To my other TR6 pages.

March 9, 2018

Interior Panels

Triumph's

version of luxury for the TR6 cockpit was thinly padded, vinyl covered

panels on each side and at the rear. The base panels were a

hardboard material that didn't suffer moisture or humidity well.

The vinyl was thin and accumulated UV exposure over the years

made it brittle and weak. All the vinyl in this car was ripe for

replacement.

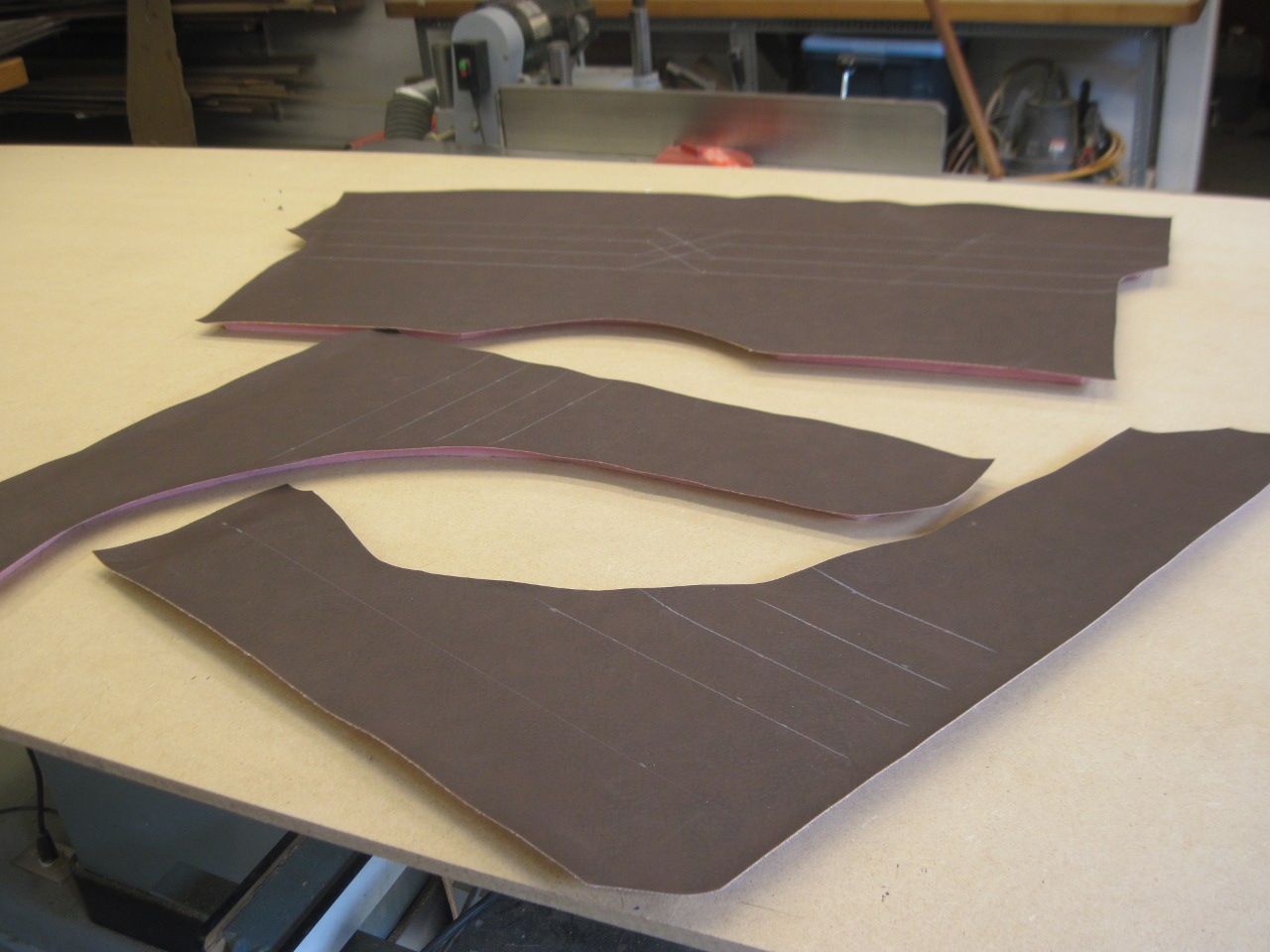

The

rear quarter panels were a dog-leg shape that fit around the rear wheel

well. The 1/4" foam covered nominal 1/8" base panels that

were badly warped and frayed. The vinyl was heat welded to the

base panel to form cosmetic detail lines.

The distorted rear panel had thinner foam--closer to 1/8".

The

rear wheel wells themselves had a foam and vinyl covering. The

vinyl was a two-piece assembly sewed together with a small plastic bead

sandwiched in the seam.

All

of the vinyl, foam, and backing boards were beyond salvage in this car.

Complete replacement kits are easily available, and I undersrtand

that most of them are at least adequate replacements. On the

other hand, riding the wave of confidence gained from making my own kidney panels,

I thought I should at least have a go at making some of the panels

myself. I thought there might even be a place or two where I

could make small improvements.

Before

even starting on the panels, I went back to something I noticed when

removing the originals. I've never been a fan of attaching

trim panels (or anything else, really) with sheet metal screws

directly in holes drilled in the body. The holes are prone to

stripping, and fixing that correctly is not easy. Most of the

trim panel attachmnents on this car were done that way, and even worse

than that, some of the holes were way out of place.

To

remedy that, I laid out new mounting holes in the flange of the rear

deck, and around the sides. There are now six fasteners for the

rear panel instead of five, and they are located to better suck the

panel to the curve. Also, the holes were sized to accept

so-called Tinnerman nuts (or "clip nuts", or "U-nuts") for a #6 sheet

metal screw. Now if a nut gets stripped, it's easily replaceable.

Similarly on the sides.

Now,

on to the panels. Since the original panels were in such bad

shape, I used them to make intermediate templates from hardboard.

These templates were then tweaked for a good fit.

It

was at this point that I realized that the side panel fit depended on

the wheel well covering, so I had to shift to that task.

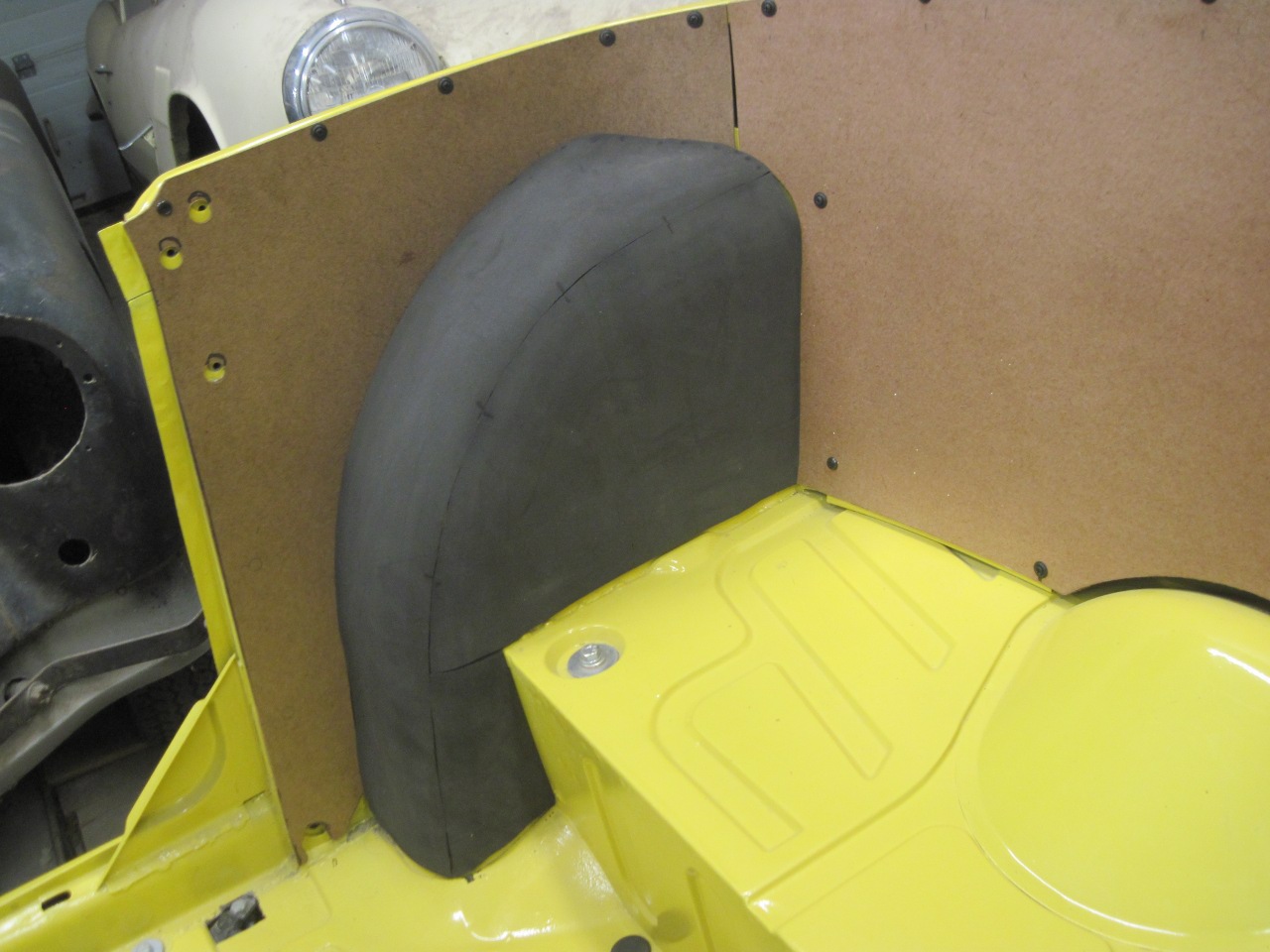

This

is some 1/4" foam that I cut and glued to the wheel wells.

Forensic study of the old coverings showed that the original

foam didn't extend all the way to the inner wing panel. Rather,

it stopped short, forming a kind of gutter along the inner wing that

the trim quarter panel seats in.

Then

the templates could be finished. The intermediate template

allowed the location of holes for the convertible top frame to be

tweaked.

So

then I couldn't avoid the scary part any longer. I had to face

the vinyl wheel well cover, which required (gasp!) a seam. My

entire history and experience with machine sewing goes back only a few

weeks, when I managed to sew some passably straight pleats for the kidney panels. I tried to rachet up my courage by re-reading Bob Danielson's pages

on doing your own panels. Like Bob, I preferred the look of a

flat seam rather than the original piped seam, but to me, this actually

meant three times the challenge to my nascent sewing skills.

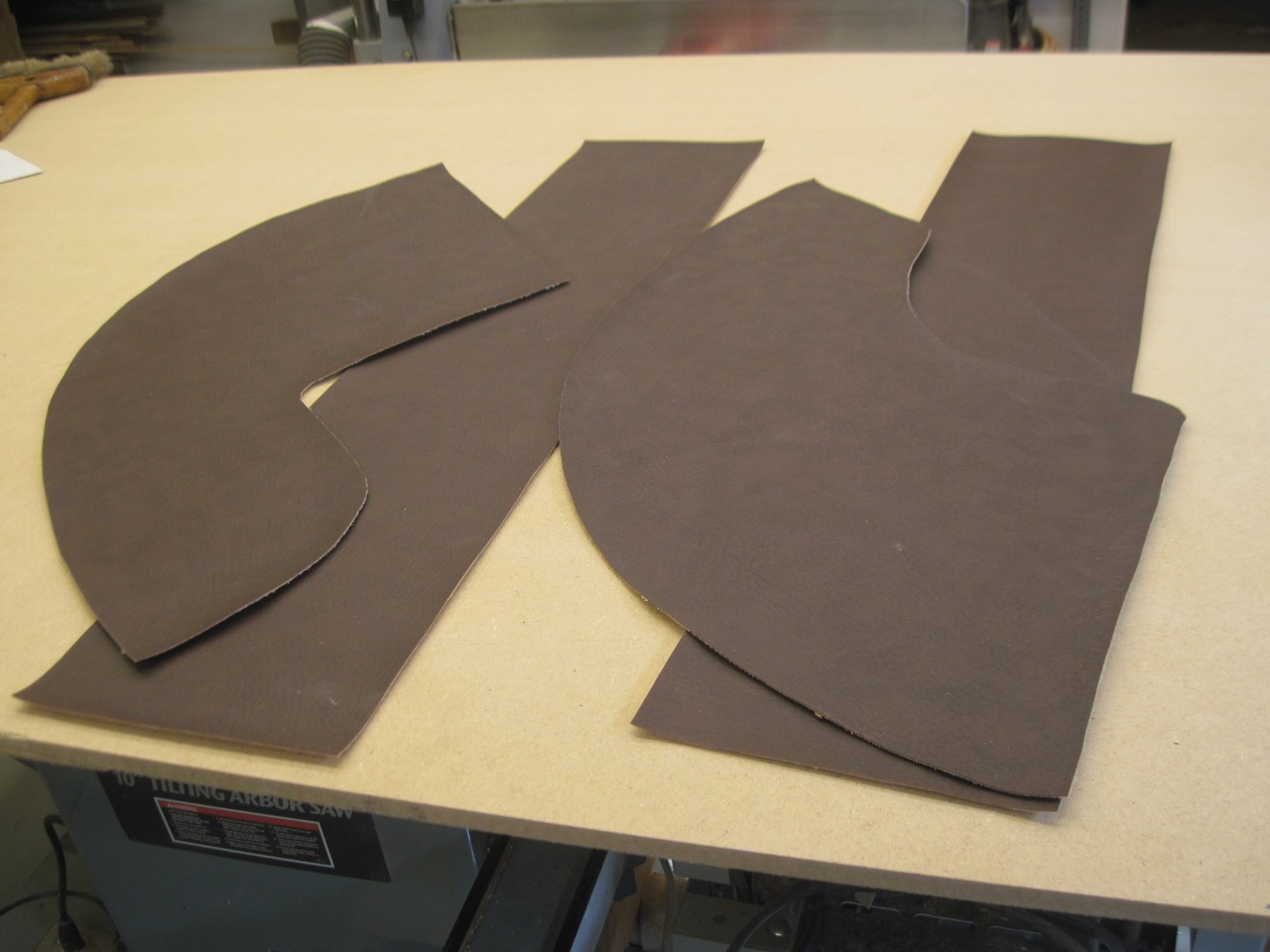

I took apart the original cover, patched it up, and used it as a template to cut new pieces of vinyl.

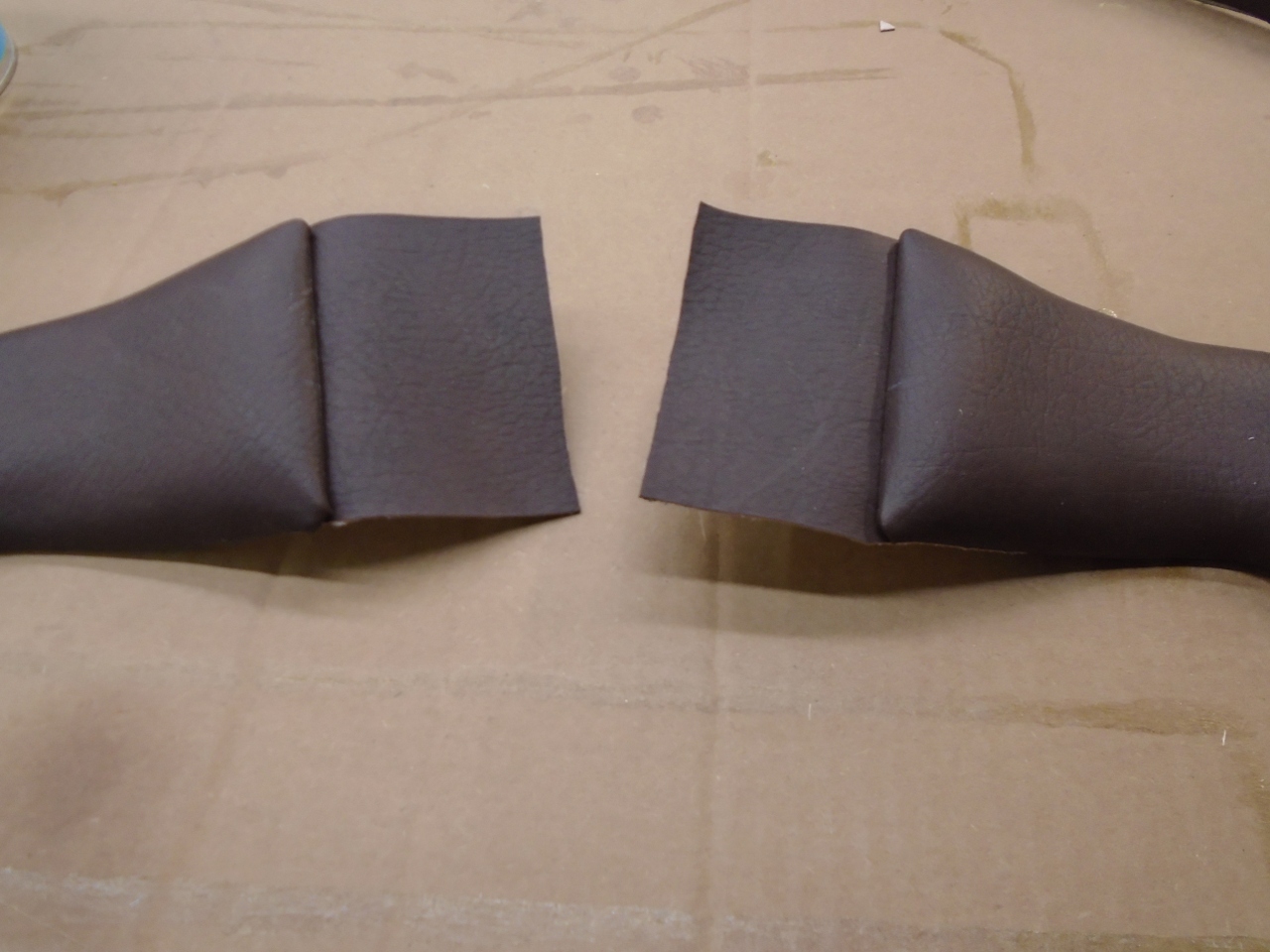

After

a lot of practice on scrap, I felt sort of ready to go. It took

me three tries to get two covers I was satisfied with.

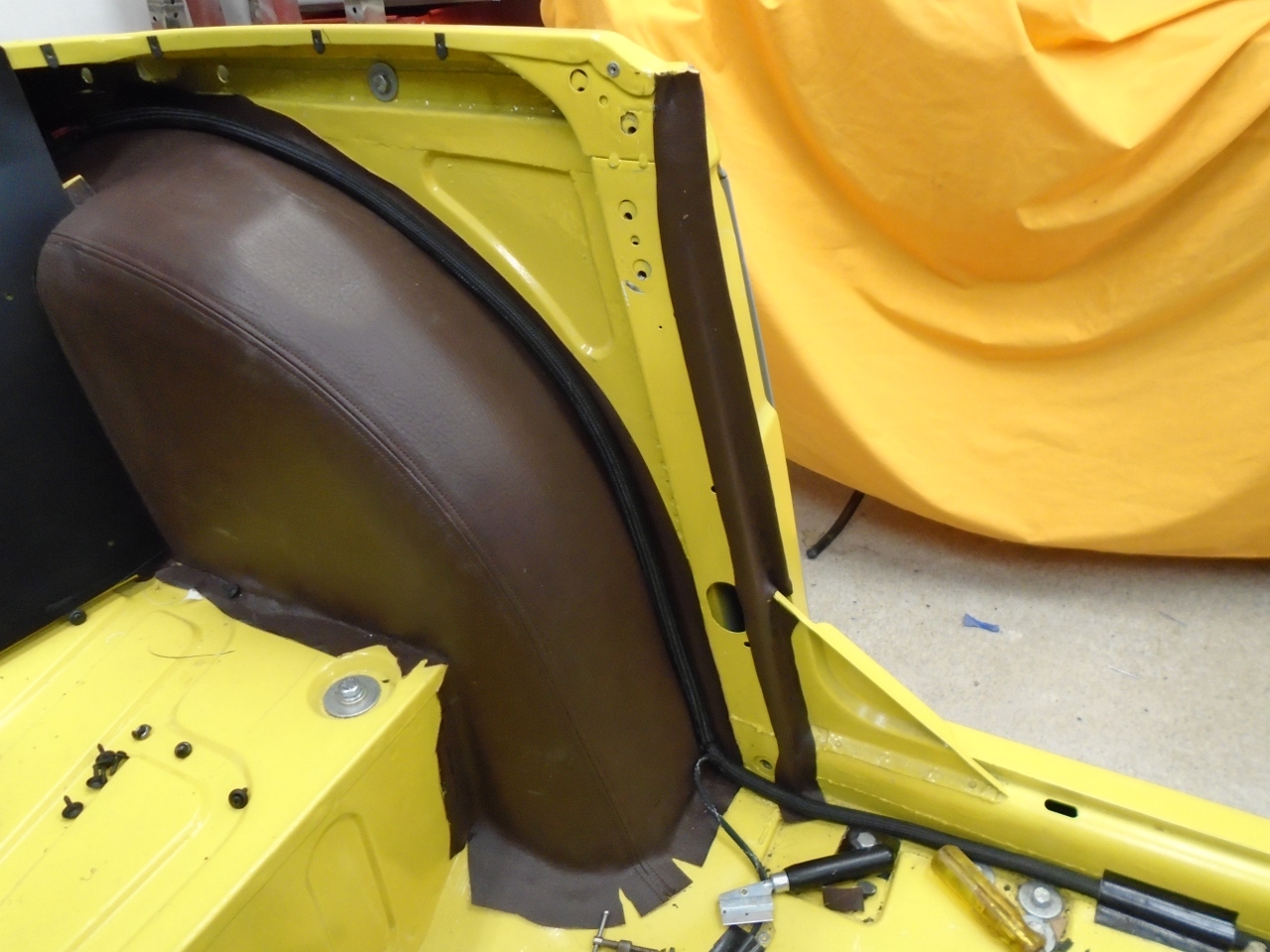

Then,

the task was to apply the covers to the wheel wells. I didn't see

any possible way this was going to work. But it did, finally.

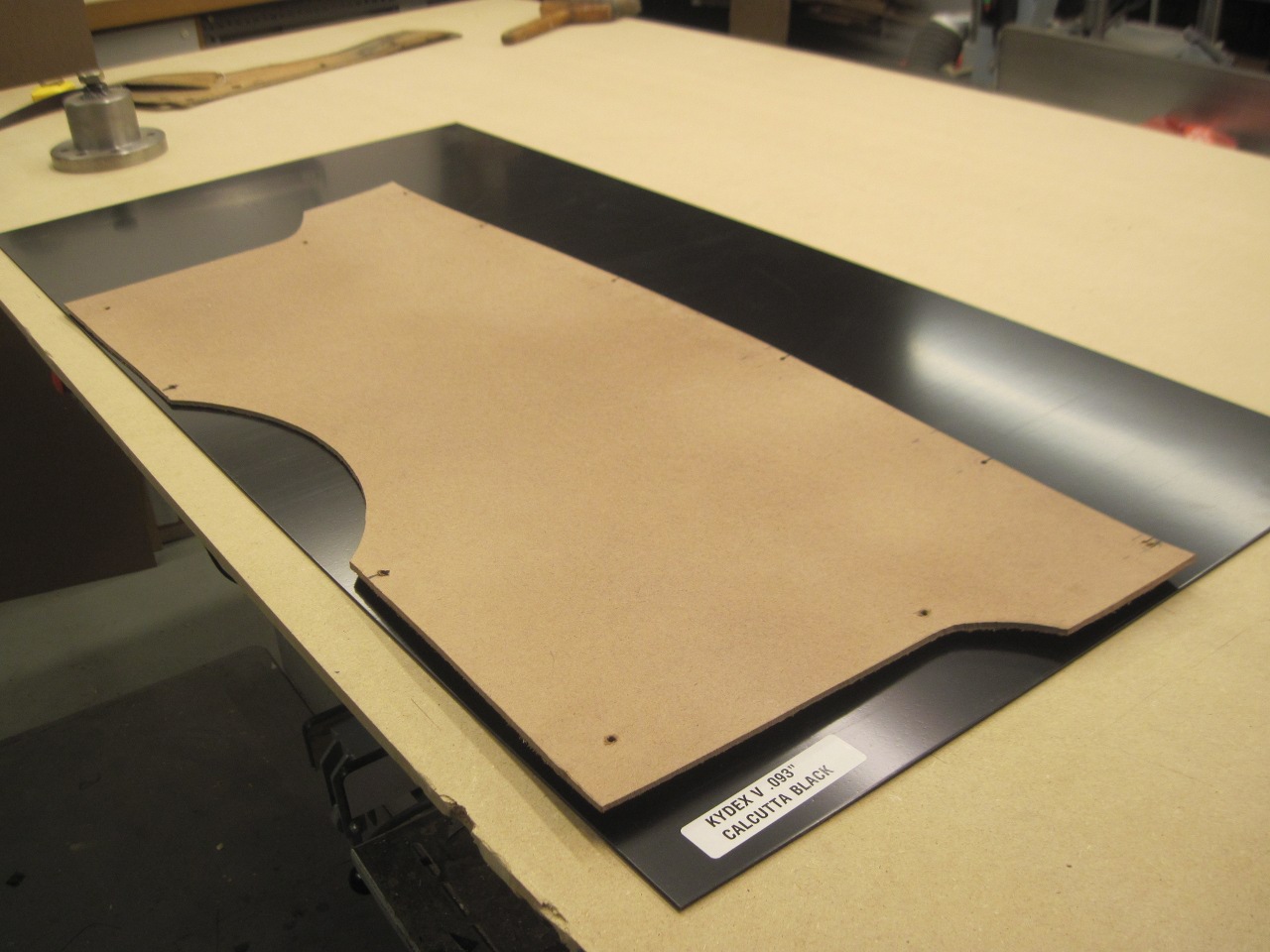

OK, then, back to the panels. Since I had some experience with it from my boot trim, I

opted to use sheet Kydex plastic for the panel backings rather than

hardboard. Kydex is an alloy of acrylic and PVC. It is

strong, resilient, impervious to moisture, and easy to work. It

can be heat formed.

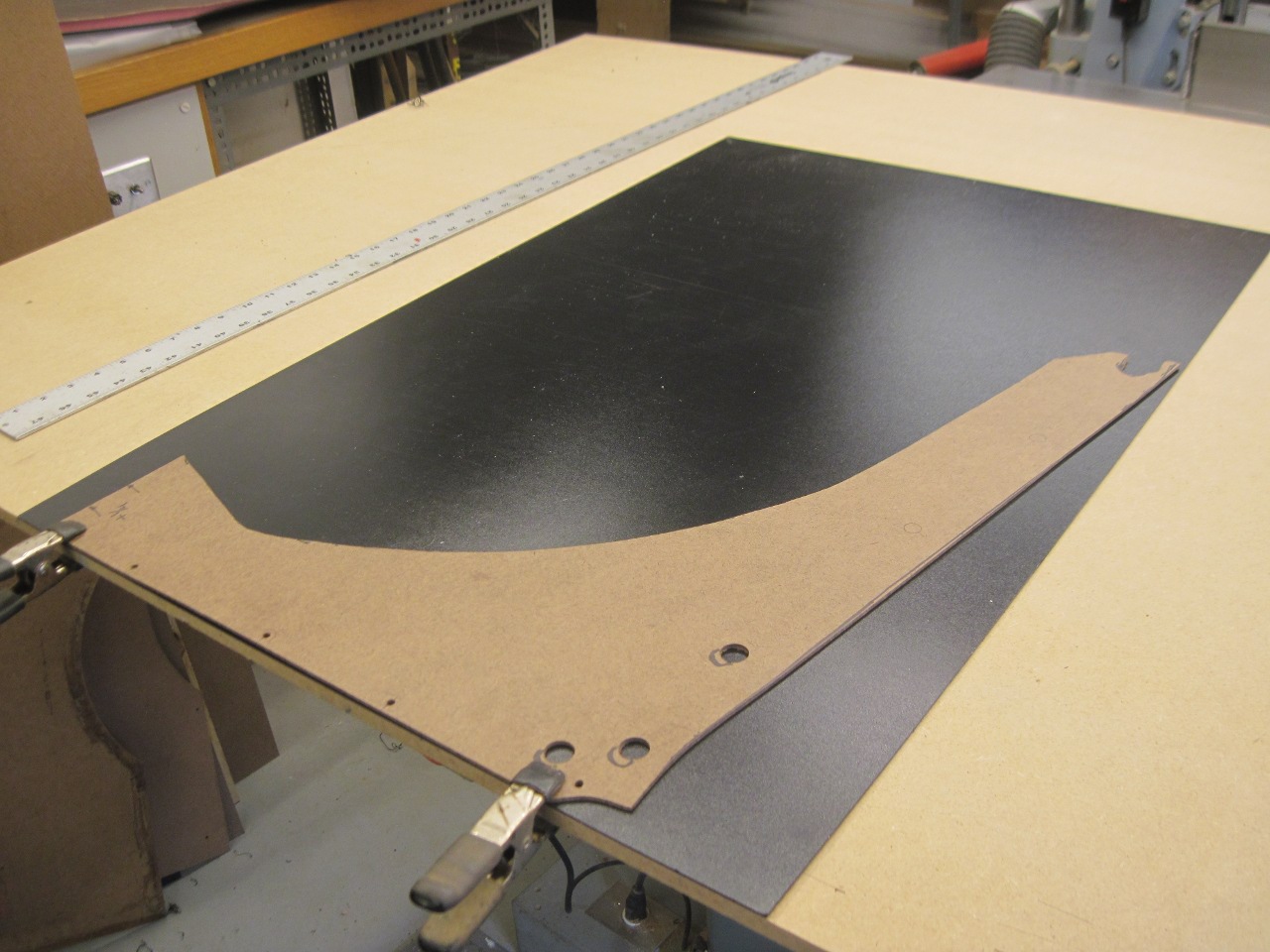

The intermediate templates were used to mark out on the Kydex.

Cut out the pieces, and test fitted them in the car.

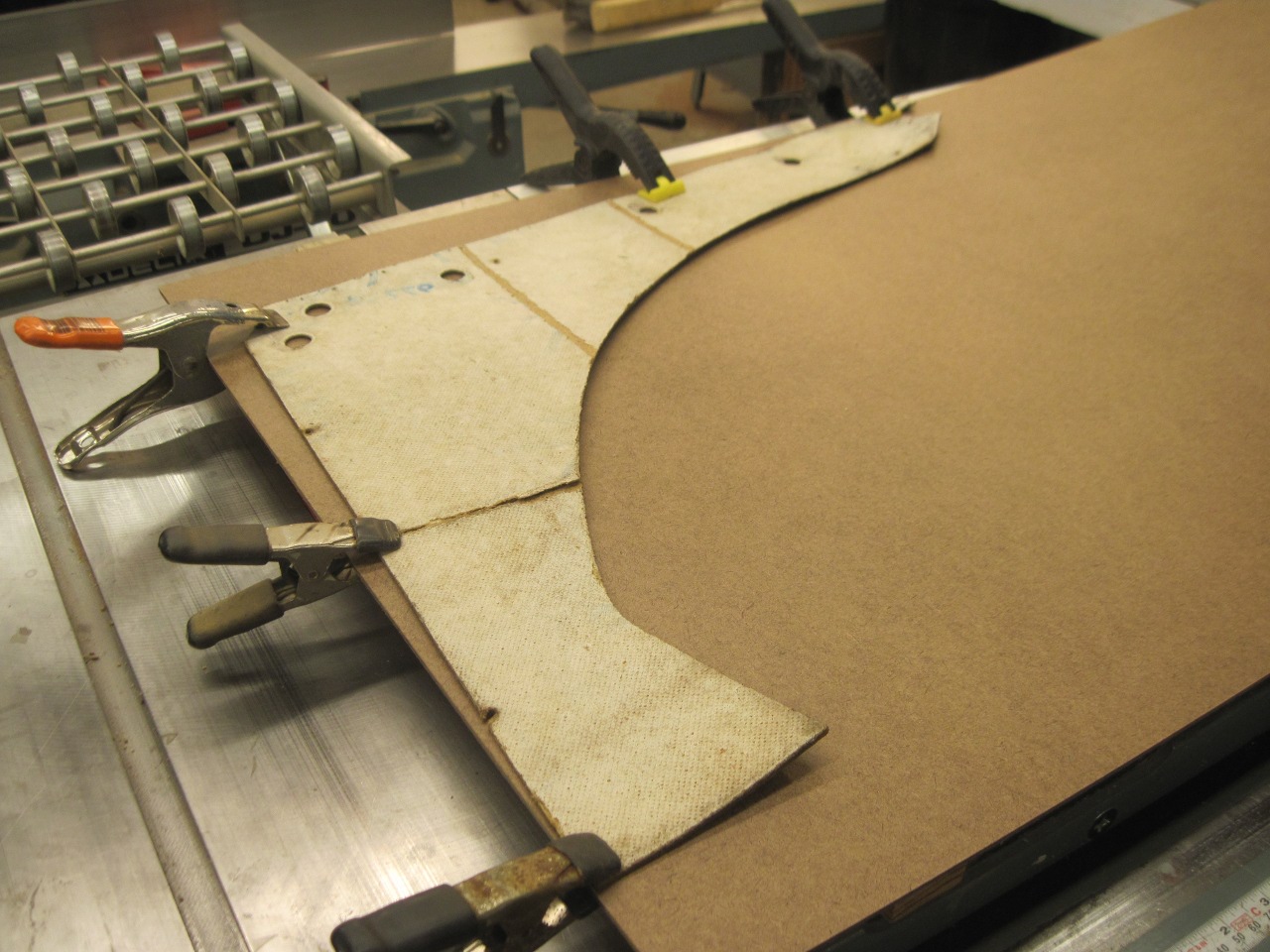

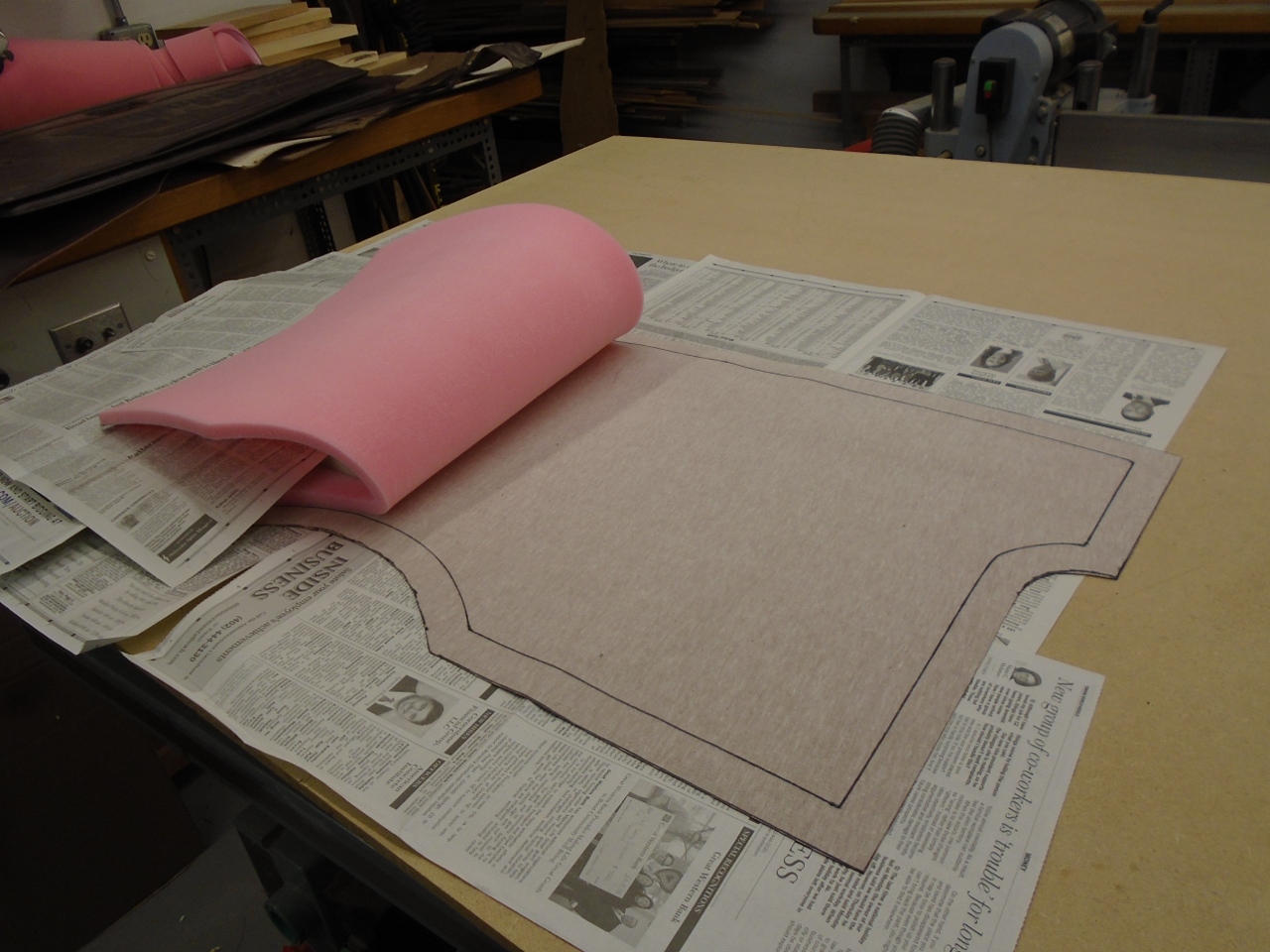

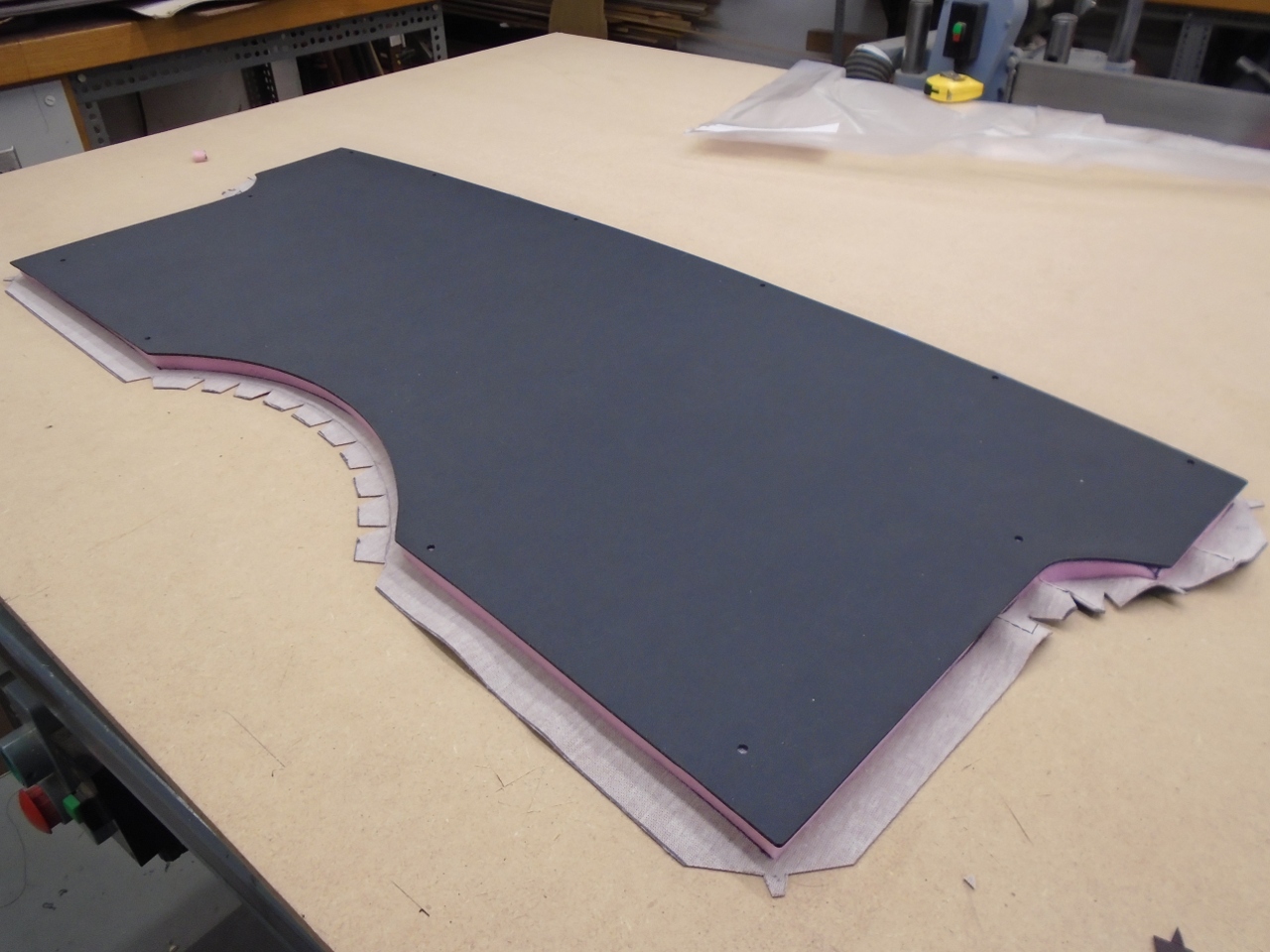

Then

marked and cut pieces of sew foam to match. Sew foam is foam with

a fabric backing on one side that will take stitches without pulling

through. I used 1/2" foam for all of the panels. This would

give a little plusher look, and I hoped it wouln't cause any unforseen

problems.

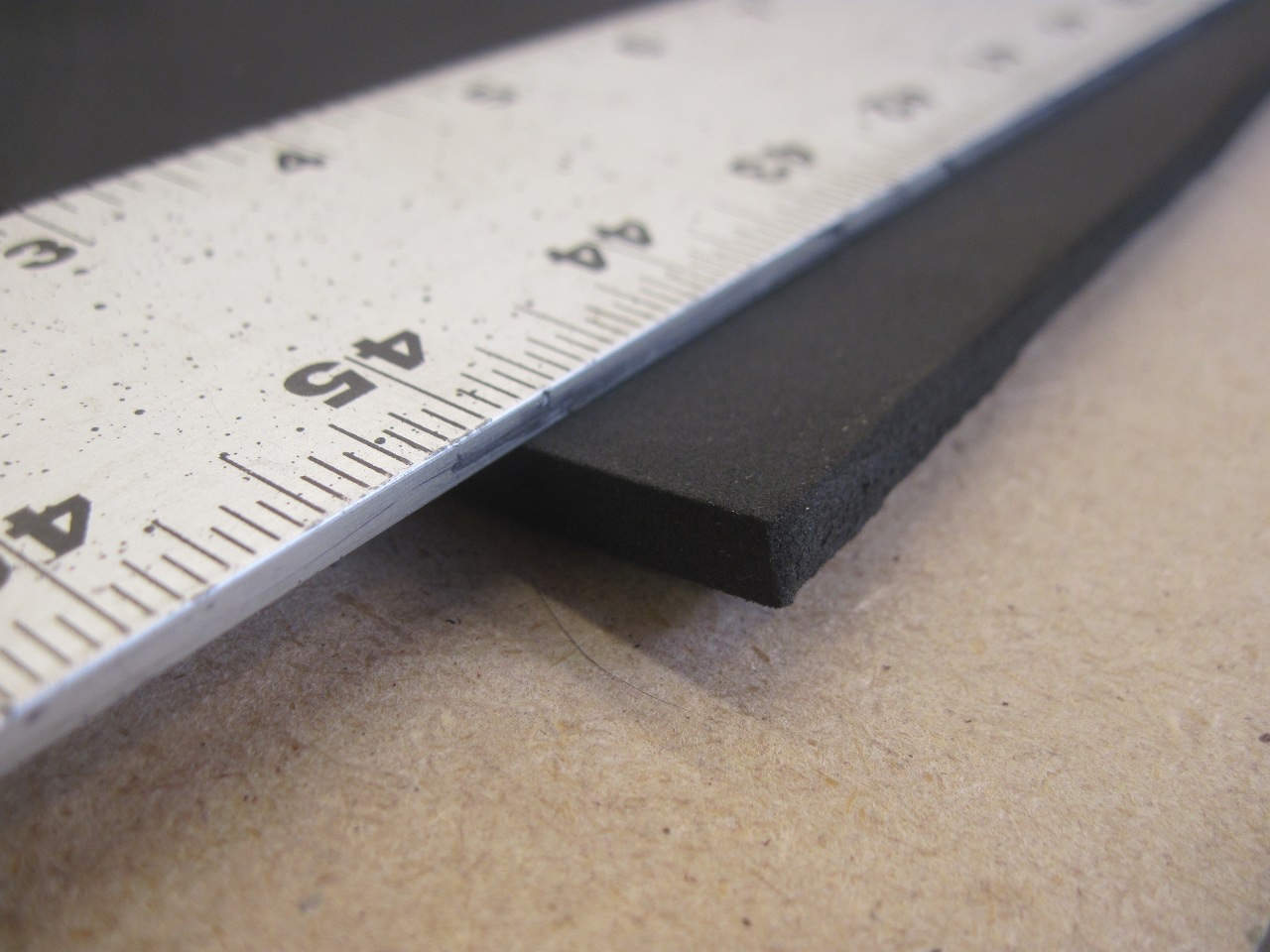

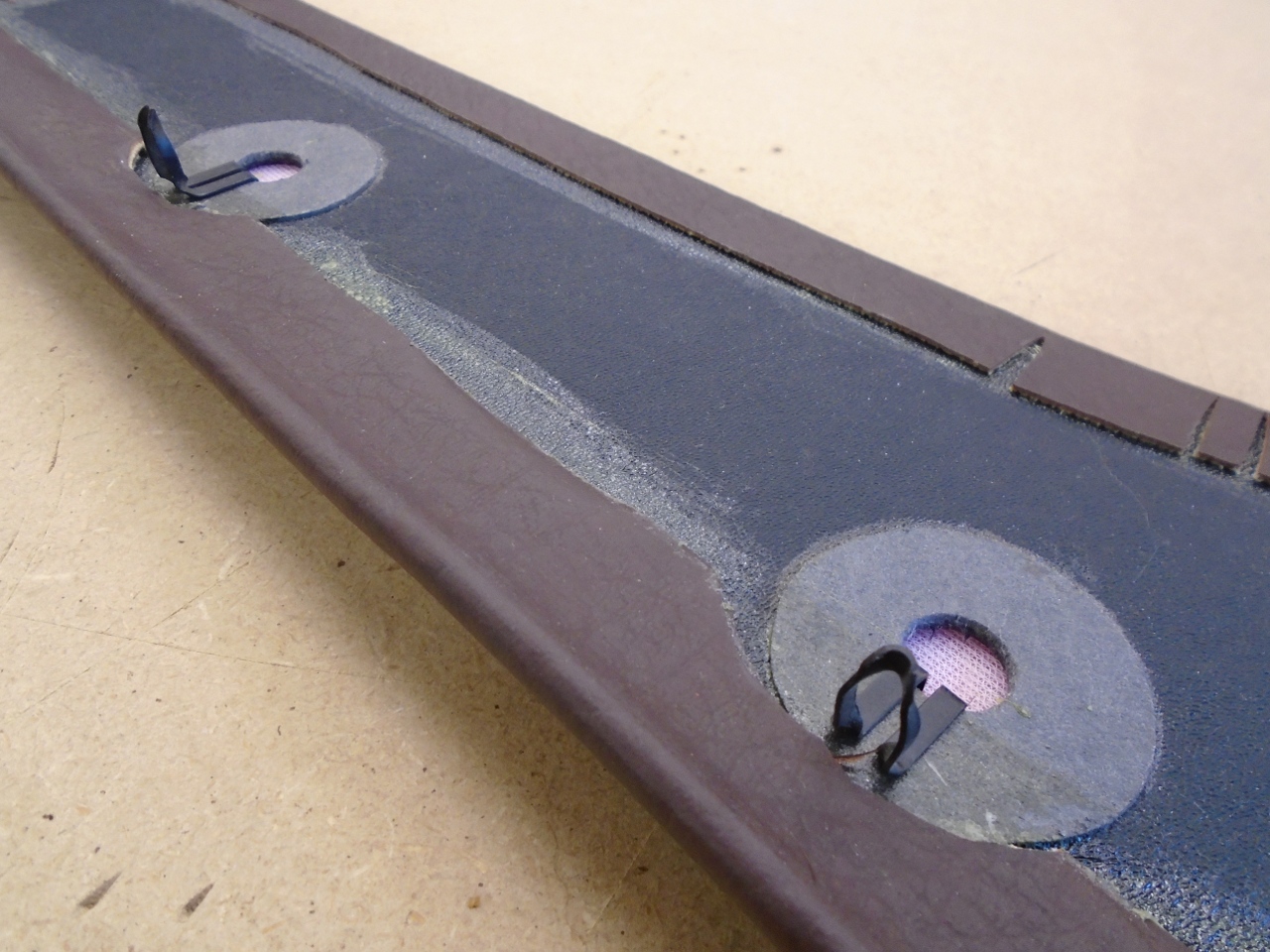

The

little gray doughnuts on the holes are gasket material glued on to

increase the thickness of the Kydex to match the original hardboard

panels. It makes the panel attachment clips fit as original.

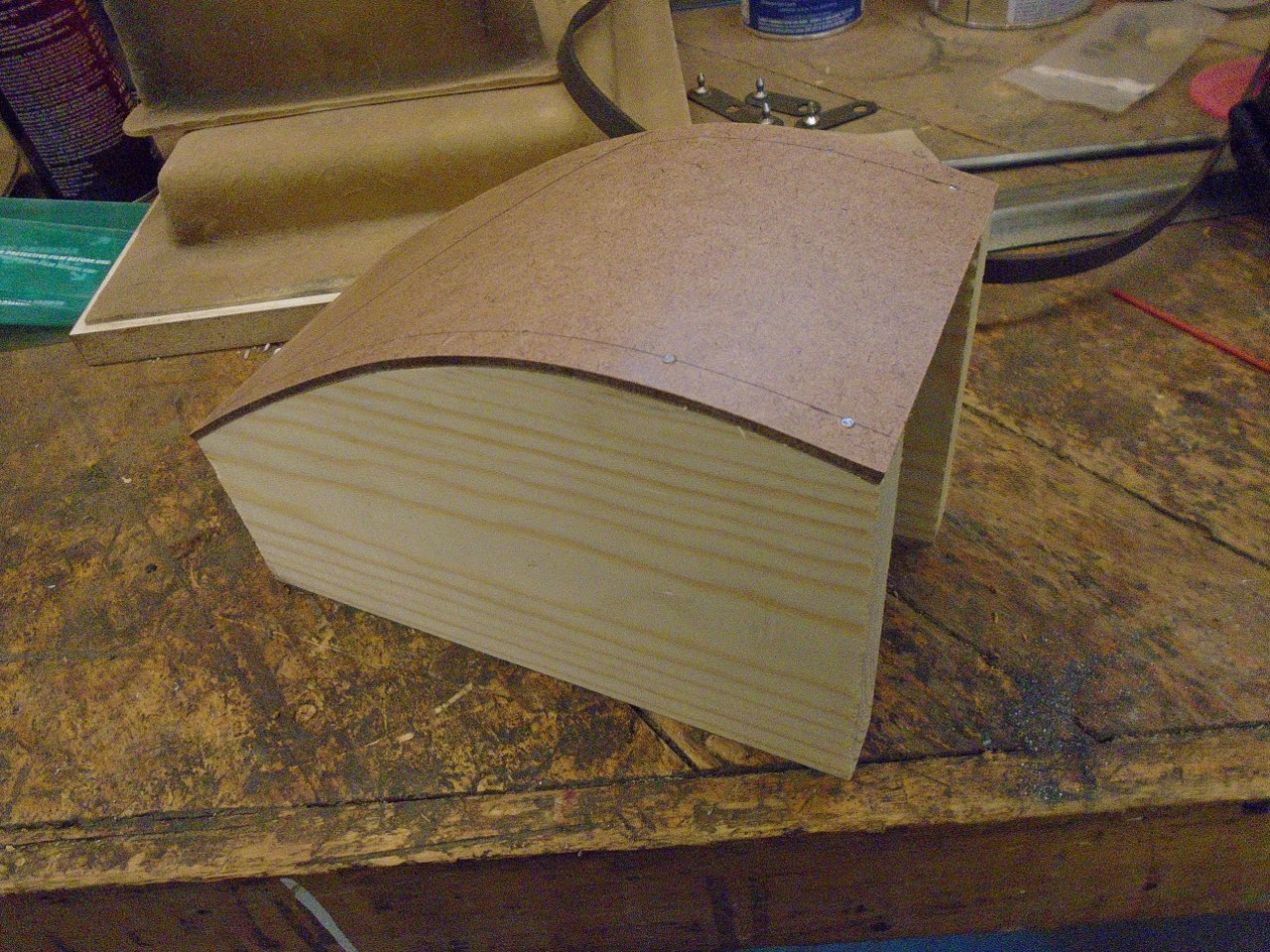

Before

covering the panels with vinyl, I took advantage of the heat

formability of Kydex by pre-shaping the

rear ends of the quarter panels where they meet the rear panel.

This

rather tight curve very often causes the vinyl to wrinkle.

Thicker

foam would make that worse. I first made a paper template of the

curve, and from that, made this bending jig. Heating Kydex to

around 300° F makes it go limp, and it will hold a new shape when it

cools.

Here

are the back and side foam pieces glued to vinyl. The vinyl of

course has to be oversized to allow for the wrap-around to be glued to

the back of the panel. The stitching pattern is marked on the

vinyl. This pattern is based on some I saw on Bob Danielson's

site. It is different from my original pattern, but maybe is

stock for some other Triumph model. The rear panel shown

was rejected after sewing, so I made another one, but with a slightly

different pattern.

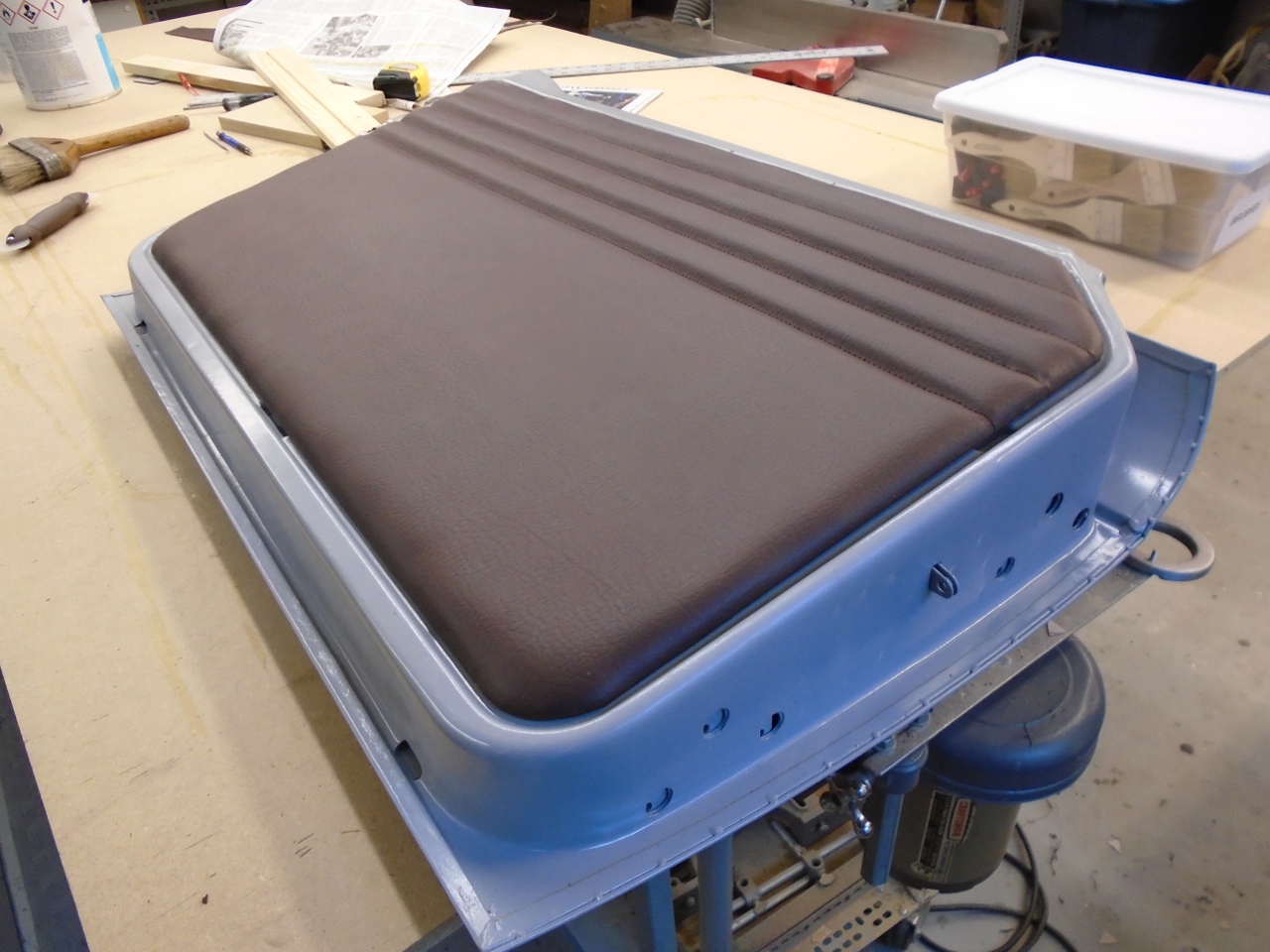

After sewing, but before mounting on the backer panels, the vinyl pieces can look pretty distorted.

Stitched foam/vinyl is glued to the Kydex backer board, and the edges are pulled around and glued.

Almost ready for install.

No wrinkles yet.

The

original quarter panels had the vinyl extend as flaps on the rear end

that fit underneath the rear panel. I'm not sure of the reason,

but maybe it was to prevent seeing any body color through a gaps

between the panels, or maybe to help seal the cockpit from vapor

intrusion from the fuel tank. I just glued some flaps on.

I

also wanted to replace the piping at the leading edge of the quarter

panels. Rather than try to use the tacky original plastic stuff,

I wanted to make some from matching vinyl. I bought a piping

attachment for my sewing machine, but couldn't get it to work very

well, so this is glued up in a little jig. The core is that

rubber cord used to secure window screens in their frames.

A

few more details before final install. First, the front edge of

the B post gets a vinyl covering. The paper template is from one

of the original pieces.

The triangular

gussets at the base of the B posts had small cardboard panels that held

a vinyl covering. The cardboard pieces were toast, so I made some

new ones out of Kydex scrap.

Finally...

Since

I'd built up some momentum, I decided to do the door cards, even though

I'm not ready for them. The originals were tired.

I

decided not to include the pouch in the door panels. I never used

them, yet they always seemed to be full of crud. I'll probably

fit a center console for tactical storage. Also, I really like

the TR4-style door pull much better than the recessed one of the TR6.

Serendipitously, both of these changes actually simplify the door

cards. On the other hand, the panels now look a little plain.

I'm thinking of two or three vinyl covered buttons in that

large lower area, but that decision will wait until the doors are done.

Addendum, March 11, 2018

I

brought one of the primed doors down to the shop to try the new card.

The fit was OK, but there was this 1/4" gap all the way around

the card. The gap was of course because the original cards had

that plastic piping bead around the perimeter. I thought that

since I'd put a bead on the front of the quarter panel, I really should

put it around the door cards, too.

Well,

I fooled around some more with the piping foot on my sewing machine,

and still couldn't get consistent results, so I just made two 8-foot

lengths of piping by gluing vinyl strips around a flexible core like

before. The second pic shows the home-made piping on the left

compared to the original. I think the larger piping is in better proportion to the thicker cards.

The bead not only fills the gap nicely, but makes the whole door look more finished and refined.

I

save money with my DIY approach on many of the jobs on this car, but

I'm not sure this is one of them. The Kydex is quite a bit more

expensive than hardboard, especially in the sizes that are easy to

ship. Got a couple of new skills, though.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages.