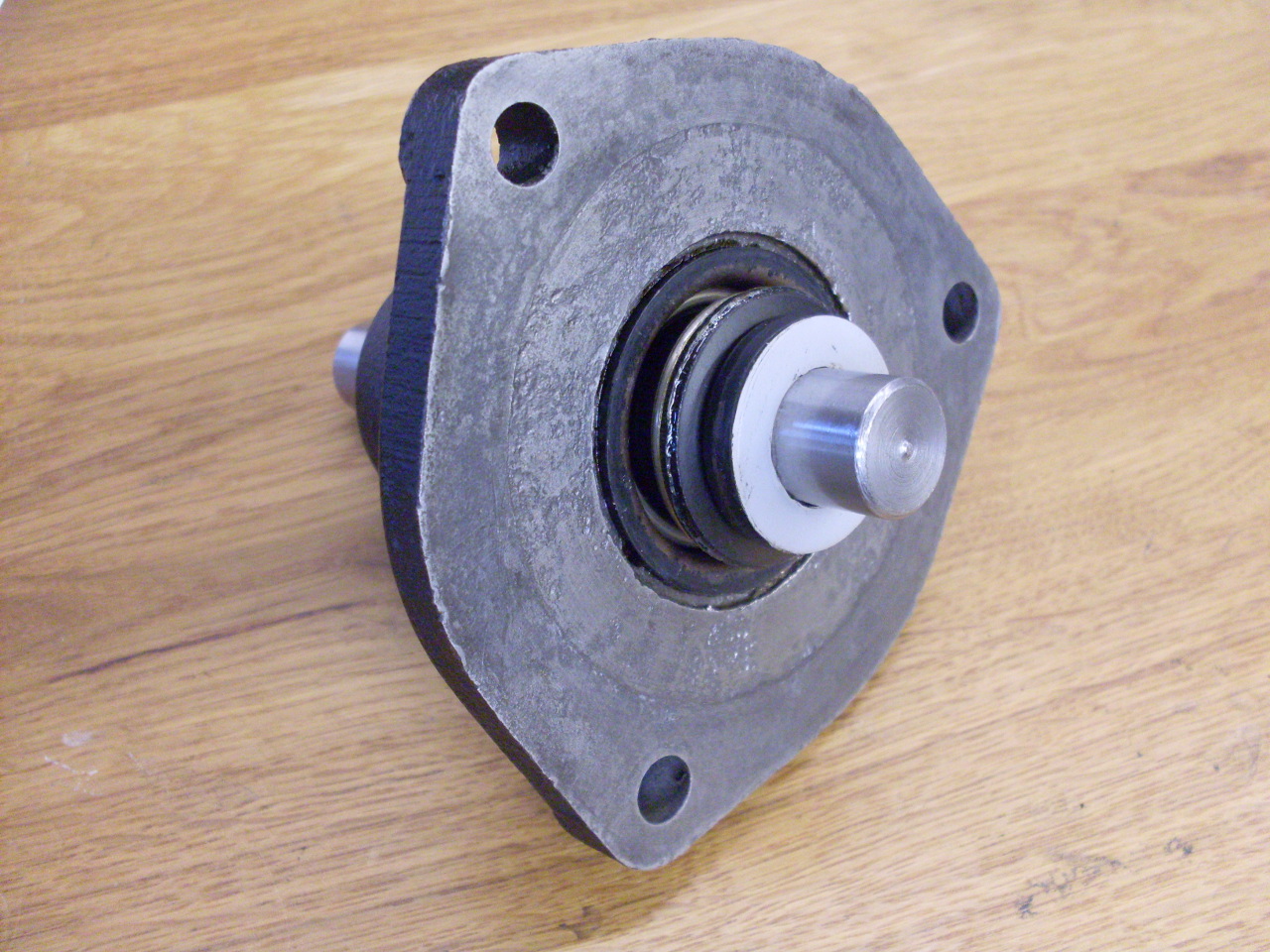

I cleaned up all the castings, and started to reassemble everything.

First, I pressed the seal into the housing using a large socket, then the bearing is pressed in.

Then

the rotating part of the seal in pushed onto the shaft. The

little white plastic washer was then placed on the shaft to give a

little (0.040") extra pre-load to the seal spring. I had done a

little arithmetic on where the impeller would end up on the shaft, and

found that the seal spring wouldn't be compressed very much. The

shim puts the spring about in the middle of it's range of travel.

The shim is necessary because of the close clearance I used

between the impeller and the housing. Since pumps and housings

are not matched sets, pumps have to have their impellers set to work

with any housing, and so a generous tolerance has to be included.

This results in the impeller being set farther back on the shaft

(towards the bearing), giving more preload to the seal spring, but

also more impeller clearance.

Then,

before the impeller is pressed on the shaft, I had to step back and

consider how I would know when it was in the right place. Even

though my numbers told me where I thought the right place was, I wanted

a little more practical method. For these pumps to work

efficiently, the clearances between rotating and stationary parts needs

to be kept to a minimum. The impeller blades need to run very

close to the housing face without fouling it. Here is the process

I used: First, I cut a little off the thickest blades so they

were all the same height and the tops of the blades were square to the

shaft. Then I pressed the impeller onto the shaft just a little

at a time until it was just very lightly dragging on the housing

without a gasket installed between the pump and the housing.

Since I had neglected to buy a gasket, I measured the old one and

it appeared to be about 0.015 thick, so I made a gasket from

0.015 gasket material. With the gasket installed and the pump

tightened down, the impeller doesn't drag, and the impeller clearance is about the gasket thickness--0.015".

With all that done,

all that remained was to push the drive pulley onto the shaft, and here

is where one of those strange things happened that probably will always

remain a mystery. The pulley bore was too big! I mean way

too big. The pulley would fall on or off the shaft by

gravity. It couldn't be the shaft--it measured the same as the

old one to within less than a thousandth of an inch, and besides, the

impeller pressed on normally. I scratched my head about this for

a while, and finally gave up trying to explain it and concentrated on

what to do. I looked for pulleys online, but there were

apparently many different pulleys used for thesde pumps, even on the

same model car. And they weren't cheap!

I finally decided

to fix my pulley by boring it out to 3/4", pressing in a slug, and

reboring the assembly for the 5/8" shaft. The first pic below is

the pulley reamed to 0.749" with a slug of .750 drill rod pressed in.

The green stuff barely visible at the joint is a Loctite bearing

mount compound. The second pic is the pulley reamed to 0.625"

(the shaft is 0.626"), and the slug trimmed flush. The pulley was then a nice press fit onto the shaft

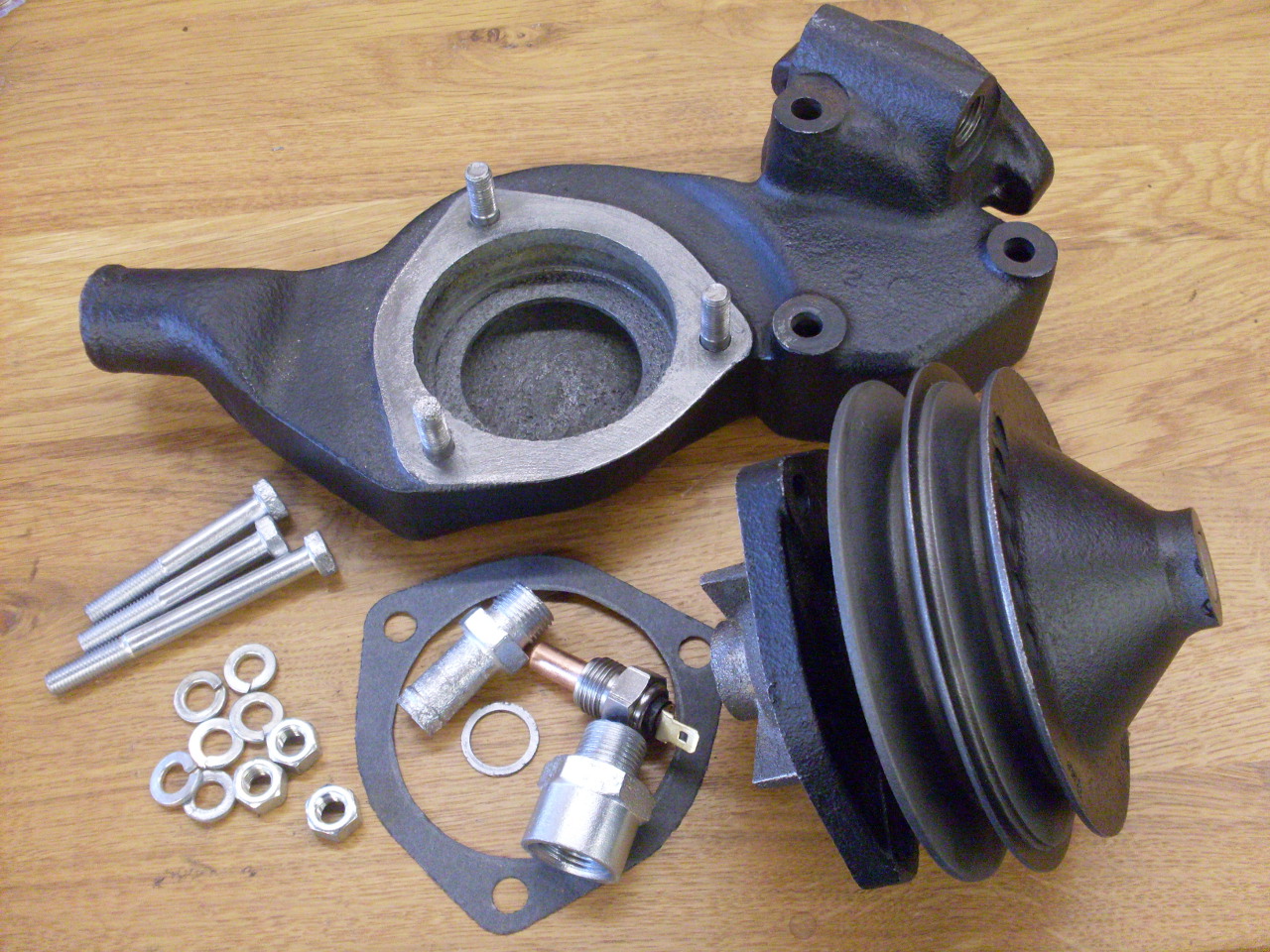

The pump was then ready to go back into the housing with replated hardware and fittings.

Total

cost of the rebuild was around $40 in parts. I have maybe 3-4

hours in it, but much of that was to repair the loose pulley bore.

To other TR6 pages.

Comments to: elhollin1@yahoo.com