To other TR6 pages.

February 13, 2014

Cylinder Head

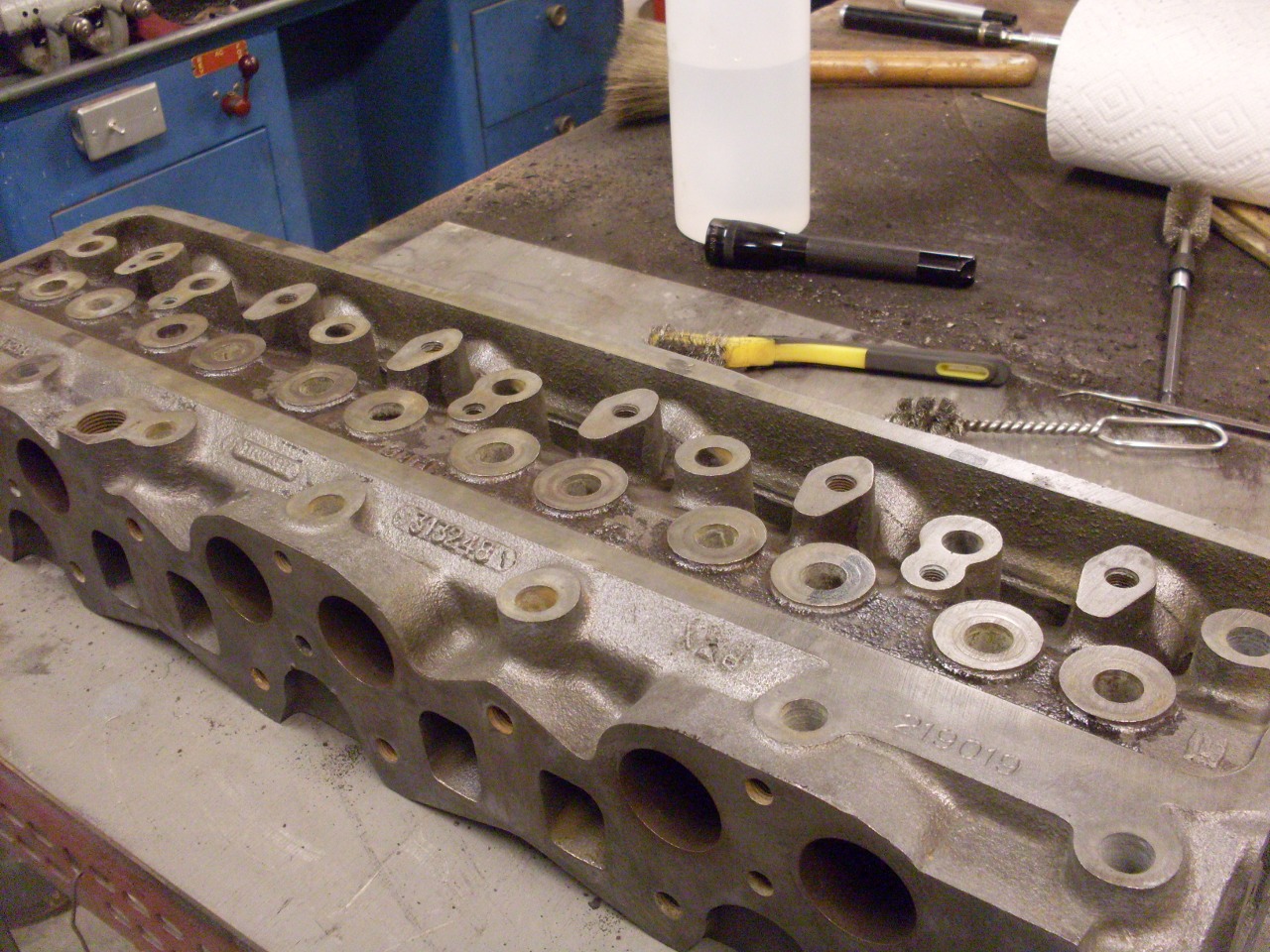

Been working on the head for the past month or so, and finally finished it.

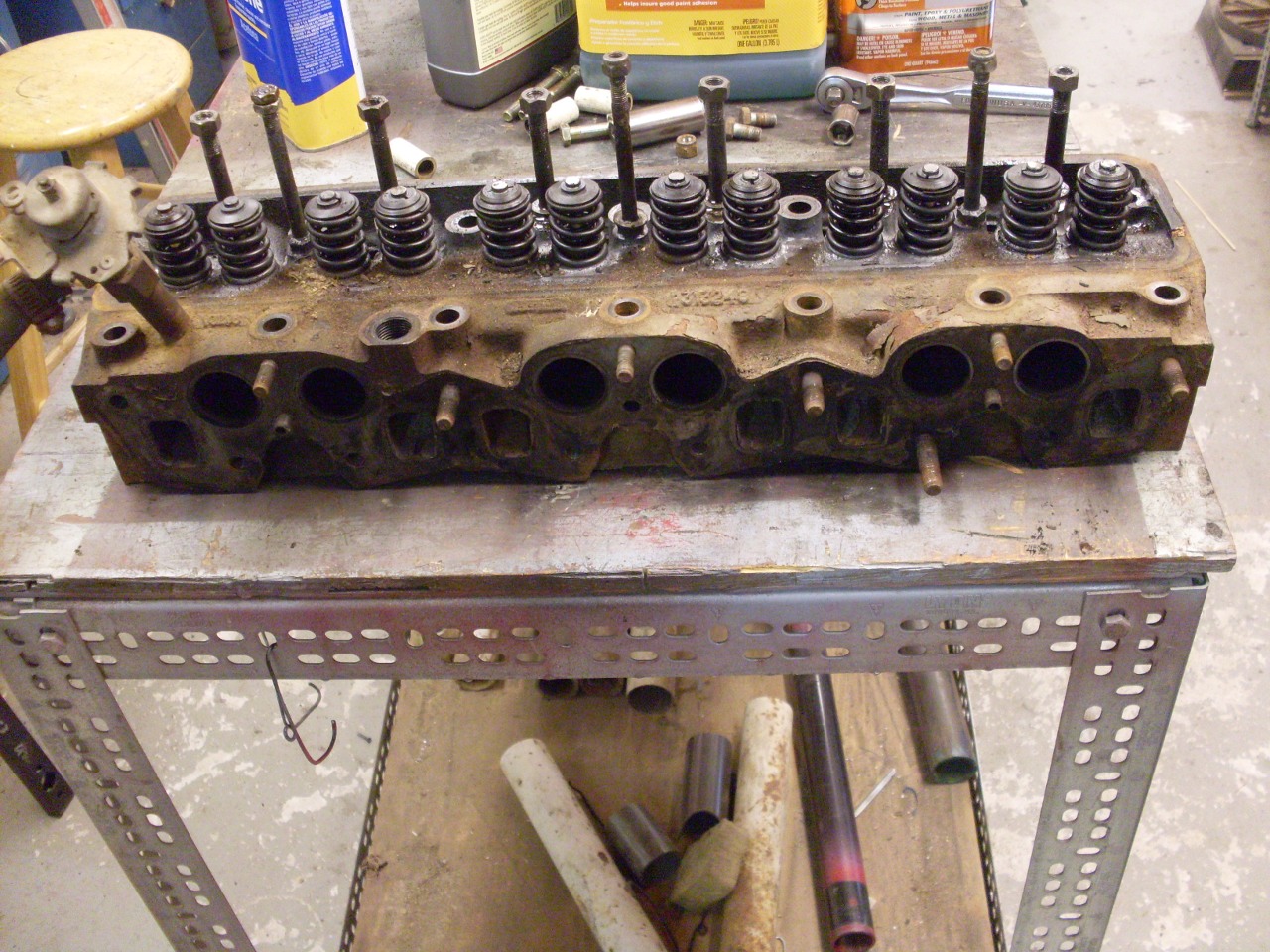

The

TR6 cylinder head is a 60-pound brick of cast iron. It's pretty

ordinary in every way, providing two vertical valves for each cylinder,

and a separate port for each valve. A conventional rocker shaft

holds the twelve rocker arms. Mine was appropriately greasy,

dirty, and rusty. Here it is after the rocker gear had been

removed.

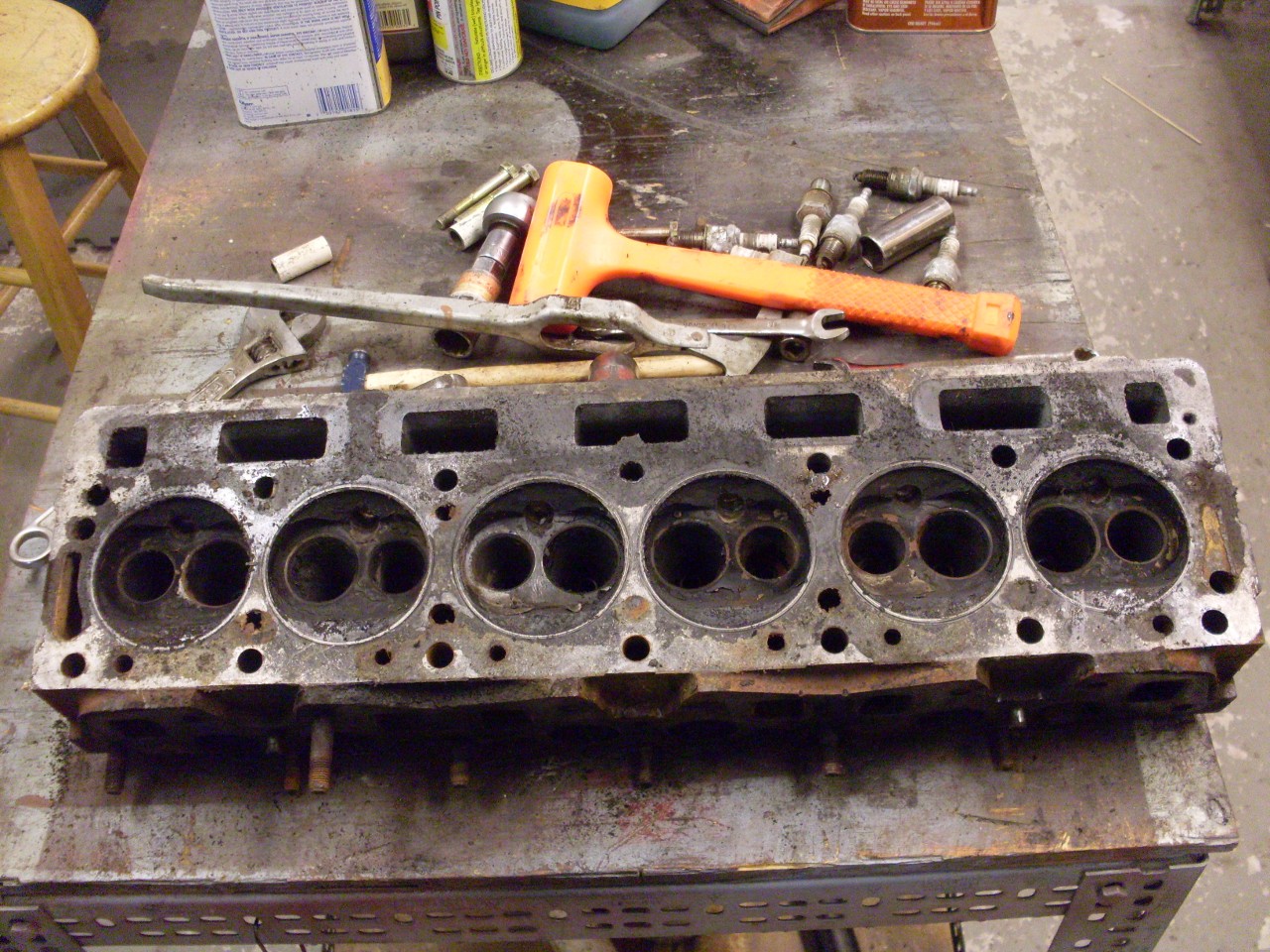

First,

I stripped out the valves ans associated parts so I could inspect and

measure them. Valve stems were right at or slightly outside the

spec range, so this meant new valves. Some valve springs were

slightly out of spec for length too, so I ordered a set of springs.

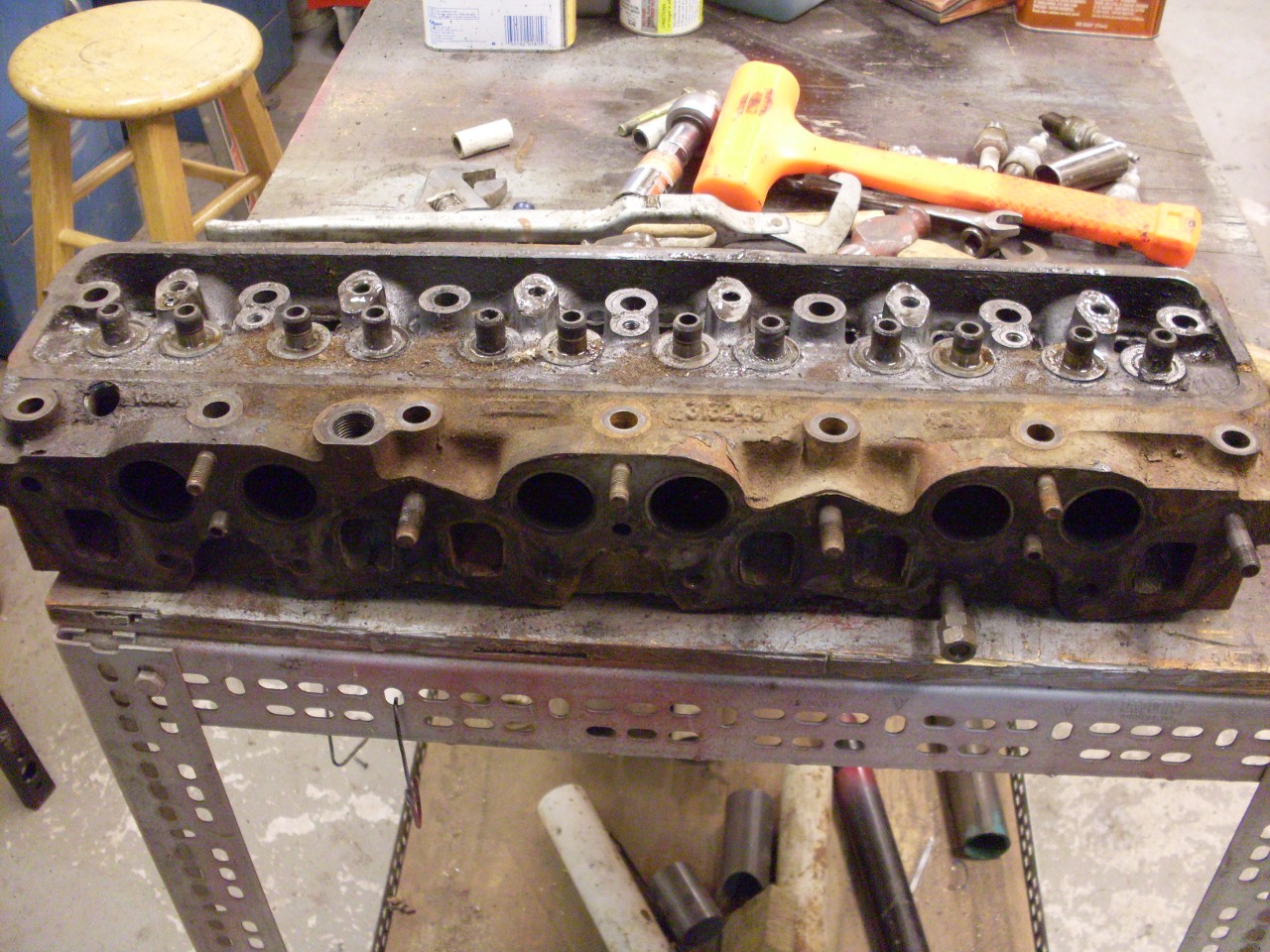

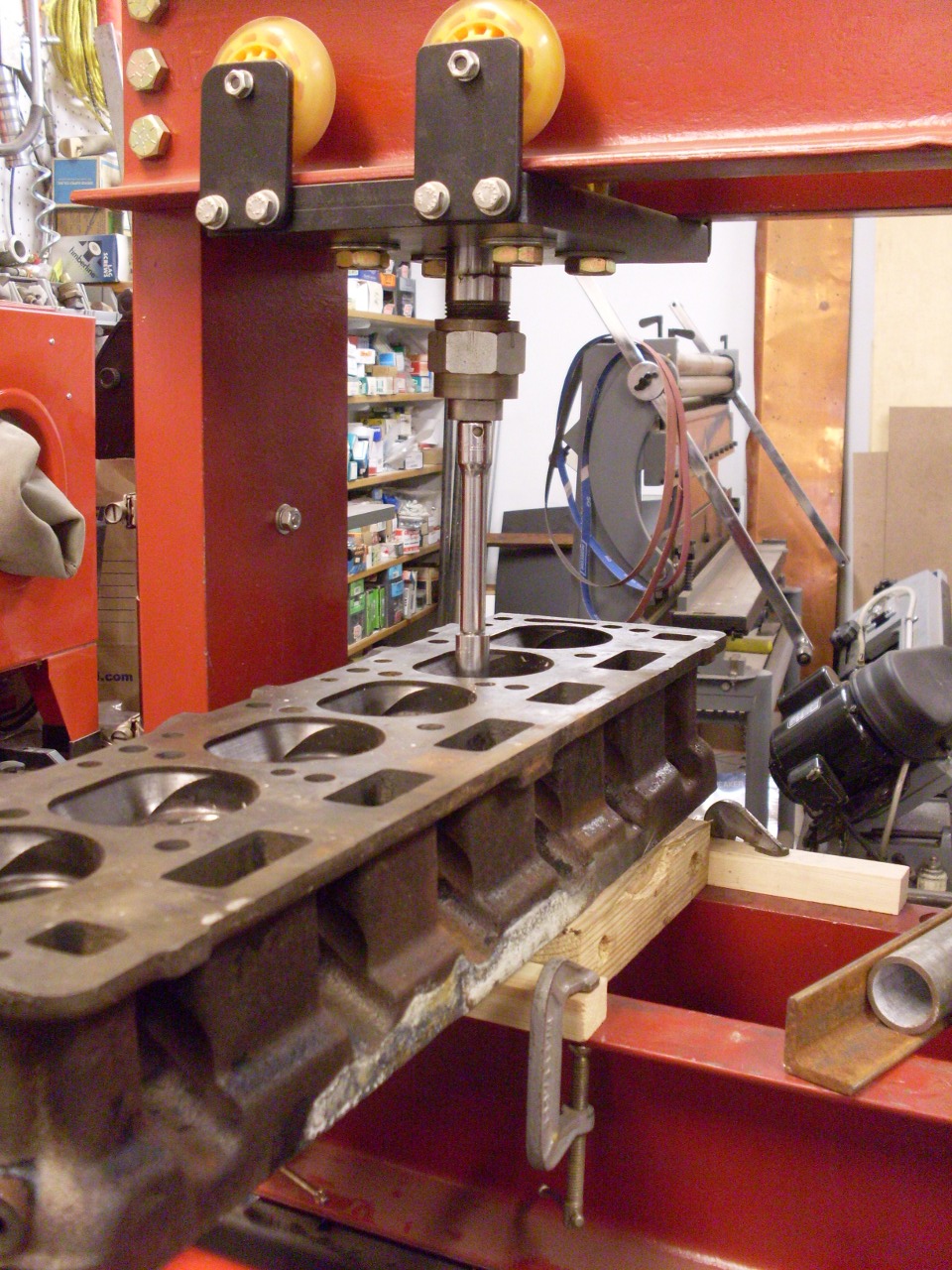

I

don't have a good way to accurately measure the valve guide bores, but

judging from the fit of a couple of the valves that were just in spec,

they seemed loose. Besides, they are a relatively low cost item,

so it seemed prudent to have new guides, too. Here is my home

made press pushing out the guides with a little shop made tool.

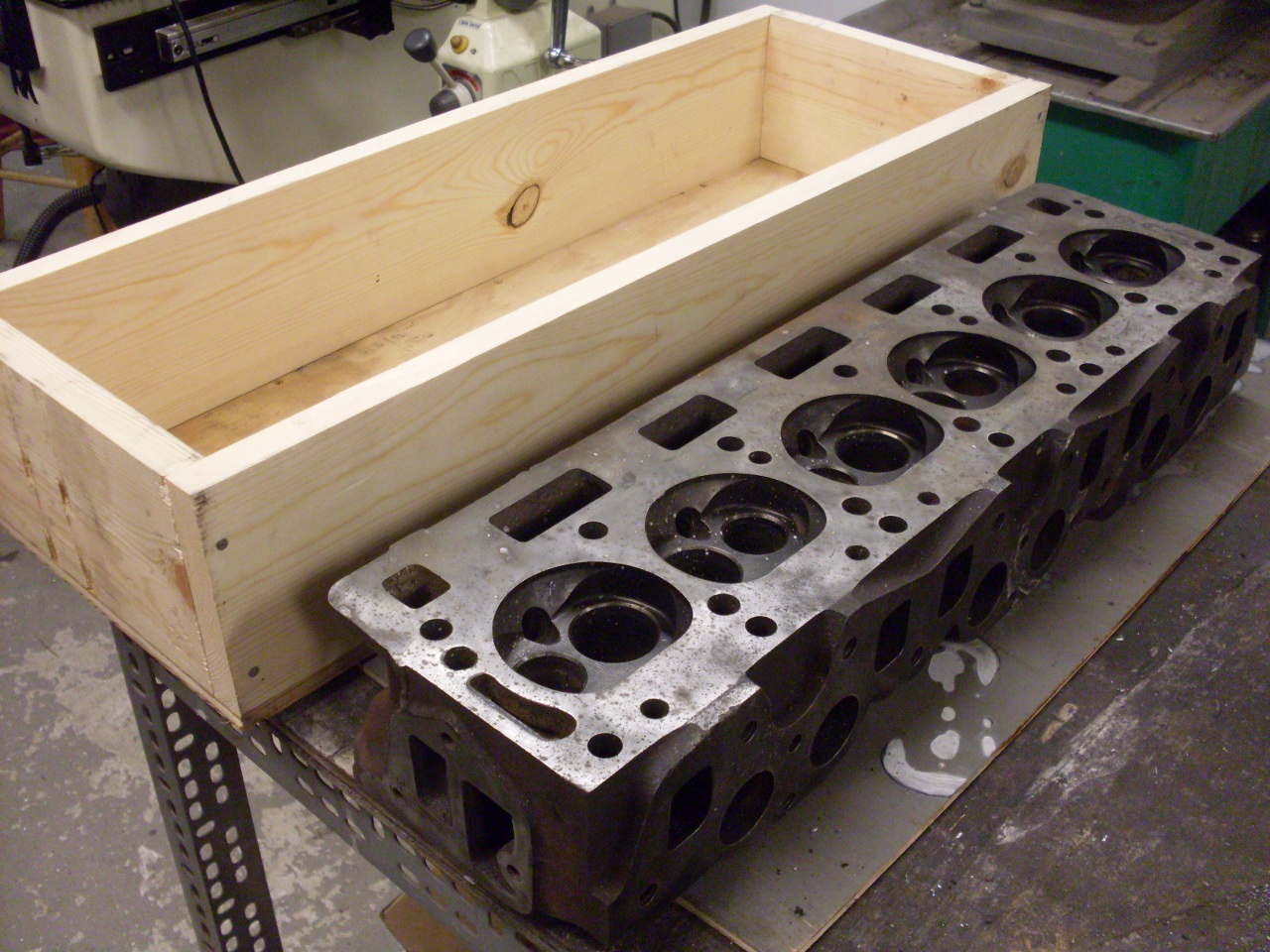

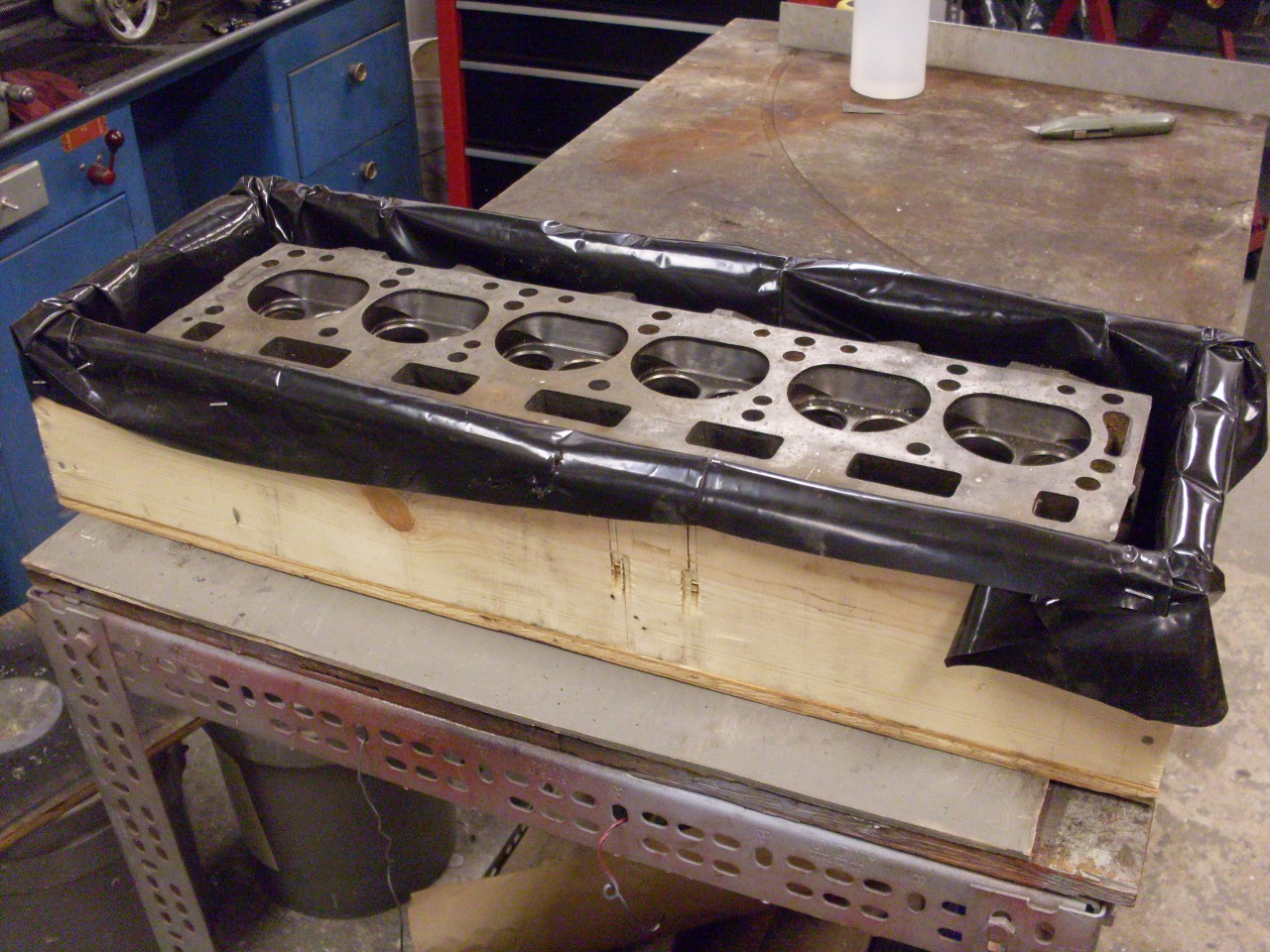

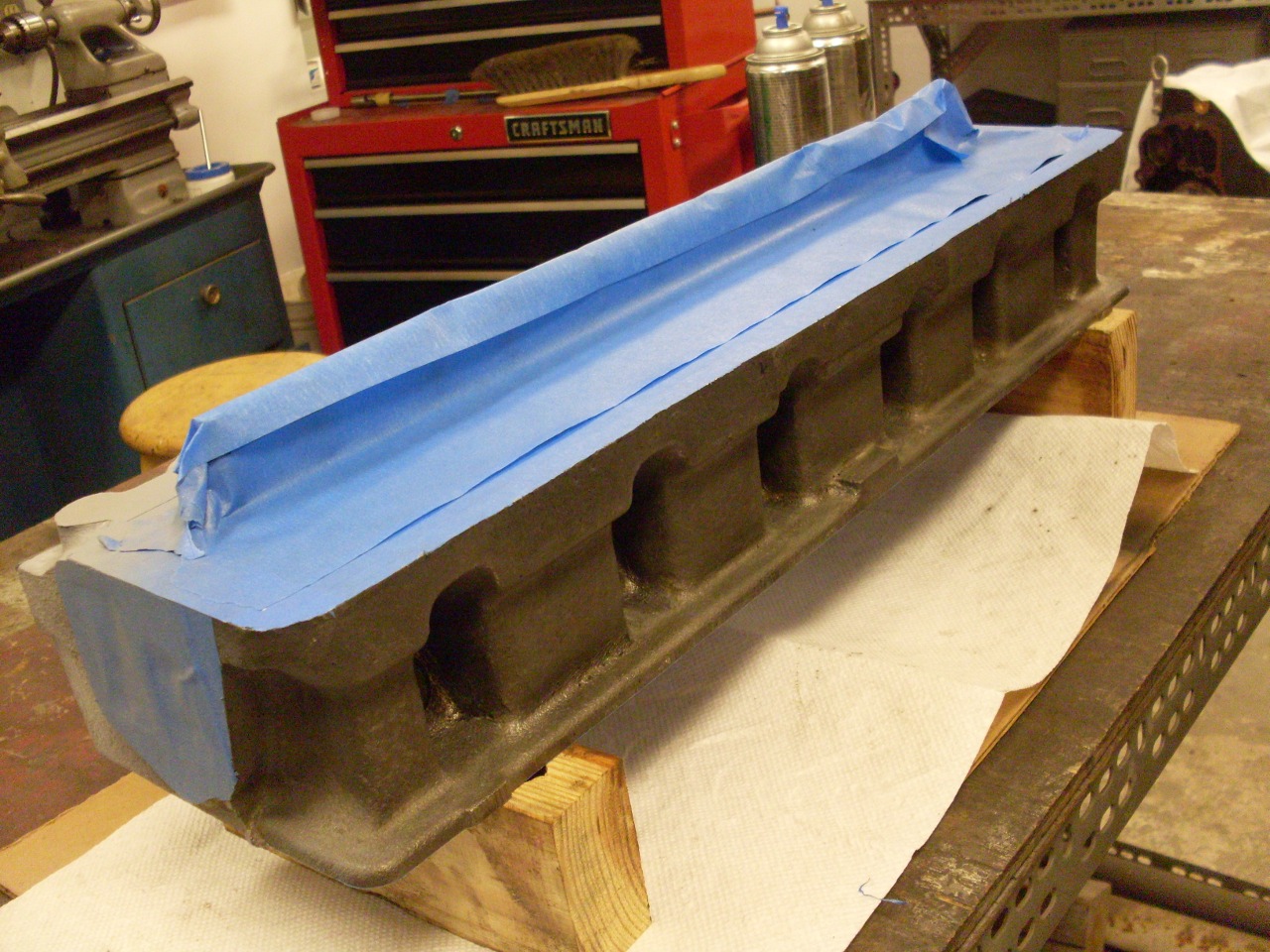

Now

the bare head needed to be cleaned up. Rather than take it to the

shop for a stay in the hot tank, I decided to tank it myself. I

made a wooden box, lined it with plastic, and put the head in it.

I

poured in a gallon or two of phosphoric acid cut 50/50 with

water. Commercial hot tanks typically use a caustic solution like

lye, which is pretty effective on grease and oil, but not so much on

rust or scale. Phosphoric, on the other hand, is really effective

on rust and scale, but less so on grease or oil. Since my main

concerns were with scale in the water jacket, and the exterior of the

head was mainly rusty, I took the head to a coin-op car wash to remove

what grease and oil there was, then gave it a soak in my acid tank.

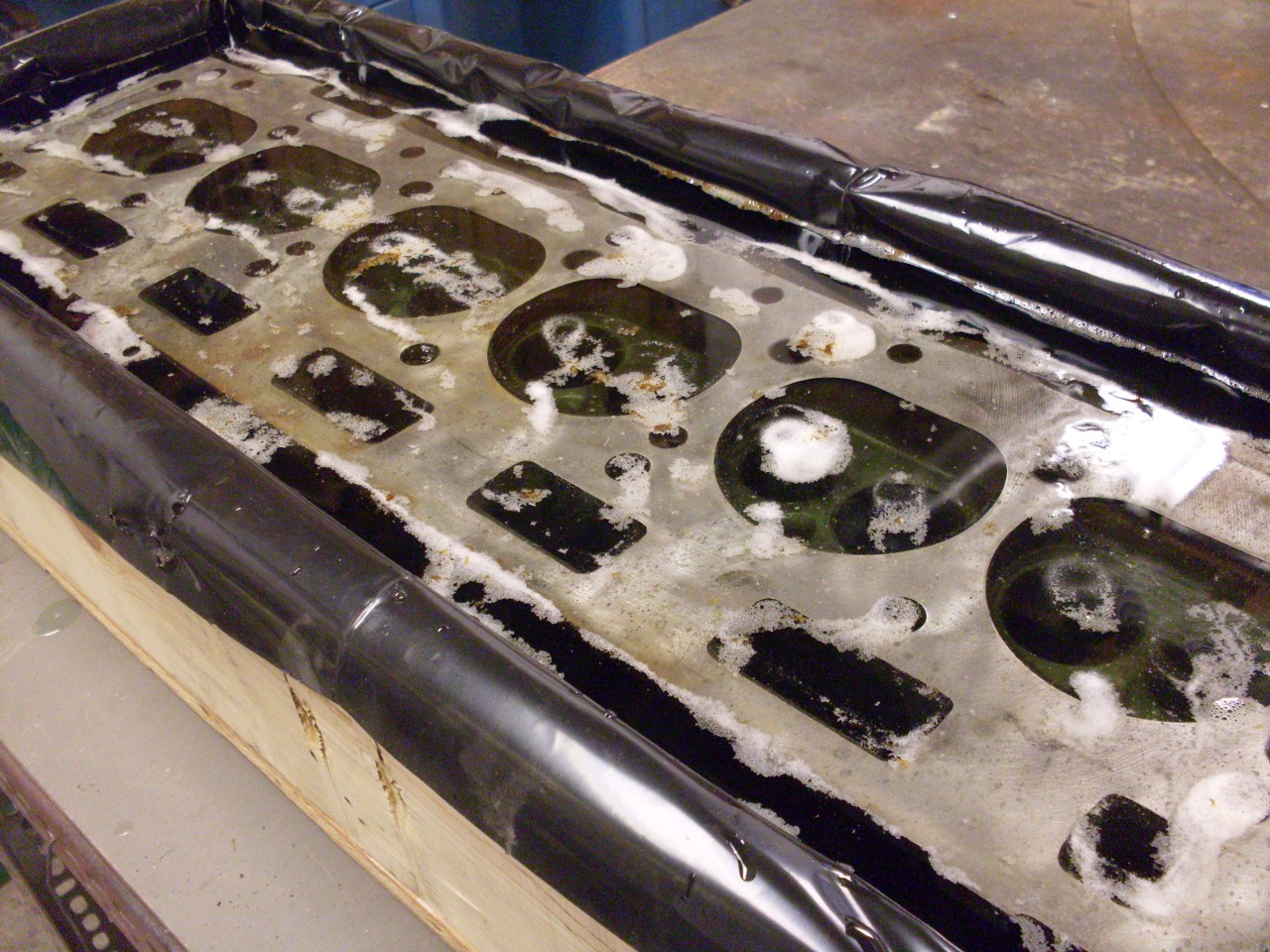

This is what it looked like after a few minutes, a couple of

hours, and the next day.

The tank did a good job, and there wasn't all that much left to do by hand--mainly just some carbon in the combustion chambers.

There

really isn't too much that needs to be done to the TR6 head, but there

are a few tweaks that can improve flow in the ports a little.

Anything that interferes with smooth air flow, like changes of

size, shape or direction, or protrusions into the flow presents

opportunities to enhance performance. For example, the

channels for the ports are formed by sand cores in the mold, and

the throats for the valves are machined to meet them. There is

usually some mismatch at the intersection of the machined throat below

the valve seat and the rough port channel. I tried to remove that

step in each port, or at least smooth it out.

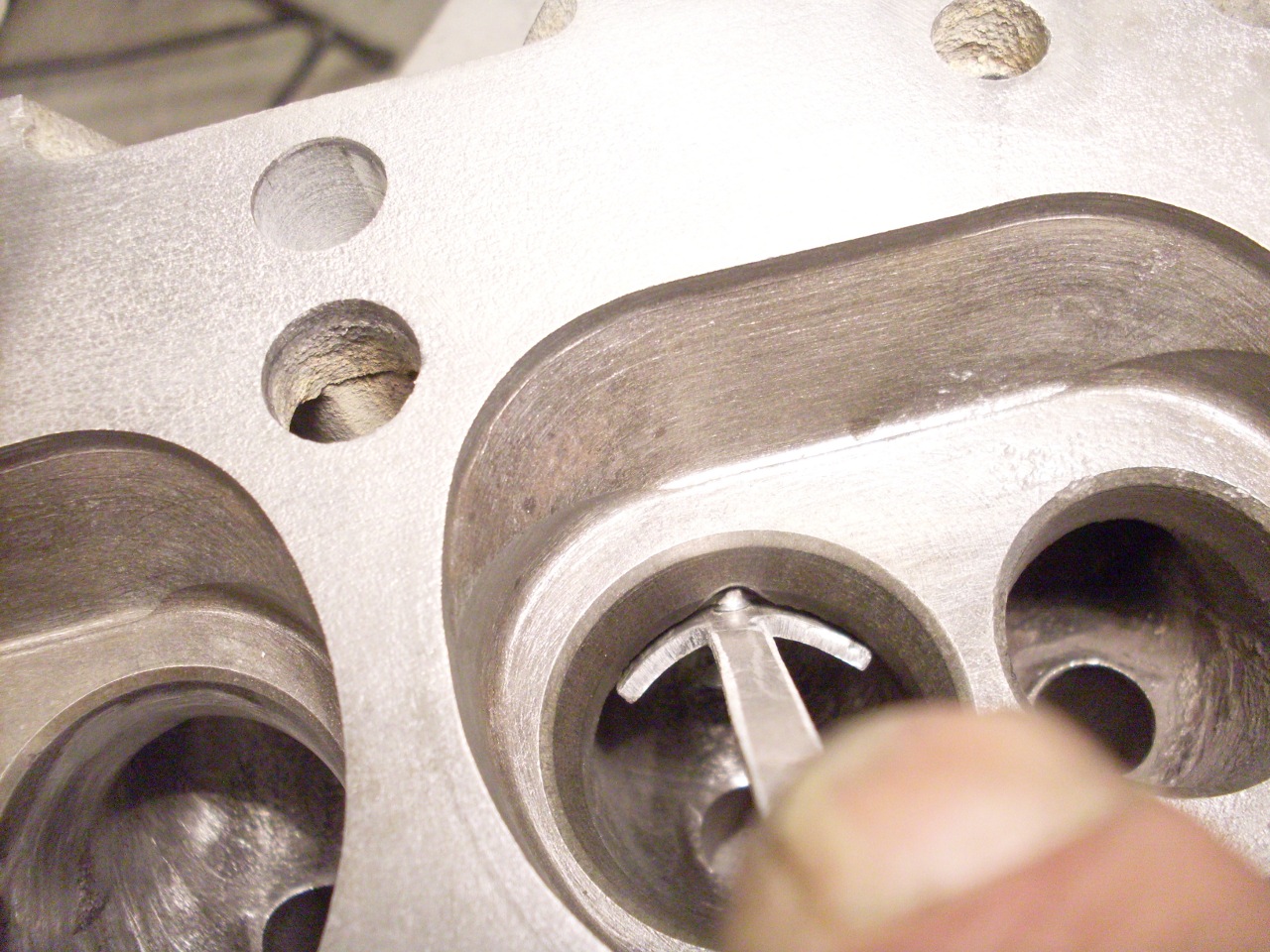

One

other thing that is commonly done to the TR6 head is to slightly

straighten the inside curve of the intake port where it changes

direction below the valve seat. Removing metal has to be done in

a controlled way, since too much enthusiasm in cutting could result in

breaking into the water jacket. It's reported that about 2 mm can

safely be carved away from the curve, but being pretty nervous about

it, I settled for a safer 1.5 mm. One common method for

controlling the depth is to use a little shop made depth gage to guide

in cutting a groove to the right depth, then using the groove as a

guide in cutting the rest of the metal away. I used a carbide bur

for gross metal removal, and then little cylindrical or conical

abrasive "cartridges" for final smoothing. Reportedly, the intake

port shouldn't be "polished", as some texture on the walls of the port

may help promote turbulence to aid fuel dispersion.

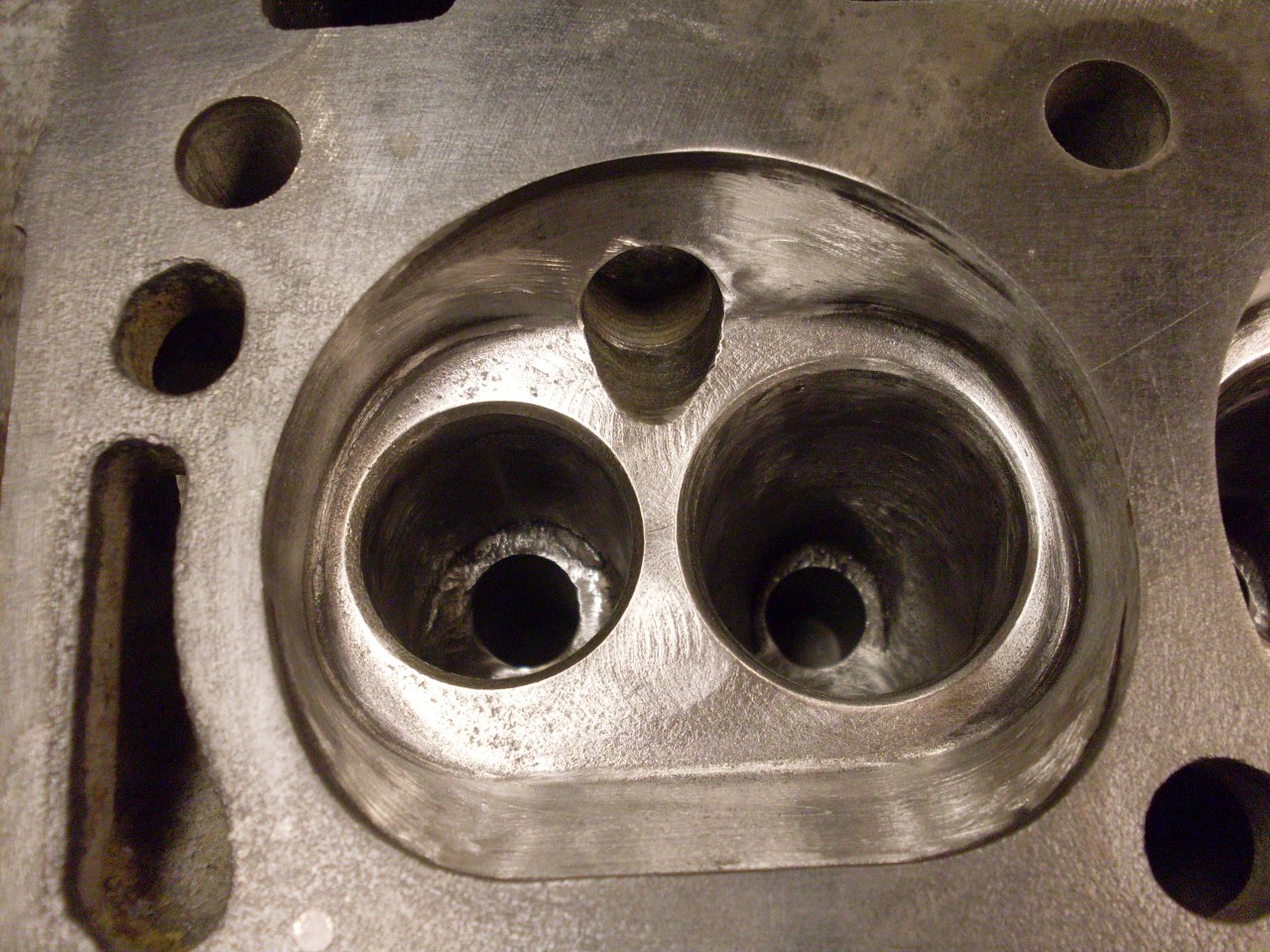

The

exhaust ports were basically just cleaned up, matched to the manifold,

and profiled so that the same rounded retangle shape is maintained all

the way into the throat below the valve seat. The profile tool

helps with this. Also, each exhaust port has a protuberance

around the valve guide that sticks into the flow path. I ground

those away. The second pic below also shows the one minor mod to

the combustion chamber itself. The four sharp "eyebrows" were smoothed to elimiate the edge.

So here is the ported head...

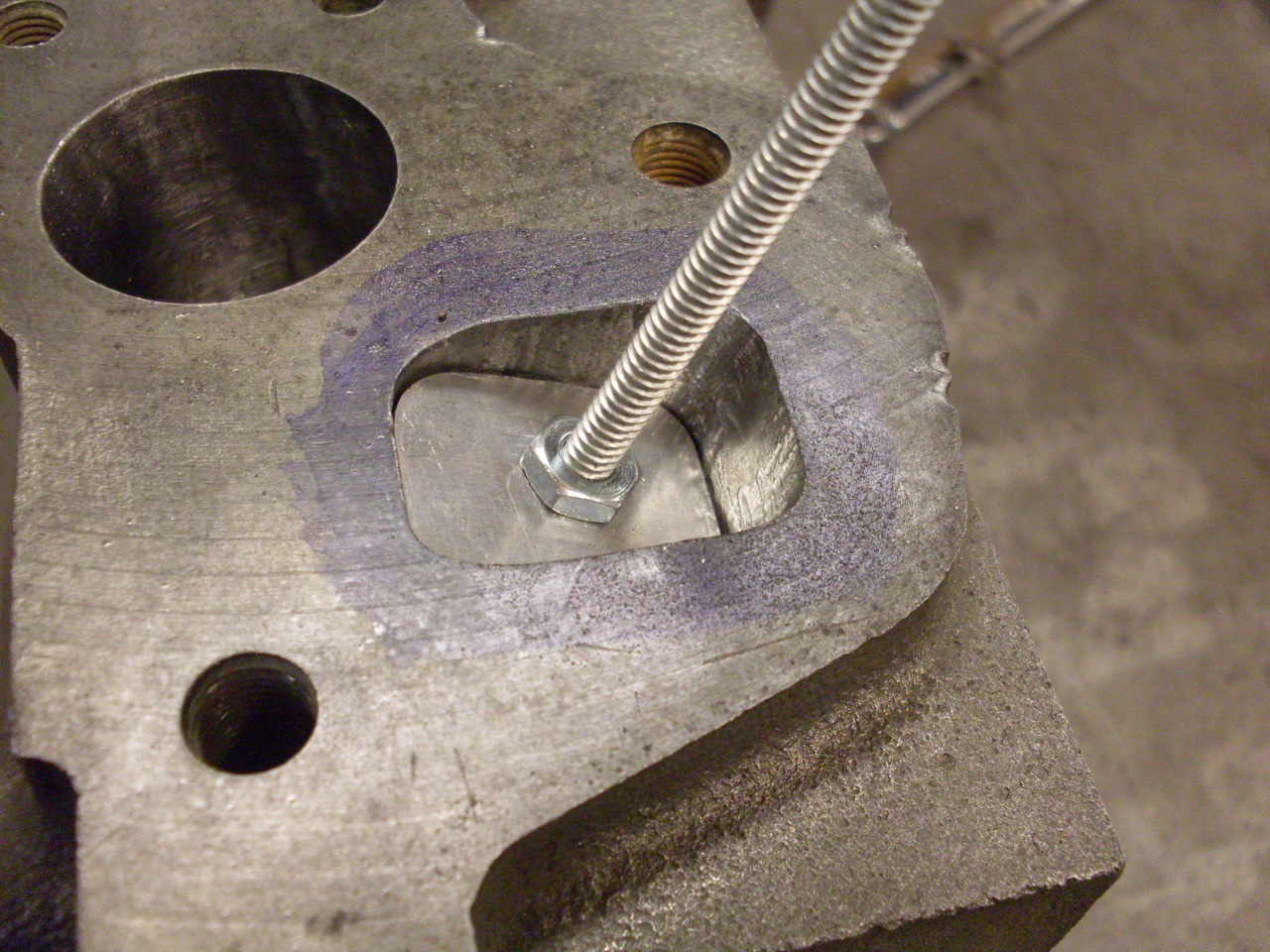

...but

there was one more thing to take care of. Notice the gaping hole

in the roof of the #5 exhaust port. That is the Exhaust Gas

Recirculation (EGR) port. I won't be using EGR, so I wanted to

not only plug the EGR port, but to restore the smooth profile to the

exhaust port.

The

EGR port on the top of the head is threaded 3/4-16, so I started with a

big 3/4-16 allen set screw. Since the EGR port isn't threaded all

the way into the exhaust channel, I cut the set screw to length and

turned the bottom end down to fit the untapped part of the hole and

extend slightly into the exhaust port.

I

then ground the bottom end of the plug so it matched the port profile.

To keep the plug from turning, I set it in place with red

Loctite. I forgot to take a pic of the topside of the plug, but

it will show up in a later picture.

At

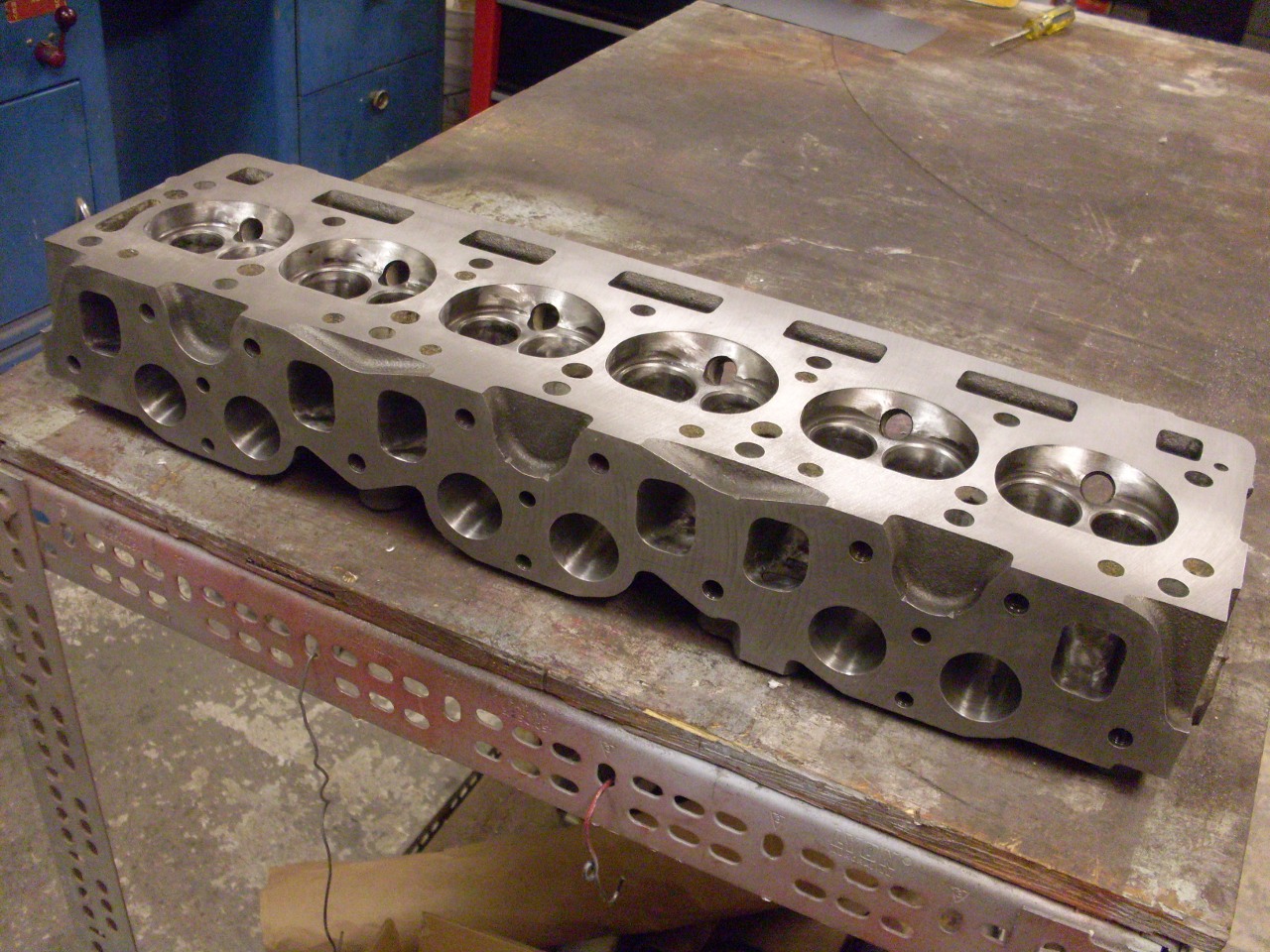

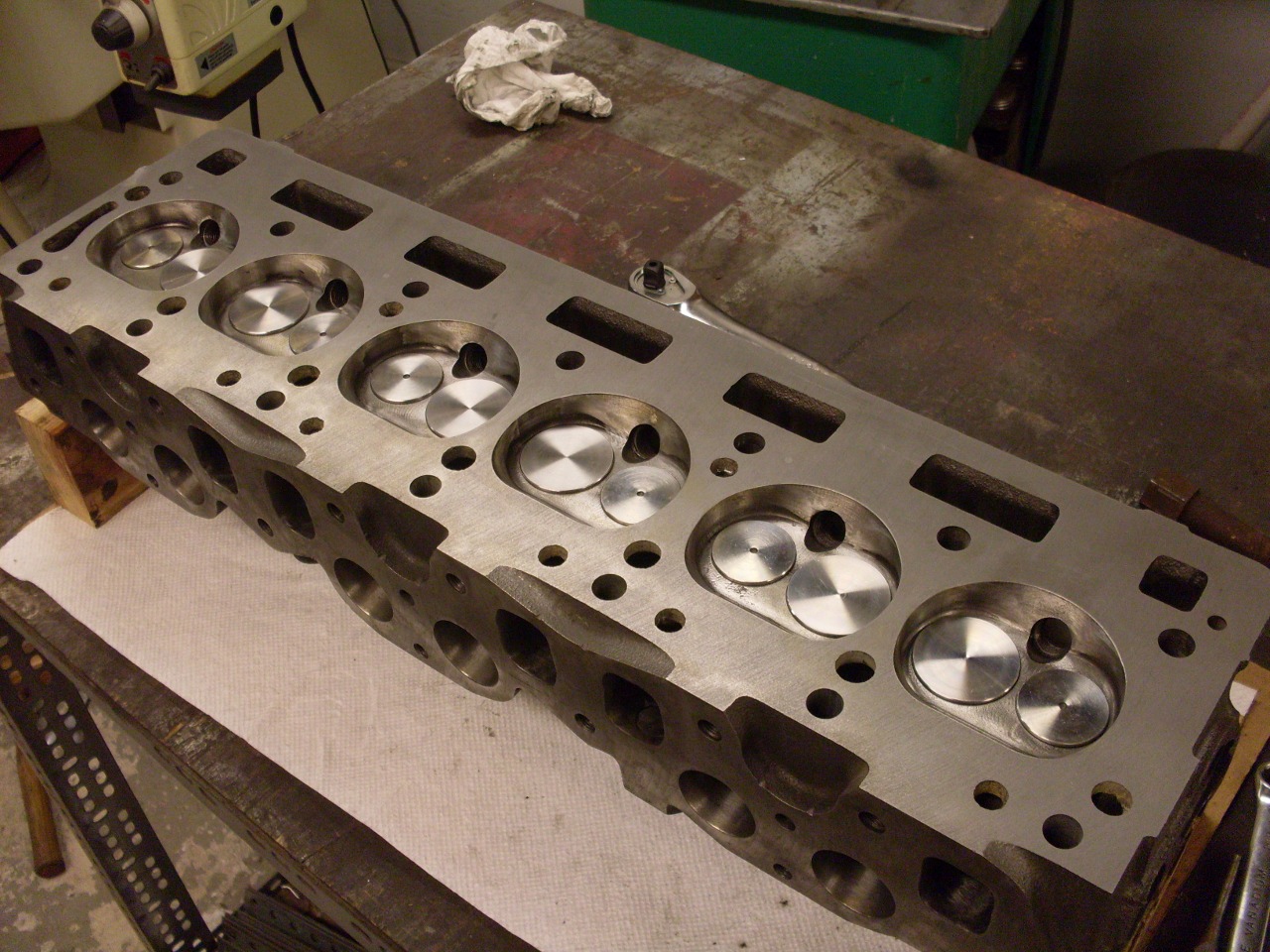

this point I sent the head out to have 0.130" shaved off. This

should take the compression ratio up to around 9.4:1. Here is the

shaved head:

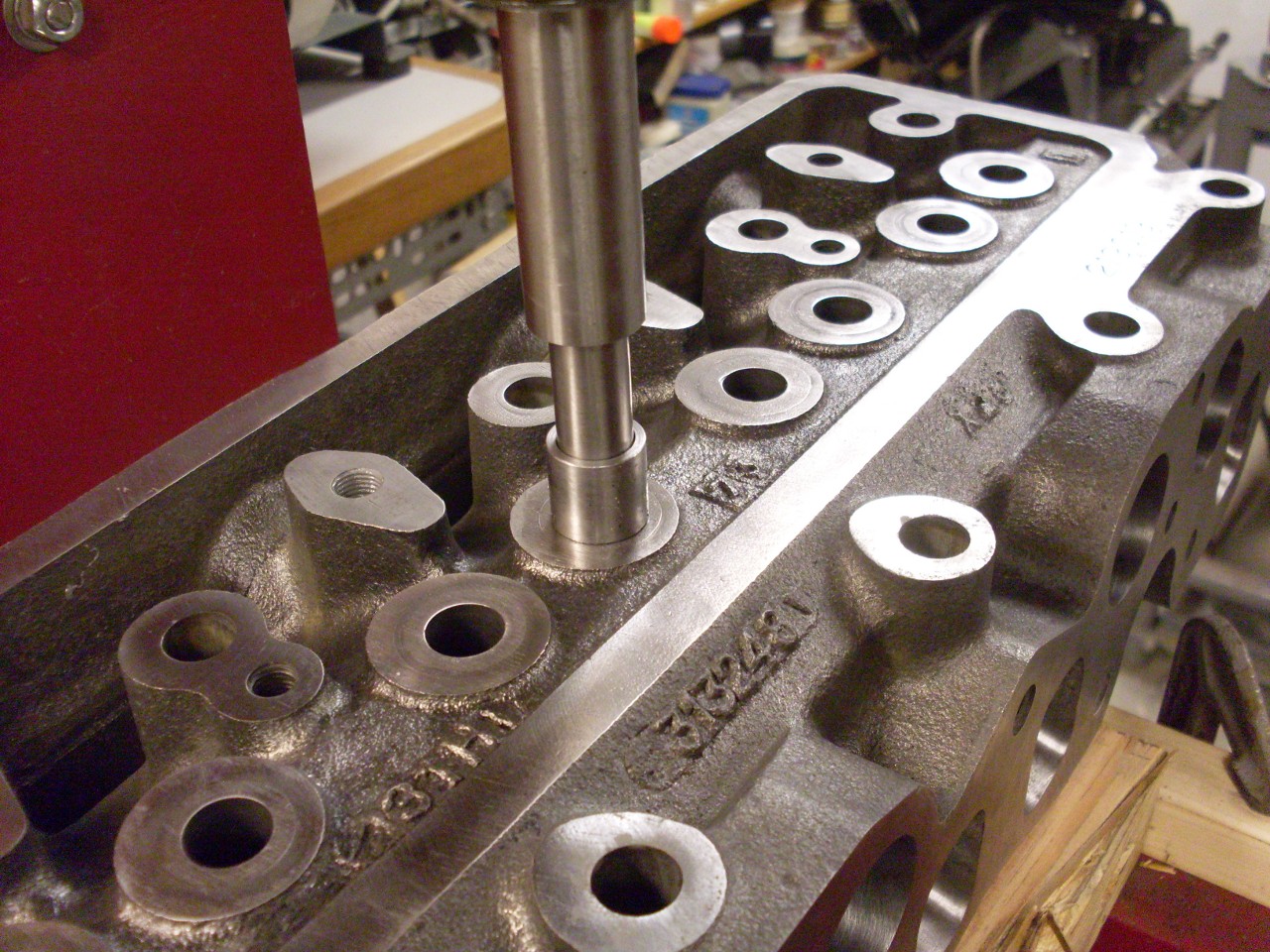

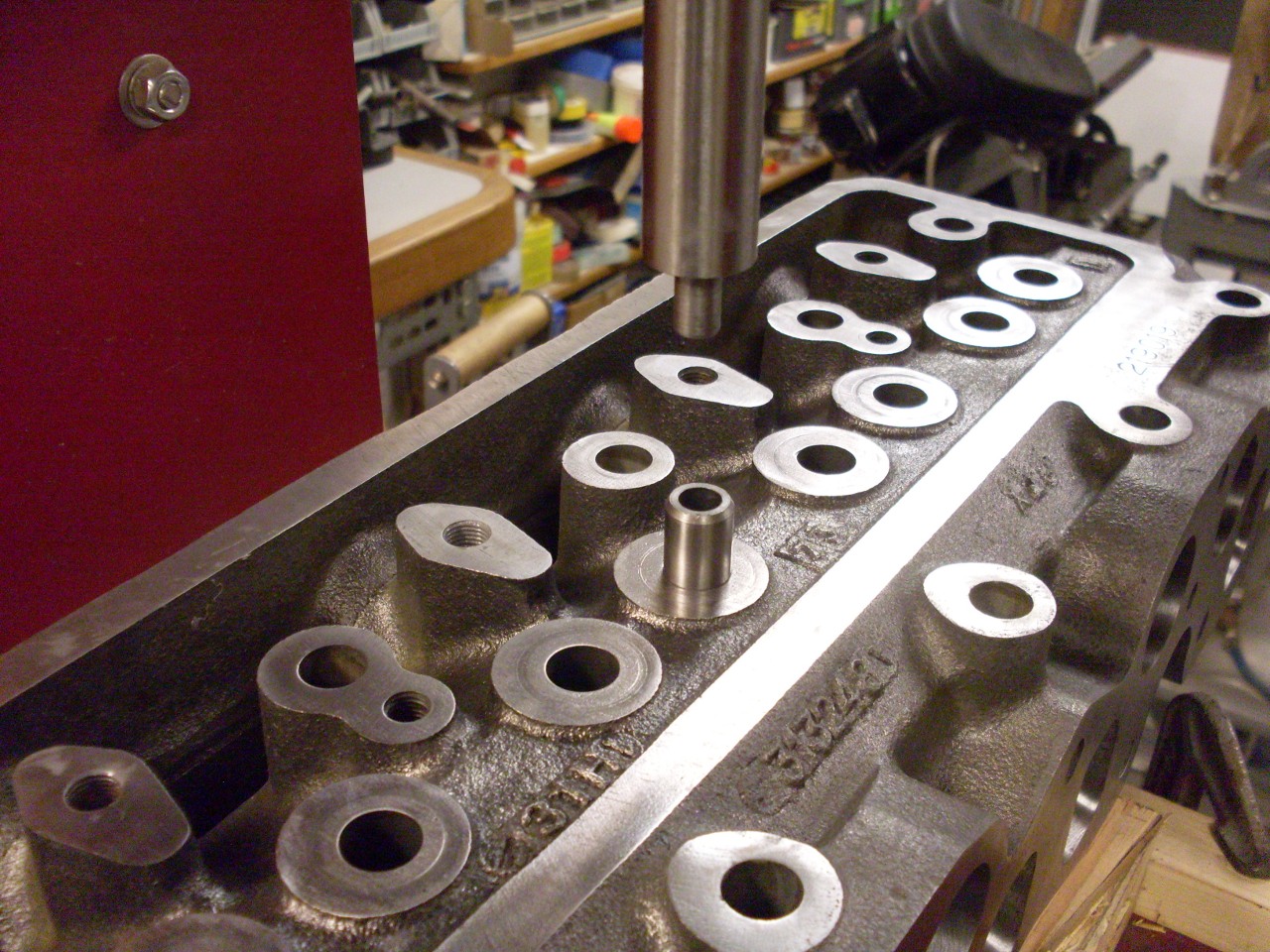

Next

up was to insert the new valve guides. The stock guides were

steel, and using bronze guides is a popular substitution. I

didn't see any particular advantage to bronze guides, so I stayed with

the steel units. The second pic shows the shop made drift to help

push the guides in, plus the collar that limits the process to the

proper stick out of 0.62" above the top surface of the head.

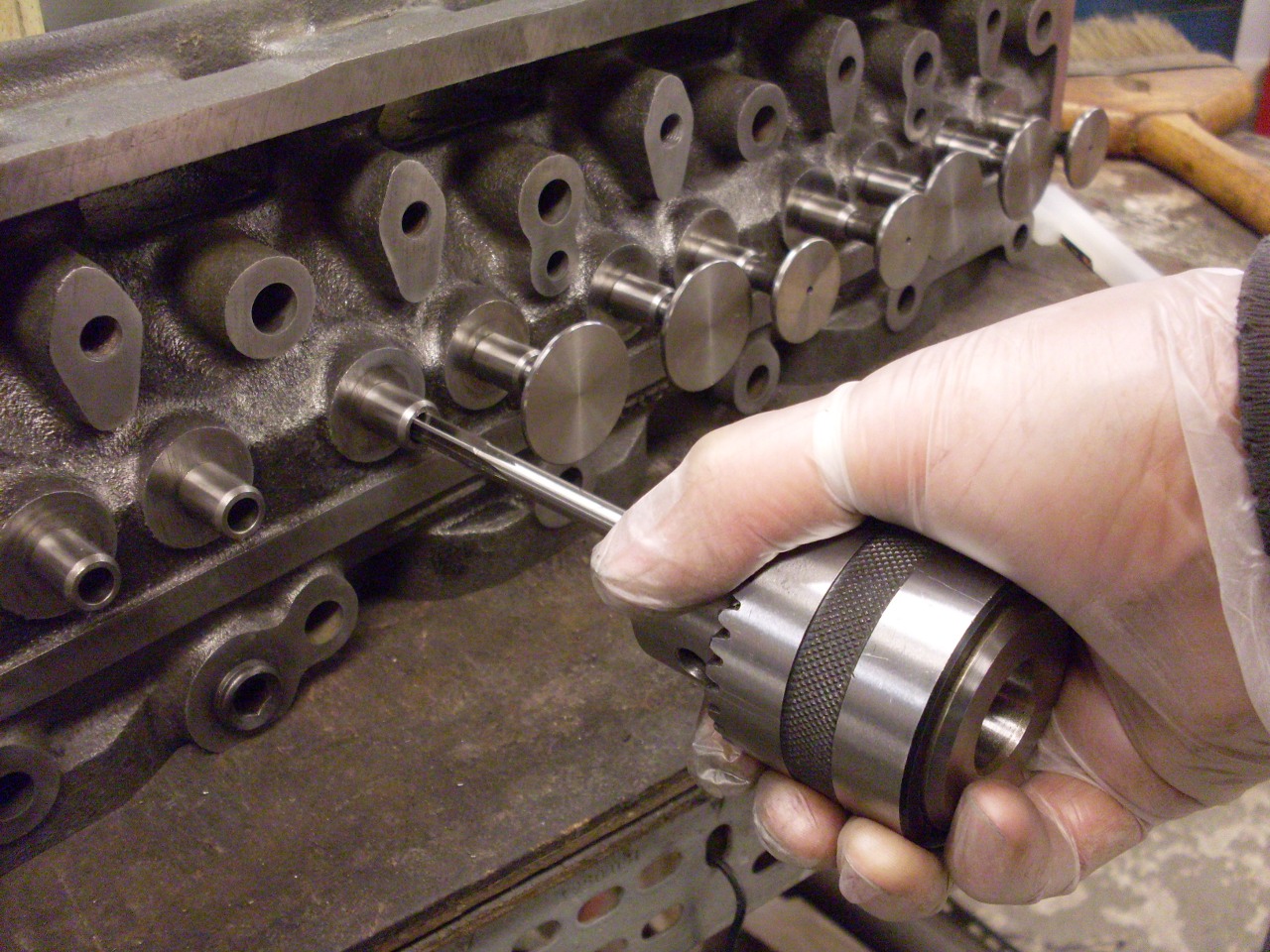

The

new guides were just a little tight on the new valves, so ran a

5/16 reamer through them. So little metal had to be removed that

I could easily do it my hand.

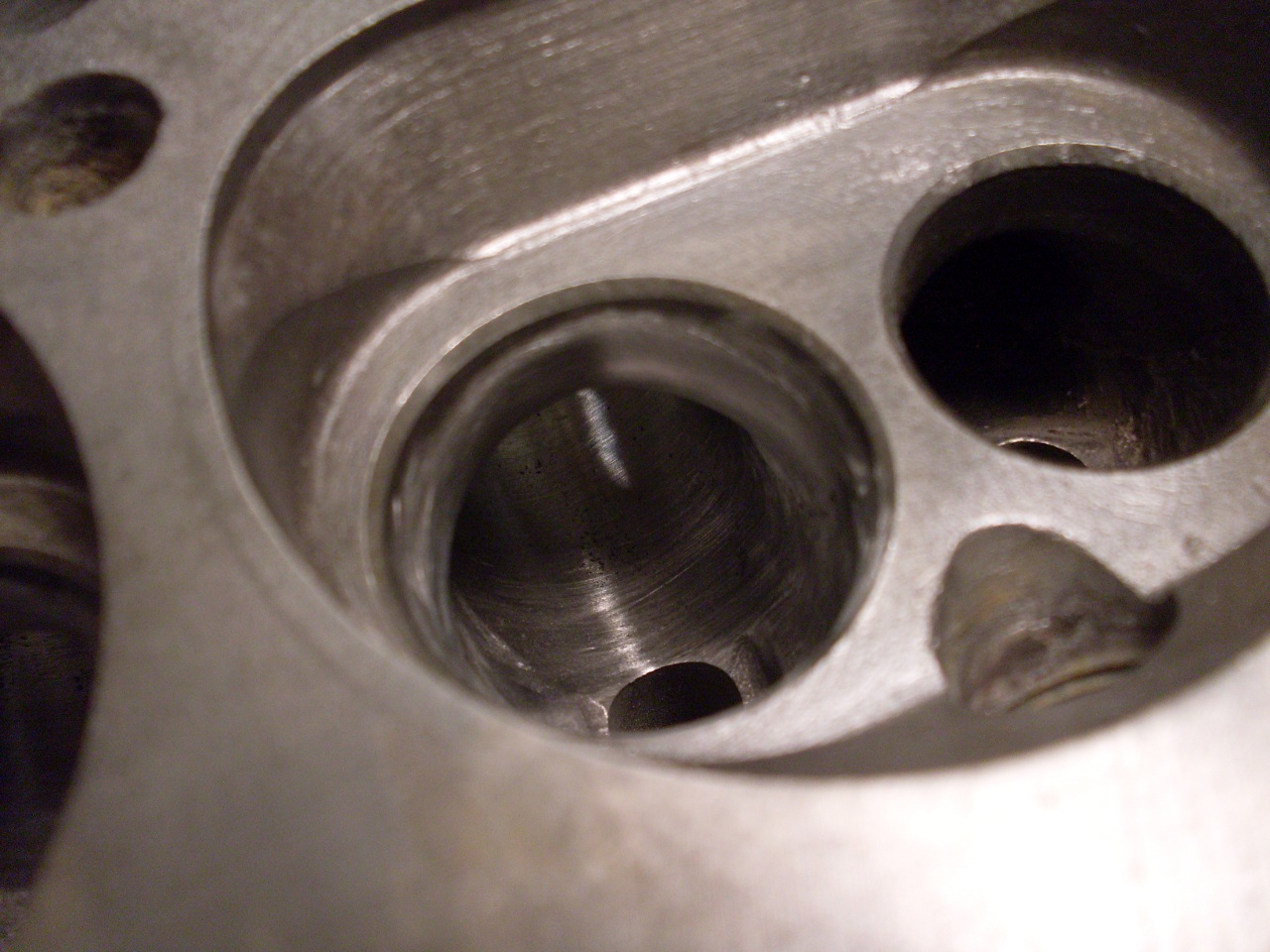

Then

it was back to the shop to have the valve seats cut. Should have

done this in the same trip with the shaving. Not sure what I was

thinking. Nice 3-angle seats:

Next

up was to lap the valves to their seats. The valves get a nice

matte ring showing that they mate perfectly with the middle angle on

the seats.

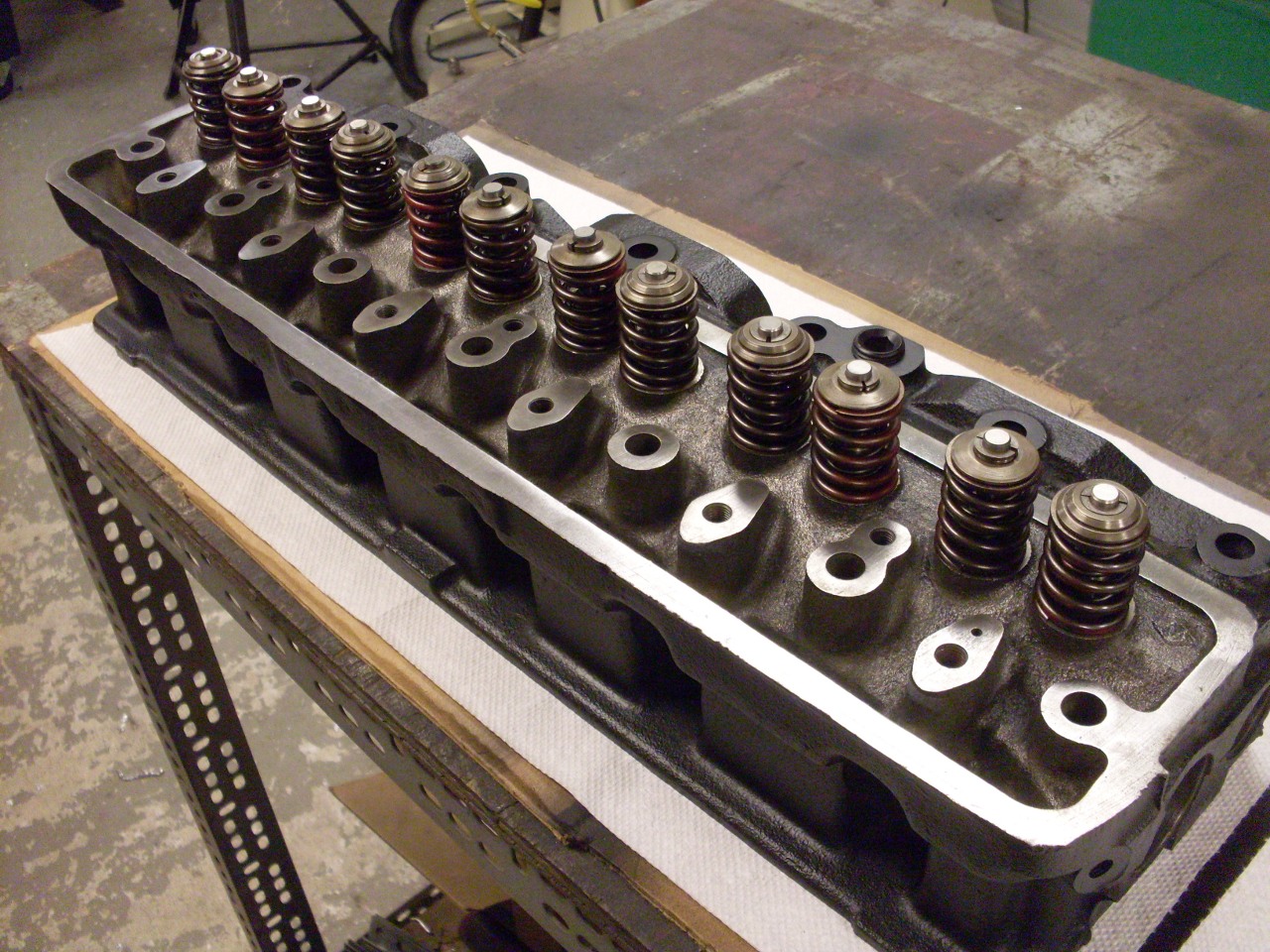

At this point, I painted the head. Would have been easier earlier.

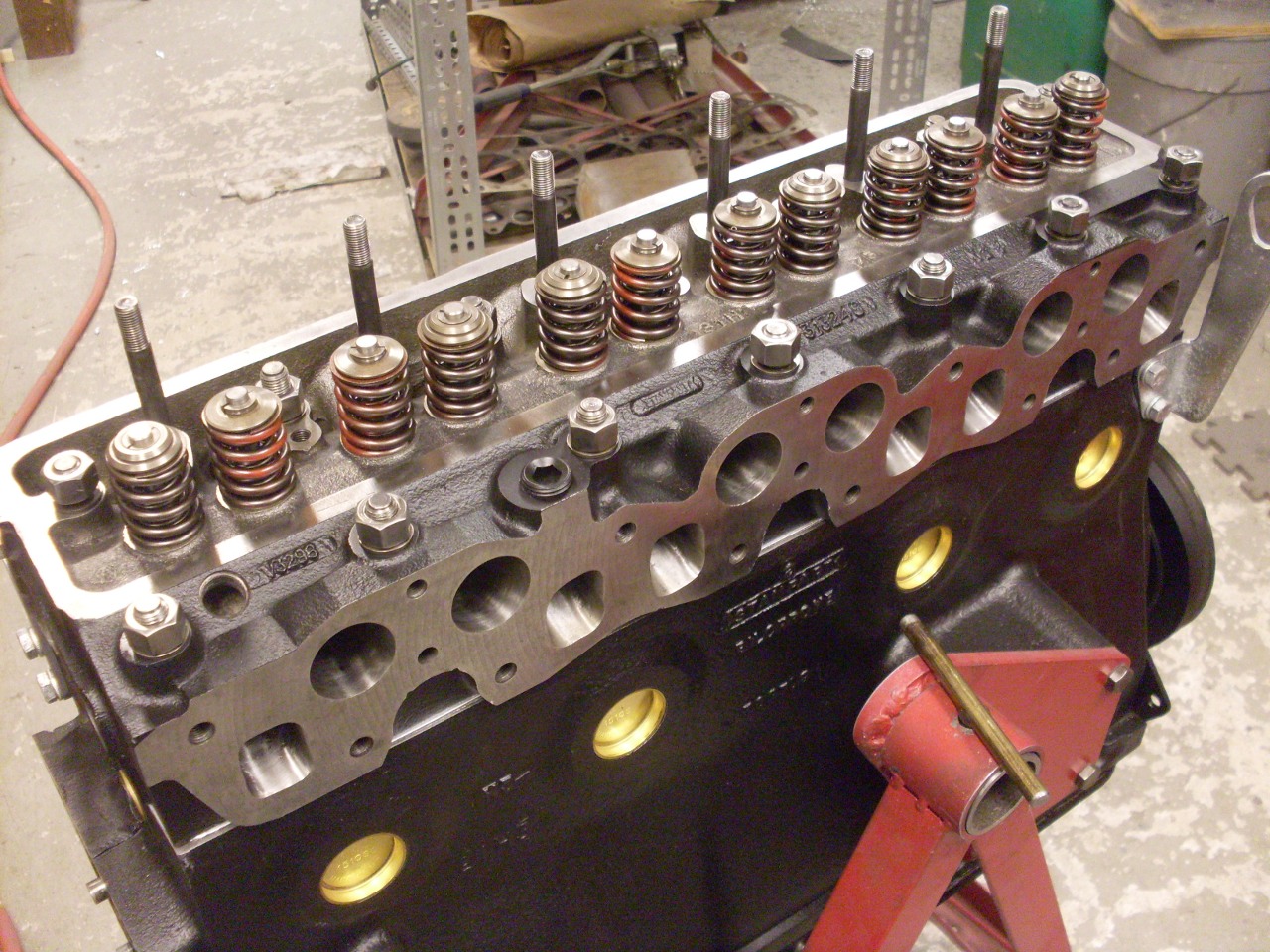

Now the springs and associated hardware:

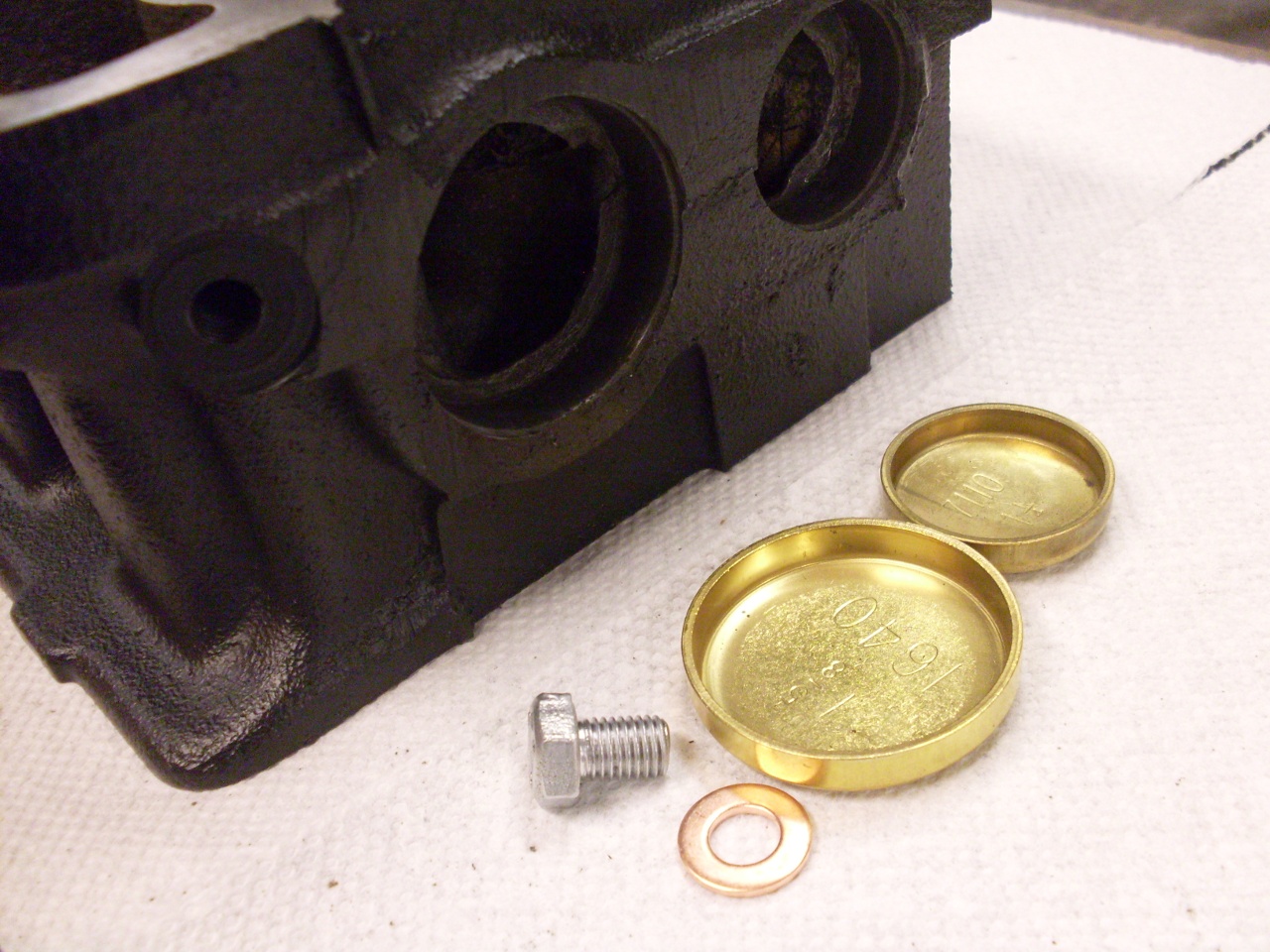

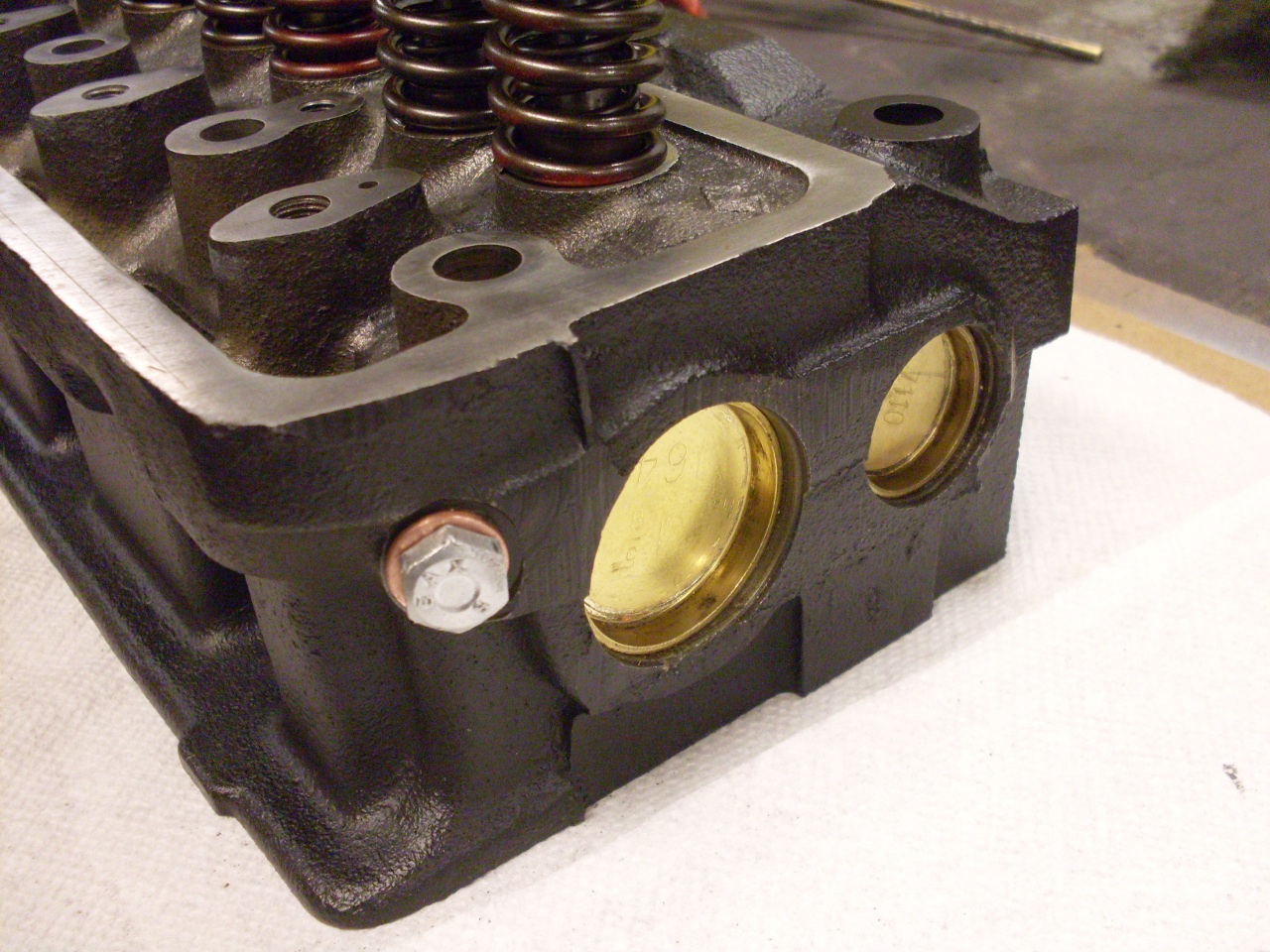

Some odds and ends: Core plugs and the oil gallery plug. I usually anneal copper gaskets, even if they are new.

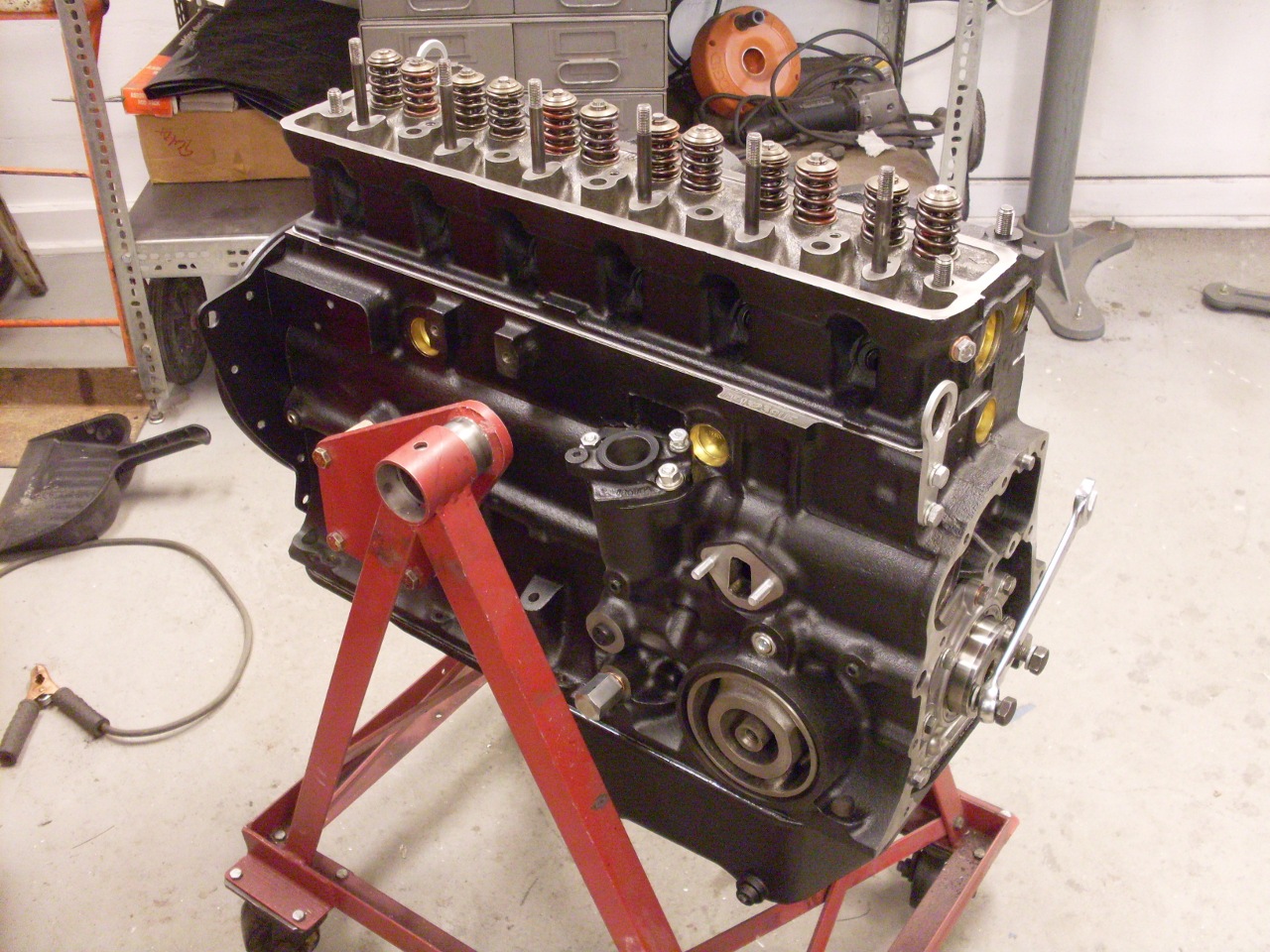

Prepare the block to receive the head:

It's a milestone! Now need to sort out the rocker gear.

Comments to: elhollin1@yahoo.com

To other TR6 pages.

.