To my other TR6 pages

November 13, 2016

Hydraulics

The

TR6 cars had a conventional hydraulic brake system, but also a

hydraulically actuated clutch. The brake system has dual

circuits, with the front and rear hydraulics separate. Though

there is only a single brake master cylinder, it effectively has two

separate piston chambers. Even a total loss of fluid in either

the front or rear brake circuit will not affect the other circuit,

though braking effectiveness will be compromised. Any significant

pressure difference in the two circuits during braking will be sensed

by a Pressure Differential Warning Actuator (PWDA), which closes an

electrical switch in that situation.

Since some of the brake and

clutch hydraulic components are mounted to the body, these systems

couldn't be finalized until the body was back on the frame.

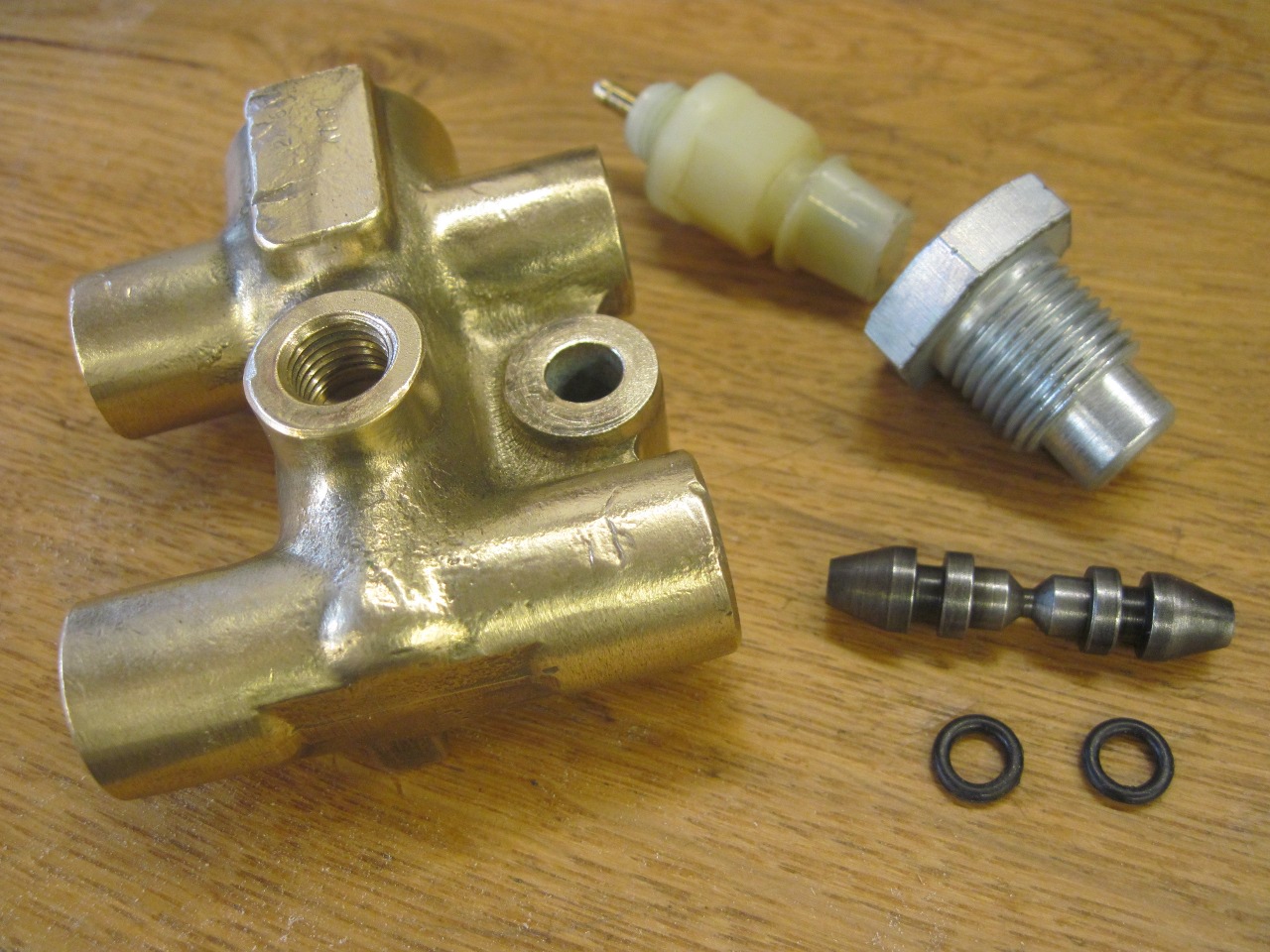

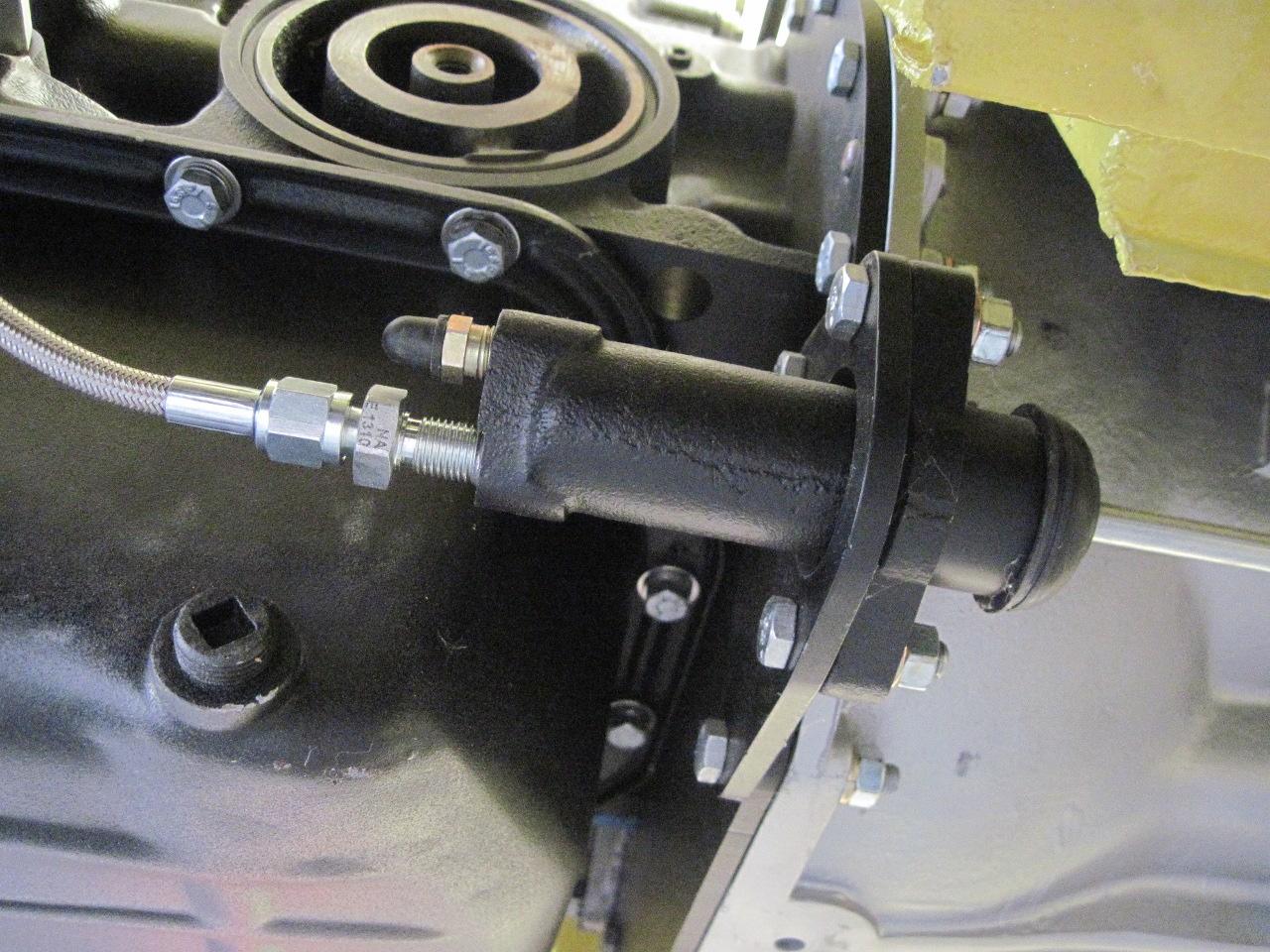

First

thing up was the PDWA. This is a pretty simple device consisting

of a sliding shuttle inside a bore. The ends of the shuttle

are exposed to the pressures in the two braking circuits, and the

shuttle carries a seal at each end that keep the circuits separate.

A sufficient imbalance in pressures will move the shuttle toward

the low pressure side, which actuates the switch.

My PDWA was simple to renew, just having two O rings and a copper seal for the end screw.

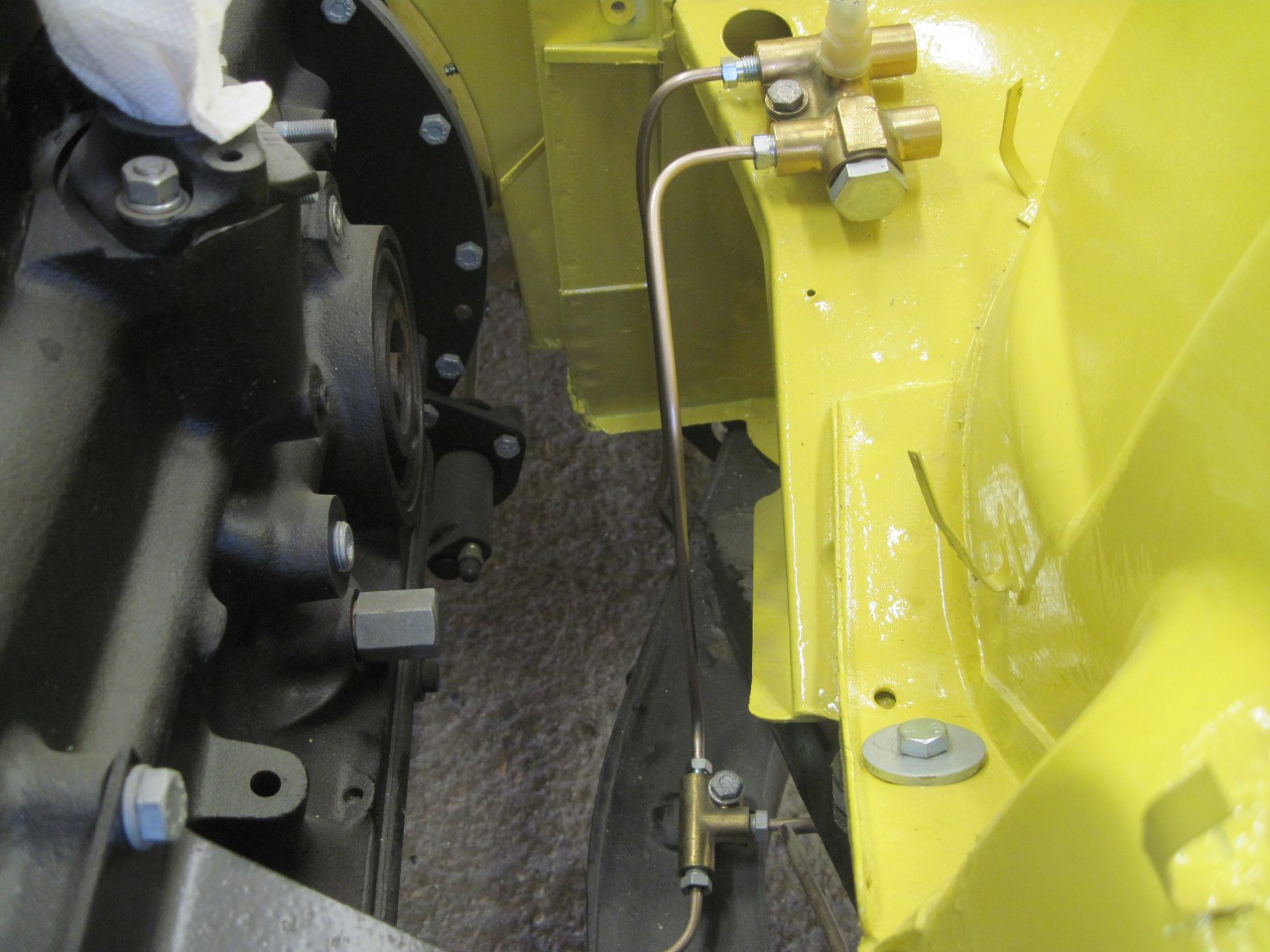

The

PWDA was mounted in its rightful place near the master cylinders, and

the hydraulic lines form the front and rear brakes were connected. To

help ensure that the lines don't get misconnected, the fittings on the

PDWA and the master cylinder for the front brake circuit are different

from those for the rear. (3/8-24 for ther rear, and 7/16-20 for the

front.) It's still possible to screw this up though if you make

your own lines.

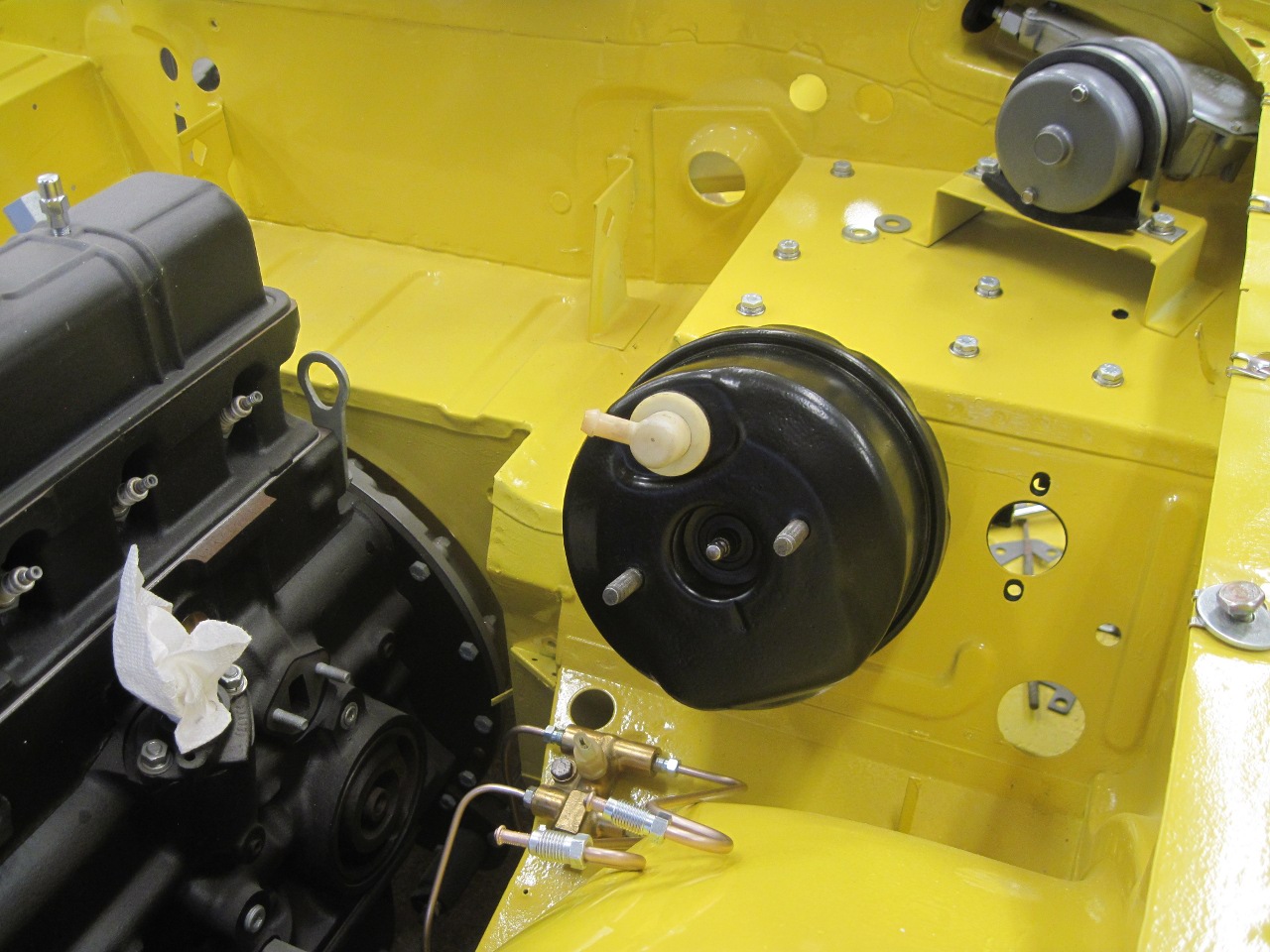

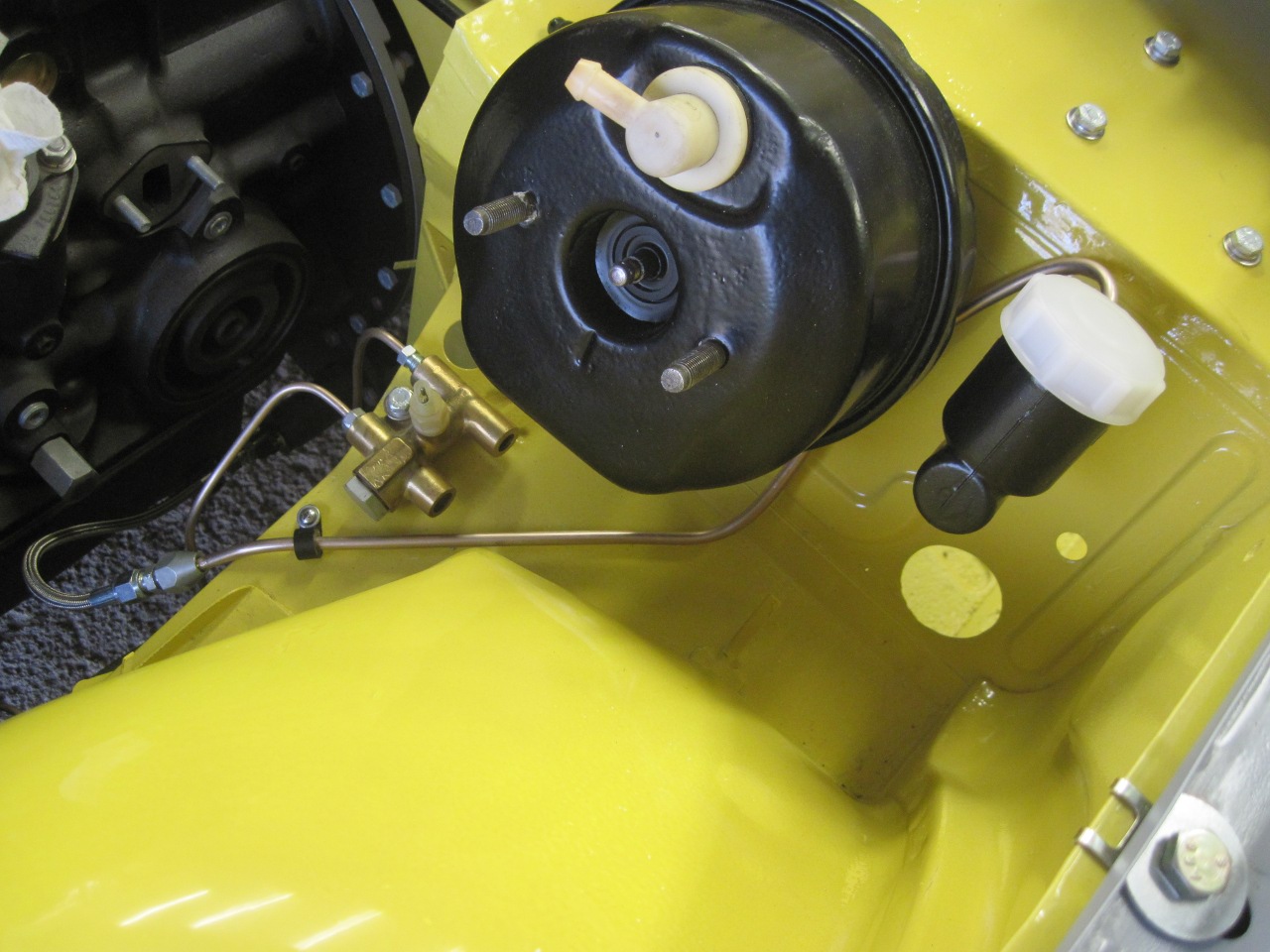

Next, I collected the rebuilt pedal box off the shelf, and screwed into place on the top of the driver's foot well with its nine fasteners.

With the pedal box in place, the rebuilt brake servo could then be mounted along with its thick aluminum spacer. A little strip-caulk seal didn't seem like a bad idea.

Hmmm, this doesn't seem quite right.

Well, a step backward and a lesson learned. This looks better.

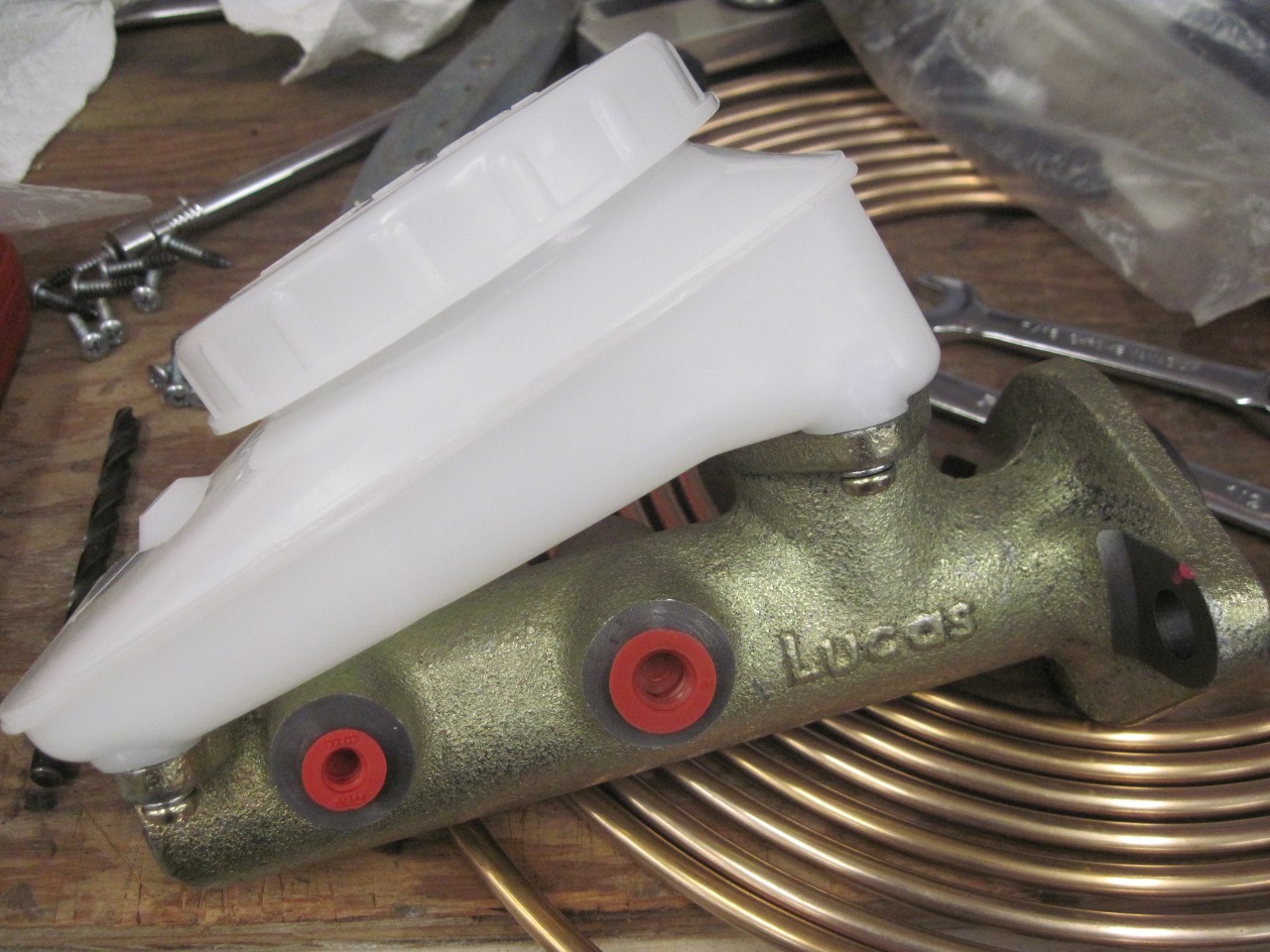

When

I unpacked the new master cylinder I ordered, I realized it wasn't the

TRW unit I specified, so I had to send it back. In the mean time

I turned to the clutch master. It's a simple device and came

apart easily. I powder coated it because...well, because I can.

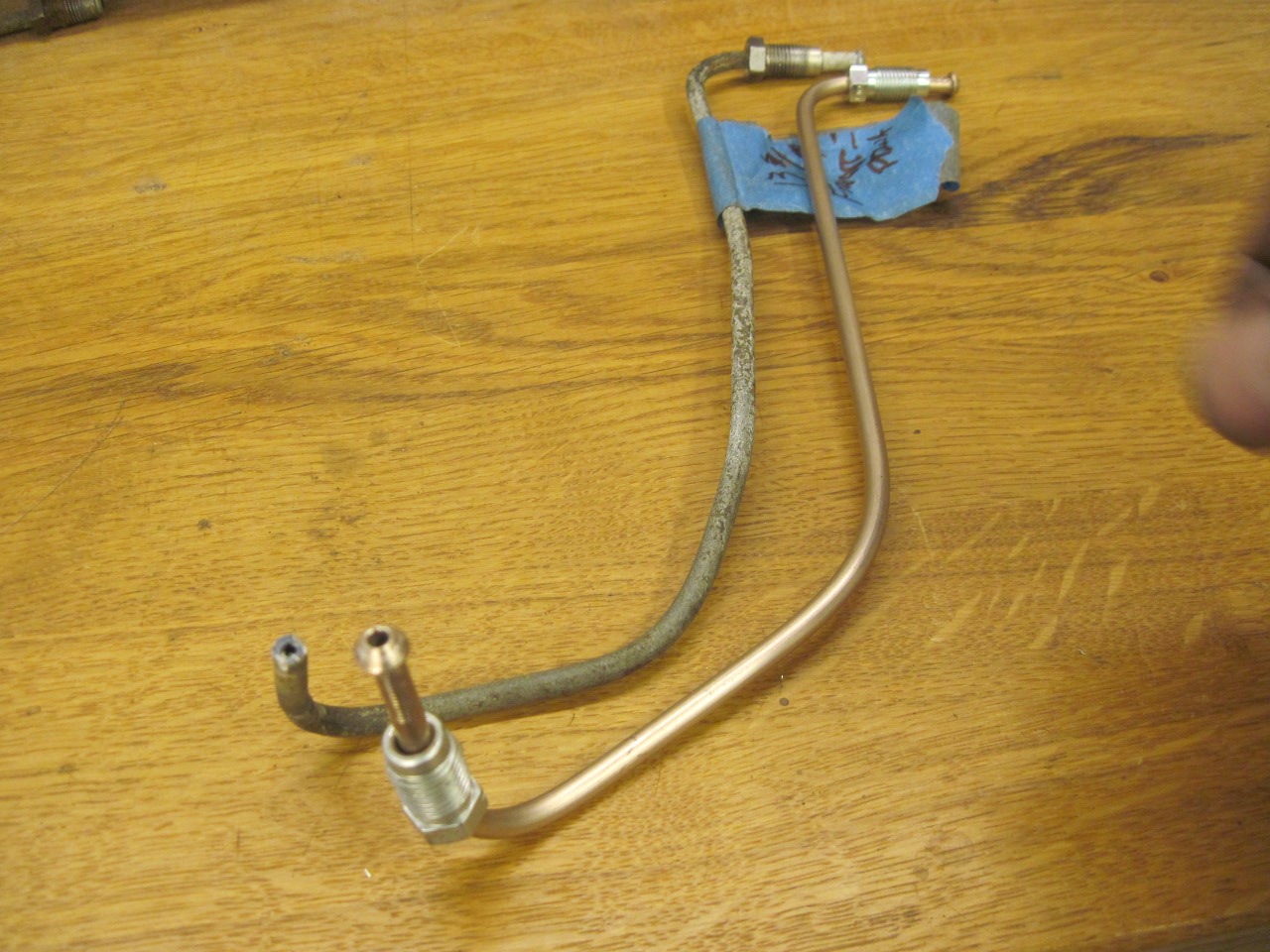

The

original clutch hydraulic connection was a combination of a short 1/4"

hard line and a flexible plastic line to accommodate relative movement

between the engine/transmission and the body.

The

plastic line was still intact, but I decided to replace it anyway.

I must have beel feeling frisky at that instant, since I sprung

for the totally unnecessary "uprated" braded stainless flex line.

I do like the looks of the stainless line compared to the plastic.

About

that time, the new brake master arrived. I dutifully read all of

the warnings on the packaging and on the reservoir cap.

Now,

looking past the mildly humorous DOT3/DOT4 disconnect, I focused

on the specific warning against silicone (DOT5) fluids. I ignored

the threat of a voided waranty, since voiding warranties is sort of a

hobby for me. My inquiring side wanted to know why TRW was so

afraid of DOT5. I had done some research on DOT3/4/5 fluids

already, and was way past many of the myths propagated on the Internet

echo chamber.

Take the claim that DOT5 is incompatible with some

brake system rubber components, for example. Under US Federal

regulation, a "brake fluid" is defined thus:

"Brake fluid means a liquid

designed for use in a motor vehicle hydraulic brake system in which it

will contact elastomeric components made of styrene and butadiene rubber

(SBR), ethylene and propylene rubber (EPR), polychloroprene (CR) brake

hose inner tube stock or natural rubber (NR)." [49 CFR 571.116]

So

it appears that any maker of brake fluid who wants to claim compliance

with US Federal standards (and every bottle I've seen does) will have

to ensure compatibility with those rubber compounds. On the other

side of the coin, any maker of brake parts for new or old cars would be

crazy to use any rubber component not on that list.

This agrees

with the large majority of anecdotal evidence I've read about the use

of DOT5 fluids--in new systems or after good flushing, most reports

indicate that there is no compatibility problem. In fact, a

liesurely stroll through the rest of the federal brake fluid regulation

shows that DOT5 is superior to DOT3 and DOT4 in nearly every measure.

There

is one area where DOT5 may have worse performance than other fluids.

Under certain conditions, DOT5 fluids can retain air, which can

increase its compressibility. This is apparently the reason that

DOT5 fluids are not recommended for use in ABS systems, which can

generate air bubbles in the fluid. Air retention in DOT5 fluids

can increase at higher temperatures, but in non-ABS systems, the effect

is reportedly minor, except possibly in racing situations.

There is a wonderful tretise on brake fluids on our own Buckeye Triumph site. I've seen it referenced all over the Internet. It dives into the compressibility issue to a good depth.

So

this is all good stuff, but it doesn't definitively answer the

question about TRW's bias against silicone brake fluids. In the

end, I decided not to spend any more time on it. I went to get

some brake fluid.

Besides

the high I get from trashing a warranty, my main motivation in wanting

to use a silicone fluid is more pragmatic: It doesn't damage

paint. Bleeding an entire brake system from scratch can be messy,

with a good chance of a leak or two.

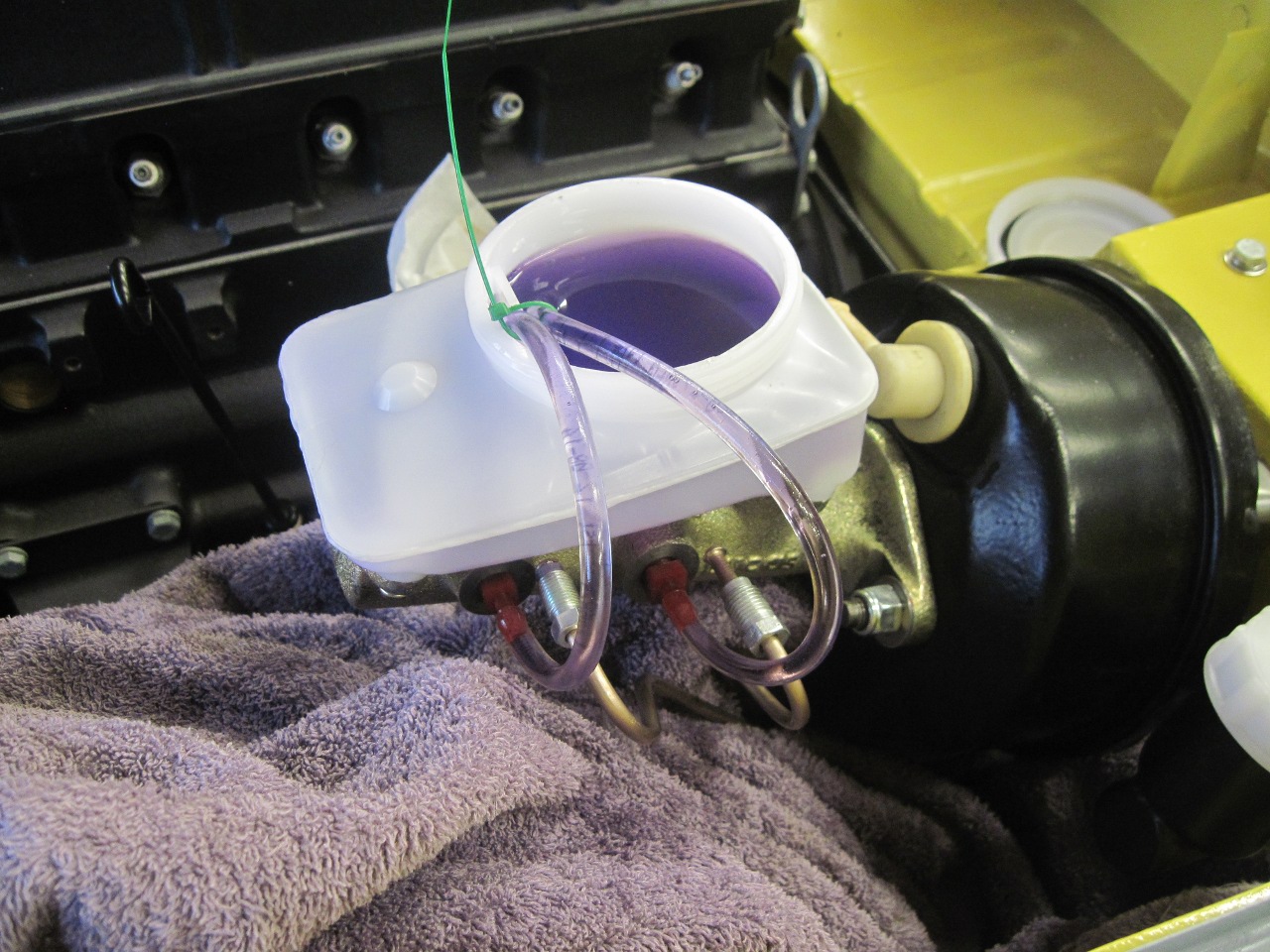

So, with that bridge crossed, and the warranty card carefully placed in the circular file--onward!

I bolted up the master cylinder and connected it to the pedal. Since the master cylinder was empty,

system bleeding can go faster if the master is bled first. Often

called "bench bleeding", I actually did it on the car. I just ran

hoses from the outlets back to the reservoirs and pumped the pedal

until the fluid ran without bubbles. Then hooked up the lines.

Then, to bleed the lines and slaves, I thought it would be easier

if all four wheels were off. This made it simple to make a few

orbits around the car, hitting each corner in turn. Since I'm a solo

act most of the time, I used the vacuum method of bleeding where a

small hand operated vacuum pump pulls fluid from the bleed screws.

It works very well, the only downside being that the open

bleeder can suck a little air around its threads. After a few

trials, it was easy to distinguish the foamy, sudsy look of the leaked

bubbles from the larger bubbles of air from inside the system.

After

fixing a couple of small fitting leaks, the clutch and brake systems

seem to be tight and functional. It's hard to evaluate the brake

pedal with no seat to sit in, but it appears to be pretty firm.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages