To other TR6 pages

February 29, 2014

Rocker Geometry

Rocker

arms are dirt simple devices on one level, but the geometry of

their interaction with other components of the valve train can get

quite complex, and has a real bearing on the performance of the engine

and longevity of the parts. I did a fair amount of research on

valve train geometry to determine if there were any improvements or

adjustments I should make to my valve train, especially since I

shaved the head.

In many ways, rocker geometry can be viewed as

two separate problems--the geometry of the valve side and that of the

pushrod side. They of course are interrelated, but it simplifies

the picture if they are addressed one at a time at least to start.

Usually, the valve side is looked at first, since there are fewer

ways to adjust things there.

There are different philosophies on

setting valve train geometry, differing mainly in which parameters are

being optimized. One popular approach is known as "Mid-Lift".

In the Mid Lift paradigm, the rockers are aranged such that the

angle the rocker tip contact point moves through is centered on the

horizontal (this all assumes a vertical valve as we have in the Triumph

engines). Having a symmetrical path of the cotact point arc

implies several things: First, the side-to-side motion

of the contact point across the valve stem tip is minimized.

Second, the actual valve lift is maximized. Third, the

force on the valve stem tip is more nearly vertical.

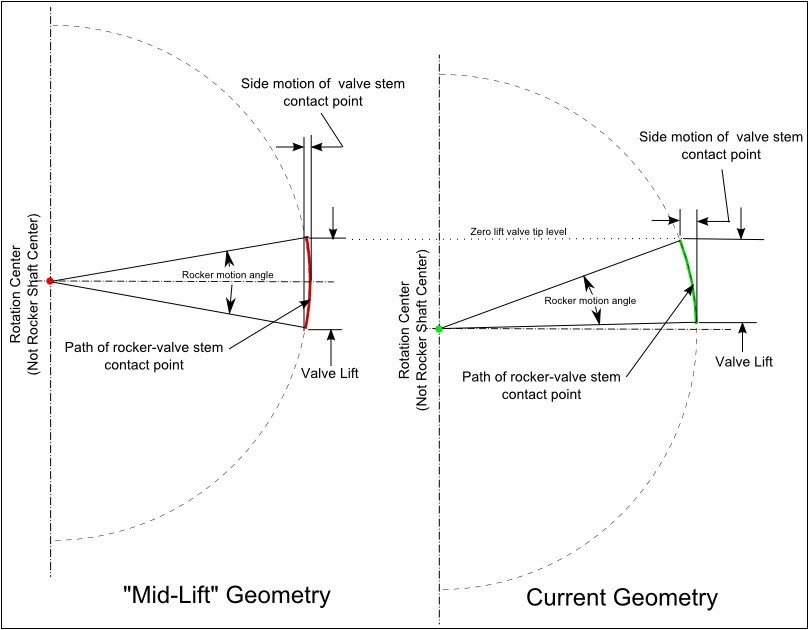

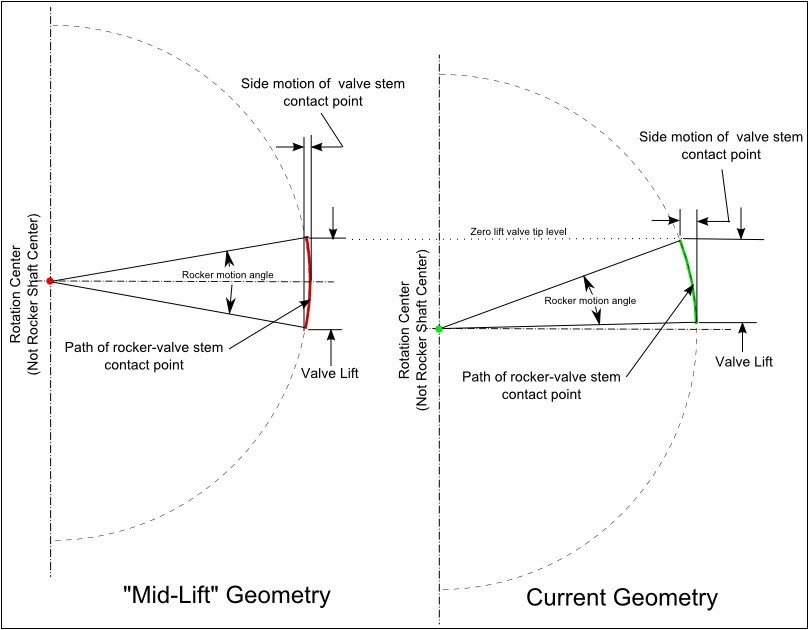

This

illustration shows the geometry I found on my head compared to what it

would be with a mid lift approach. The angle the rocker moves

through and the radius of its arc are the same for both situations--the

arc just occupies a different place in the circle.

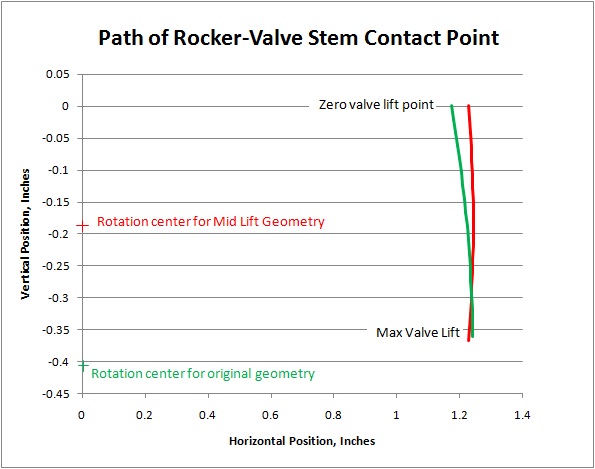

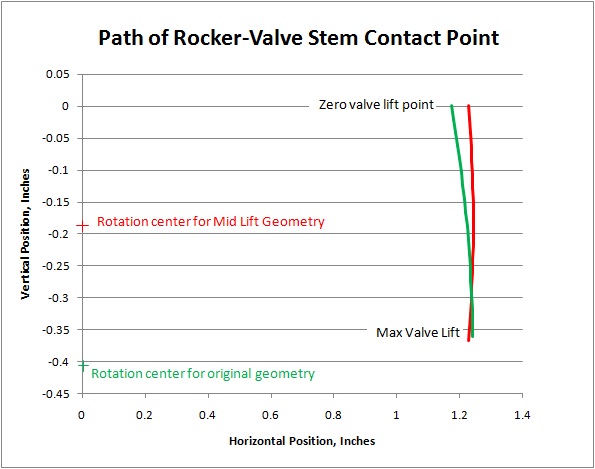

Here is the same information shown with the two arcs superimposed:

One

little complexity here is that the "rotation center" for the contact

arcs is not the rocker shaft axis. This is because the contact

point is actually on the radius of the shoe of the rocker, and the shoe

rotates through the same angle as the rocker, and so the contact point

moves outward on the shoe surface as the rocker rotates downward.

It turns out (and you can easily prove this if you know your way

around geometry and trig) that the rotation center is directly below

the rocker shaft axis by the radius of the shoe.

I was

serious enough about converting my valve gear to mid lift that I

calculated how much the rocker shaft would need to be raised (0.224"),

and made the appropriate shims for the shaft pedestals.

To

check some of the theory, I installed the shims and measured

the side motion of the contact point by bluing the tip of a valve stem

and rotating the crank a few times. The first pic shows the

pattern for the stock setup, the second for the mid lift.

As predicted, the mid lift pattern was skinnier and centered

slightly farther out than the stock pattern.

On

some hardcore racing sites, there is a holy war about how to interpret

these patterns. One camp categorically states that a centered

pattern indicates proper geometry. The mid lift folks counter by

saying that centering the pattern is not as important as minimizing

side motion and maximizing lift. Triumph Engineers were

apparently in the first camp (though, as I understand it, Mid Lift as a

design approach may not have been popularized until after the TR6

era).

In the end, I decided not to use the mid lift approach for

the following reasons. First, since the position of the valve

doesn't change, raising the rocker shaft raises the pushrod end of the

rocker even more, to the point that I'd have to find different push

rods, probably custom ones. Second, I realized that in both the

mid lift and stock cases, the rocker shoe does a combination of rolling

and sliding across the contact area on the valve tip. In the case of

the stock arrangement, most of the motion is rolling, with a little

sliding. With mid lift, there was almost three times as much

sliding. Maybe this is what the Triumph Engineers were optimising

for. Third, the pedistal studs would have been too short, and I'd

have to make or buy longer ones.

I think that if someone

is building for maximum performance, they might well consider a

mid lift approach, especially if they are using roller rockers, since

the sliding issue then goes away.

One thing became apparent to me while

going through this exercise is that fooling with valve train geometry

shouldn't be undertaken unless the side effects are well understood.

For example, it is commonly stated that when a head is shaved, rather

than getting shorter pushrods, the rocker pedestals can be shimmed to

compensate. The potential danger here is that this kind of change,

while possibly correcting pushrod-side geometry, will also affect the

valve side, which isn't otherwise affected by head shaving.

Comments to elhollin1@yahoo.com

To other TR6 pages