To my other TR6 pages

April 10, 2015

Dash Switches & Indicators

[Click the pics for larger view]

The re-veneered dash looks nice, but it really won't come into its own until it's populated with all its assorted gadgets and doodads. The speedo, tach, and other instruments are done, but there are the various switches and indicators to attend to.

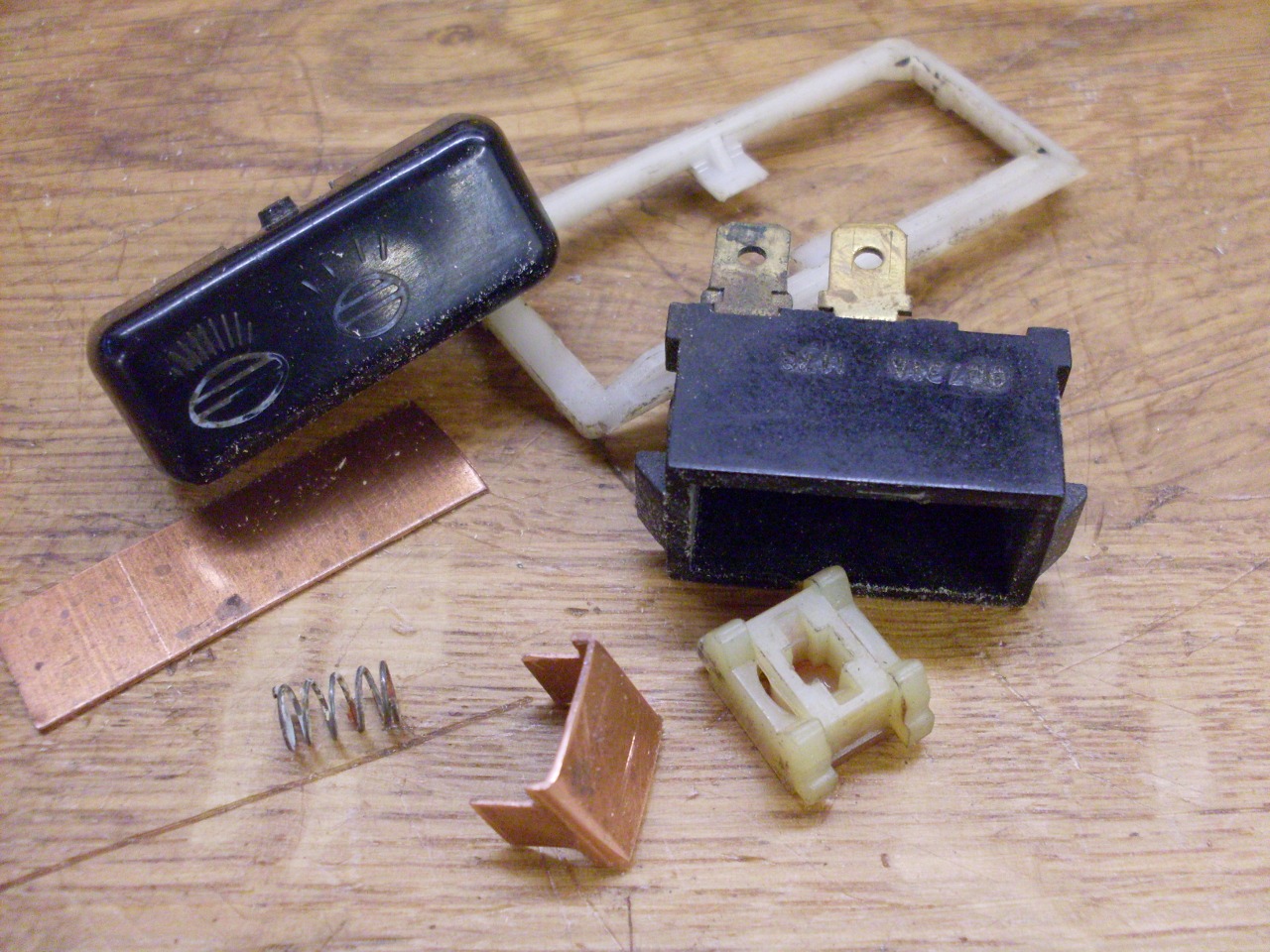

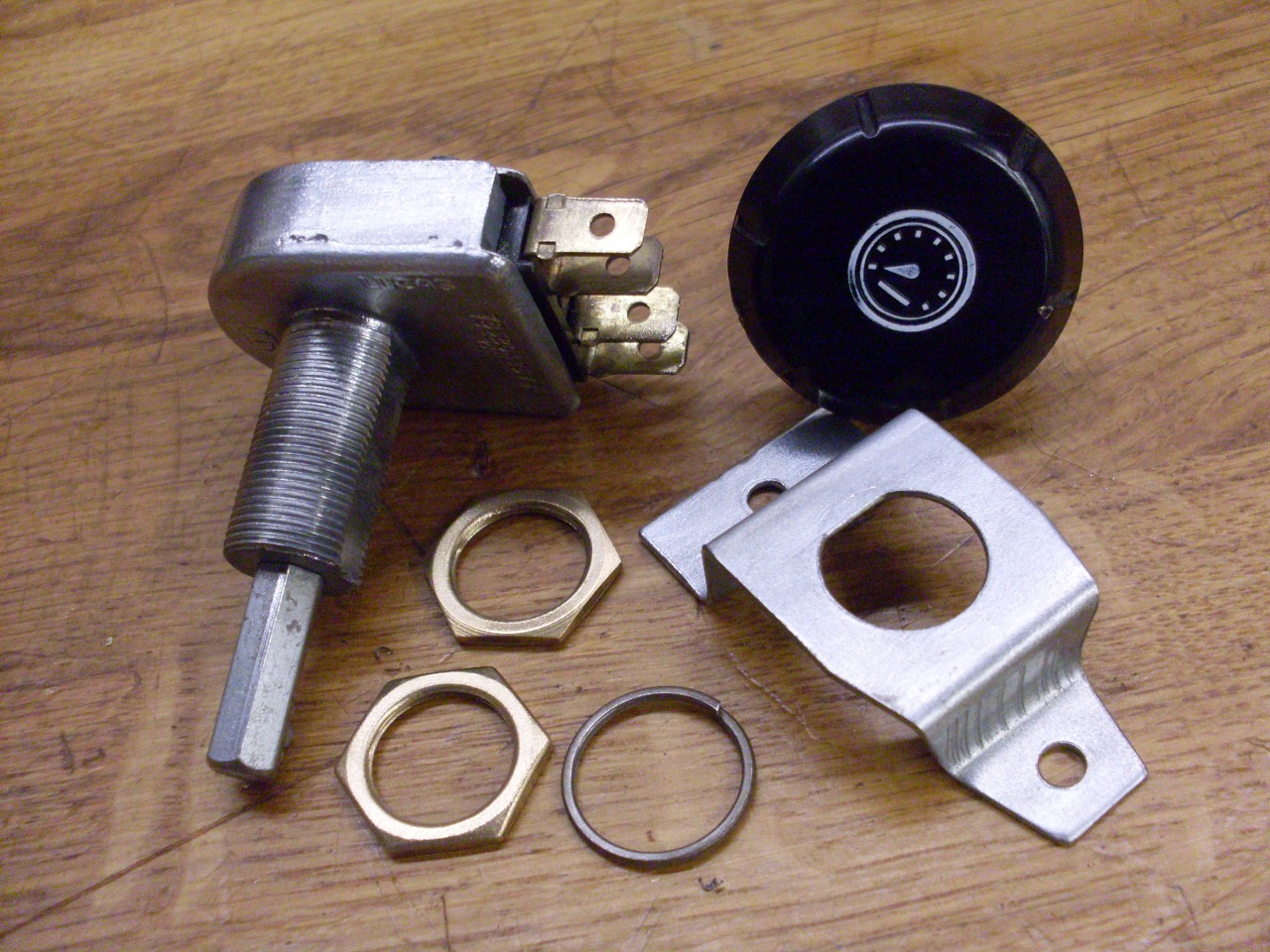

The

first item I picked out of the box was the main lighting switch.

I must have had trouble with the switch somewhere along the line,

since it was in pieces in a bag.

Besides

the outer bezel, there was the actuating rocker, and the actual

switch part with the contacts. There was a little nylon piece

that slid inside the switch, and a small spring. I could infer

how it was supposed to go together, but there was obviously a piece

missing--there had to be a piece of copper or brass that fit on the

bottom of the nylon slider to bridge the contacts in

the switch. My theory was confirmed by a nice web site

that showed a switch being refurbished. All I needed was that

little piece of copper. Without much hope of sourcing it, it was

pretty simple to make.

The

only other thing wrong with the switch was the legend on the rocker.

Luckily, water-slide decals are available. None of the ones

I found were a perfect match to my switch, but the one I got was

pretty close. The rocker has to be flattened to receive the

decal, since the original legened appeared to be heat-embossed.

Some

dielectric compound to protect the contacts, a little grease for the

other moving parts, and this switch is ready for another 40 years.

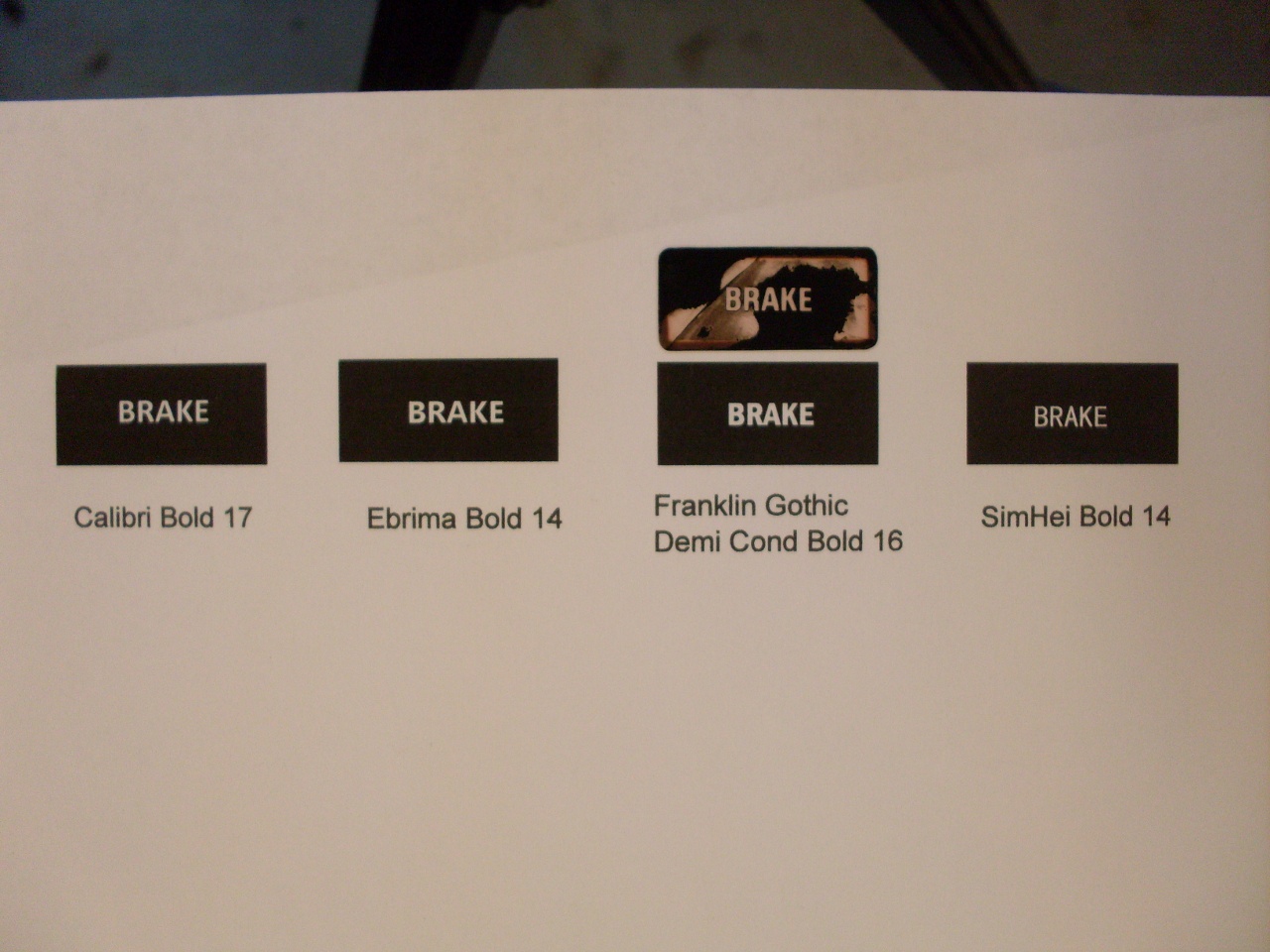

Next up was the "BRAKE" warning indicator light. Something had gone wrong with the legend.

Taking

it apart, I saw that the legend was just a piece of film in front of a

red diffuser. I thought I could just print a new legend on some

transparency material and be good to go.

I

wasn't able to make an exact match on the font, but found a few that

were pretty close. None of them duplicate the original "R" very

well.

It

turns out that my inkjet printer won't print the black quite dense

enough to black out the back light. A laser printer at the local

OfficeMax did the job.

Putting the indicator back together, it compares pretty well with the other red lamp, even though the font is not a great match.

Doing

the comparison got me thinking about that "FASTEN BELTS" message.

I remembered how annoying that light and its companion buzzer

were on this car and others of the era. Since the "Seatbelt

Module" on the car had failed decades ago, and I don't plan to replace

it, the indicator would be about as useful as a bicycle to a fish.

This opened up a train of thought on how to repurpose the lamp.

It would be a simple matter of changing the legend, and providing

the wiring to match.

Well, at least changing the legend was easy. If I think of something better to use it for, it will be easy to change.

So here are the four indicators. The slightly different font is much less of an issue for me now.

The

hazard switch is a pretty robust item, and was in beautiful shape.

I did no more than brush the dirt off and test it. A squirt

of contact cleaner and some dielectric compound should keep it healthy.

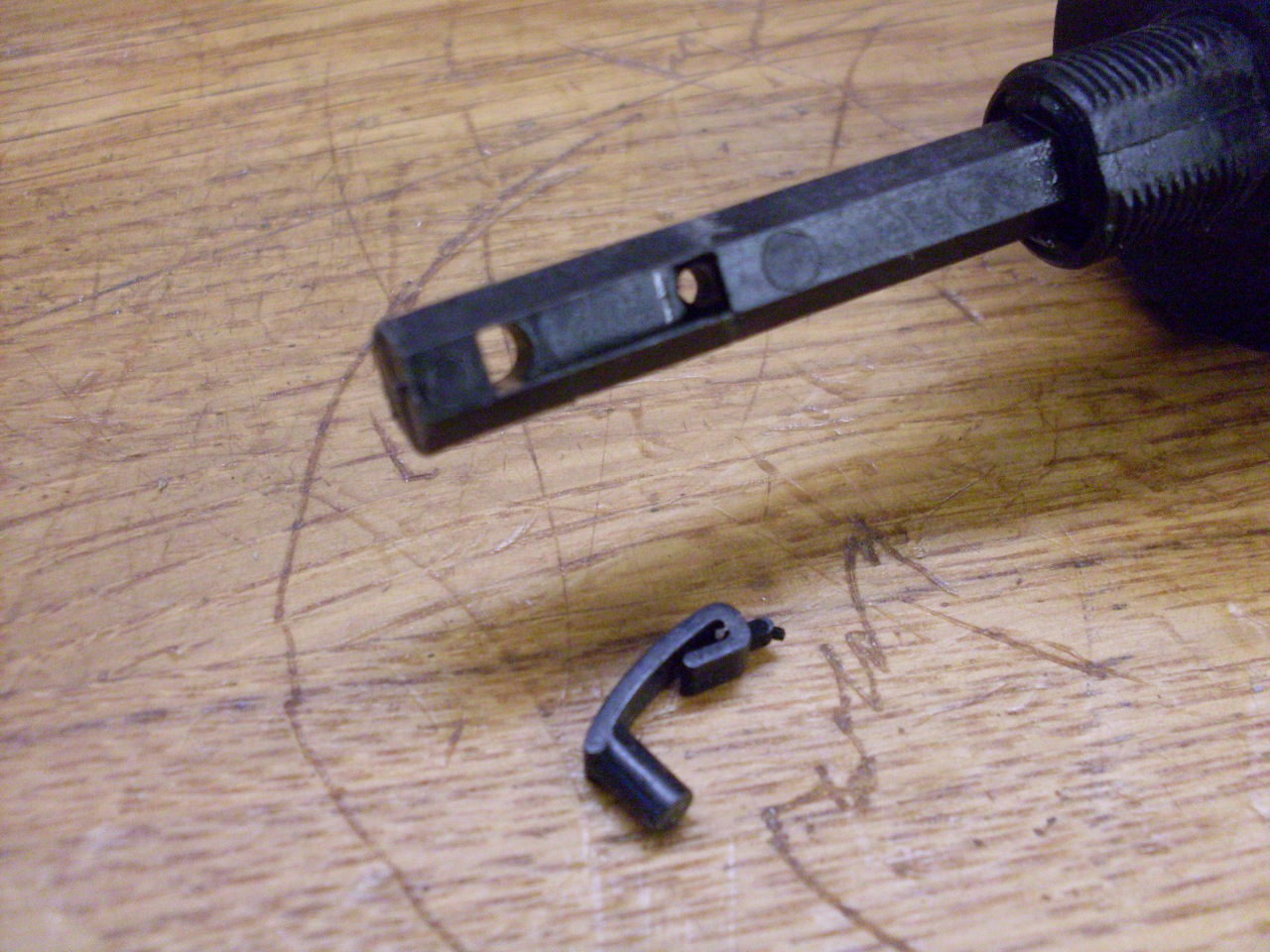

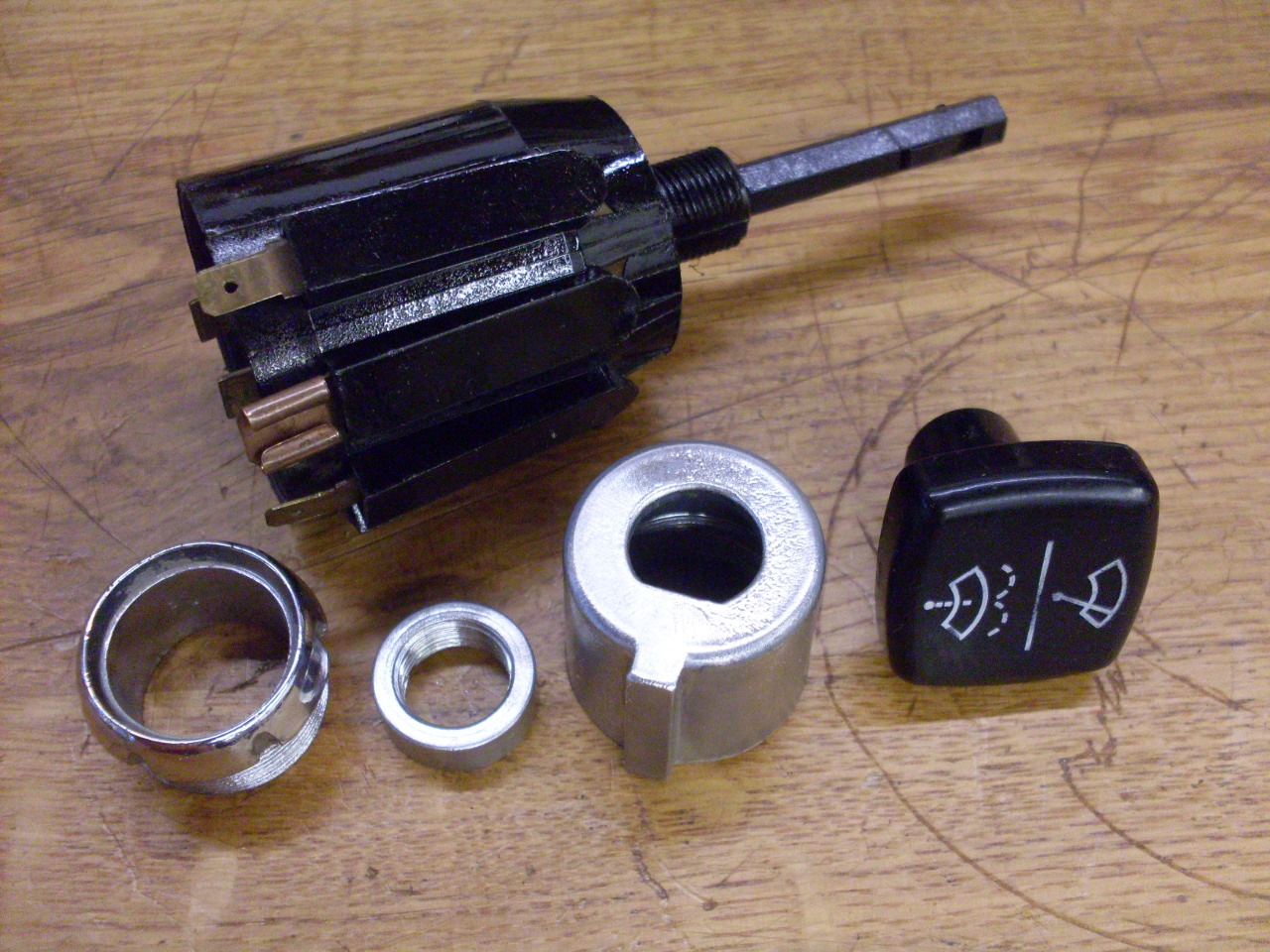

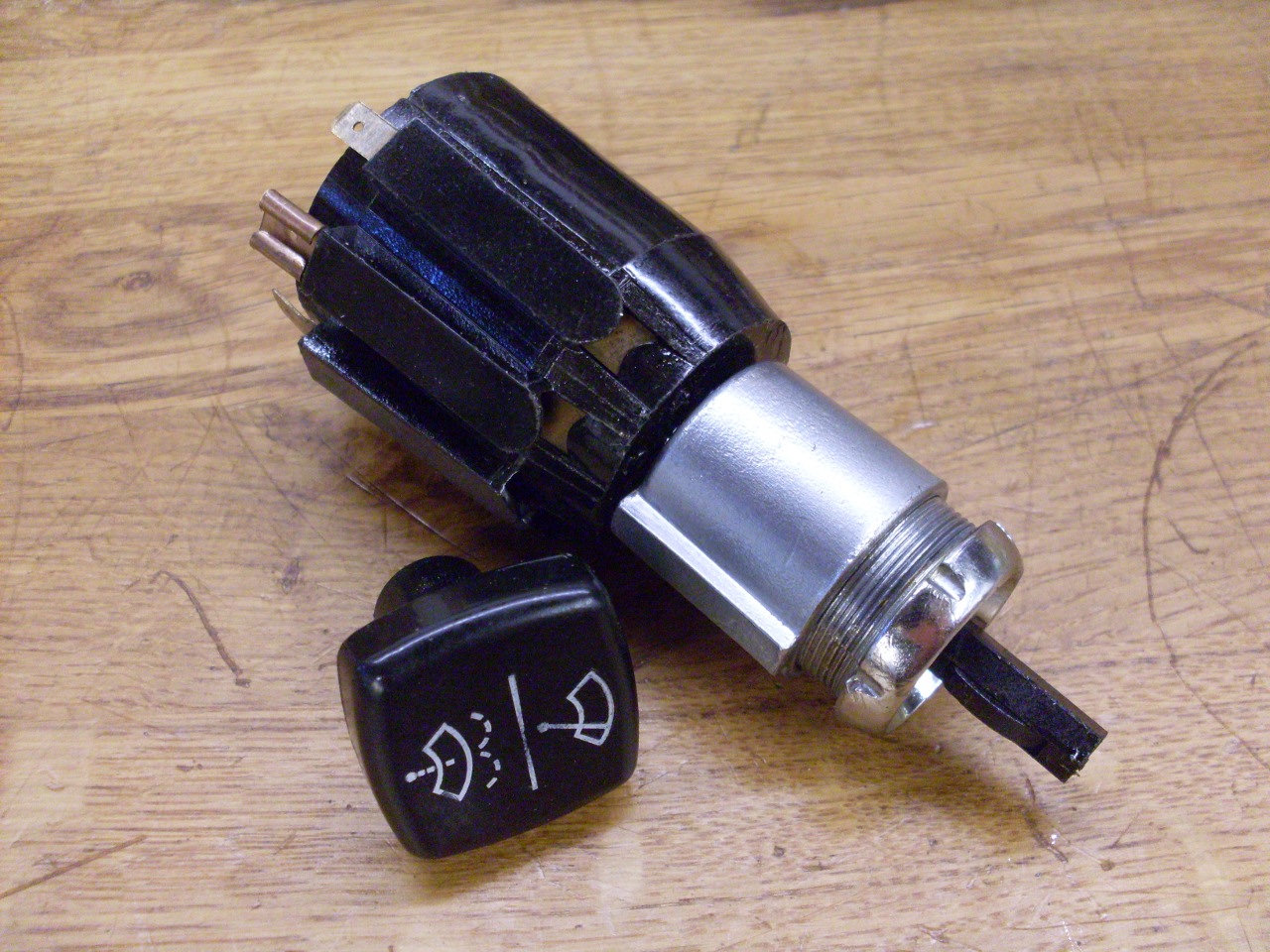

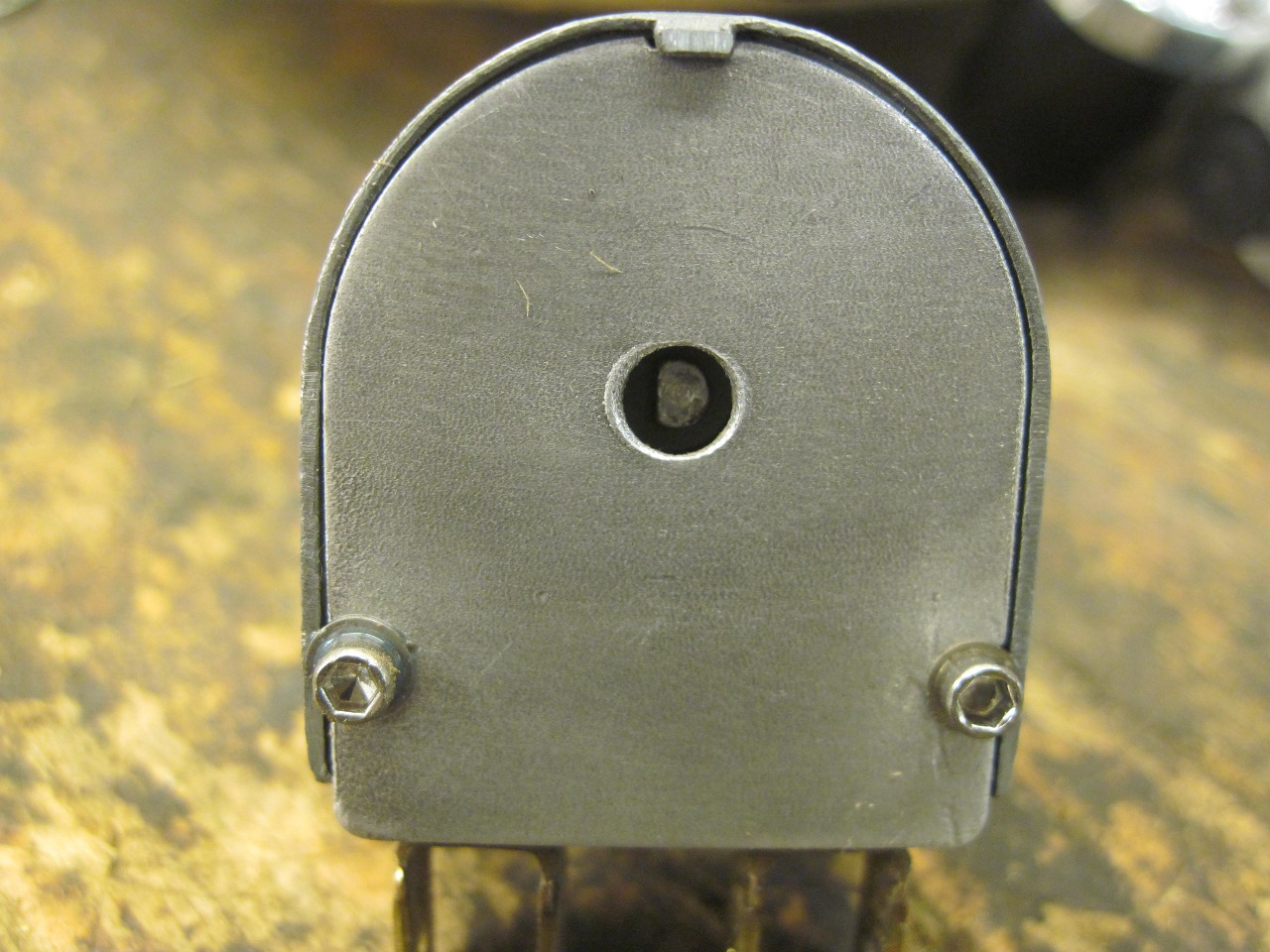

By

comparison, the wiper switch feels a little cheesy. Its plastic

shaft that torques noticably in normal operation doesn't give a feeling

of solid construction. On the other hand, the device was intact,

and tested fine. The little knob keeper had lost most of its

spring, but I'm not going to do anything about it.

Standard

cleanup made it look better. Has anyone ever seen a tool that

fits the little nut that goes deep inside the barrel? Me neither.

Easy to make one, though.

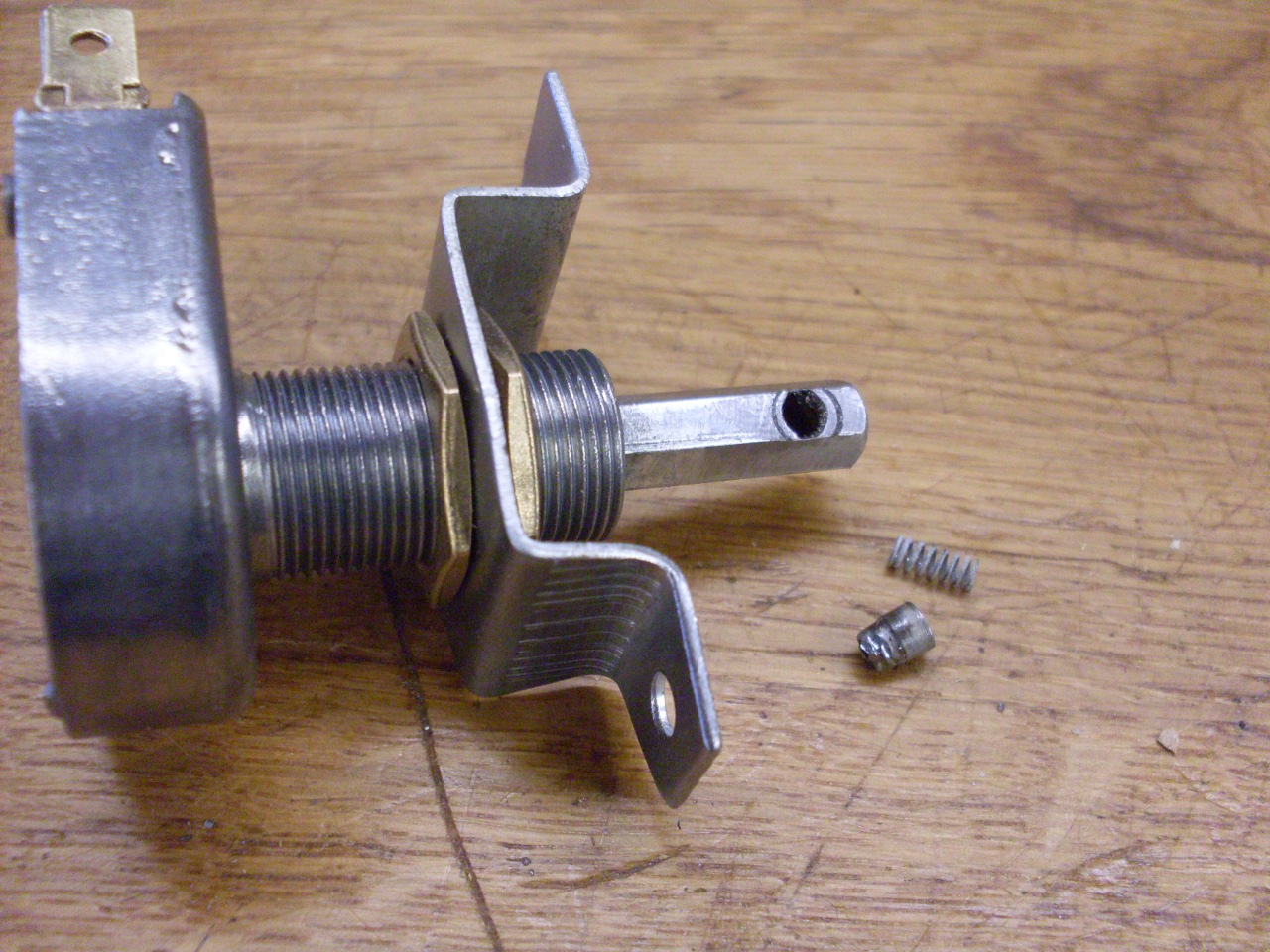

The

dash light dimmer rheostat appeared to be intact and undamaged. Though this device is a good candidate for replacement

with a more modern solid state design, and I have the skills to build

one, I'm going to resist the urge right now. At present, I plan

to stick with the stock incandescent lighting for the instruments.

If I feel the calling to go to LEDs in the future, I'll revisit

the dimmer question.

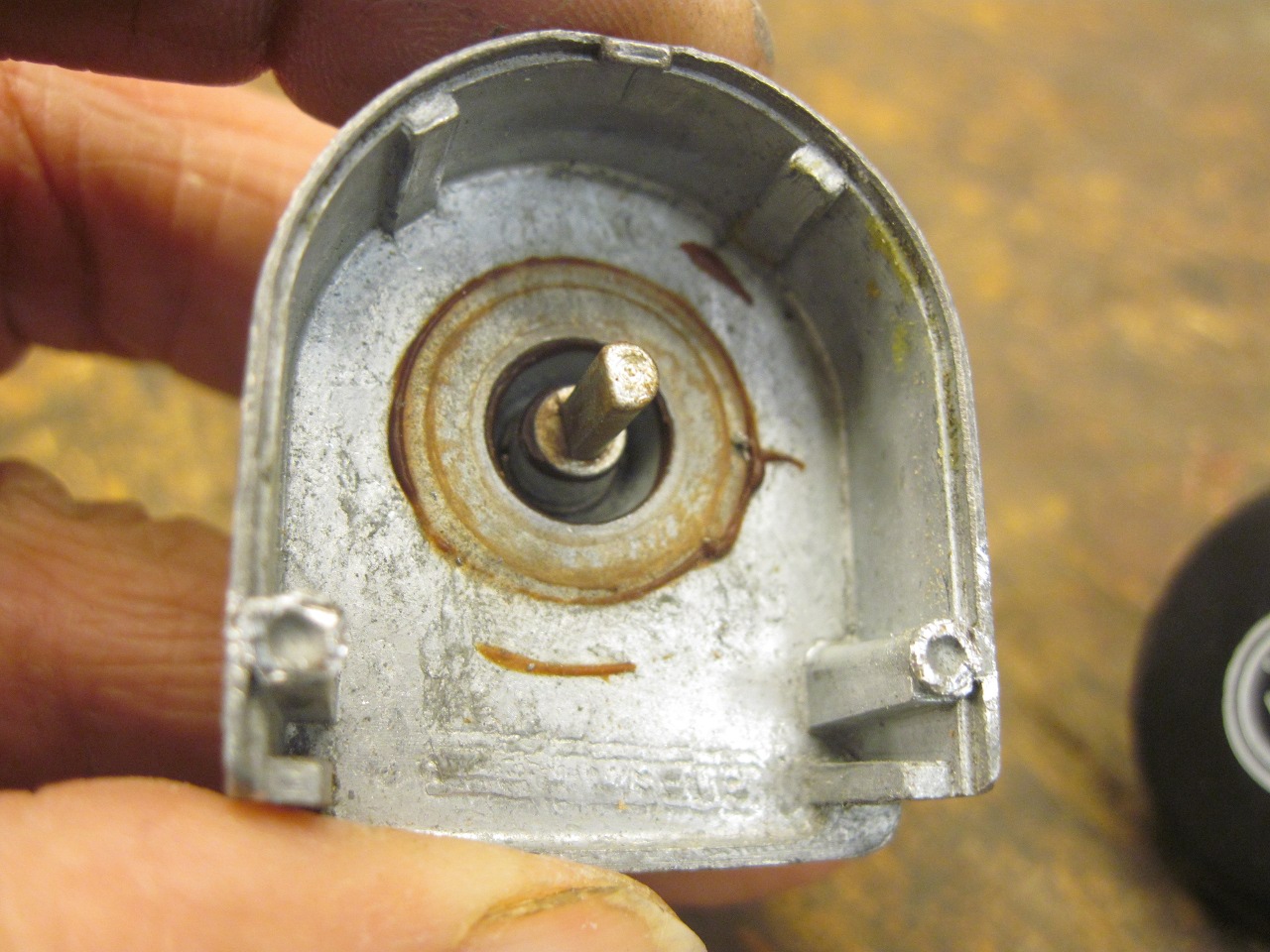

On

testing the dimmer with an ohmmeter, its operation seemed erratic.

Unsure whether this might be caused by some internal damage, or

just accumulated crud, I ground off the two little stakes on the back

and removed the back cover.

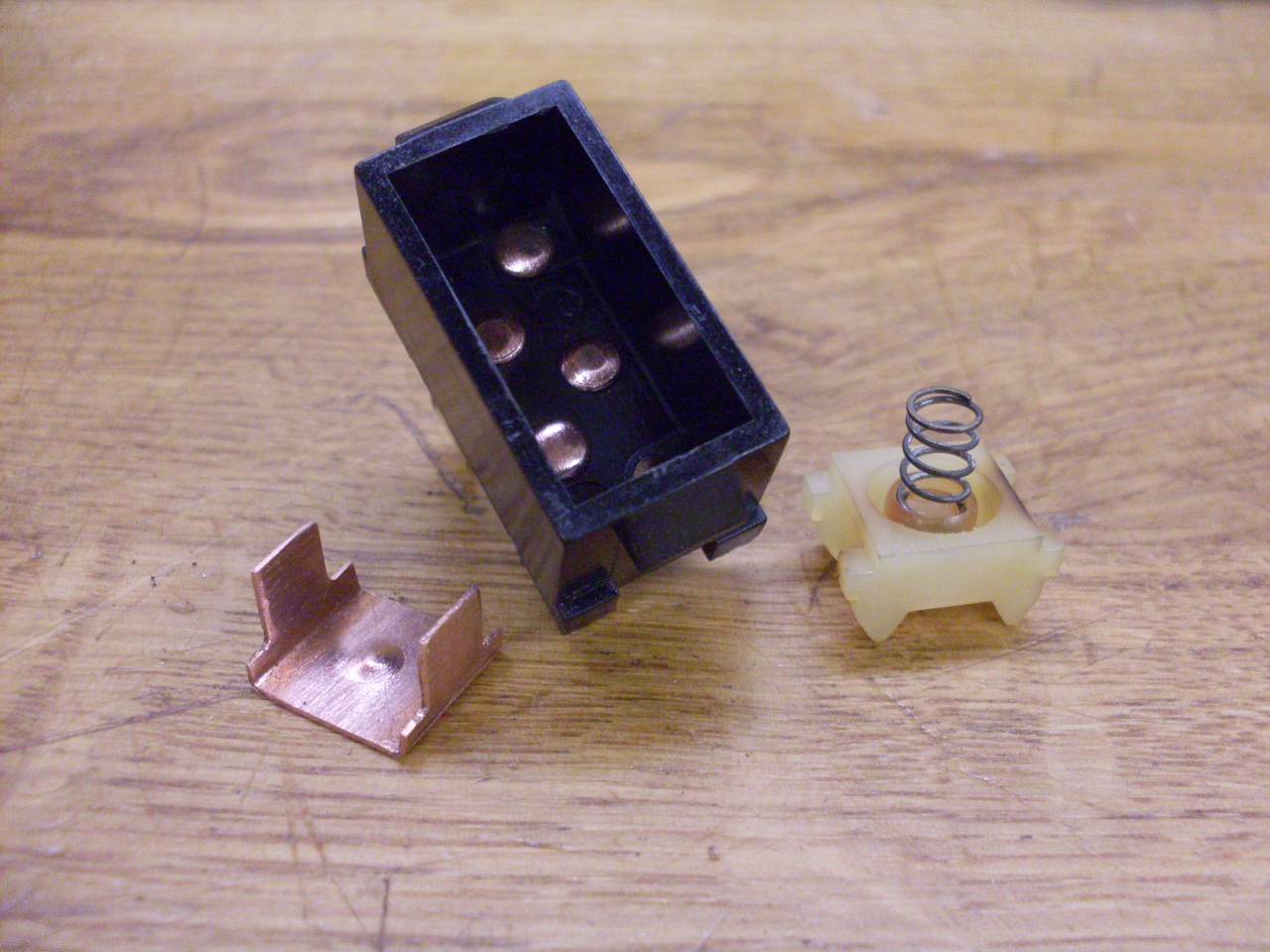

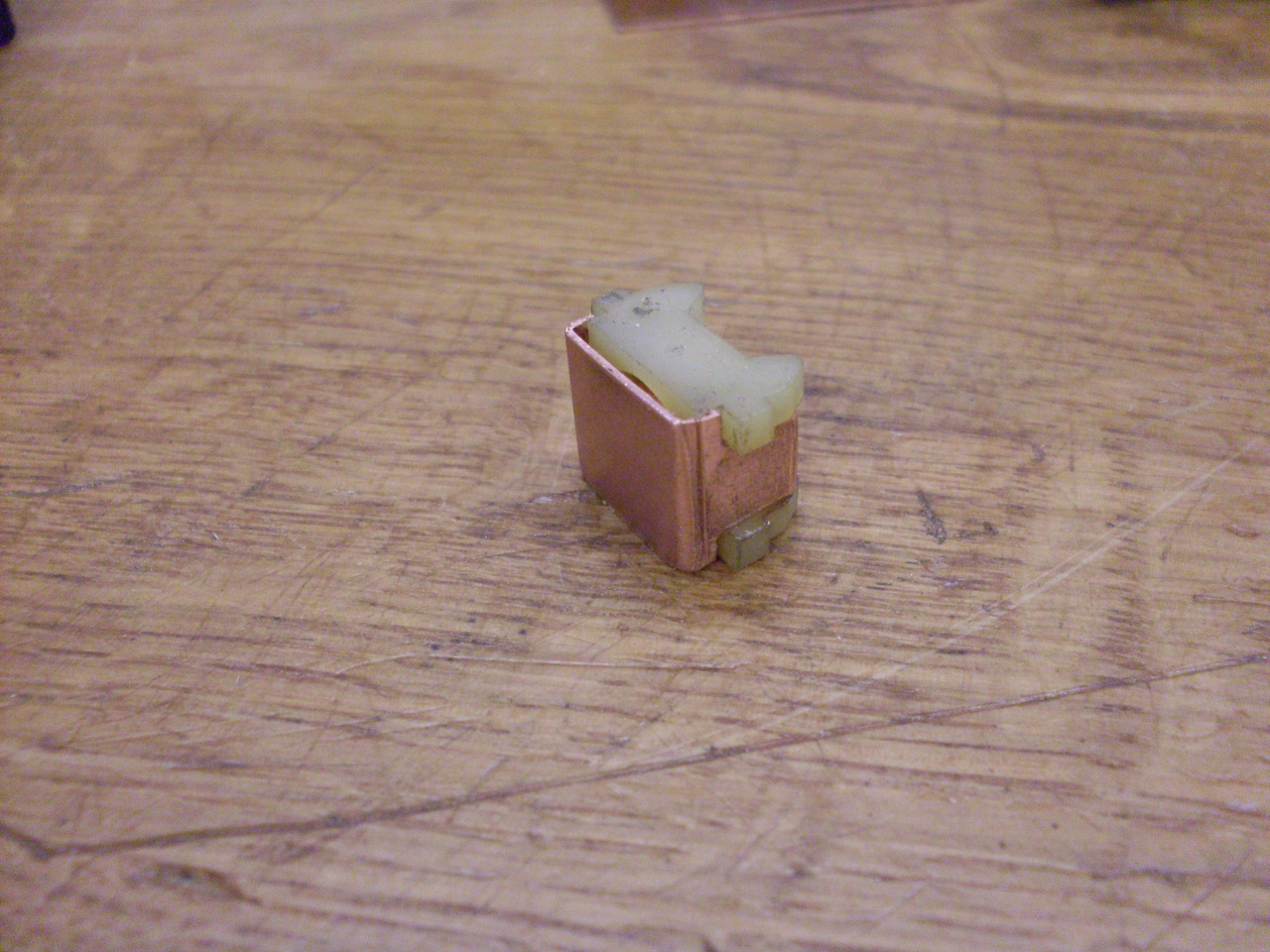

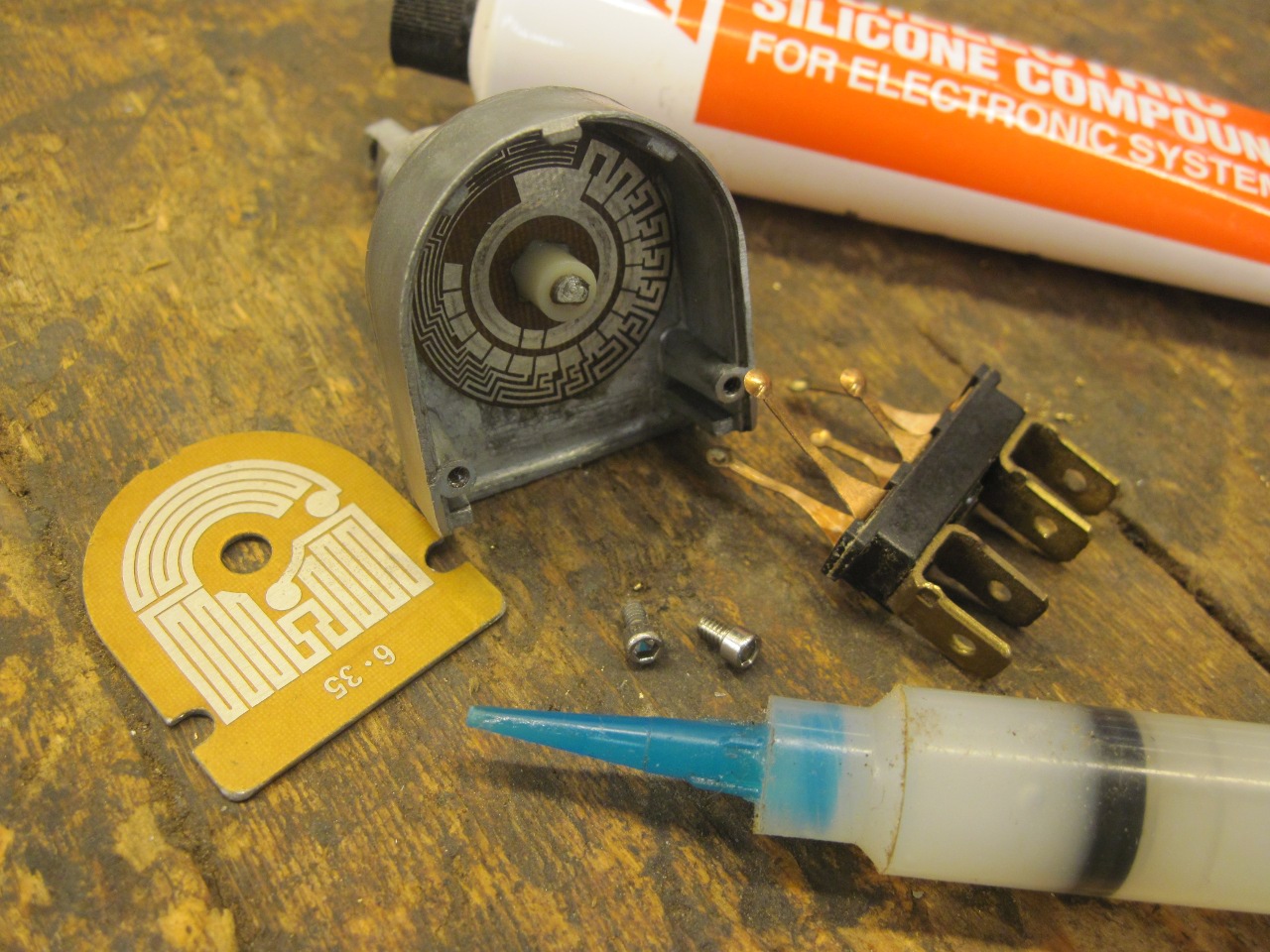

The

back plate actually had a PC trace resistor on it. The legend

"6.35" apparently refers to the resistance of the metal trace from end

to end. An internal wheel, also with metal traces on it, rotates

with the knob shaft. The traces on the wheel form a series of

resistances with 15 taps points, and an inner ring that serves as a

common contact. Between the fixed back plate and the rotating

wheel, there are three spring fingers. that touch both the inner

wheel and the back plate resistance. As the wheel is turned, the

resistance between two of the fingers changes in 15 steps. The

back plate resistor is in parallel with the stepped resistance, and

serves to set the resistance range of the dimmer for different

applications. One very nice page outlining a dimmer rebuild shows a back plate with a 4 ohm resistance.

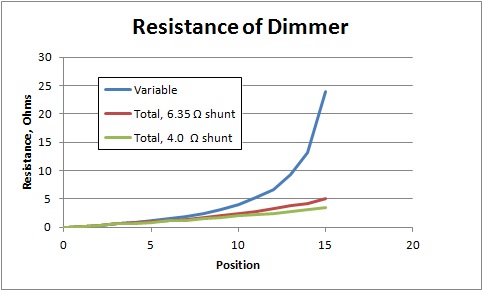

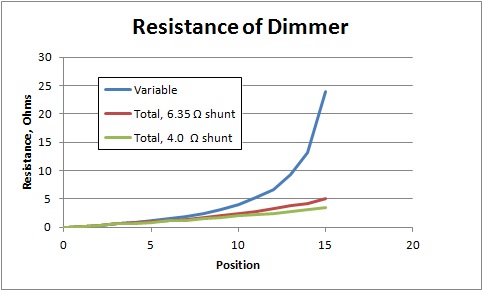

Here is a graph of the resistance of the variable part of the resistance, and the effect of the back plate shunt resistor.

The

contact surfaces for the spring fingers looked OK, but were dirty.

I cleaned them up, along with the finger contact points, and

cleaned and lubricated the case and shaft bearing. I also drilled and tapped the case for some tiny 2-56 screws to replace the original stakes.

Then

I coated the contact surfaces with some dielectric grease, and put the

device back together. Testing again with an ohmmeter showed a lot

better results.

One

other thing on the dimmer--since its knob has no hole for a keeper

pin (and you couldn't get to it if it did), it seems that the spring

loaded pin on the dimmer shaft can't contribute anything but trouble,

so I removed it. I also cleaned up the hex shaft where the metal

was upset to retain the pin. This distortion was probably part of

the reason the knob was so hard to remove.

Not

actually an indicator or switch, but still an accessory to the dash, I

fished the air vents out of the box of parts. The inner spherical

eyeballs on these vents are supposed to swivel freely in felt bearings.

Mine were essentially seized, and were very hard to move. I

found that by just cleaning the ball and polishing them a little, I

could restore smooth motion. On one vent, the ball caught the

felt strip and dislodged it. It took me forever to get it back in

place, but all four vents work well now.

So

here are all the bits and pieces, other than the instruments, that

fit on the dash, including brand new knobs for the wiper and dimmer

controls.

This

was a sort of nitpicky set of projects, but I think it will pay off in

reassembling the dash when the time comes. The only out of pocket

cost was the two knobs and $0.54 for the transparency printing at

OfficeMax.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages