U Joint Math 101

Automotive

drive shafts typically consist of a driving flange that couples to the

gearbox output shaft, an intermediate shaft, often with a sliding

coupling, and a driven flange that connects to the differential

pinion shaft. At the intersections of the driving flange and the

intermediate shaft, and also the intermediate shaft and the driven

flange is usually found a cardan joint, more commonly called a

"universal joint" or U-joint. It is the universal joint's job to

deliver rotation across the joint even when the two sides are at an

angle to each other.

The U joint consists of a yoke on both

sides connected with a cross-shaped piece. Two opposing ends of

the cross have bearings that fit into the yoke arms of one shaft, while

the other two cross ends connect similarly to the other shaft yoke.

The cross allows rotation across an angle by rocking back and

forth inside the joint.

Though the basic function of a U joint

is fairly simple to grasp just by playing with one, there are some

nuances that aren't apparent. The primary one is that the rotary

motion is not transmitted across the U-joint uniformly. This is

not a secret, and is certainly old news among car people, but it's not

often that the math behind the concept is shown. While not that

easy to visualize, the derivation of the relationship between input and

output motion just uses highschool trig and algebra.

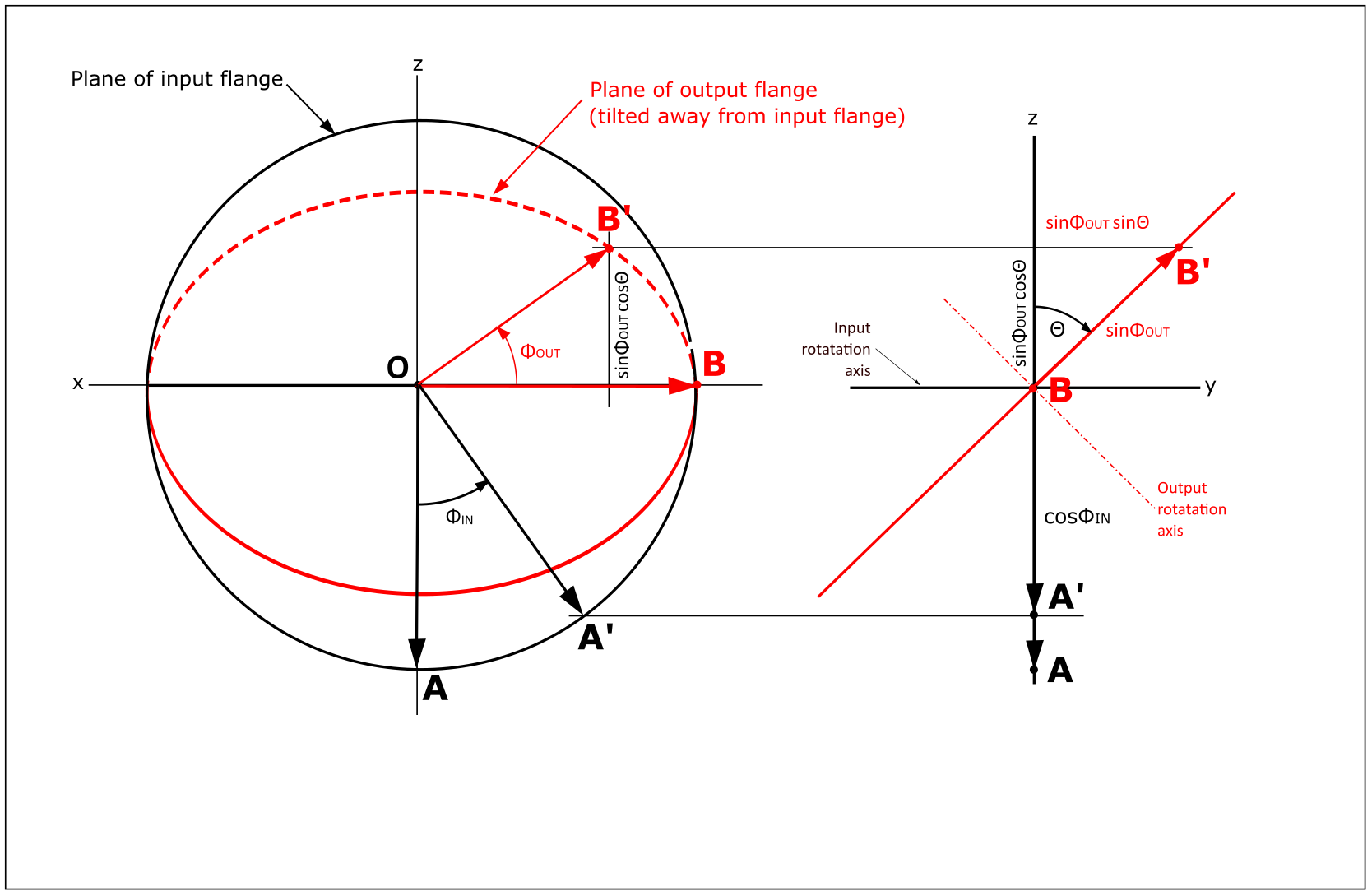

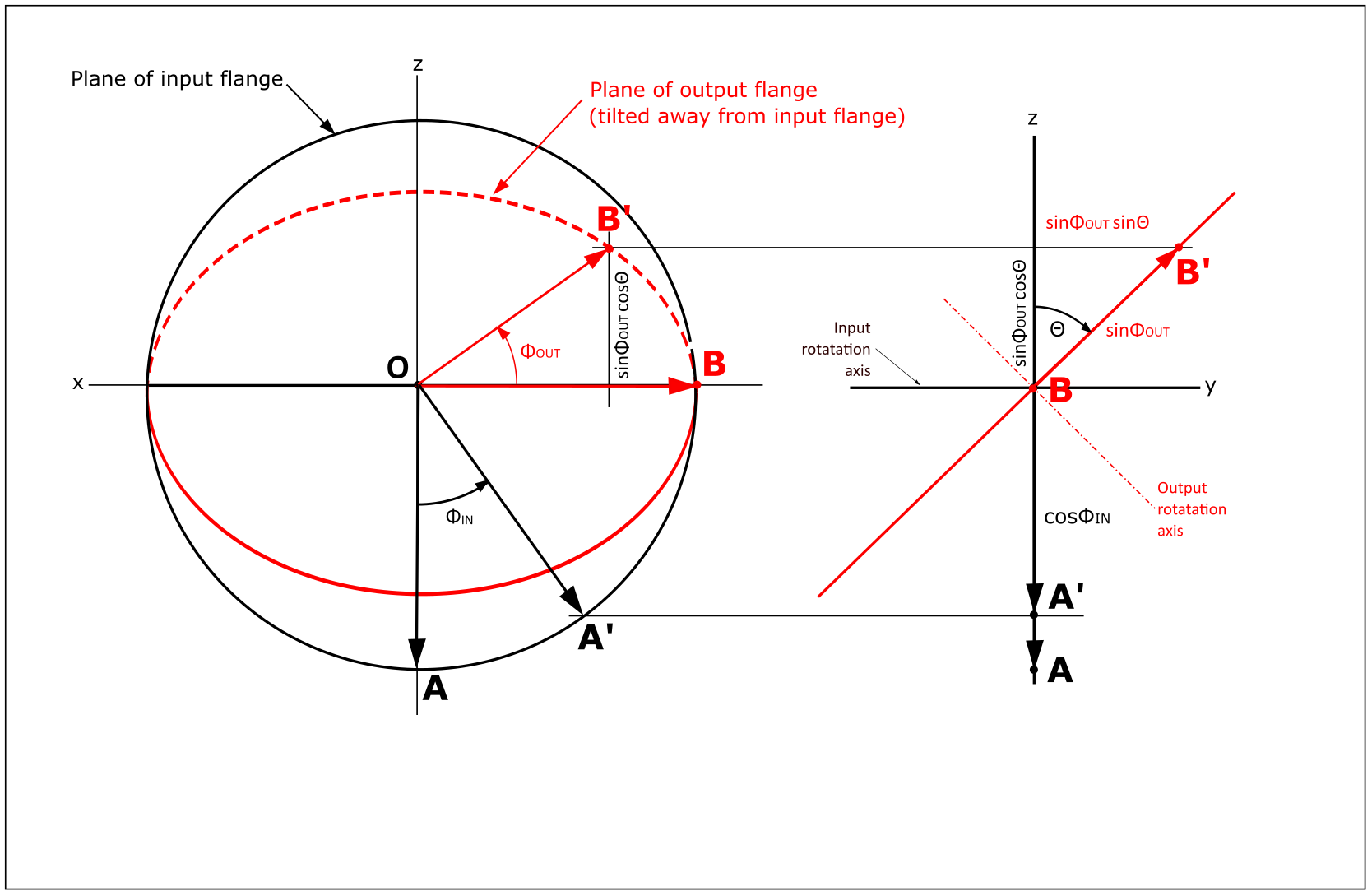

The

diagram shows a schematic rendering of a U-joint. The black

circle represents the path of points on the rim of the driving, or

input flange of the joint. It is viewed directly inline with its

axis.

The red ellipse is similar for the driven, or output

flange. Since it is at an angle Θ to the input (driving) flange,

it is tilted back and appears as an ellipse from this viewpoint.

To the right of the circles is a side view of the schematic

joint, showing the flanges edge-on. and clearly showing the angle Θ

between them.

Also on the drawing are vectors OA and OB.

Point A represents one of the yoke arms on the input flange while

point B is one of the yoke arms on the output flange. They are 90

degrees apart. As the joint turns, the black vector OA traces the black

circle, and the red vector OB traces the red circle (which looks like

an ellipse in thie view), but the two vectors are always constrained to

be at right angles to each other. Note that in the position shown

for vectors OA and OB, they are both in the "black" plane, since point

B is on the line where the two planes intersect.

Now, if we rotate the input flange through angle ΦIN,

we arive at the situation shown by the vectors OA' and OB'. Point

A' is on the black circle, but point B' is now "behind" the black plane

on the red circle. OA' and OB' are still at right angles to each

other, though it may not look so because one of the vectors is out of

the plane of the picture. The rotation of the red vector on

its red circle is ΦOUT.

At

this arbitrary position of the vectors, we can start to characterize

their positions. To simplify the notation, we assume both vectors

are unit vectors (length=1).

The projected length of the red vector in the side view is sinΦOUT, and this can be used to get the y and z coordinates of the point B' as shown.

Gathering the remaining coordinates of the ends of the two vectors, we have:

A' = (sinΦIN , 0 , -cosΦIN), and

B' = (cosΦOUT , sinΦOUTsinΘ , cosΦOUTcosΘ)

Next,

we invoke the requirement that the angle between vectors A' and B' be

right. We do this by deriving an expression for the 3D distance

between A' and B', and setting it equal to √2 (since the hypotenuse of

two unit vectors at right angles is √2).

The result is a fairly gnarly trig expression that reduces to:

tanΦ

OUT = tanΦIN/cosΘ.

As

a sanity check, we look at how the input and output angles are related

for a couple of special values of Θ. At Θ=0 (no angle between the

input and output), cosΘ = 1 and tanΦOUT = tanΦIN, or ΦOUT = ΦIN, just what we'd expect. With Θ = 90°, cosΘ = 0, and we get no rotation (no rotation around the output flange's axis, that is).

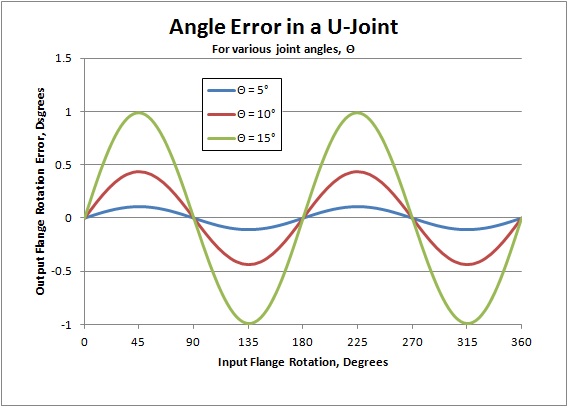

So

what does this mean? It means that for every revolution of the

input flange the output flange alternates between leading and lagging

the rotation of the input at a frequency of double the rotation speed.

Graphing the relation shows that for a 15 degree joint angle, the

rotation error will be +/- about 1 degree.

While

this illustrates the problem with single U joints, it is even more

instructive to look at the rotational speed. (or RPM for car folk).

It should be apparent that when the output flange is

transitioning from a lagging angle condition to a leading one, it will

have to be turning faster than the input flange, and slower for the

lead to lag situation.

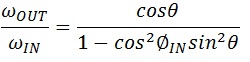

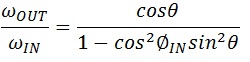

If we take the time derivative of the angle expression, we get an expression for angular velocity (or RPM for car folk).

In this analysis, we will assume that Θ doesn't vary with time, so cosΘ is a constant.

dtanΦOUT/dt = dtanΦIN / cosΘ dt

sec2ΦOUT dΦOUT/dt = sec2ΦIN / cosΘ dΦIN/dt

But dΦOUT/dt and dΦIN/dt are just angular velocities, so we'll rename them ωIN and ωOUT.

ωOUT/ωIN = sec2ΦIN / (sec2ΦOUT cosΘ) .

Through some trig manipulation and eliminating ΦOUT, we get

.

.

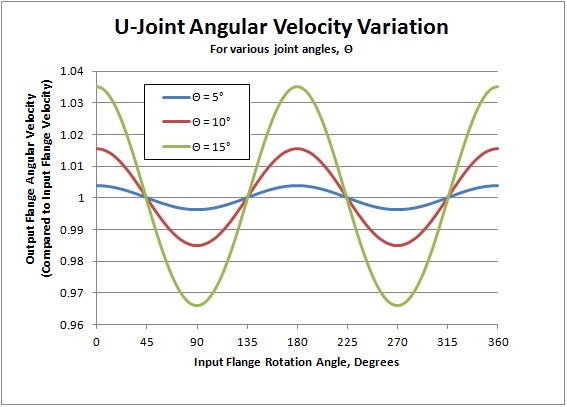

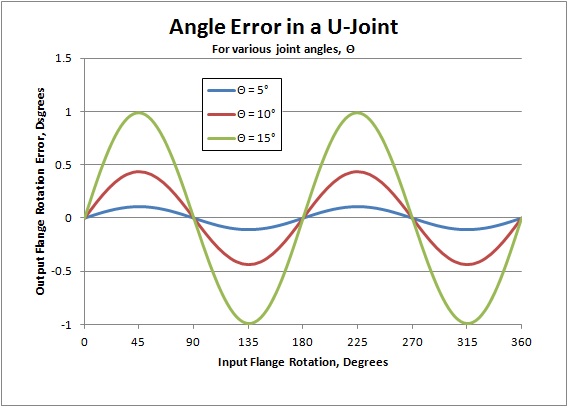

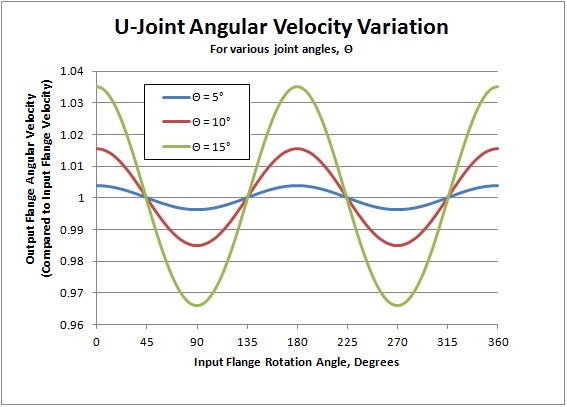

Graphing

this relation shows how the output flange speed (e.g. RPM) varies

during a revolution of the input flange for various joint angles.

When the angle error is moving from lagging (negative) to leading

(positive), the velocity is necessarily higher. The range of this speed variation from minimum to maximum is given by

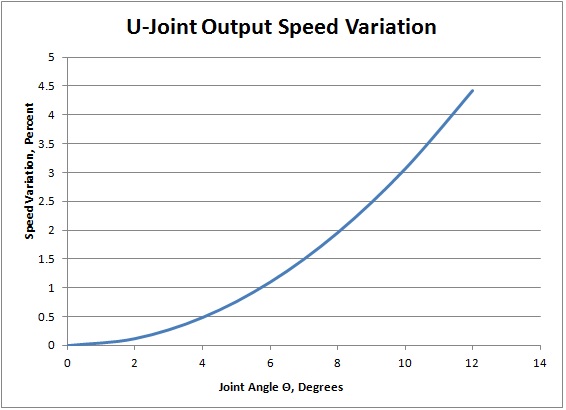

ωIN (1/cosΘ - cosΘ).

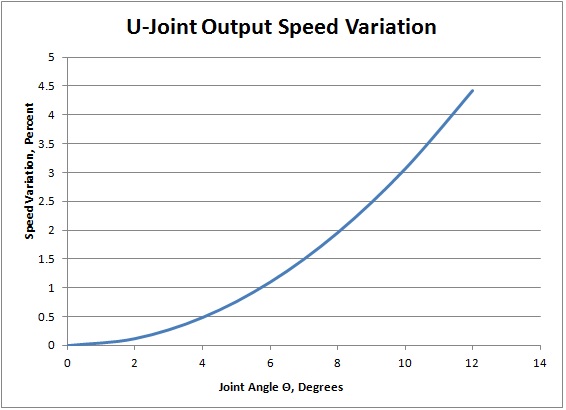

Graphing this relationship shows that the variation grows at a faster rate for larger angles.

This

is of course why single U-joints are never used where speed or angle

distortion can't be tolerated. In practice, U-joints are always

used in pairs for automotive applications, arranged such that the

second joint exactly cancels the distortion introduced by the first one.

If

the joint schematic illustration above is duplicated, but with all

vectors rotated 90° counterclockwise, the angle equation then becomes

tanΦOUT = tanΦIN * cosΘ.

It

should be obvious that applying one equation after the other, with the

output of the first joint becoming the input of the second one, the

cosine terms cancel, leaving tanΦOUT = tanΦIN, and ΦOUT = ΦIN. In turn, this also makes the speed variation disappear.

There are two major caveats in this perfect error cancelation, though.

First, the "phasing" of the joints must be correct. The driving (input) yoke of the second joint must be rotated 90° from

the driving yoke of the first joint. If it is not in this

orientation, the cosΘ terms don't cancel--they multiply, giving an

overall function

tanΦOUT = tanΦIN/cos2Θ.

This

effectively doubles the angle and speed distortion rather than

canceling them. In a typical drive shaft, it is often pretty easy

to assemble the parts with incorrect joint phase, leading to driveline

vibration due to the speed variation.The

second caveat has to do with an assumption we made when we added the

second U joint. We assumed that the joint angle Θ was the same

for both joints, and this is true only under certain

conditions. If the two joint angles are different,

cancellation will be imperfect, and some speed distortion will

remain. The effective relation is

tanΦOUT = tanΦIN * (cosΘ1 / cosΘ2),

where Θ1 and Θ2 are the joint angles of the two joints.

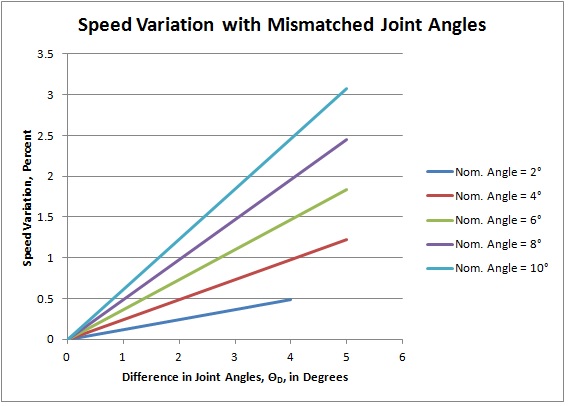

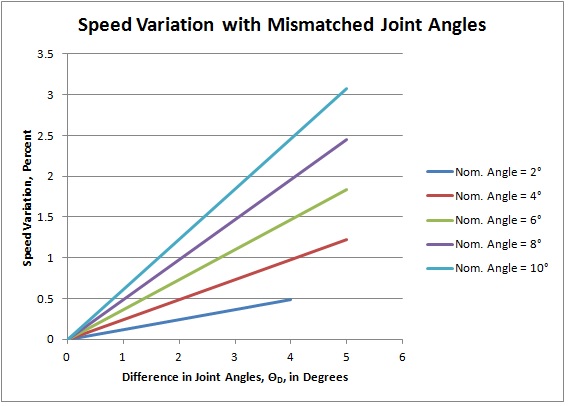

If we identify ΘN, the "nominal" angle of the center shaft as the average of the two joint angles, and ΘD as the difference between them, the graph below shows how speed variance is affected by angle mismatch.

This

should be convincing evidence that the two joint angles must be equal

to get perfect cancellation of angle and speed distortion, but what does that mean on a practical level?

It

basically invokes the basic axiom of geometry that a straight line

crossing two parallel lines will cross them at equal angles. This

means that if the axis of the input flange of a drive shaft is parallel

with the axis of the output flange, the angles of the two U joints will

be equal. This in turn implies that the axis of the gearbox

output shaft must be parallel to the axis of the pinion shaft of the differential.

The two axes can certainly be offset (it's sort of a drive

shaft's job to accommodate this), but they have to be parallel for perfect cancellation.

Any deviation from parallel will introduce some speed distortion

at the rear end, which could be felt as driveline vibration.

.

.

.