To My Other TR6 Pages

November 8, 2017

Final Dash Install

[Click the pics for a larger view]

I

wanted to get some of the wiring finished and tested before installing

the last bits of the dash. The steering column, glove box, and

the ventilation air duct system all hamper access to the back of the

dash, so I saved them for last.

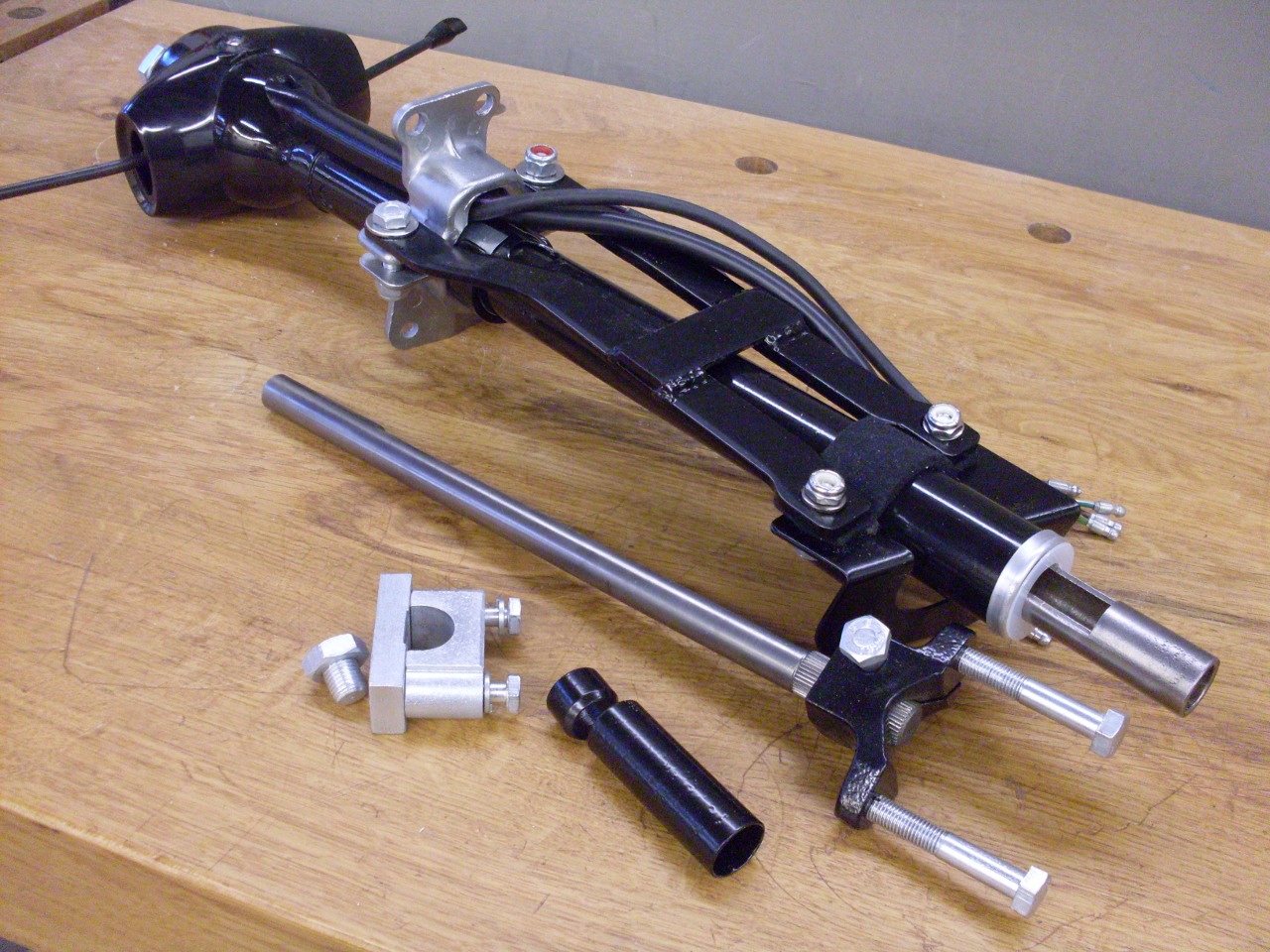

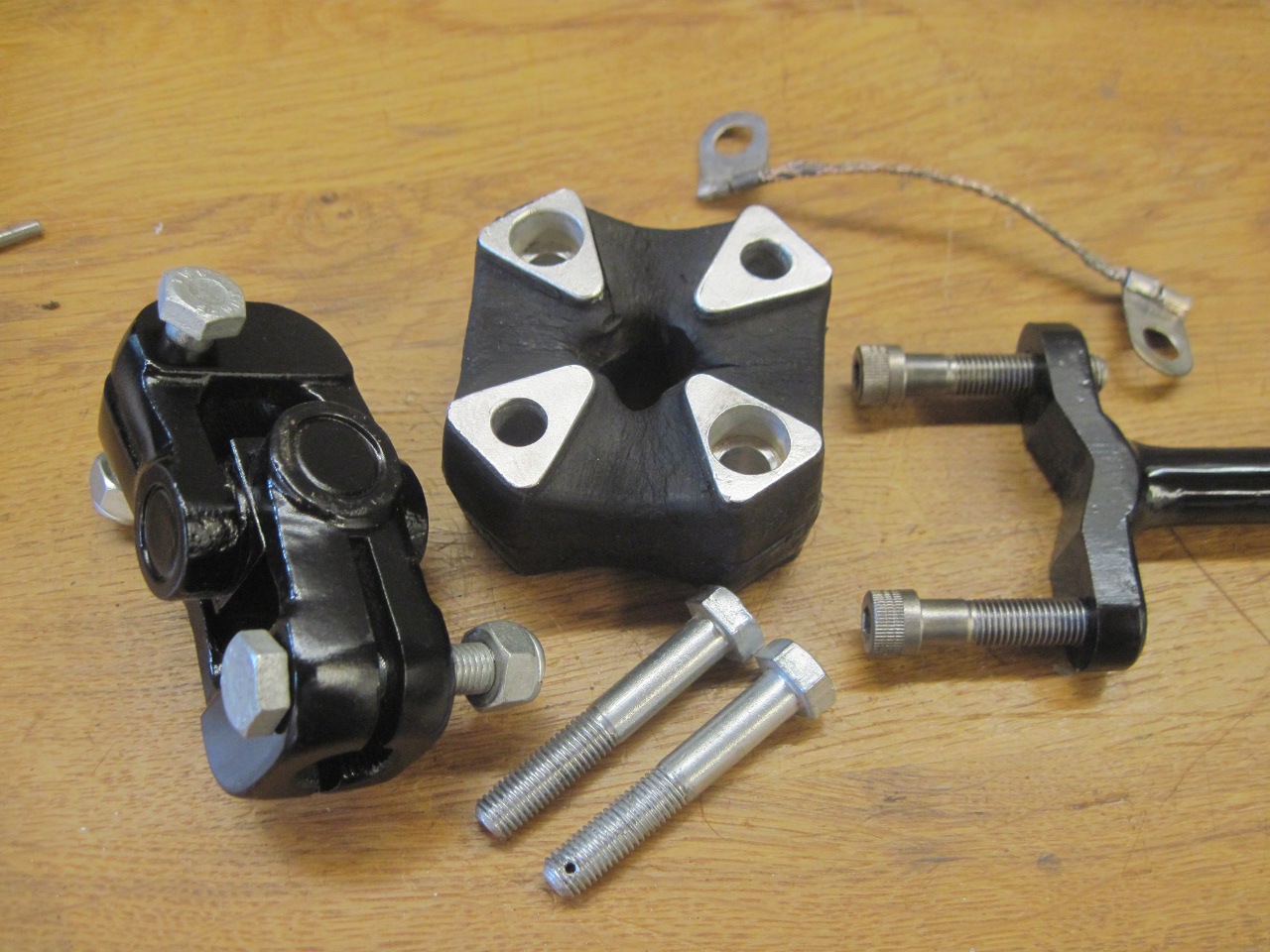

The

last piece of the electrical system was the steering column, so it was

next. I thought there might be an issue with installing the

column with the wood dash already in place, but there wasn't.

Possibly if I were using the original ignition switch and lock,

there would have been trouble. I don't know--my spatial reasoning

isn't good enough to figure that out.

So down came the rebuilt steering column from the shelf where it's been collecting dust for over two years.

The

upper column assembly slid in place easily. The sort of complex

fixing bracketry behind the dash was not quite so simple, but

eventually it all got tightened down. It goes much better if the

tach and speedo are removed.

The

steering wheel is connected to the outer upper shaft. An upper

inner shaft slides inside it. The two are locked together with a

friction coupling that allows the assembly to telescope in the event of

a frontal crash. In that case a pair of special collars

absorb crash energy by one riding up over the other.

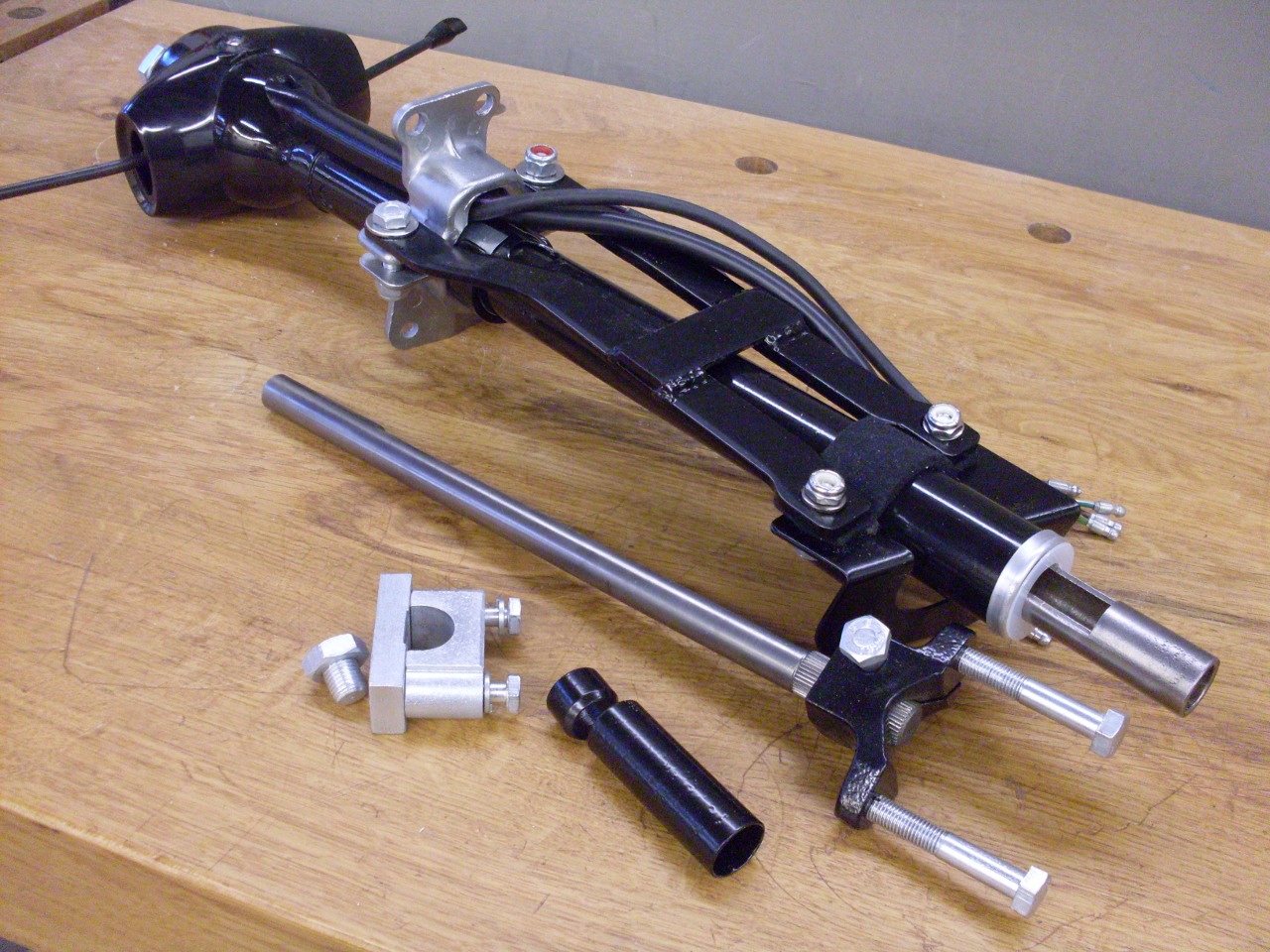

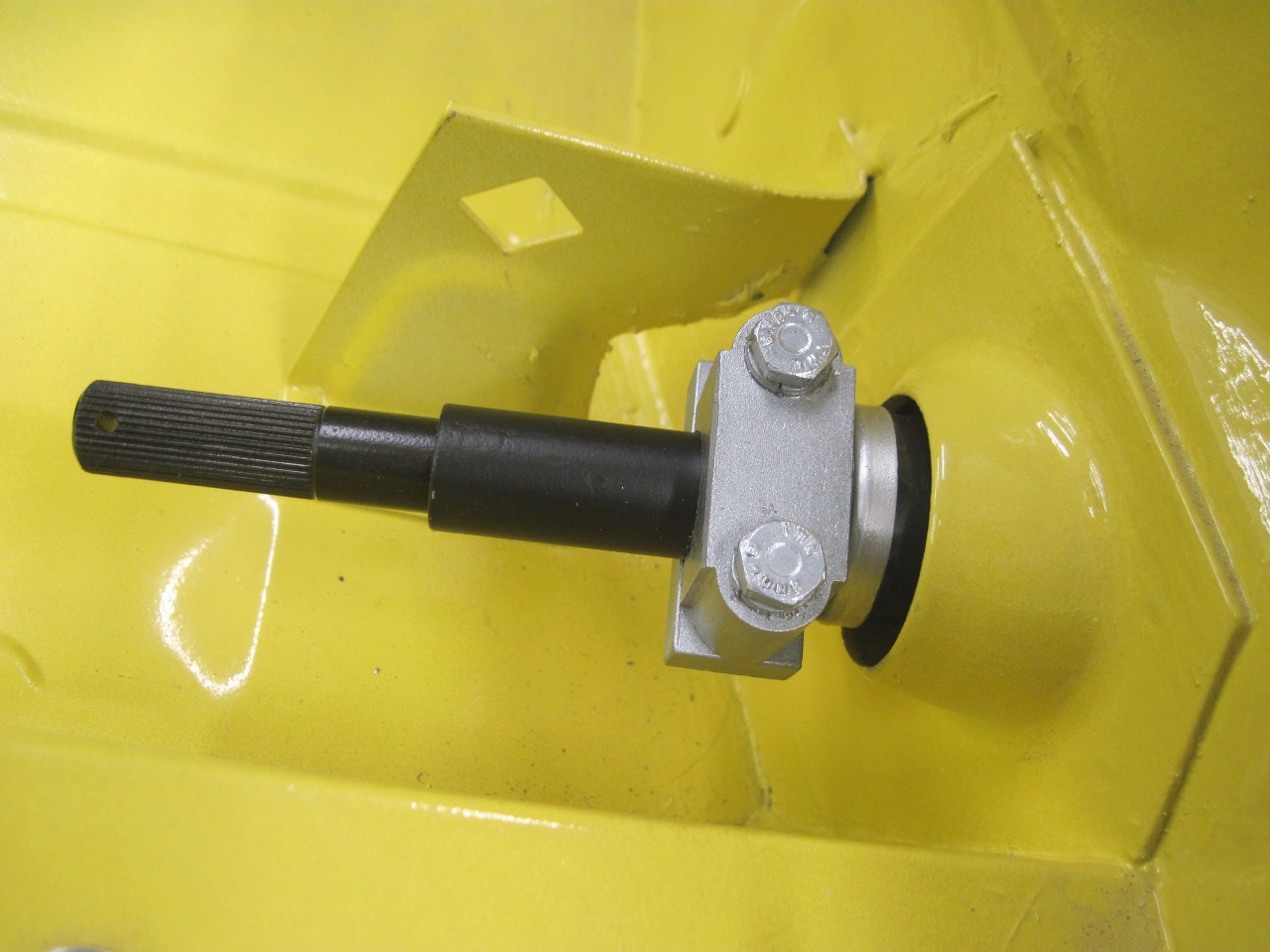

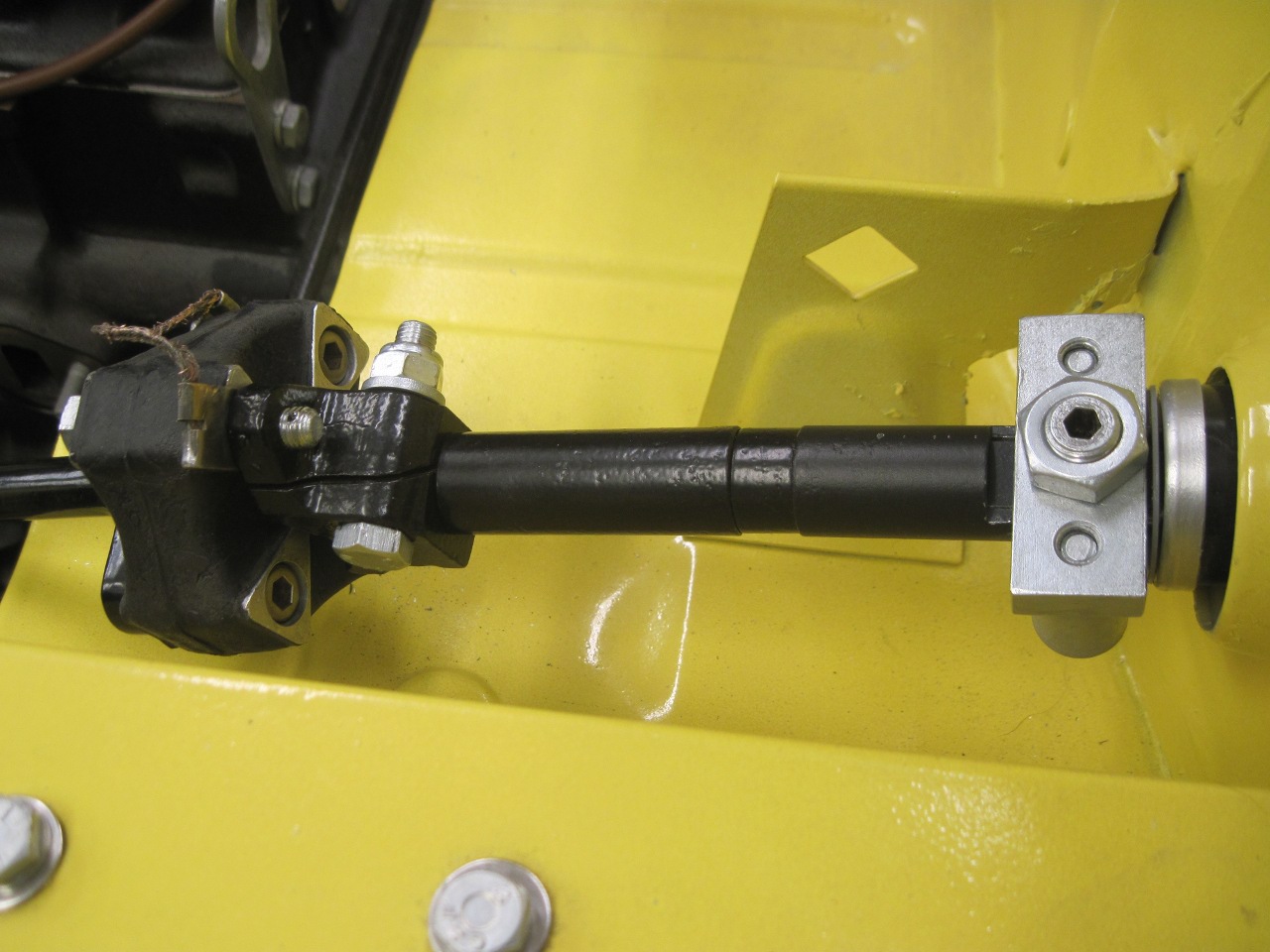

A

rubber U joint connects the upper shaft to an intermediate shaft, which

in turn is connected to the steering rack through a conventional U

joint.

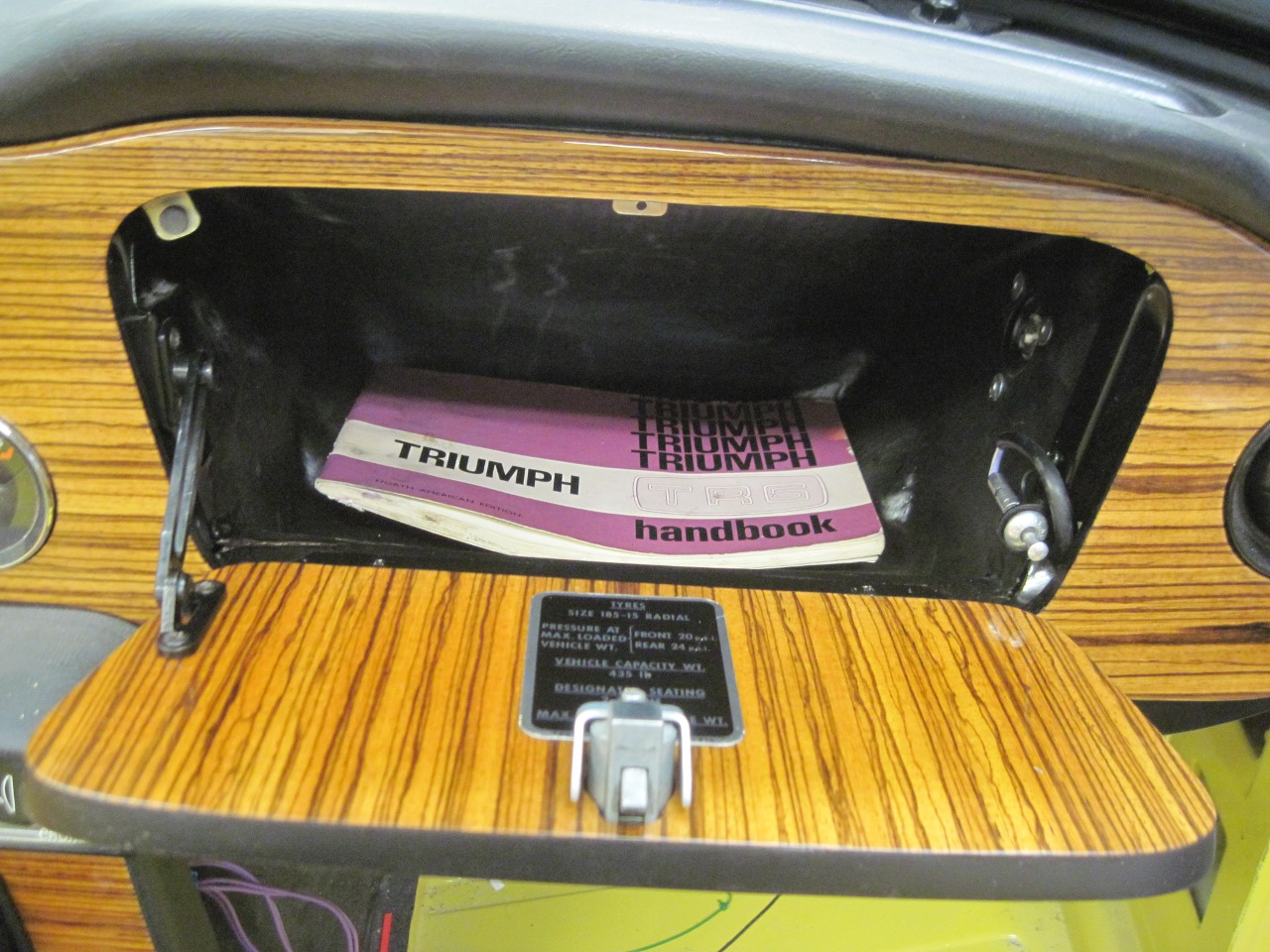

Next up was the glove box. I got my pimped original down from the shelf and dusted it off.

There

are various little widgets associated with the glove box. The one

on the left in the first pic is the catch for the door latch. The

one with the rubber button is a travel stop for the door. I

stripped and replated them. I usually do a clear chromate on zinc

parts, but in this case, I used a yellow chromate to recreate the

original finish.

Then

there is the light switch for the glove box door. In my quixotic

quest to eliminate the car body as an electrical return path wherever

possible, I added an explicit ground wire. It is soldered to a

brass band that is a tight sliding fit on the barrel of the switch.

The

glove box is a tight fit, especially since I eliminated much of

the flex in the original cardboard part. It finally went

home, though I had to remove the bottom metal dash brace to pull the

dash out a little.

Then

the glove box door. Here are the parts that go with it: The

hinges, the latch and bracket, and the limiter strap assembly.

The hinges cleaned up easily, and didn't even need painting. The screws, though, looked pretty rough.

I

tried to match the screws, but they appear to be something between a #1

and #2 wood screw. A #2 screw has to big a head, and the #1 would

be loose on the hole. In any case, for small shallow screws like

these, I always much prefer to use the originals since replacements

won't necessarily have the same thread pitch, and will likely

crossthread the already miniscule threads in the wood. I cleaned

up the rust on the screws, resurfaced the heads, and here they are

ready for paint.

The

latch was sticky, but some lube fixed that. The bracket was in OK

shape, but I replated it with some other assorted stuff.

The

plastic check strap anchor to the door was broken, so that is a new one

made from aluminum. Faced with that problem today, I'd probably

try to 3D print it.

Everything ready to go back together.

Then

it was on to those infernal ventilation hoses and fittings. It's

already pretty tight behind the dash, but room has to be found for

these and a few feet of largish hose. One of the main reasons for

prewiring the dash was to avoid having to contort under the dash, but

to do the hoses, it's unavoidable.

So,

after an hour or so of forcing myself into unholy positions, the hoses

were all in place. There aren't any pictures. To avoid

rattles, while I'm snaked in under the dash, I look for anything loose

that could hit anything else. Where I find such a situation, I

apply one of these self stick felt pads to at least muffle the noise.

Next

up were the lower crash pads. These would have been a lot easier

if I'd put them on before the wood dash. The left one is the 40+

year old original. The right one is the original recovered with new vinyl.

Finally, the DIY steering wheel.

This

was pretty big milestone for me. In principle, I could bolt

up the fenders, start the car and drive it now, but I'll try to

restrain myself until next Spring, after the final bodywork and

painting is done.

As

a recovering woodworker, I love wood. Nonetheless, I acknowledge

that there can be such a thing as too much wood. I might be

crowding that line a little here, but I probably won't change it.

No more wood for this interior, though.

Commnets to Ed at elhollin1@yahoo.com

To My Other TR6 Pages