To Other TR6 Pages

July 2,2014

Exhaust Manifold

[Click the pics for a better view]

To finish up the engine attachments, I hauled the exhaust manifold up to the bench.

The

manifold is a pretty standard iron casting. The

only possibly remarkable thing about it is that instead of dumping

all six exhaust ports into a single downpipe outlet, the fore and aft

sets of three ports each dump into a separate downpipe. With the

inlet manifold arranged the same way between the two carburettors, it

may be reasonable to think of the engine as two separate three cylinder

plants for some purposes. There is, however, an opening between

the two halves of the exhaust manifold just above the downpipe outlets.

I'm not sure of the purpose of this passage, but considering the

speed and inertia of the moving pulses of exhaust gas, it's doubtful it

has a large effect on exhaust flow.

My manifold was appropriately dirty and rusty.

All four of the downpipe studs sacrificed part of themselves on disassembly.

After

several rounds of penetrants, heat, and swearing, I eventually removed

two of them by welding a bar to them for additional torque.

Unfortunately, in a case of pure defiance, the other two decided

to mock me by simply breaking off inside the casting.

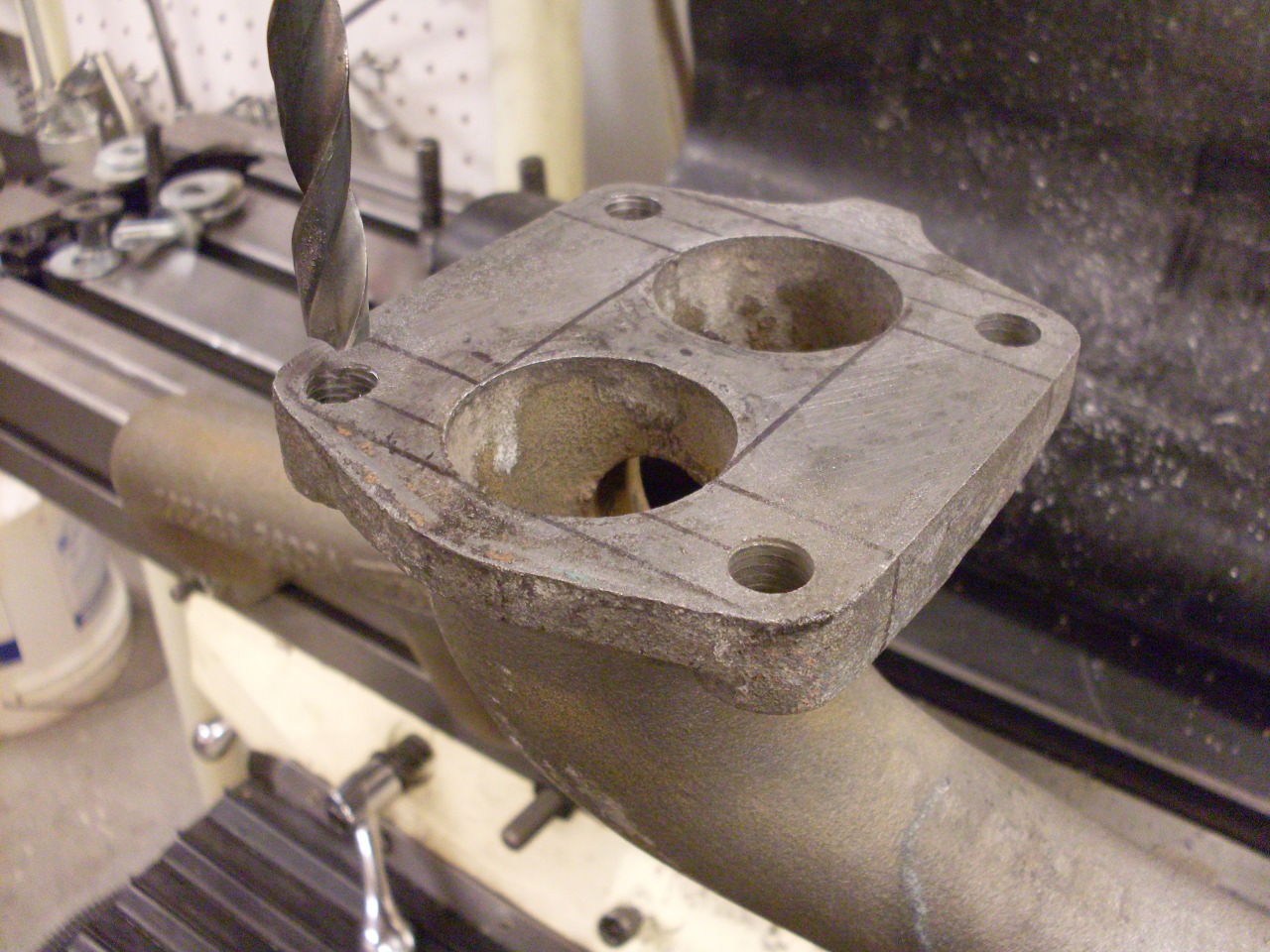

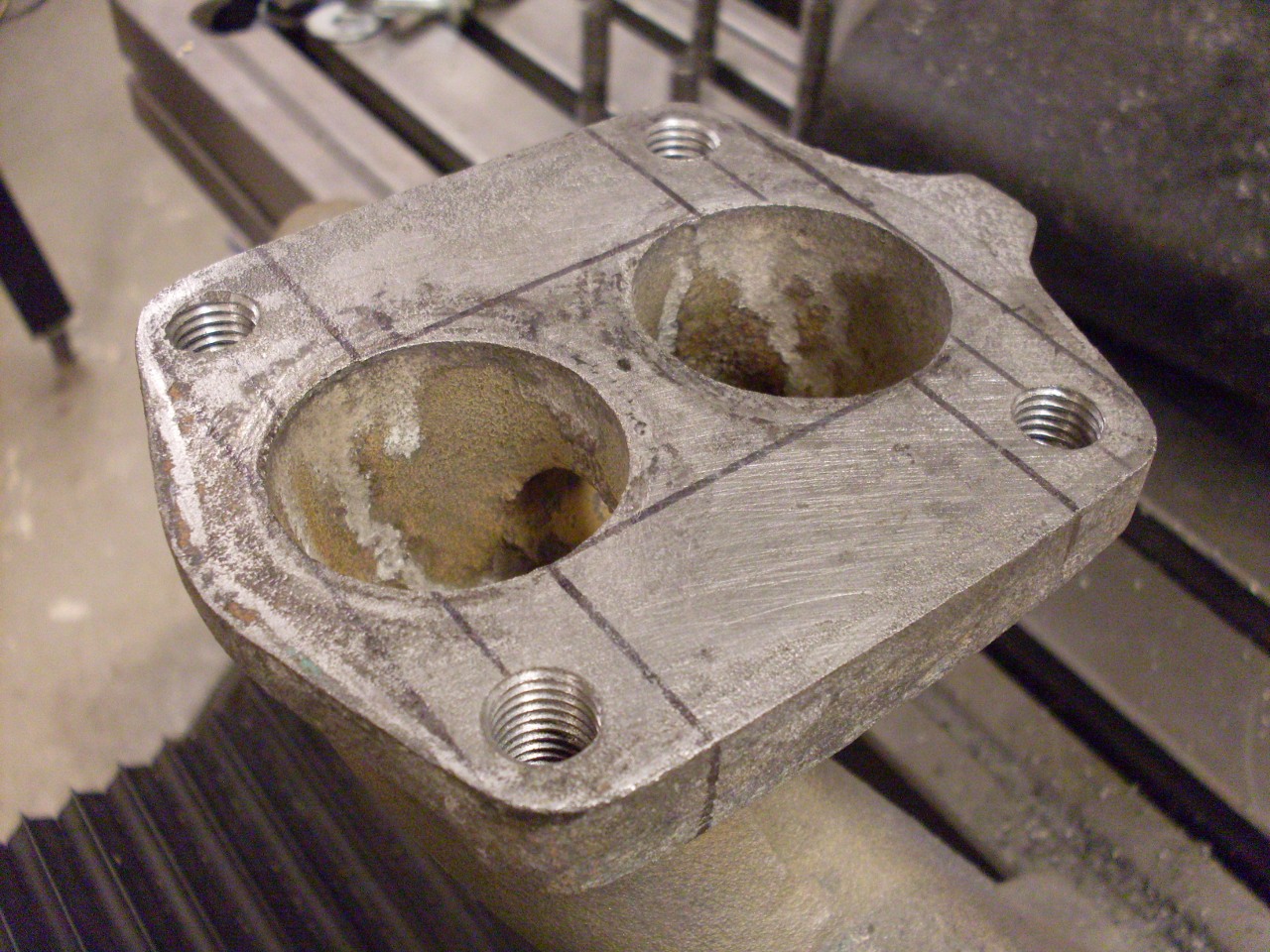

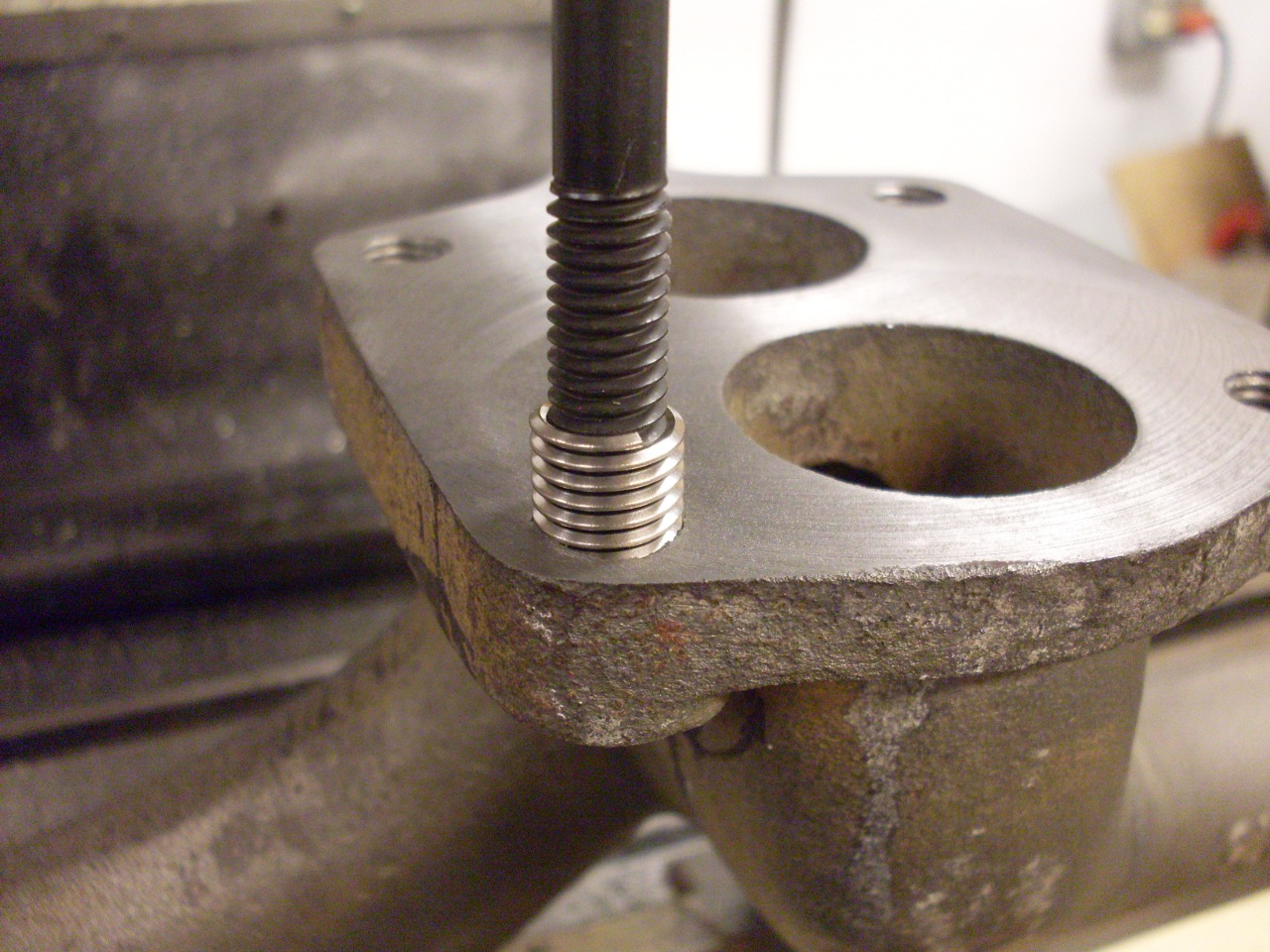

I

drilled out the two bad boys, but in the process managed to damage the

threads in one of the holes. This meant some kind of insert, and

I decided it wasn't much more work to just do them all.

While

waiting for the mail order Helicoils, I derusted the manifold to make

it more pleasant to work on. My derust tank isn't big enough to

do the whole manifold at once.

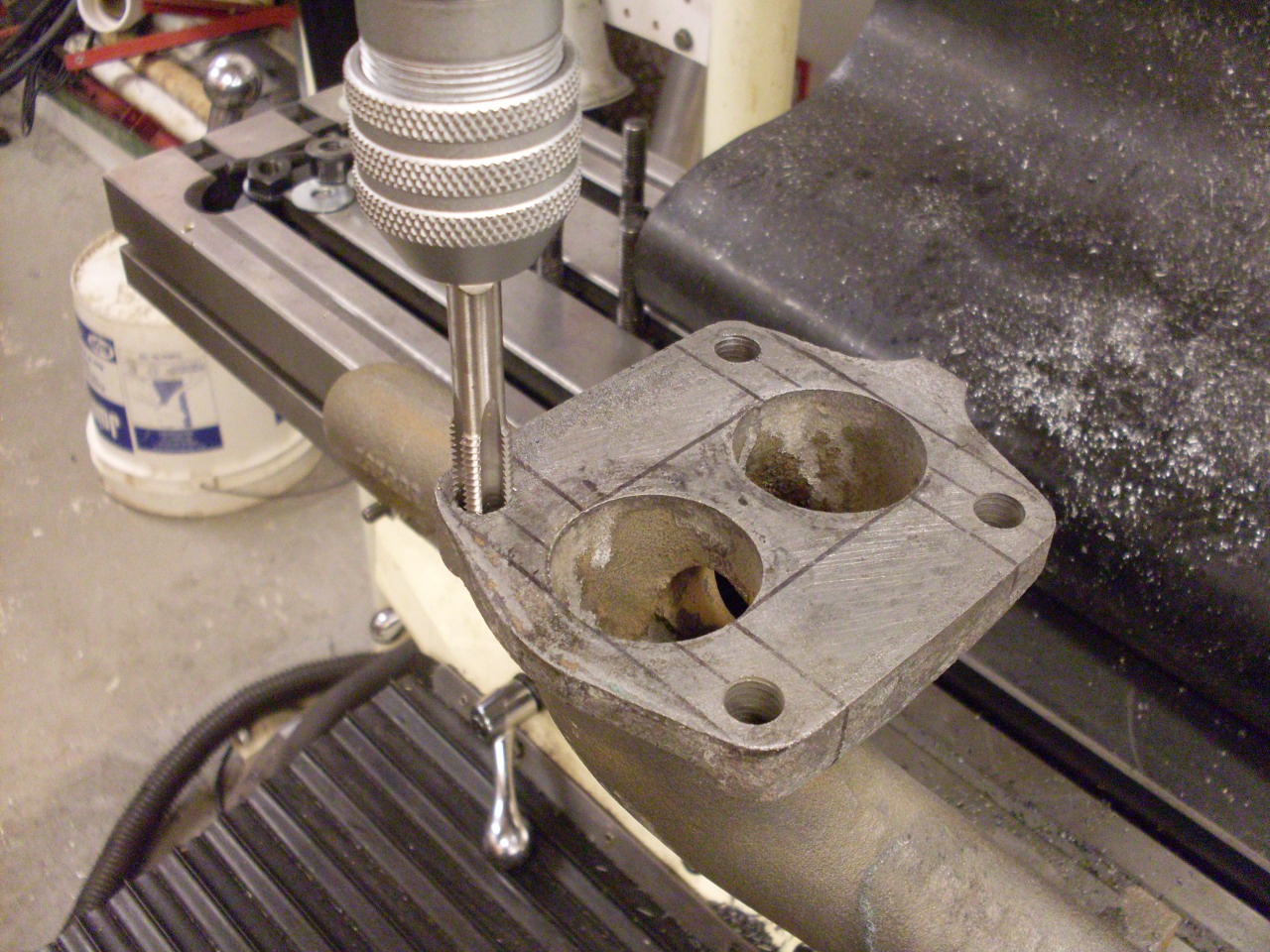

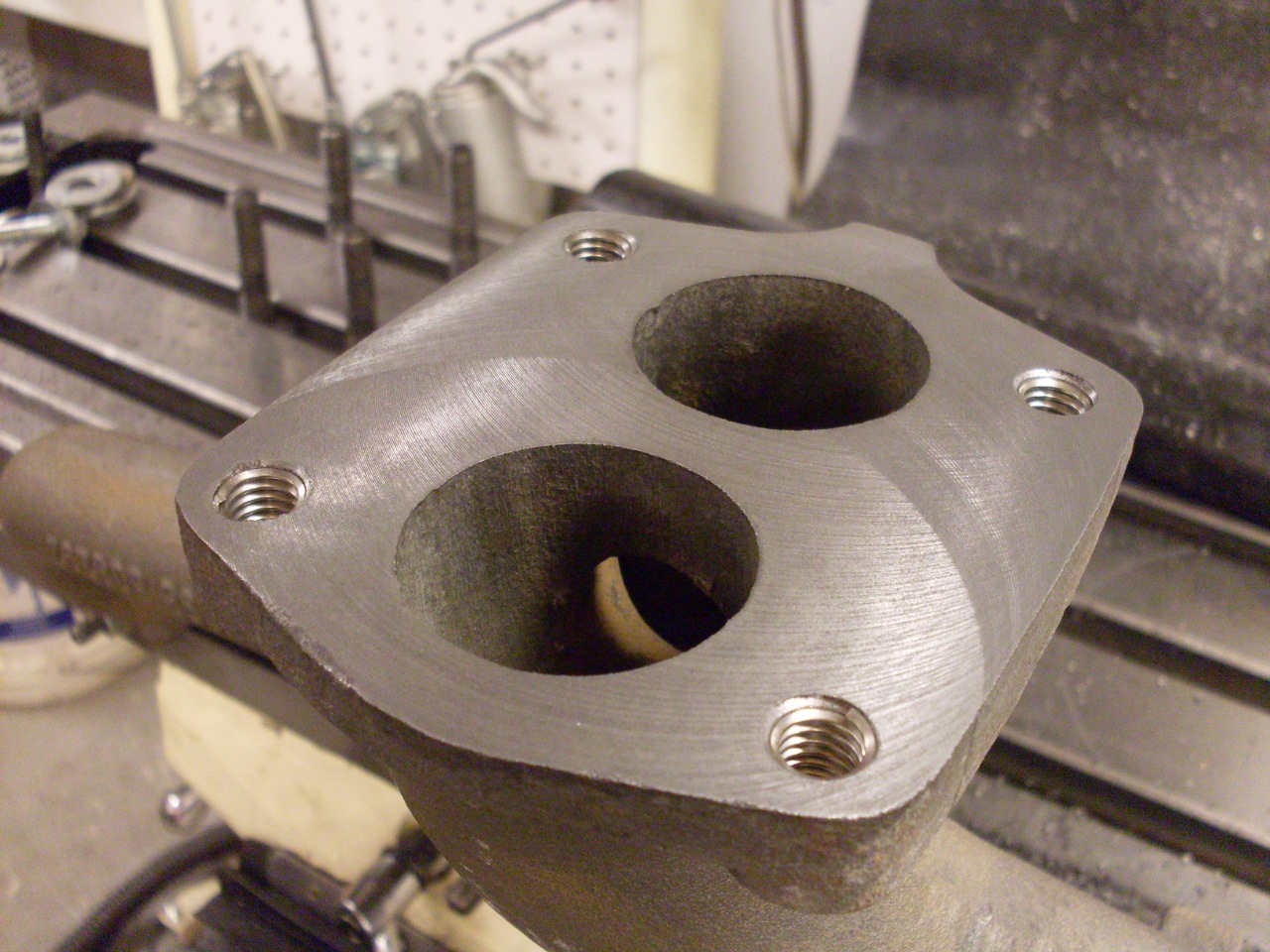

Setting

up the manifold on the mill was a challenge in work holding.

Luckily, the machined surface on the head end of the manifold is

at a right angle to the downpipe end, so I could just clamp the top end

to the front surface of the table to drill and tap for the inserts.

Since I already had the manifold mounted like this, it seemed

silly not to face off the rough pitted surface. The layout lines

were for a plan I had to install two bungs for oxygen sensors. I

ended up deciding to put them in the downpipe instead.

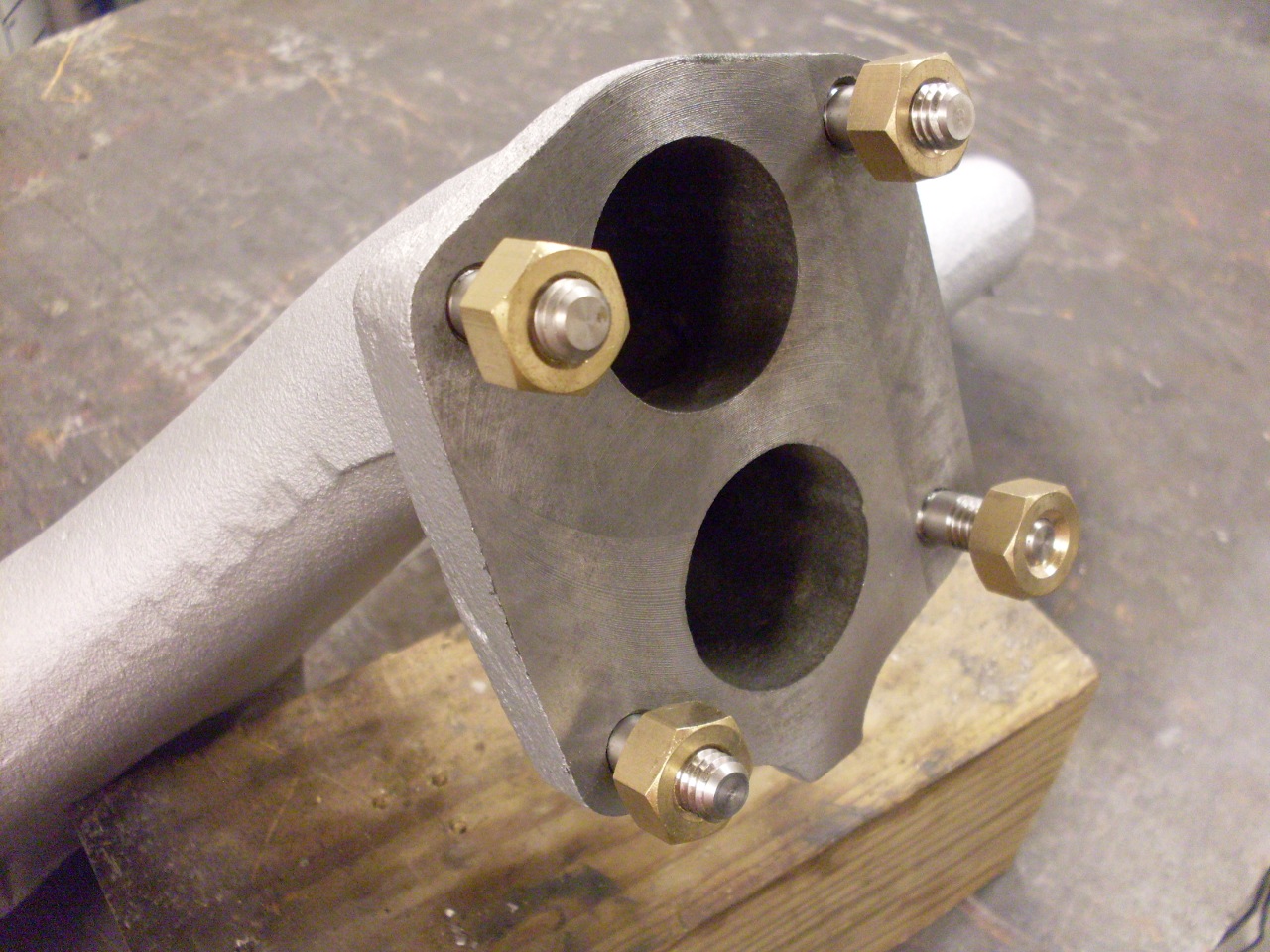

A coat of high temp manifold paint, and new stainless studs, installed with plenty of anti-sieze.

To Other TR6 Pages

Comments to: elhollin1@yahoo.com