To my other TR6 pages

July 25, 2017

Driveline Geometry

I

had cause recently to be pondering drive shaft U joint angles. I

vaguely knew that the geometry of a drive shaft was important, and that

a lot of thought goes into it (or should go into it, at least) for

highly modified cars, especially things like rock climbers or cars with

radically raised bodies.

The

drive line geometry is something I didn't give much thought to on the

TR6 project, since I made no modifications in that area. But in

response to a question about TR6 frame sag and how it might affect the

alignment of drive components, I decided to take a little deeper look.

My frame did have some rear end sag, and I had to address that to

get decent panel gaps and get the rear bumper brackets to fit right.

(Some pictures here of how I did that.)

During that project, I had calculated that the sag at the rear

suspension was probably on the order of 1/4" or so, and I decided not

to pursue fixing that. I didn't, however, consider what affect

frame sag would have on drive line geometry. Rear frame sag would

have the effect of rotating the differential into a slightly more "nose

up" orientation, and this could theoretically affect the drive shaft

angles.

A

little Internet research suggested that even small amounts of driveline

misalignment could cause vibration and premature wear, so I sat down

with a pad and pencil and worked out some of the math behind U joints.

Those with an unhealthy curiosity about that math can see it here,

but for the rest, take my word for it that the main takeaway is that

the axis of the gearbox output shaft and the axis of the differential

pinion shaft need to be parallel for all drive shaft speed and angle

distortions to fully cancel. If frame sag tips the differential

up, it could be a problem.

This is where my usually fairly latent OCD kicked in, and I decided I needed to determine the alignment of my drive line.

So, out came the exhaust system, the rear part of the tunnel, and the drive shaft.

Now,

I can't think of a good way to measure gearbox output or pinion shaft

angles directly, so I worked from the respective flange faces, which

should be pretty close to perpendicular to their axes.

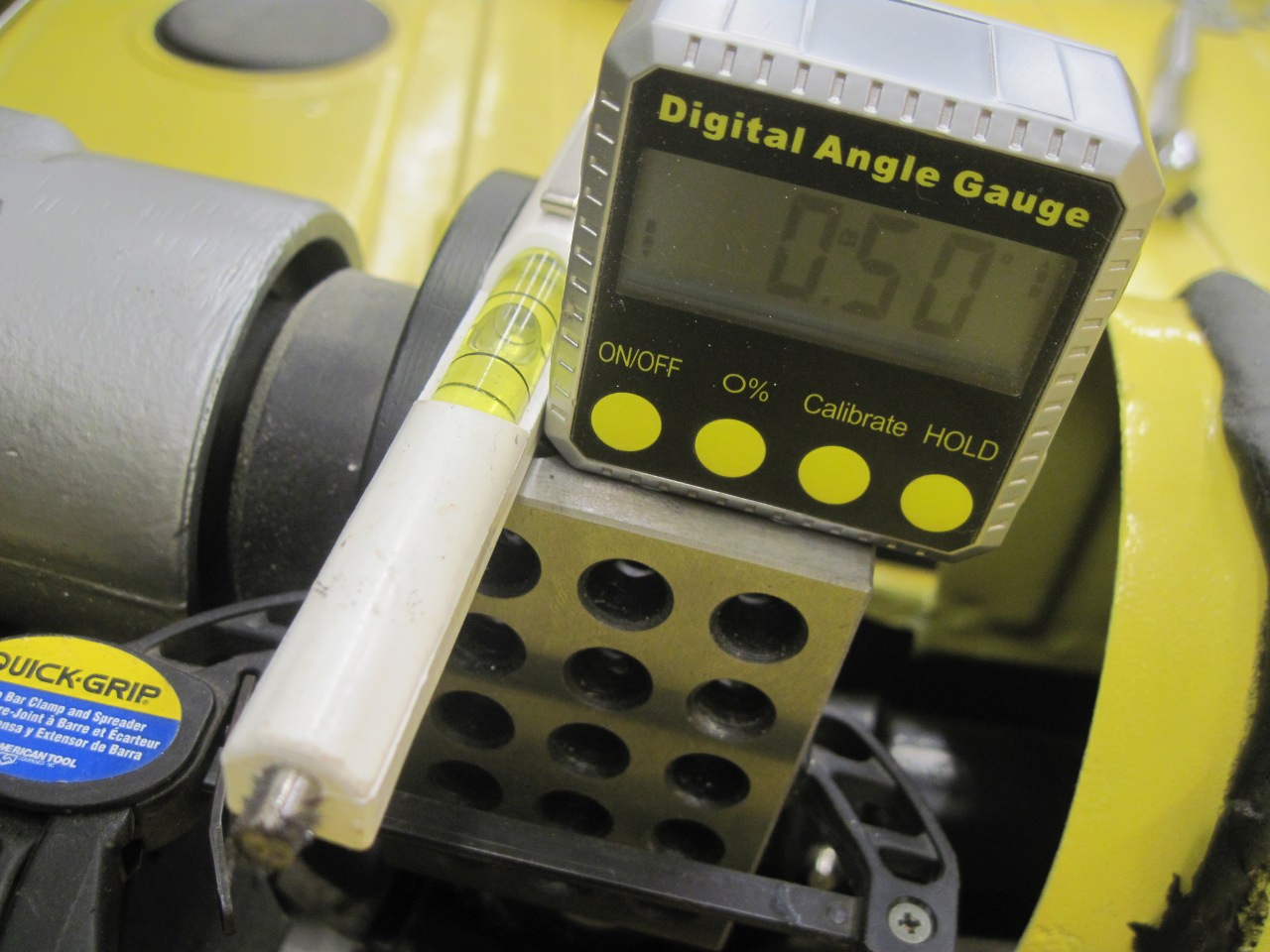

In

the left picture, a machinists 1-2-3 block was clamped to the flange

and leveled side-to-side. Then the magnetic angle gauge was

placed on top. Though I did calibrate the gauge to true

horizontal, it really wasn't necessary since the angles of these axes

to horizontal is irrelevant. We just want to know their

relationship to each other. In fact, the back of the car was

jacked up, so these don't represent any angles we'd see in normal

operation. The more artsy picture on the right shows the gauge

attached directly to the diff flange.

The

upshot of this foolery was that with the car in this attitude, the

gearbox flange was pointing up at about 0.5°, and the pinion flange was

also pointing up at about 1.3°. For the axes to be parallel, the

diff flange should be pointing down at 0.5°.

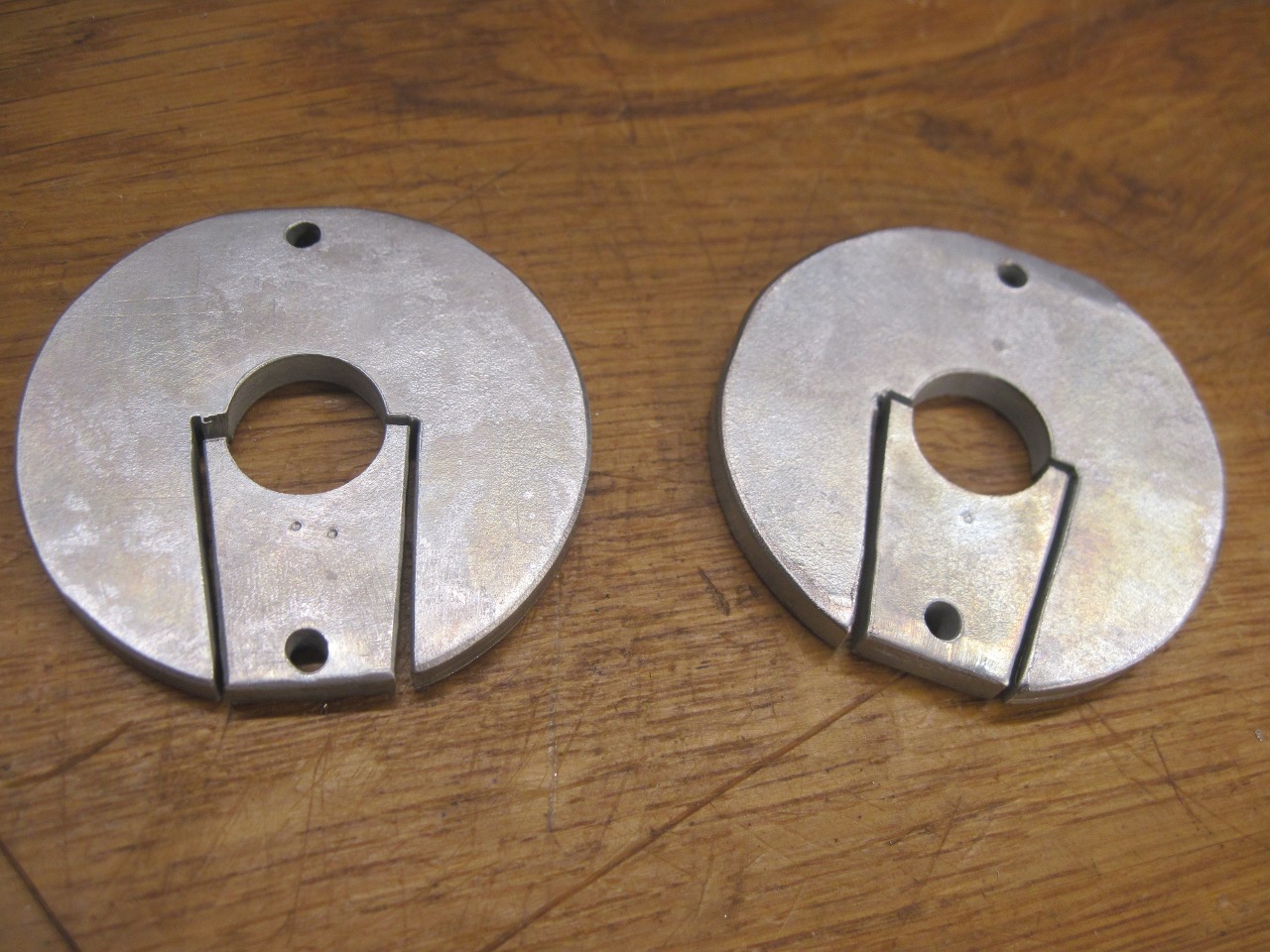

A

little math told me that, based on the distance between the front and

rear diff mounts, to rotate the diff by 1.8 degrees, I could shim down

the front mounts by a little over 5/16", or shim up the rear mounts by

the same amount. Unfortunately it looked like neither mounting

point would accommodate that much extra thickness, but I could split

the shims. For the front, I made up a couple of these two-piece

shims from 3/16" stock. The little wedge pieces are so I could

just lower the diff slightly on the studs, and insert the larger part

of the shim, then slide in the wedge to lock it in place. The

shims went on top of the rubber mounts.

For the rear, I just used an extra 1/8" thick washer between the diff cover and the rubber mount brackets.

On

re-measuring the angles, I got a final angle mismatch of only about

0.3°, so this approach got rid af over 80% of the angle error. I

decided that chasing the remaining 0.3° just wasn't worth it.

Things like frame flex and flexing of the rubber mounts will probably cause more variation than that.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages