November 29, 2013

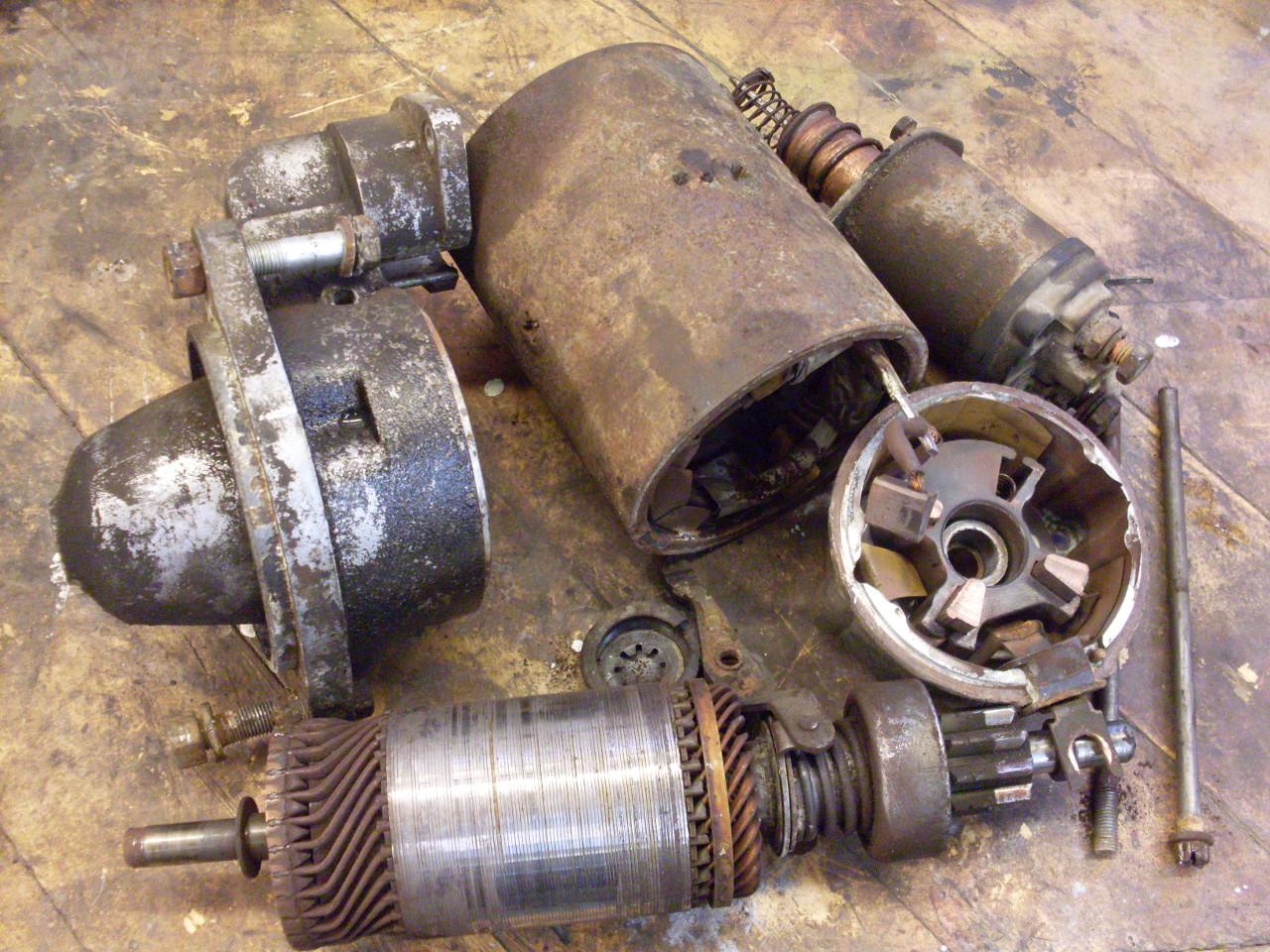

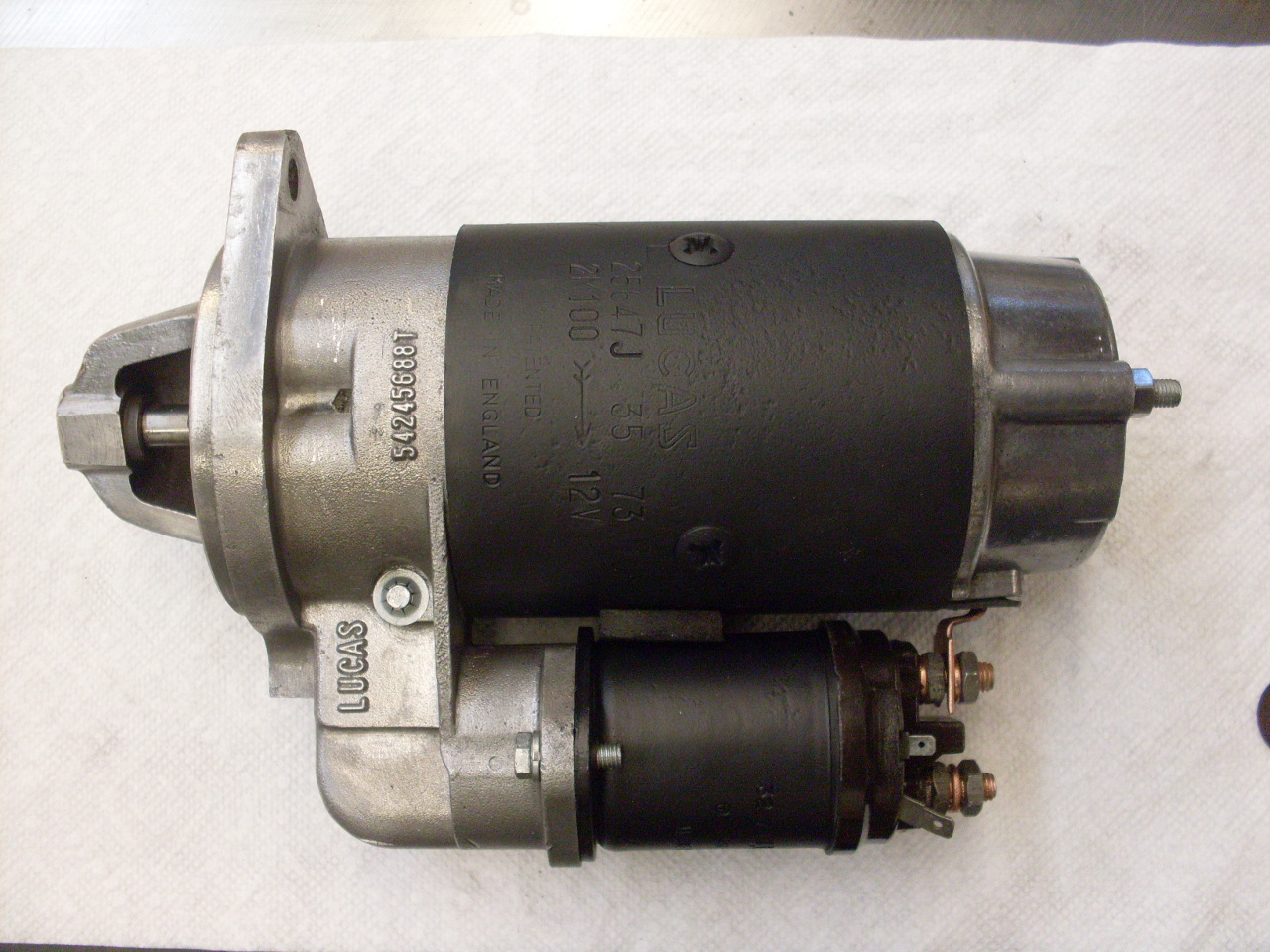

Starter Motor

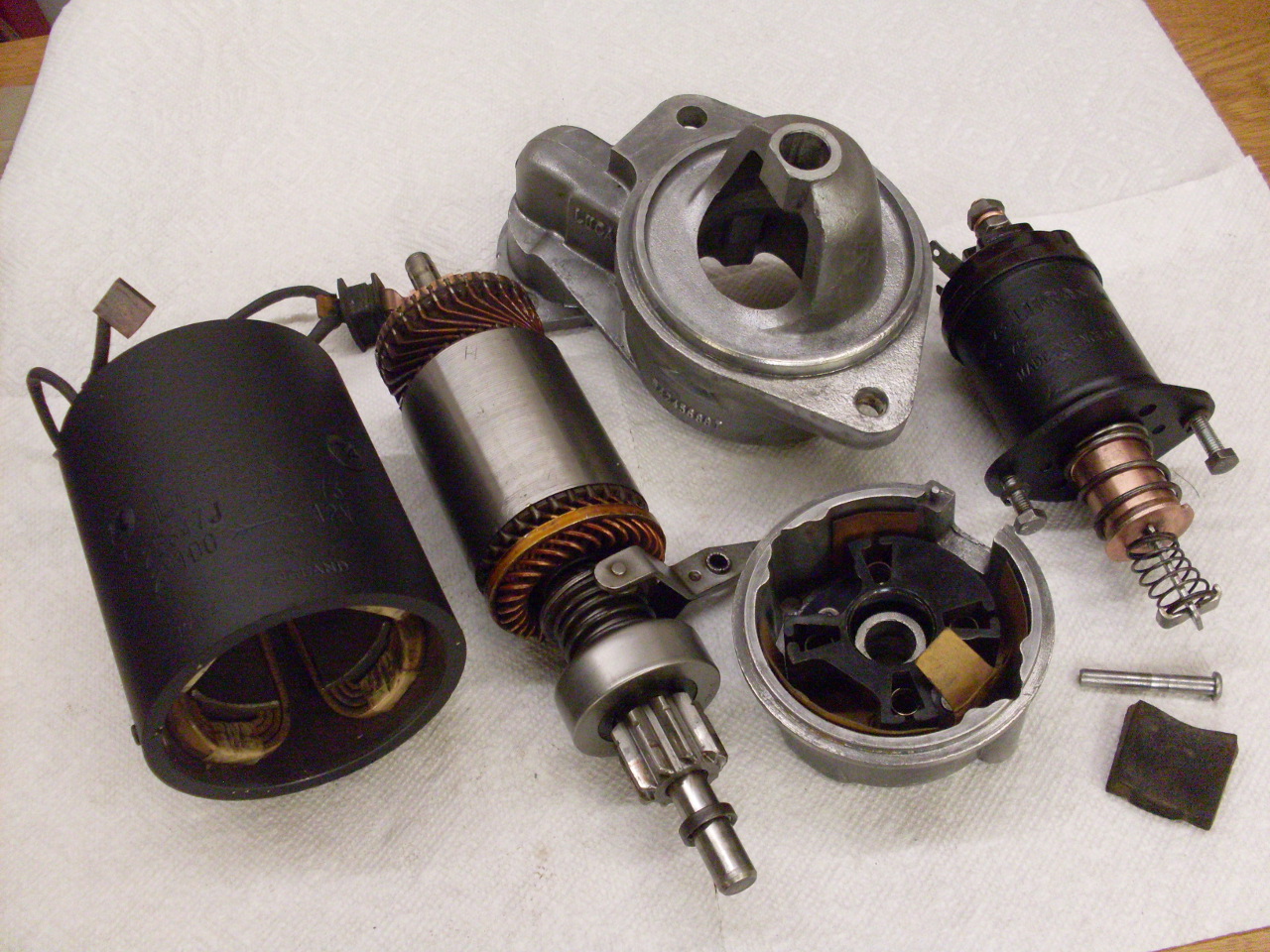

The

TR6s used several Lucas starter motors during their run, but mine is a

2M100 unit used on the later cars. It's a pretty ordinary design,

and the only remarkable thing that I hadn't run across before was the

face-oriented commutator. In this design the brushes are spring

loaded against the commutator, which pushes the armature up against a

thrust collar that bears against the drive gear housing. The unit

uses an external solenoid that both mechanically moves the drive

gear to mesh with the flywheel's ring gear, and also electrically

connects the motor to the battery positive. There is a one-way

roller clutch behind the drive gear that keeps the starter from being

driven from the flywheel when the engine starts.

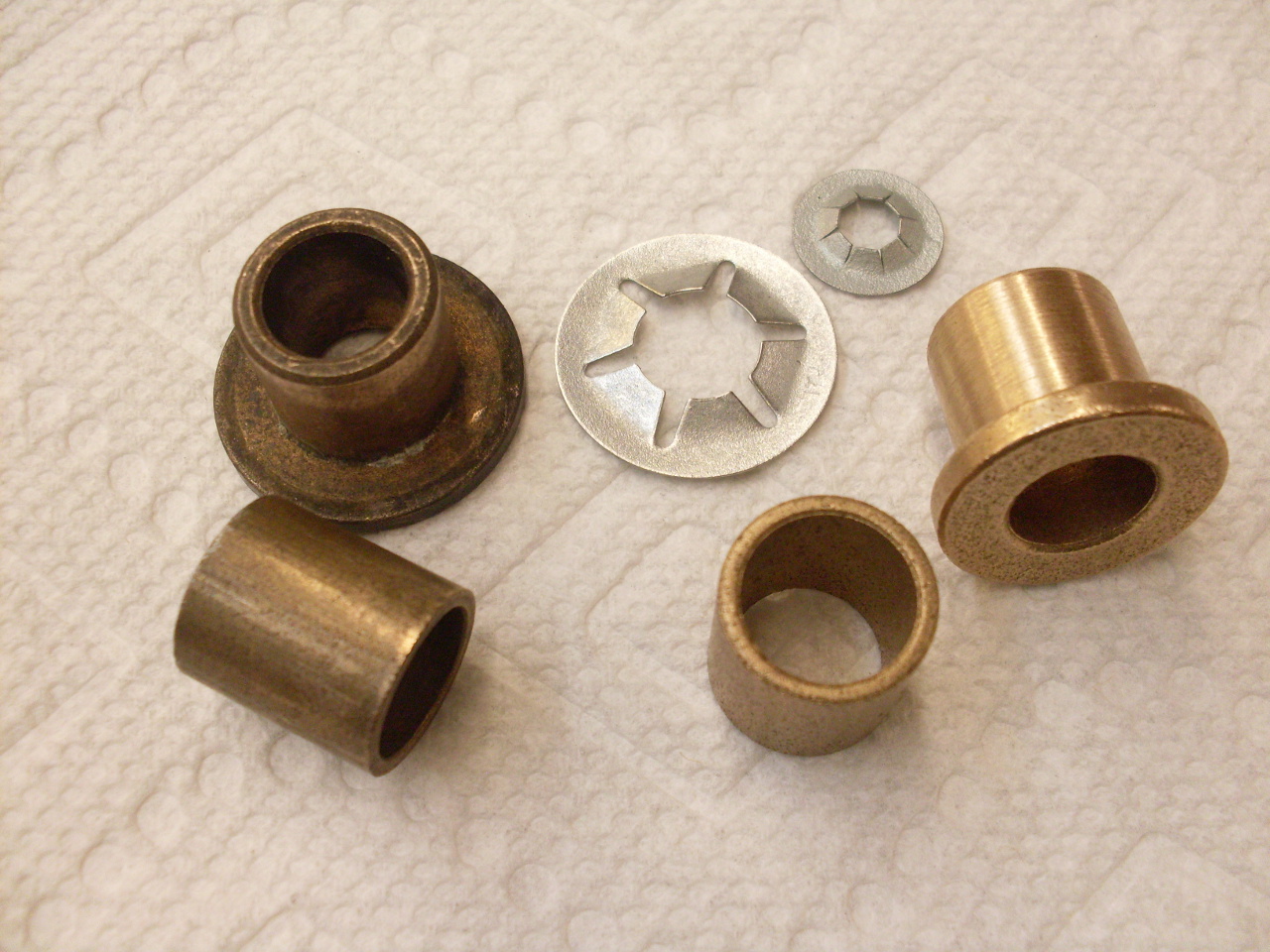

Bushings and brushes are apparently available for these staters, but not much else in the way of replacement parts.

I

believe this starter is original, or possibly an early 80s

replacement. Its condition was nothing unexpected for a 30+ year

old unit.

Disassembly

went OK except that one of the long through bolts broke off in the

drive end casting. Damn. Have to deal with that later.

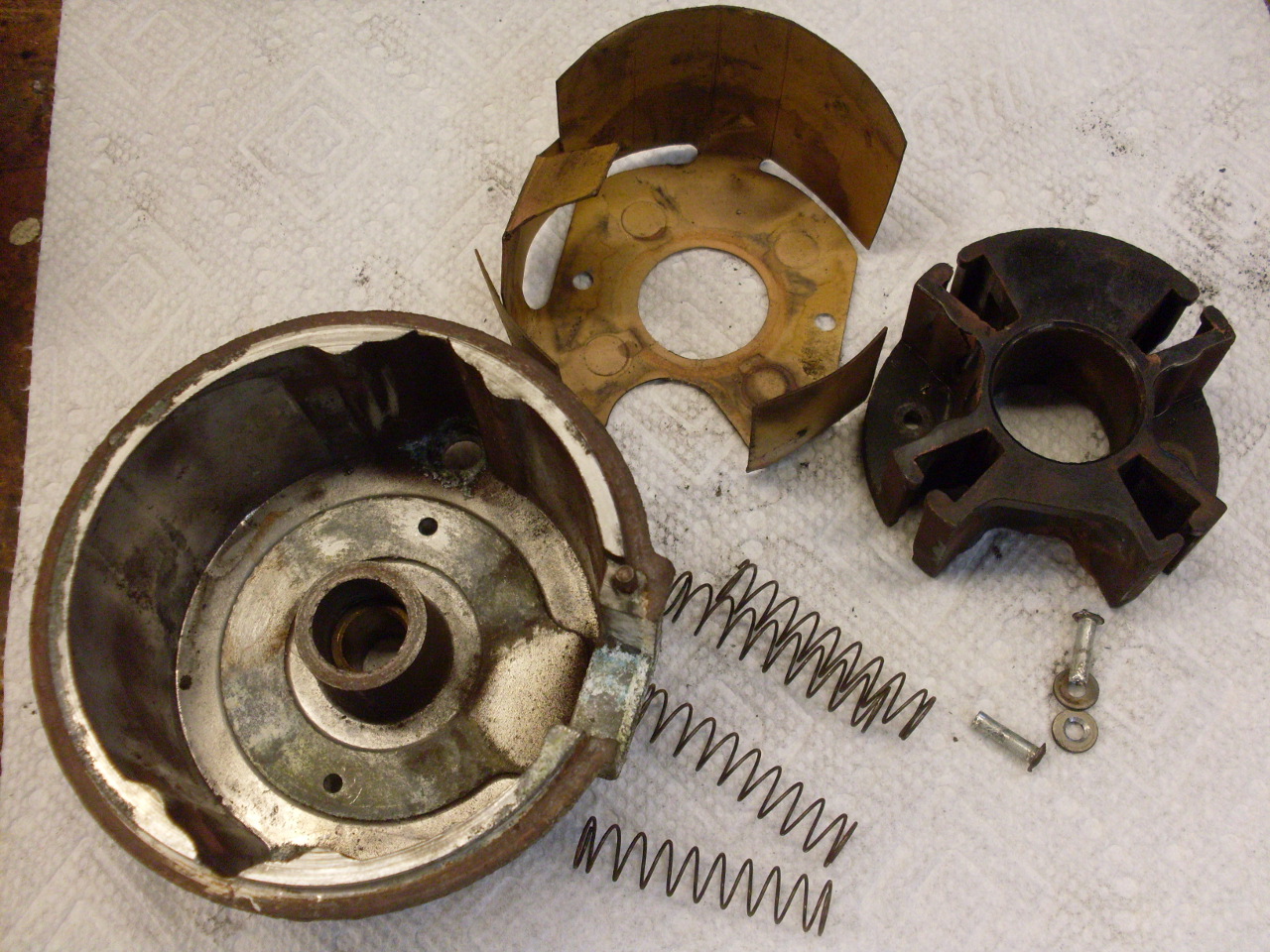

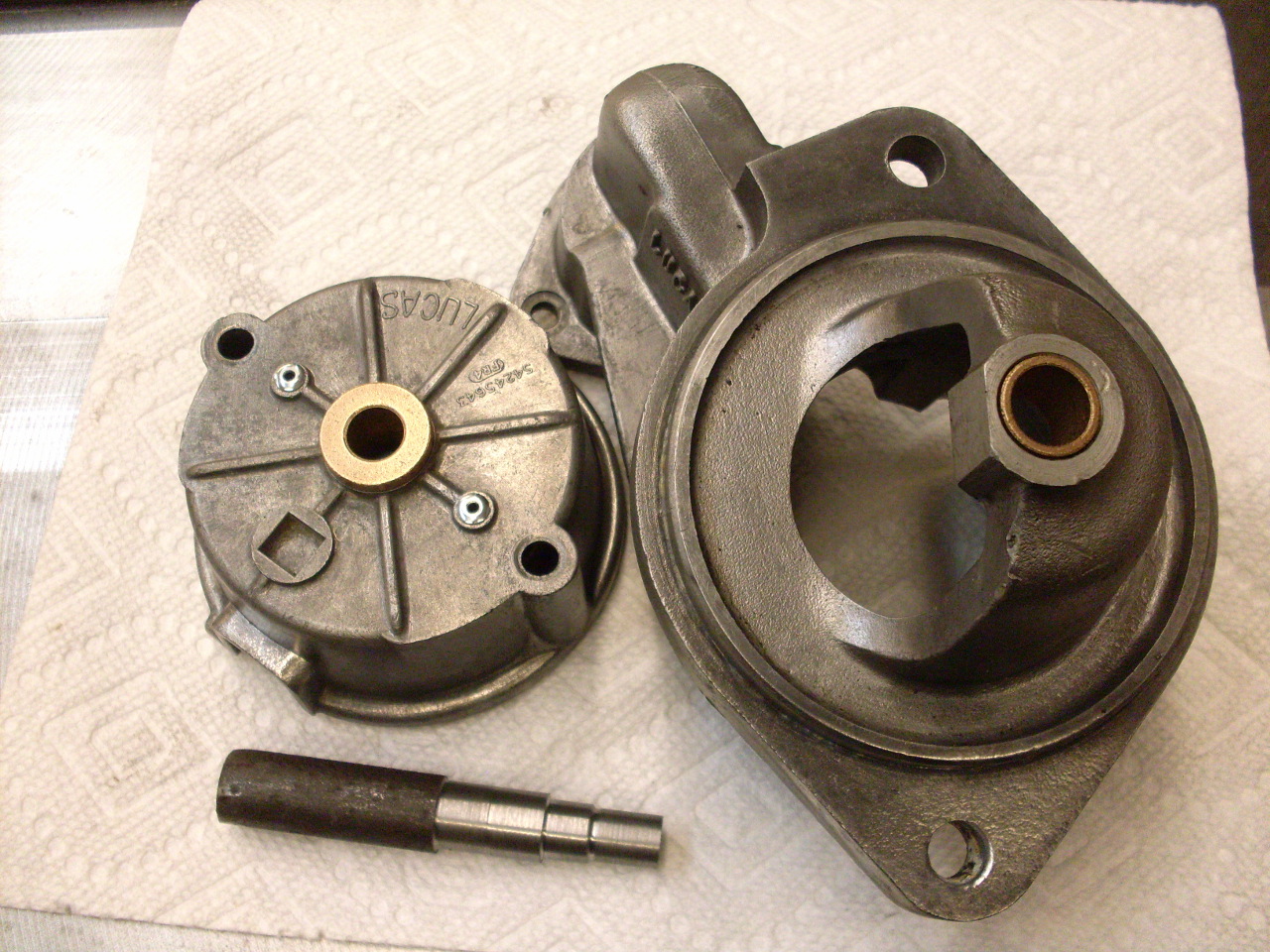

There

is a phenolic brush box in the commutator-end casting that holds the

four triangular-shaped brushes, and the springs behind them.

The brush box is riveted to the casting.

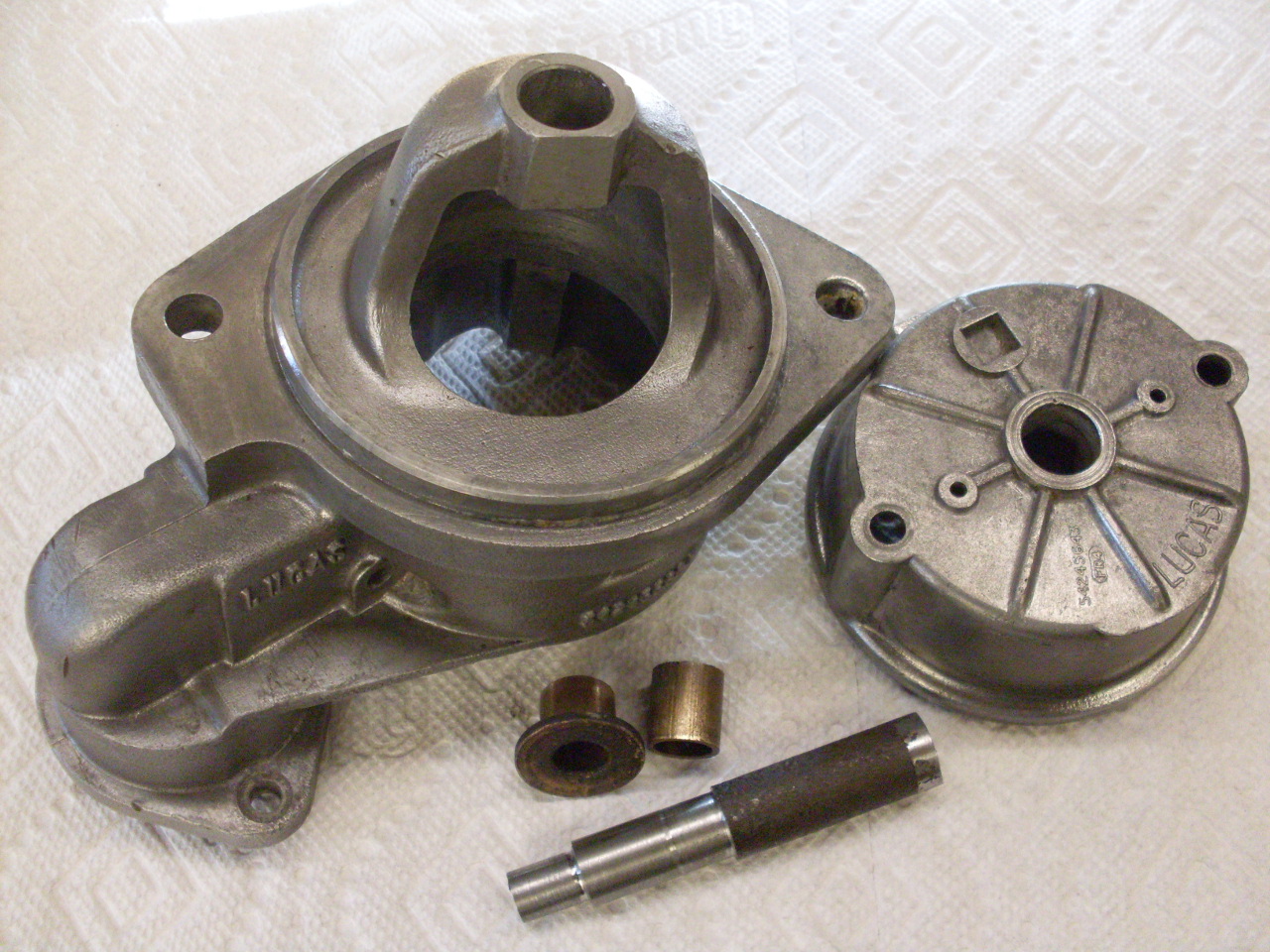

Each of the end castings has a bronze bushing for the armature shaft. A simple drift helps to drive them out.

The

yoke carries the field windings. I didn't remove the windings

themselves, but cleaned out the inside of the yoke pretty well with

compressed air. Also cleaned up all the rust and grease on the

outside.

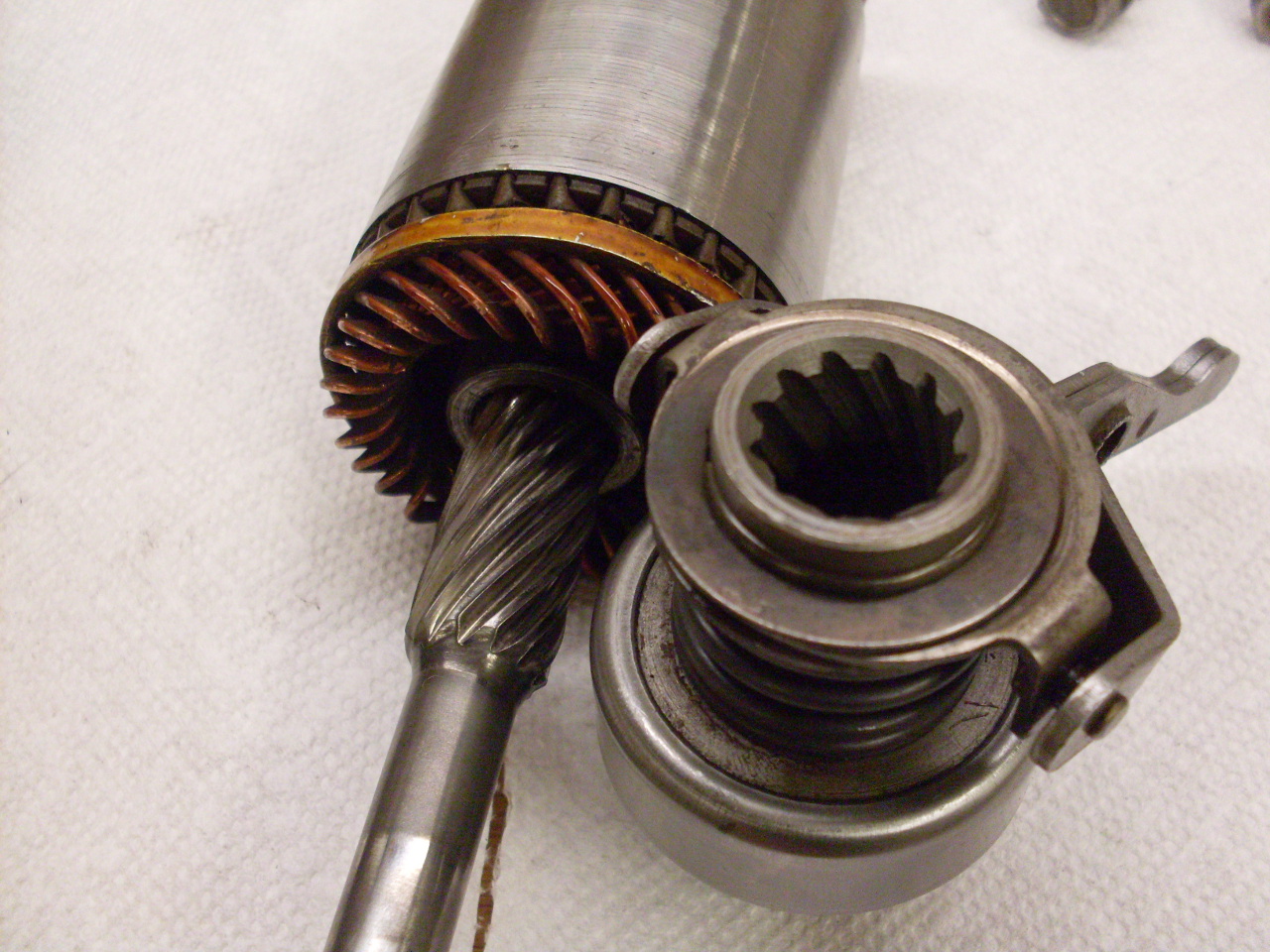

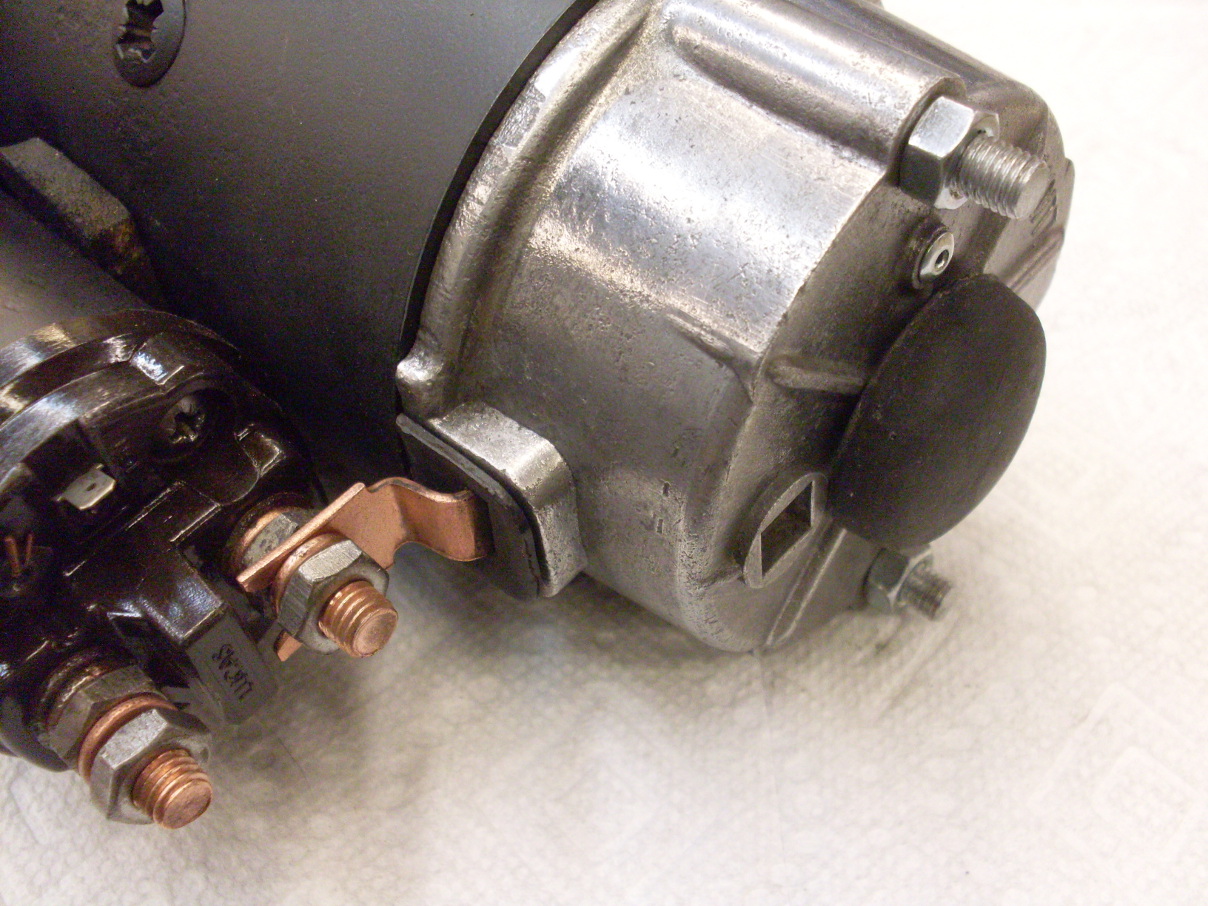

To

clean and lubricate the helical splines on the armature, the drive gear

and the roller clutch drive have to be removed from the armature shaft.

To do that, the thrust collar and "jump ring" have to come off.

That requires a simple drift tool that probably isn't available,

but isn't hard to make. Even so, it's a pissy little job that

takes way longer than it should.

The

face commutator was in pretty good shape, and didn't require any

attention. Brush length and brush spring pressure were both well

within spec.

Pretty much just cleaned up the solenoid.

So here are all the major parts ready for reassembly. At this point, I was still waiting for the bushings.

New

parts (on the right). I think these may be available from some

Triumph parts outfits, but I got them from an industrial supply place.

Then

there was the matter of the broken through bolt. I successfully

drilled out the remains of the old one, but wasn't able to locate

replacement parts. The bolts are 7mm metric by about seven inches

long. Even my usual industrial suppliers failed me. I might

have been able to get used ones, but judging from the difficulty I had

getting them out, it was likely that used ones would have jimmied up

straight-slot heads. I decided to make some bolts with threads

on both ends as replacements. I got some 7 mm rod, and found

that I already had a 7mm x 1.0 threading die. I've had that

metric tap and die set for probably 30 years, and I'm pretty sure this

is the first time I've needed the M7 x 1.0 die.

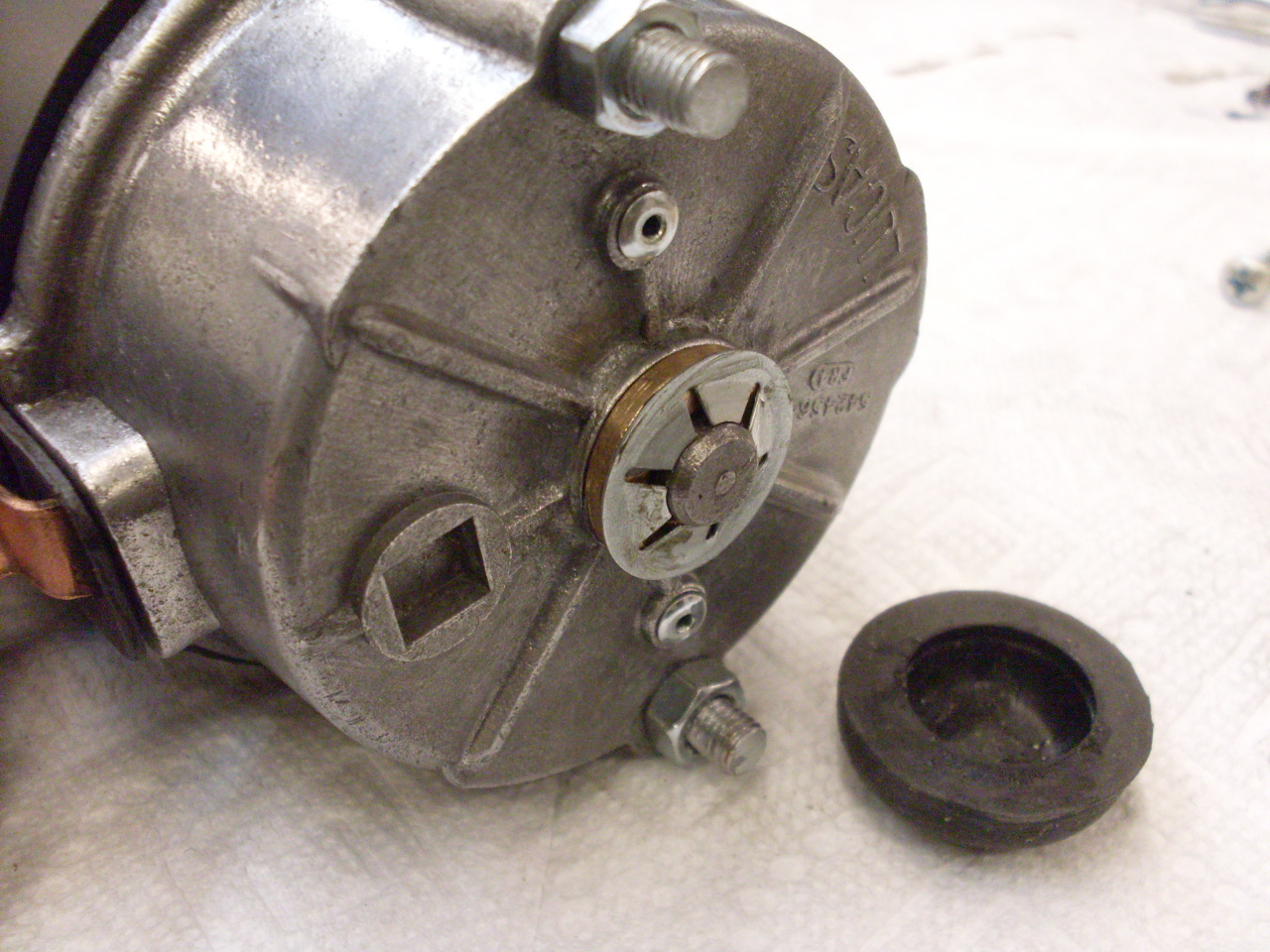

I

also have been fooling around with home zinc plating recently, so I

plated the bolts and also the solenoid bolts and the solenoid pivot pin.

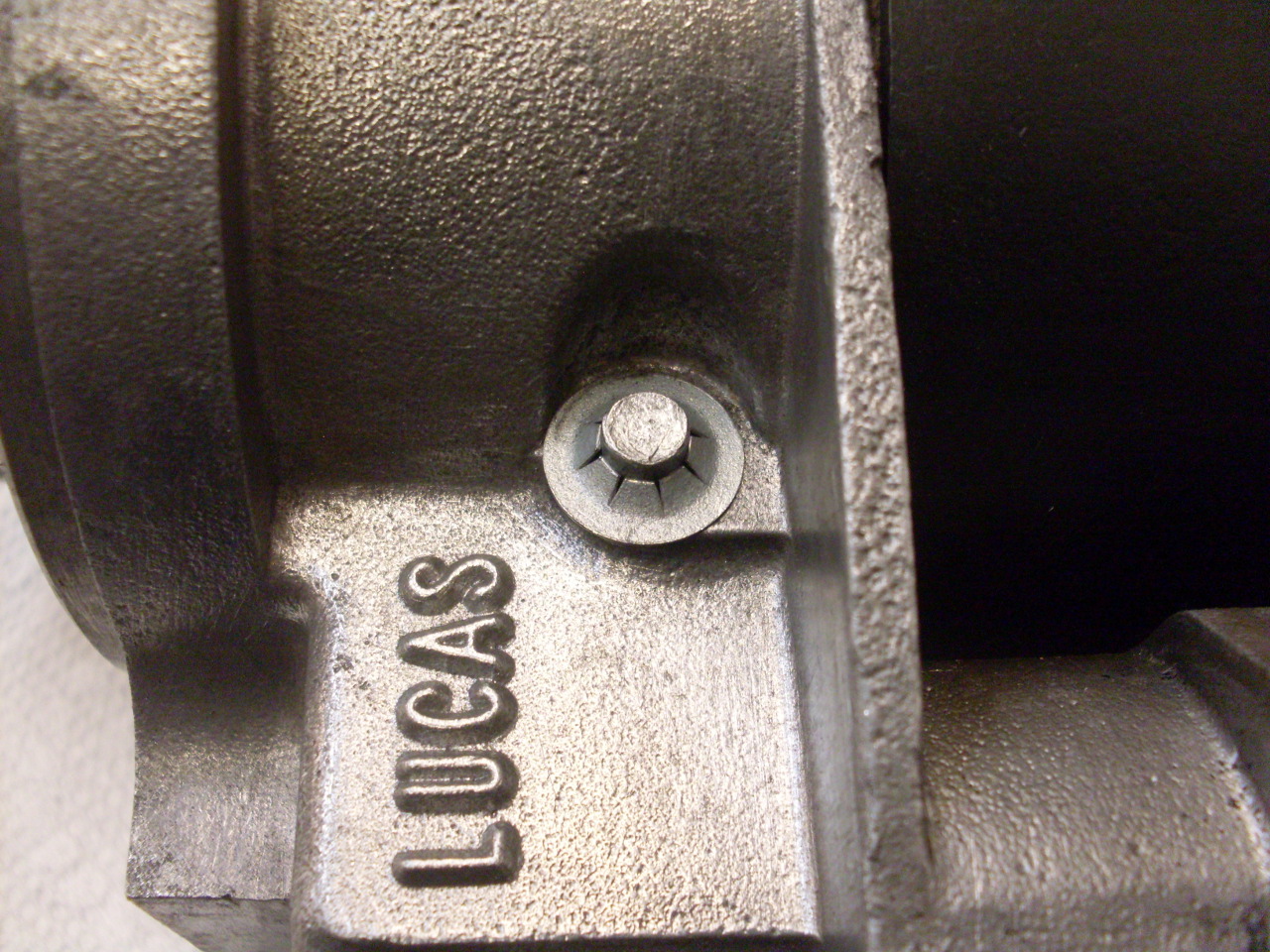

The new "spire nut" ("push nut" on this side of the pond) on the solenoid pivot pin.

The

only thing lacking is the rubber cover for the end of the armature

shaft. Originally, it was held on by gripping the spire nut.

The new spire nut has a smaller OD, which is actually moot right

now, since the cover is too rotted to grip anything anyway.

Still working on what to do for this.

Final

assembly goes on the shelf for eventual installation. I guess I

should test it first. Total cost for this rebuild was under $10,

plus a few hours time.

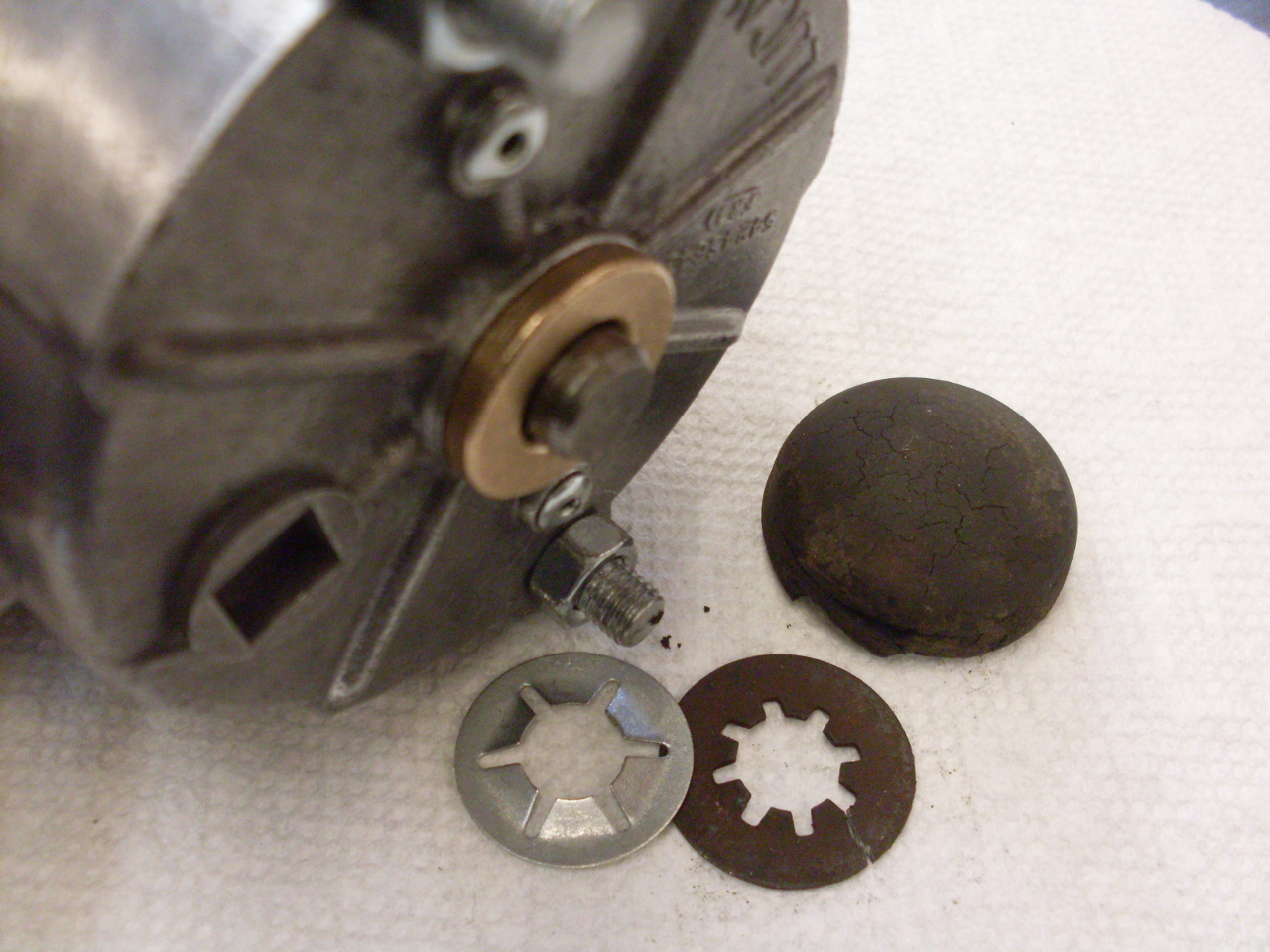

Update, December 3--

I

wasn't successful in finding a rubber cap for the end of the armature

shaft, so I resorted to casting one. Here is the cast rubber part

(on the left in each pic) compared to the old one. The thicker

wall on the new one was necessary because the new spire nut was smaller

in diameter than the original.

Here is the new part installed.

For those really interested in the casting details, go here.

Other Pages

Comments to: elhollin1@yahoo.com