To other TR6 pages

March 3, 2014

Valve Train

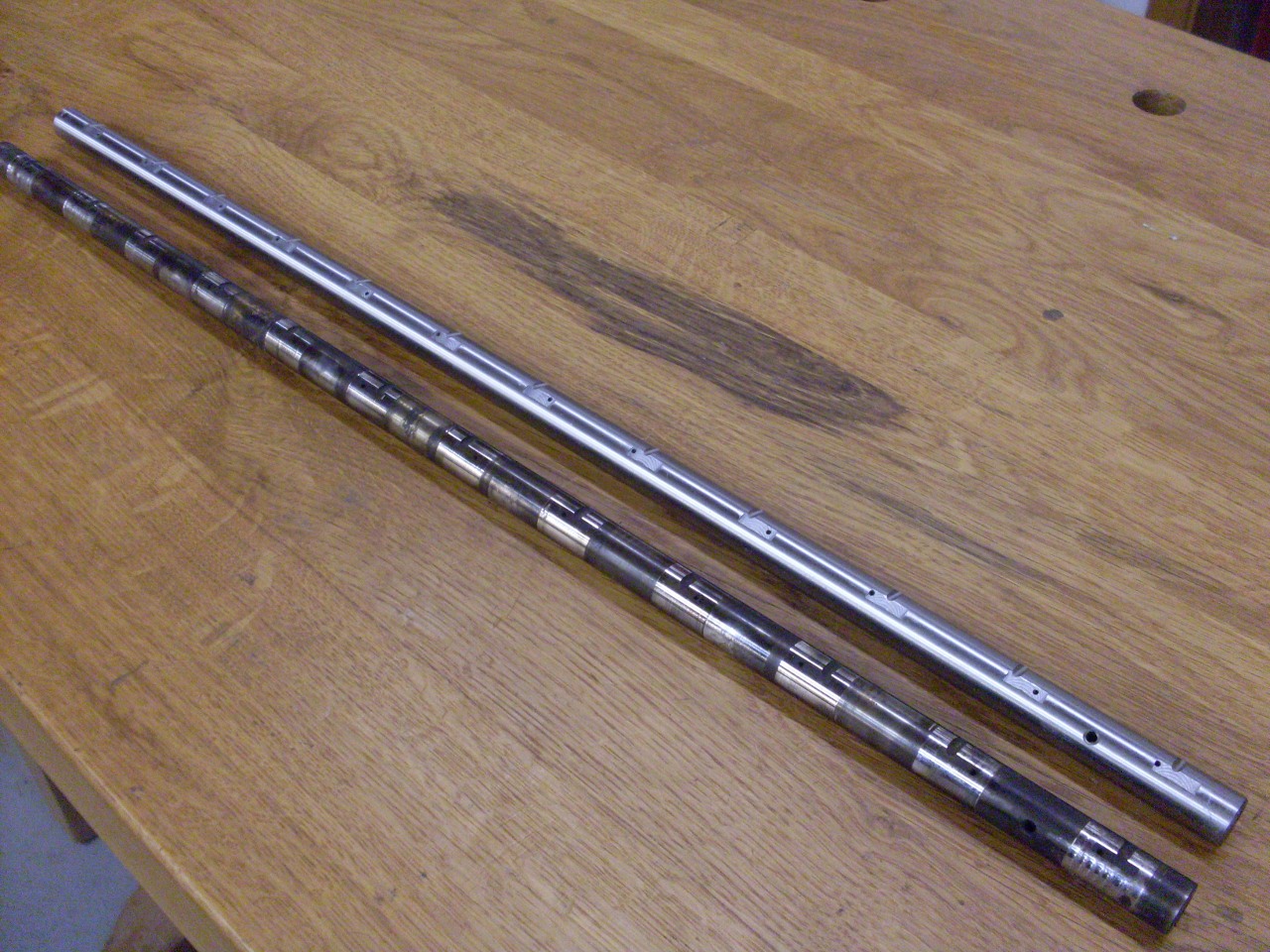

The

valve train in this project was fairly involved. There was a lot

of wear, especially on the rockers and rocker shaft. I bushed and refurbished the rockers, and bought a new shaft.

I'm

always a little hesitant about aftermarket parts, and this shaft

reinforced my feelings. Even though the shaft measured within

spec for OD, the rockers didn't slide on easily. The reason was

tiny burs left on the machined areas on the shaft. A light touch

with a wire wheel on these features fixed that problem. Seems

like the manufacturer should be doing that.

Also,

on the suggestion from a few people on TR6 forums, I decided to check

the bore of the shaft for foreign material. Though many of these

shafts have plugs pressed in both ends of the shaft, I lucked out, and

mine had simple set screws threaded in each end. I pulled them

out and ran a brush down the bore and probed the oil holes. This

produced a worrying amound of metal machining swarf, some pieces big

enough to plug a rocker oil passage. In sighting down the bore,

there also appeared to be a partial blockage on one side. I

finally decided this was a step left where the holes drilled from both

ends didn't meet perfectly. This probably doesn't materially

affect the function of the shaft, but it doesn't leave me with a warm

feeling of confidence, either.

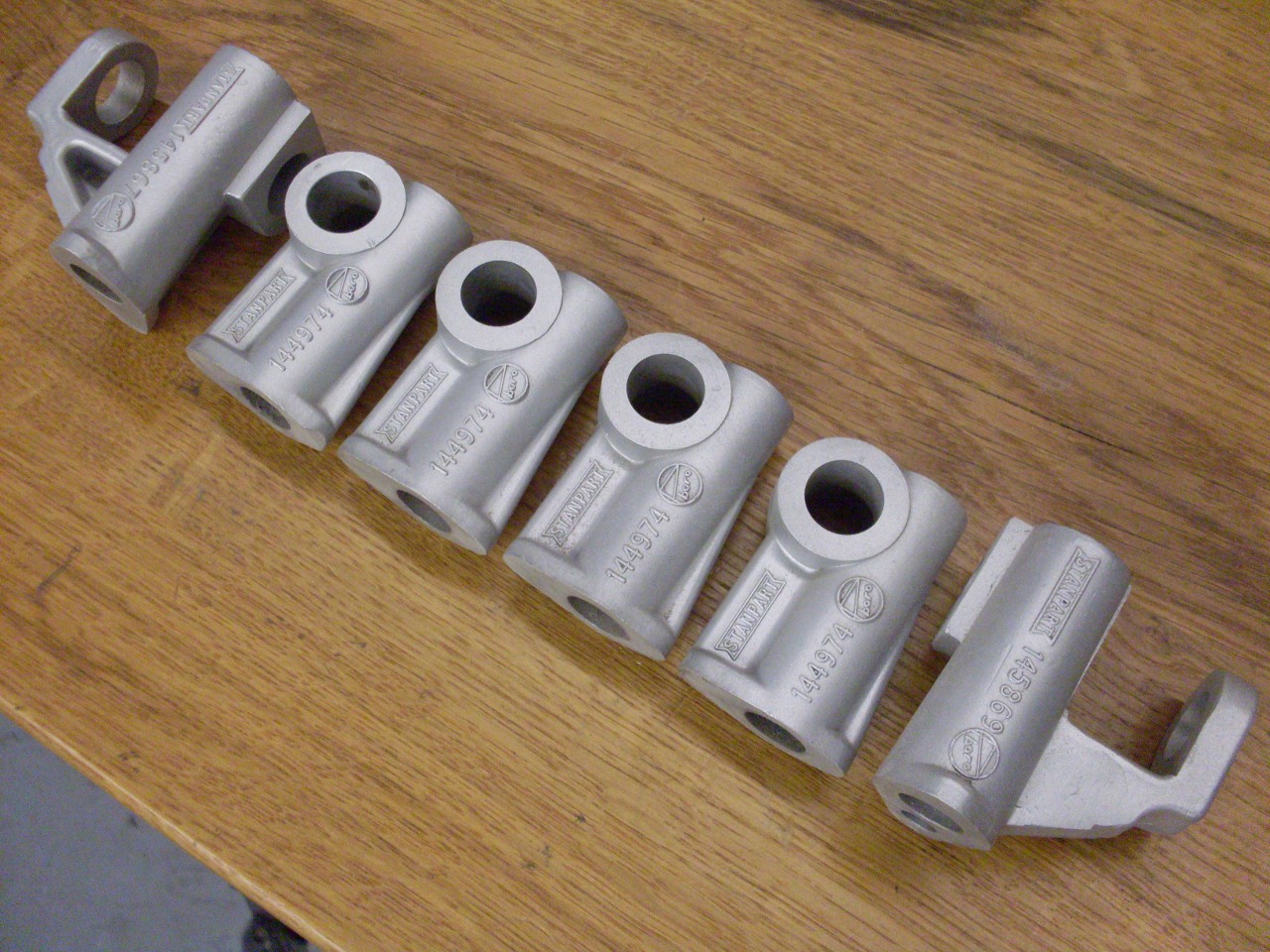

I now had everything I needed to build the rocker shaft assembly. The shaft pedestals clean up nicely.

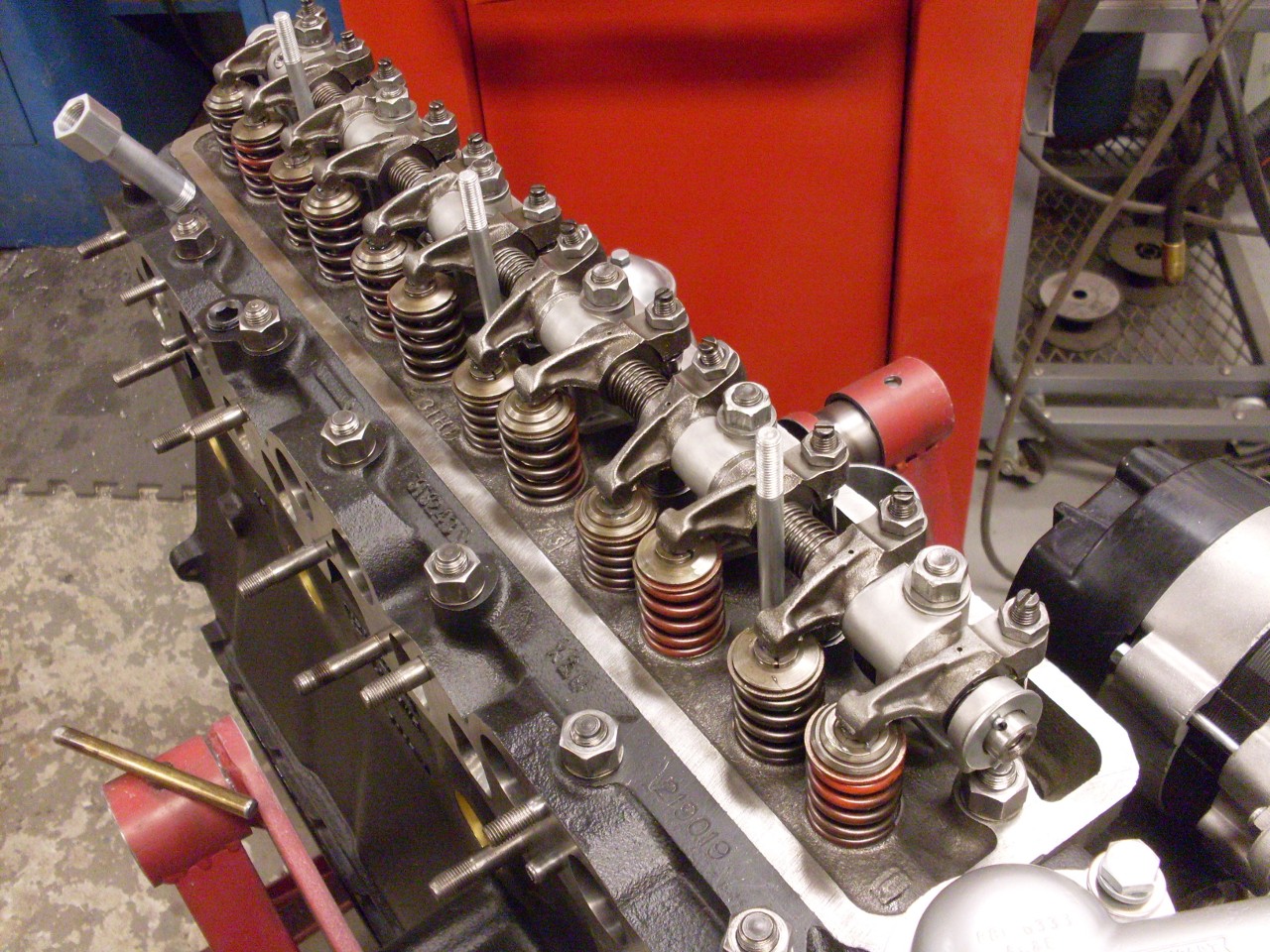

With the shaft assembly built, and the new valves and springs

installed in the head, the only remaining piece of the chain was the

pushrods. Since I had shaved 0.130" off the face of the head, the

rocker shaft and rockers, plus the valves and springs had all been

lowered relative to the cam shaft. This made the stock pushrods

too long. They would bearly fit, but left no allowance for lash

or adjustment. I assumed that there would be some Triumph

part--possibly from earlier, higher compression versions of these

engines--that would fit, but I wasn't successful in finding them.

There

is a school of thought that says that the rocker shaft pedestals can

simply be shimmed to account for the compressed distance between the

lifters and rockers. I looked into this, but it appeared to me

that this would change the valve-side rocker geometry in an undesirable

way (Link).

In

the end, I ordered a set of custom pushrods 0.130" shorter than stock.

This should restore factory geometry both for the pushrod and

the valve sides of the rockers. The new rods are a little larger

in diameter than the stock ones, and are tubular. They also are

about 15% lighter than the stock ones, not that I'm counting grams or

anything.

Going

on the premise that it would be good to have all the metal-to metal

wear surfaces new to start with, I also ordered a new set of stock

adjusters.

I

assembled everything with a daub of ZDDP grease on the wear surfaces,

torqued down the pedestals, and set rough clearances onthe rockers.

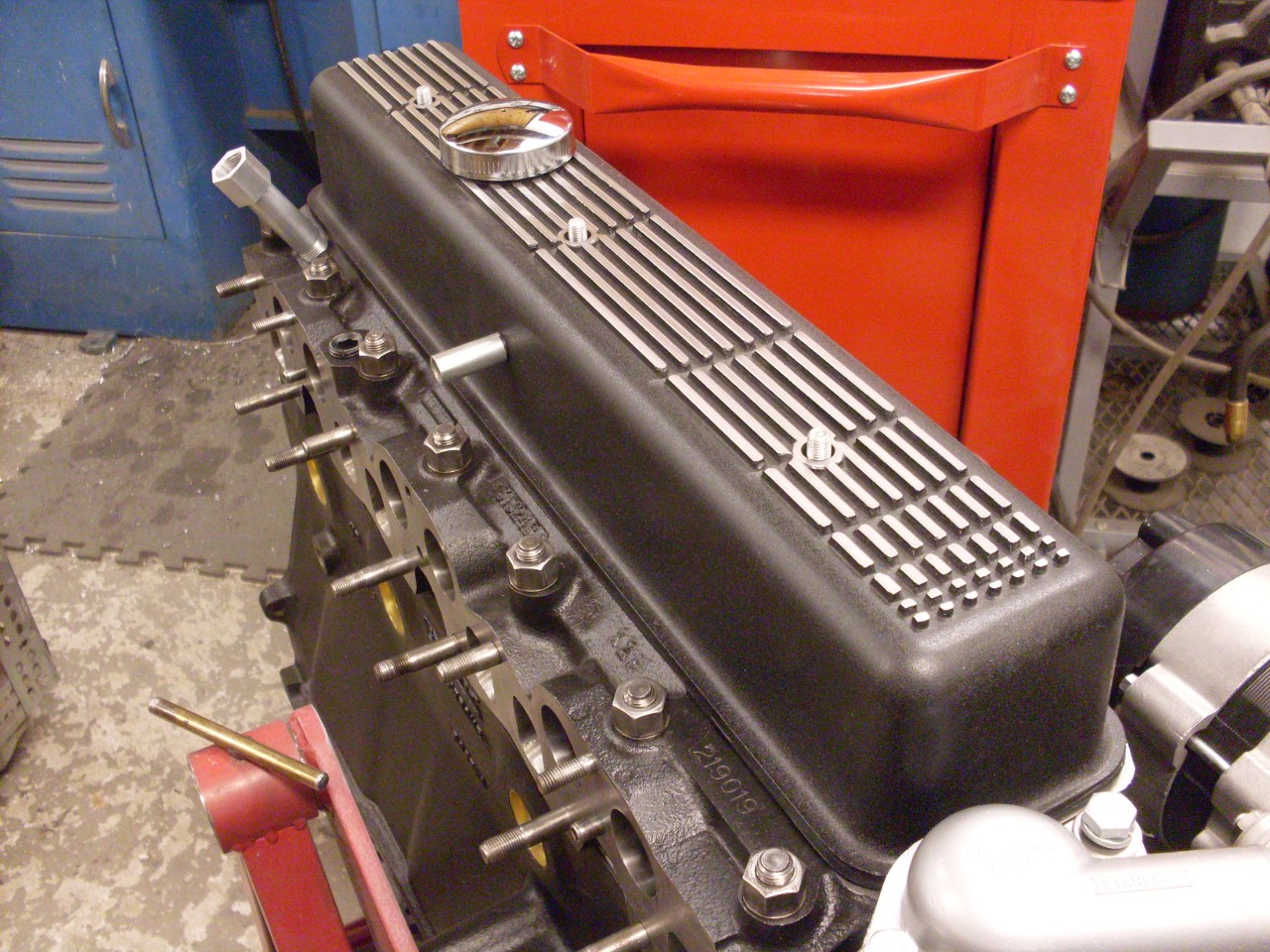

Topped it off with my new trick valve cover, and this engine is getting pretty close to finished.

Comments to: elhollin1@yahoo.com

To other TR6 pages