To my other TR6 pages

December 17, 2014

[Click the pics for a bigger view]

Drive Shaft

The

TR6 drive shaft (or propeller shaft) is a pretty standard item.

It has a flange connected directly to a universal

joint at each end, and a sliding spline joint in between.

This arrangement accommodates the changing alignment between the

transmission output shaft and the differential input shaft. All

the parts of my drive shaft were dirty and rusty. This is after

pushing out the U joints.

After some cleanup and derusting:

After powder coating. The main shaft is too big for my small oven, so it got a couple of coats of POR15.

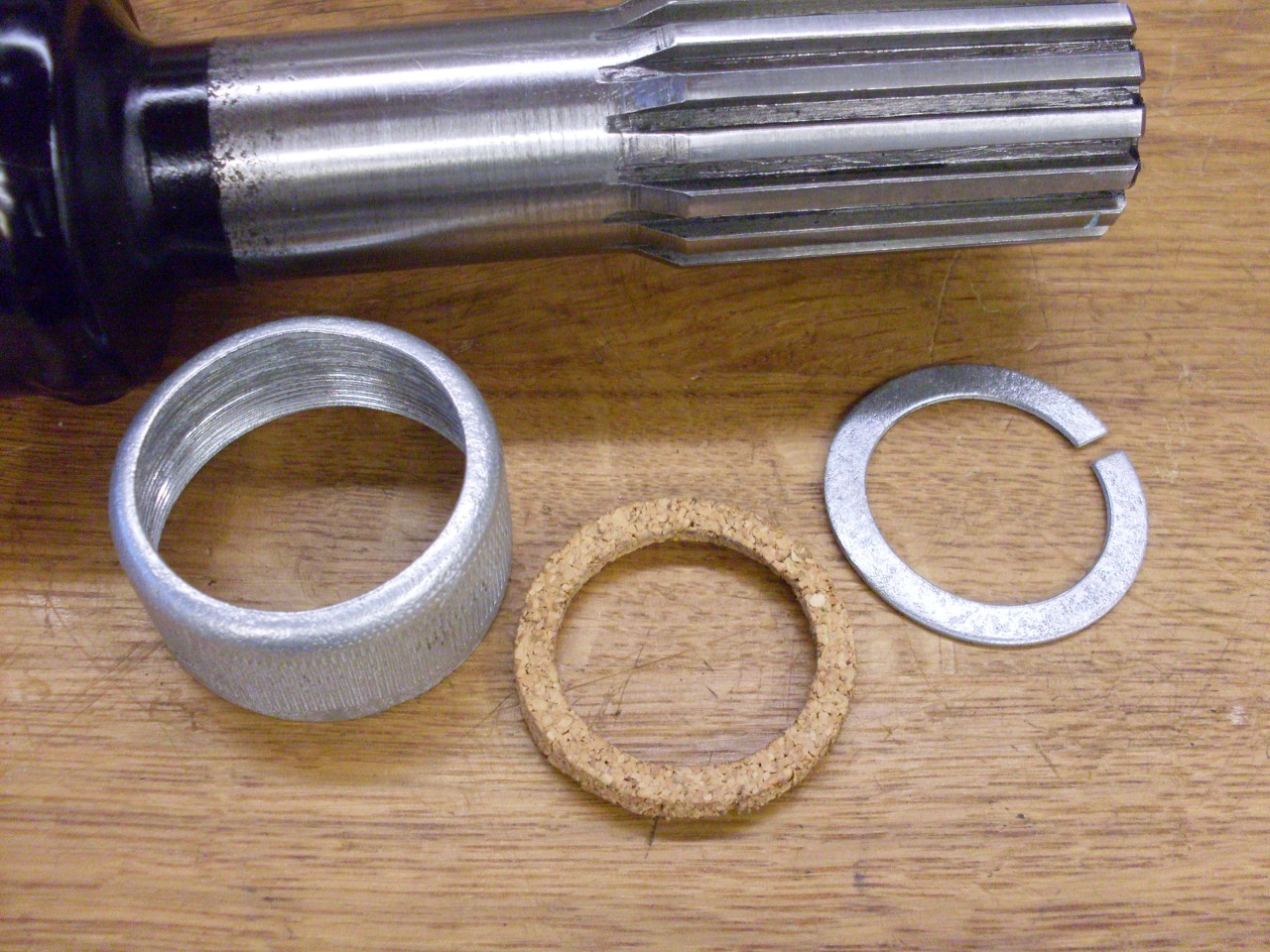

The

sliding spline has a cork seal to keep dirt out. It was hard and

brittle, and came out in small pieces. As far as I can tell, it

isn't available anywhere, so I fashioned one from some cork sheet.

The steel split washer and the cap were re-plated.

Here

is where the story takes a grim turn. Any time someone uses a

powerful tool like a hydraulic press to move something, there is a real

potential for unintentional carnage. Installing U joint bearing

caps is a relatively routine process, but occasionally something goes

awry. I was pressing one of the caps into the sliding yoke when

something apparently got cockeyed in a direction I didn't see.

When I should have stopped and investigated the reluctance of the

cap to go into the bore, I kept pouring on the tons, believing the cap

would right itself. The sad result was a bent ear on the yoke.

A disappointing

Internet search revealed that no one was selling just the yoke, and

that everyone who was selling a complete drive shaft apparently

believed it was made of platinum.

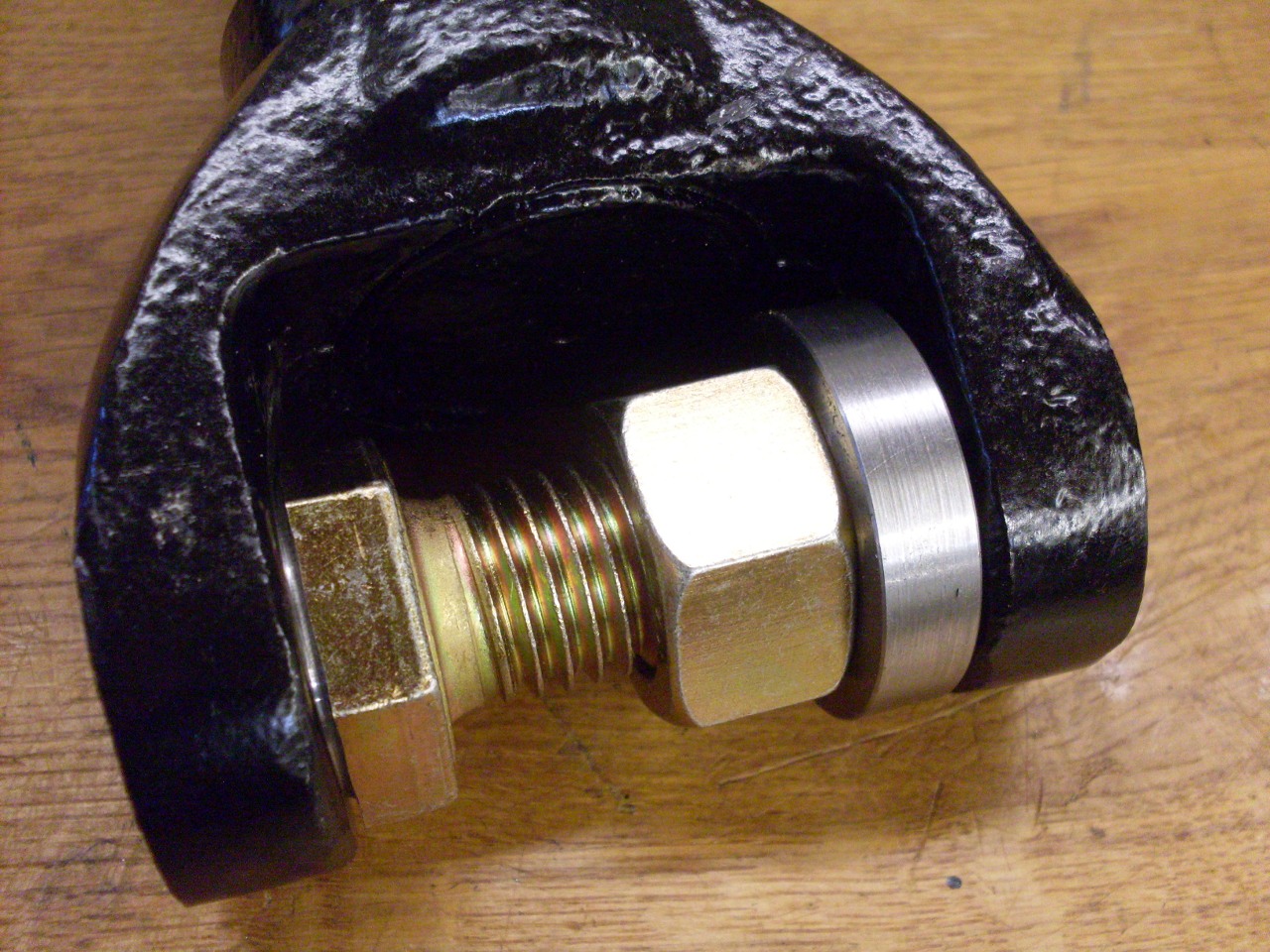

This made me think a

little harder about undoing what I had done to my yoke. Within

limits, bending is usually a reversible process, so maybe I could

unbend what I had bent. Careful measurement showed that the

extreme end of one yoke ear was bent in by about 0.080". The

deformation extended down only to about the center line of the bore.

Another Internet search revealed that some people have

successfully repaired this kind of damage, and I adapted one of the

methods to fit my situation. The head of a 3/4" Grade 8 bolt was

modified so that it would slip into one of the cap bores, which would

keep it centered. A nut on the bolt presses on a stepped collar

that fits into the other yoke bore. This arrangement can apply an

enormous amount of pressure--probably as much as my press. The

little shim in the last pic was inserted to apply all the pressure at

the outer end of the bent ear, since that's where the deformation was

the greatest.

I

went through several cycles of pushing and measuring, and the ear was

slowly moving. I was able to get the ear within a few thousandths

of the correct dimension. I was prepared to use heat, but didn't need to.

After

this success, I noticed that the cocked cap had also left its mark

inside its bore. There was a small ridge of upset metal in

the bore. I was also worried about some lingering distortion of

the bore, so I decided to carefully ream the bores to ensure that they

were round, but also that they were colinear. I used a

cheap adjustable hand reamer for this. Its blades happend to be

just long enough to span both bores. I opened the reamer just

enough to clean up the ridge.

Of

course the danger here is that one or both bores will get too big, and

the bearing caps will be too loose. Luckily, this wasn't the

case, and both caps were still a nice firm press fit.

The

final shaft, ready for install. When assembling the sliding

joint, it's important to get the phasing of the U joints correct.

A single U joint can produce a slight oscillation in speed which

can be canceled by a second U joint if the relative orientation is

correct.

Comments to: elhollin1@yahoo.com

To my other TR6 pages