To my other TR6 pages.

January 26, 2018

Kidney Panels

In

a nod to a more civilized cockpit experience, Triumph included

some panels to conceal the space behind the H frame console.

Besides making the cabin look a little more finished, they

provided a place to mount radio speakers.

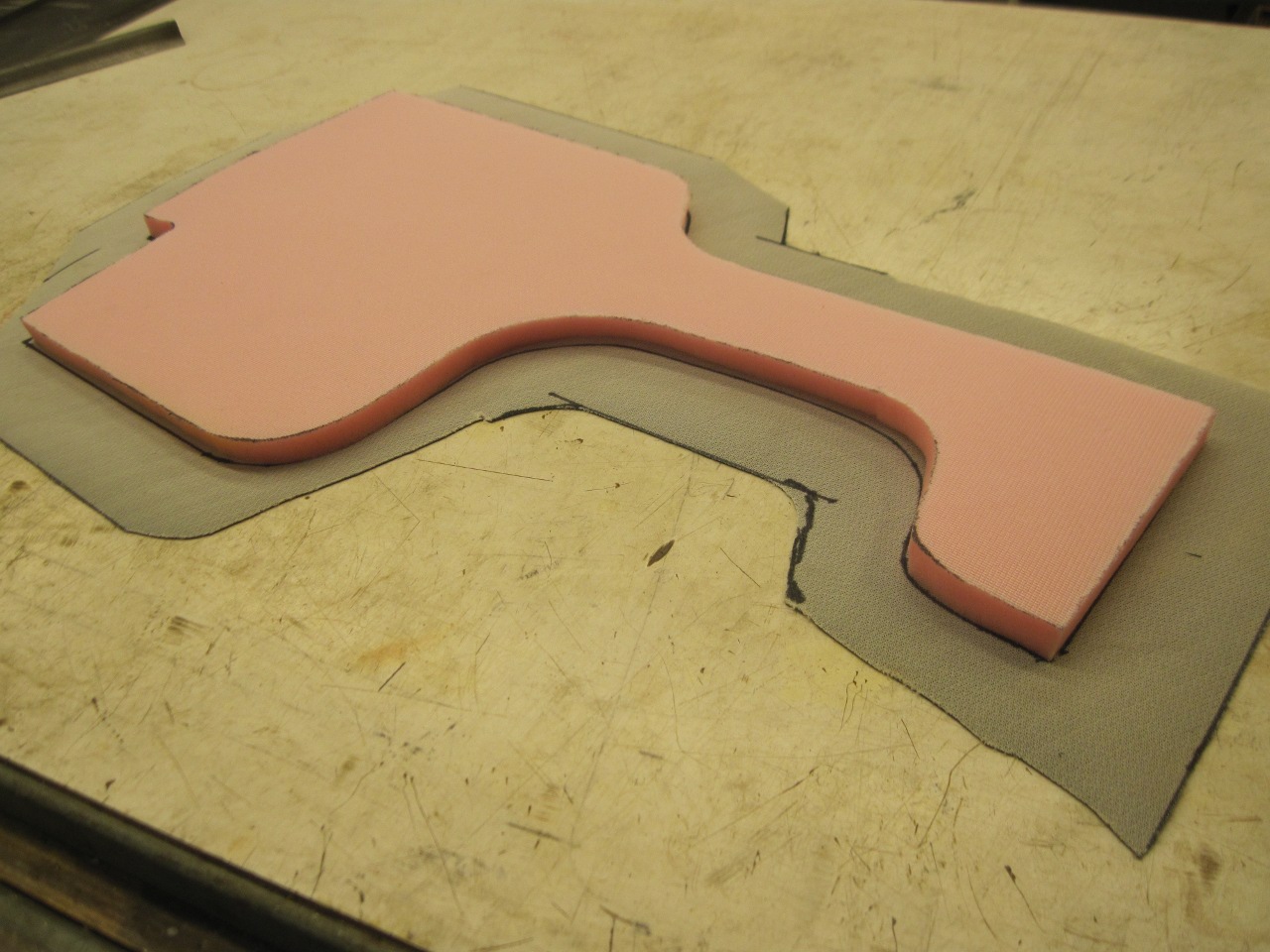

The odd-shaped,

kidney-esque panels were made of 1/8" hardboard, padded with thin foam,

and covered with vinyl. I think I may have recovered my panels

back in the 80s, but they were pretty tired looking. The

hardboard was twisted and warped.

I

used the old hardboard panels as a starting point, but since my tunnel

is a little skinnier than original, the new panels needed to be a

little larger. Since this underdash area shouldn't be in much

danger of getting wet, I made the new panels from hardboard, but took

some steps to try to make them a little more moisture resistant.

.

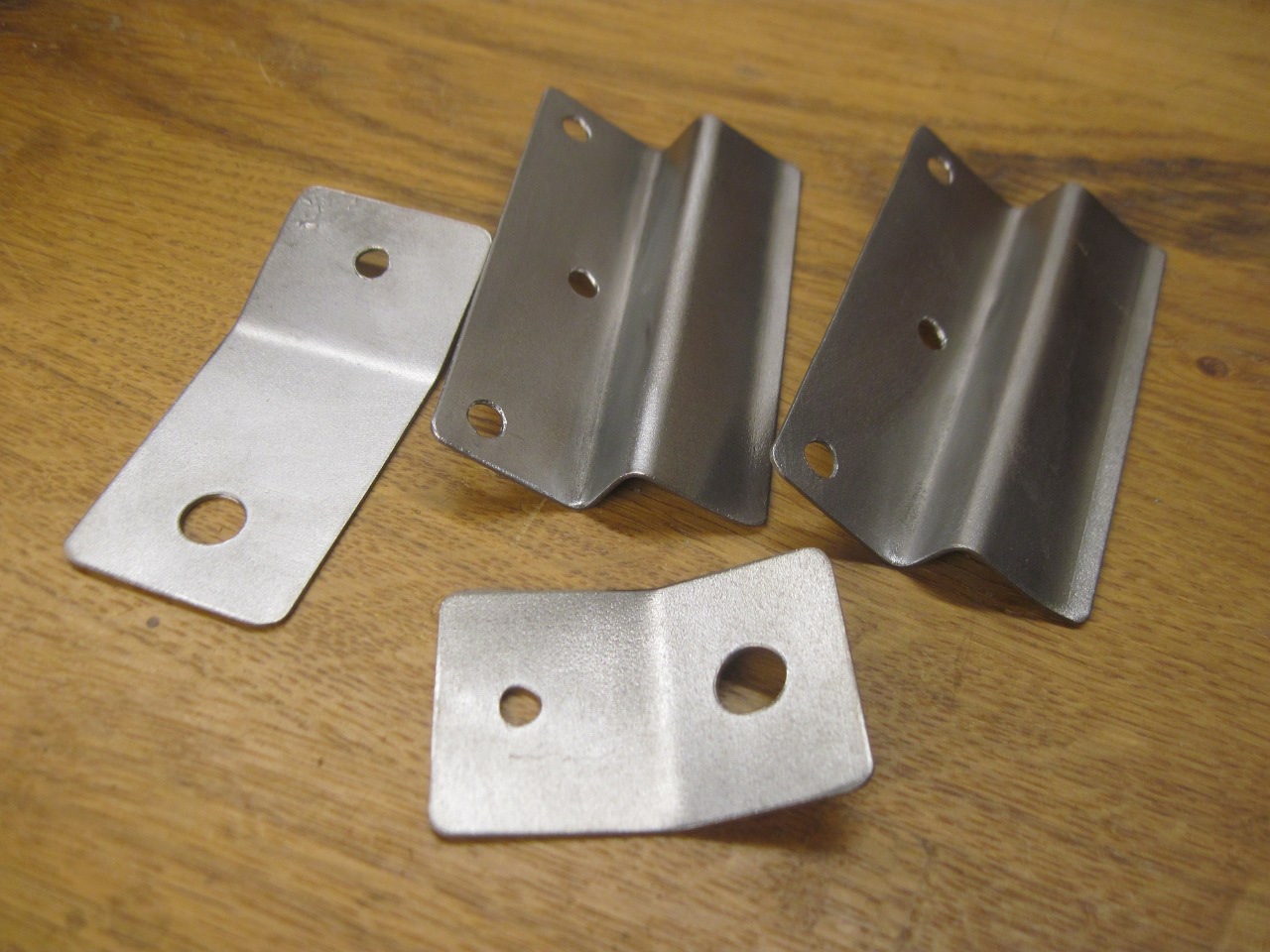

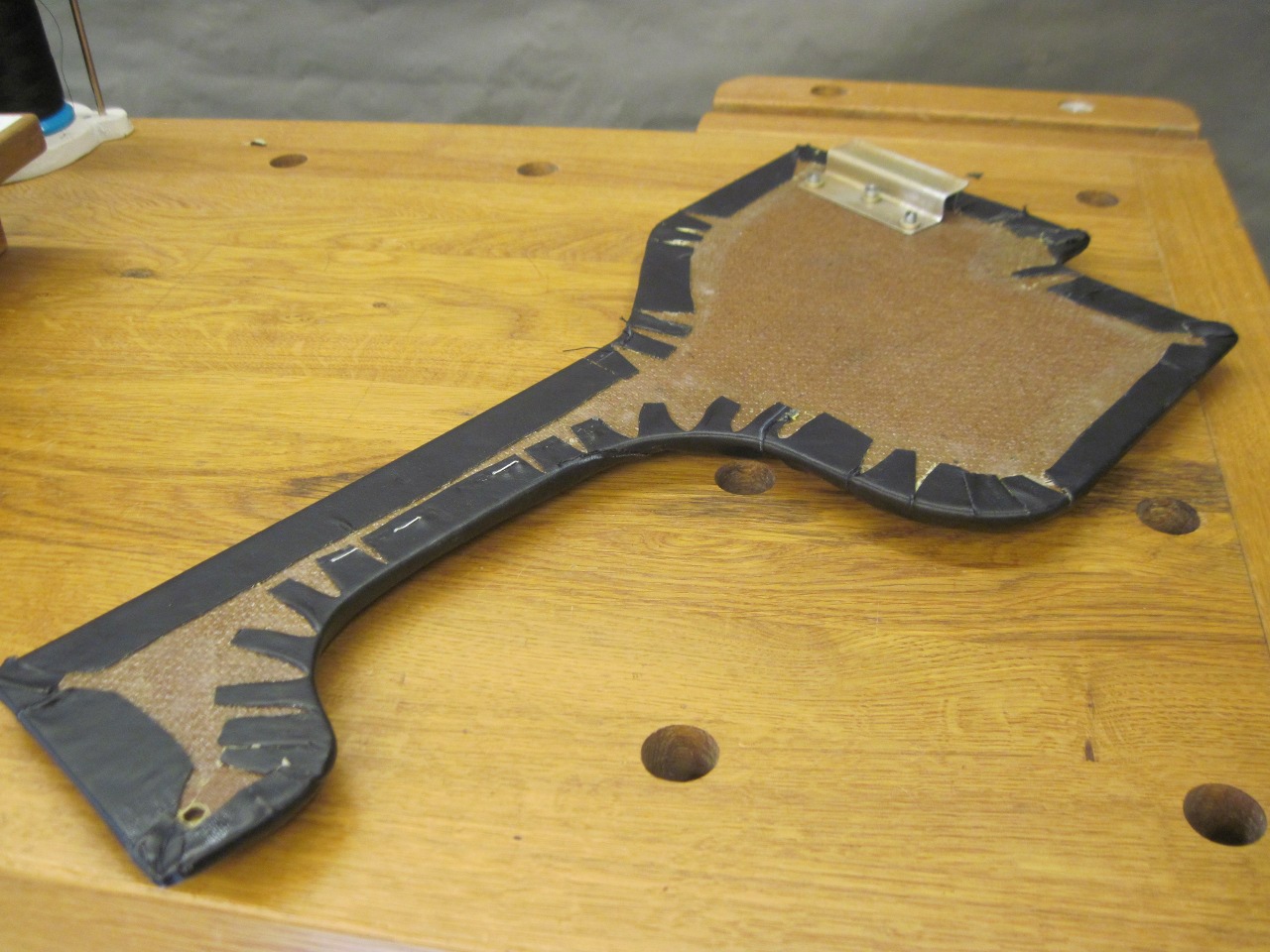

Also,

since my shop-built H frame his uprights a little thinner than the

stock one, the original metal fittings were too loose to use. I

had to make some new ones. The little dog-leg brackest are to

hold the panels to the tunnel at the forward end. At this stage,

the panels had been coated all around with three coats of polyurethane.

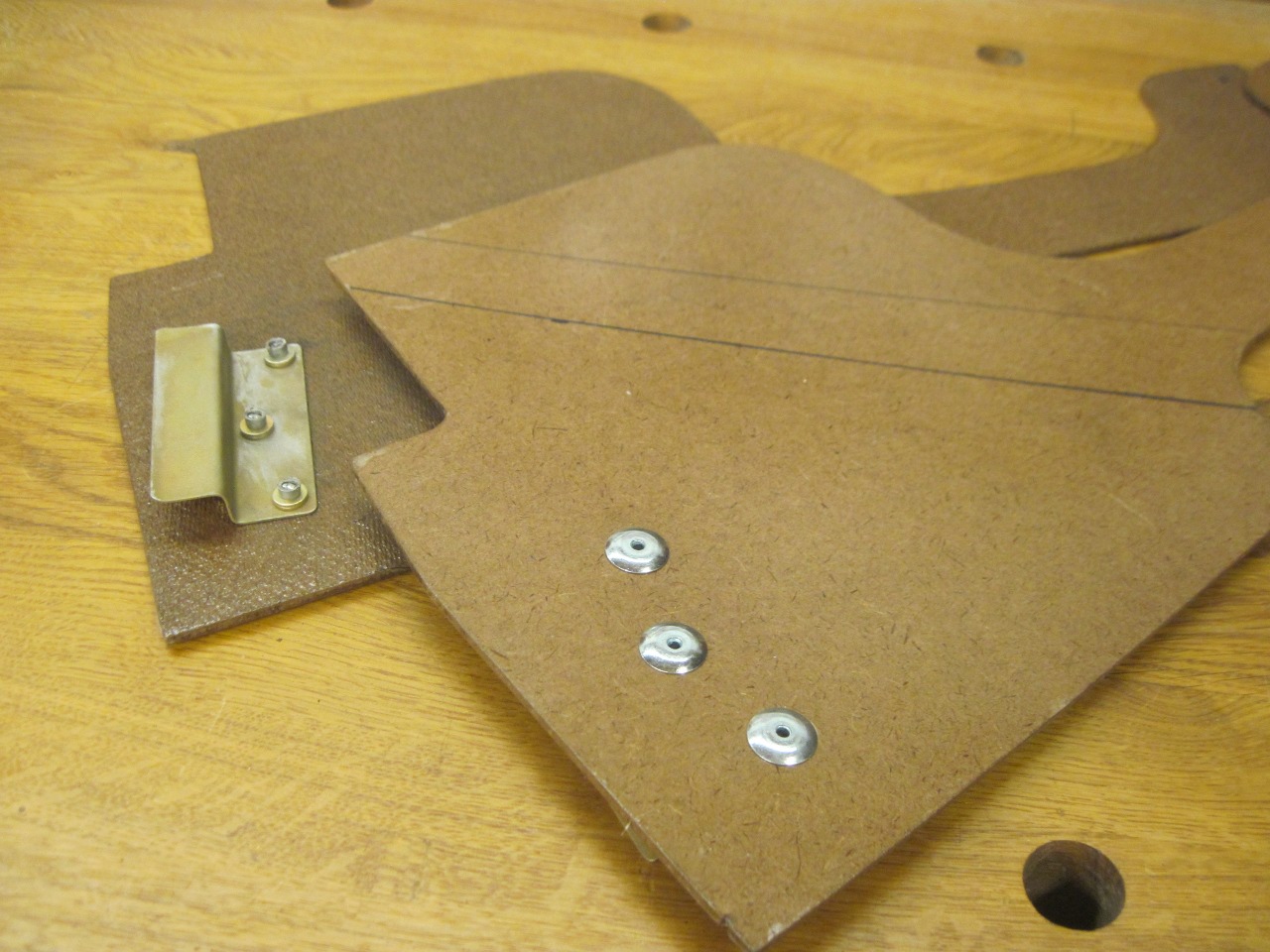

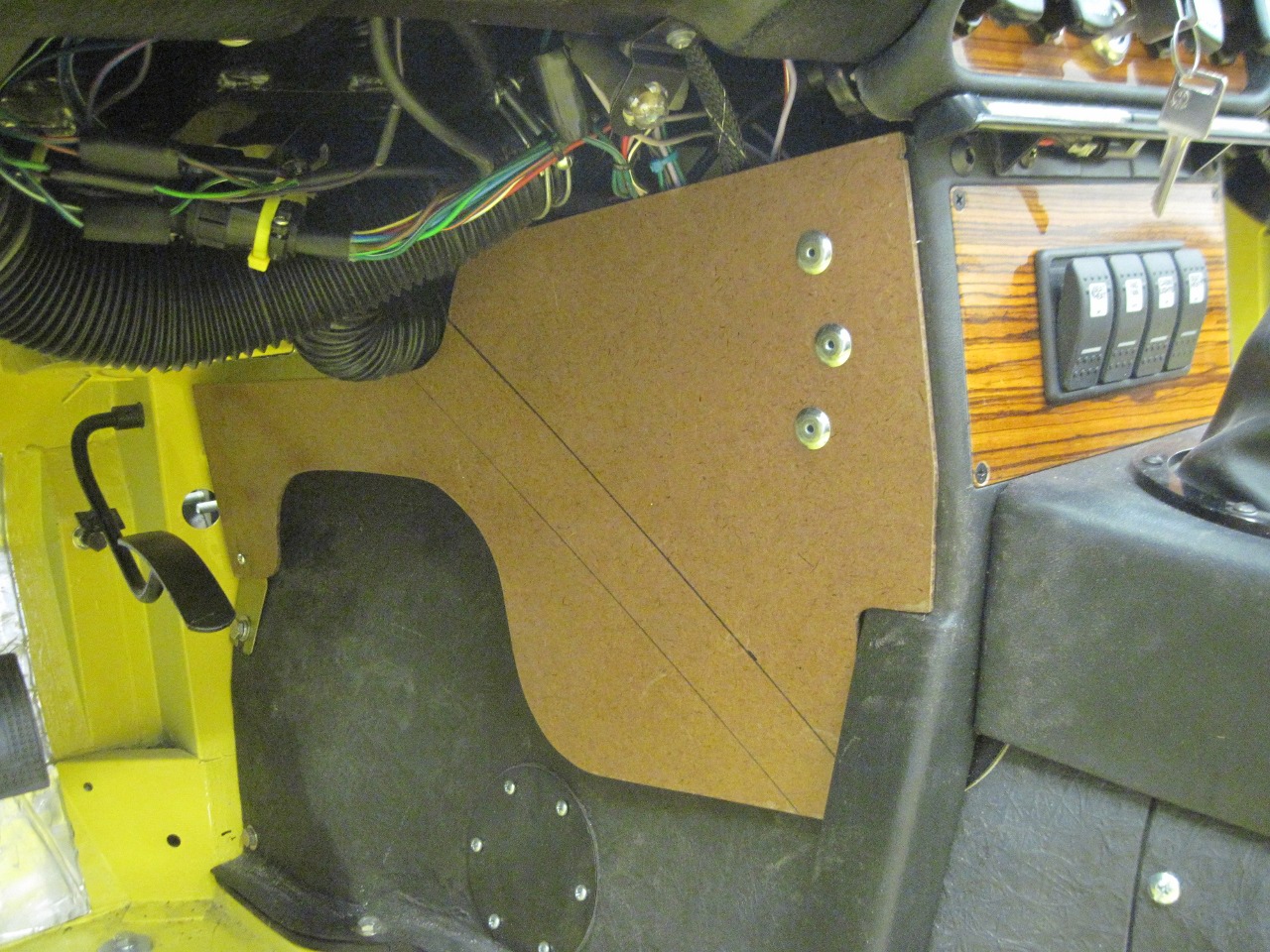

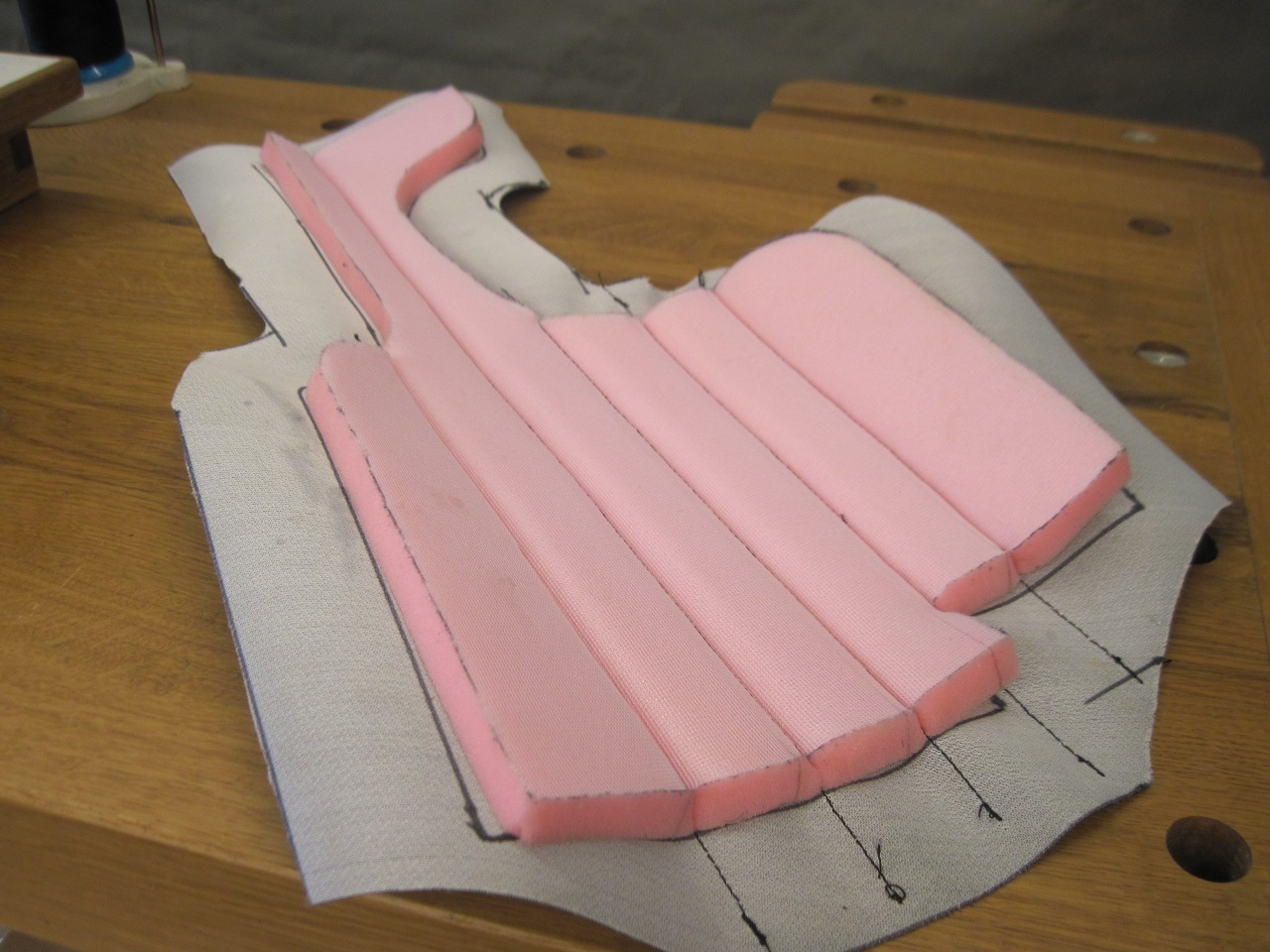

Test

fit of the panels and bracketry. The upsweep near the far end of

both panels is to allow warm air from the heater to reach the fooewells.

Now, the foam and vinyl covering.

I have to give a big shout out here to Bob Danielson and his wonderful website. In particular, Bob has a beautiful section on his site about making interior panels. Once I saw his treatment of the kidney panels, the option of just using plain flat foam and vinyl was off the table.

The

only rub is that I didn't own nor know how to use an adequate sewing

machine. But in a leap of inspired faith, I bought one.

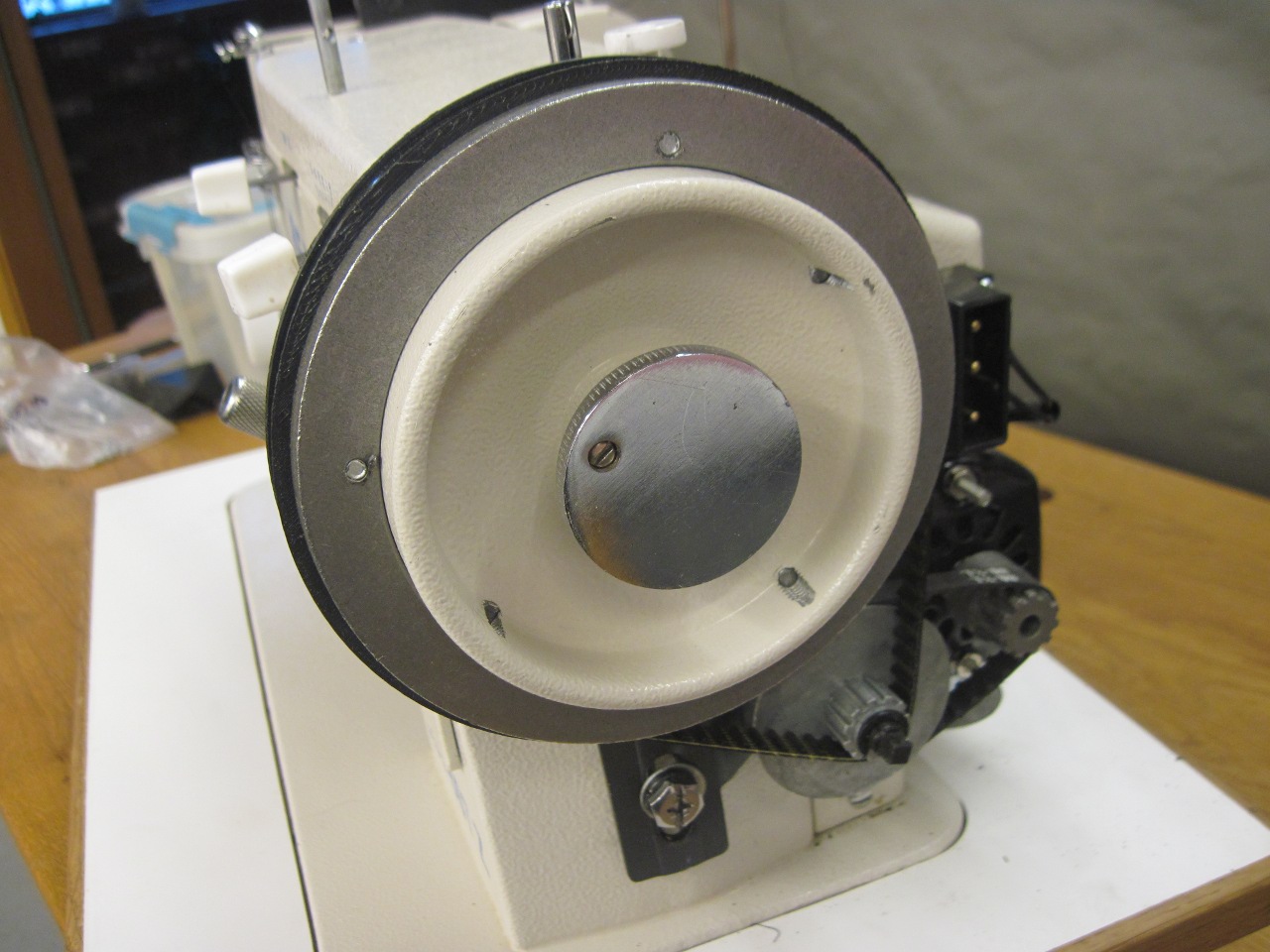

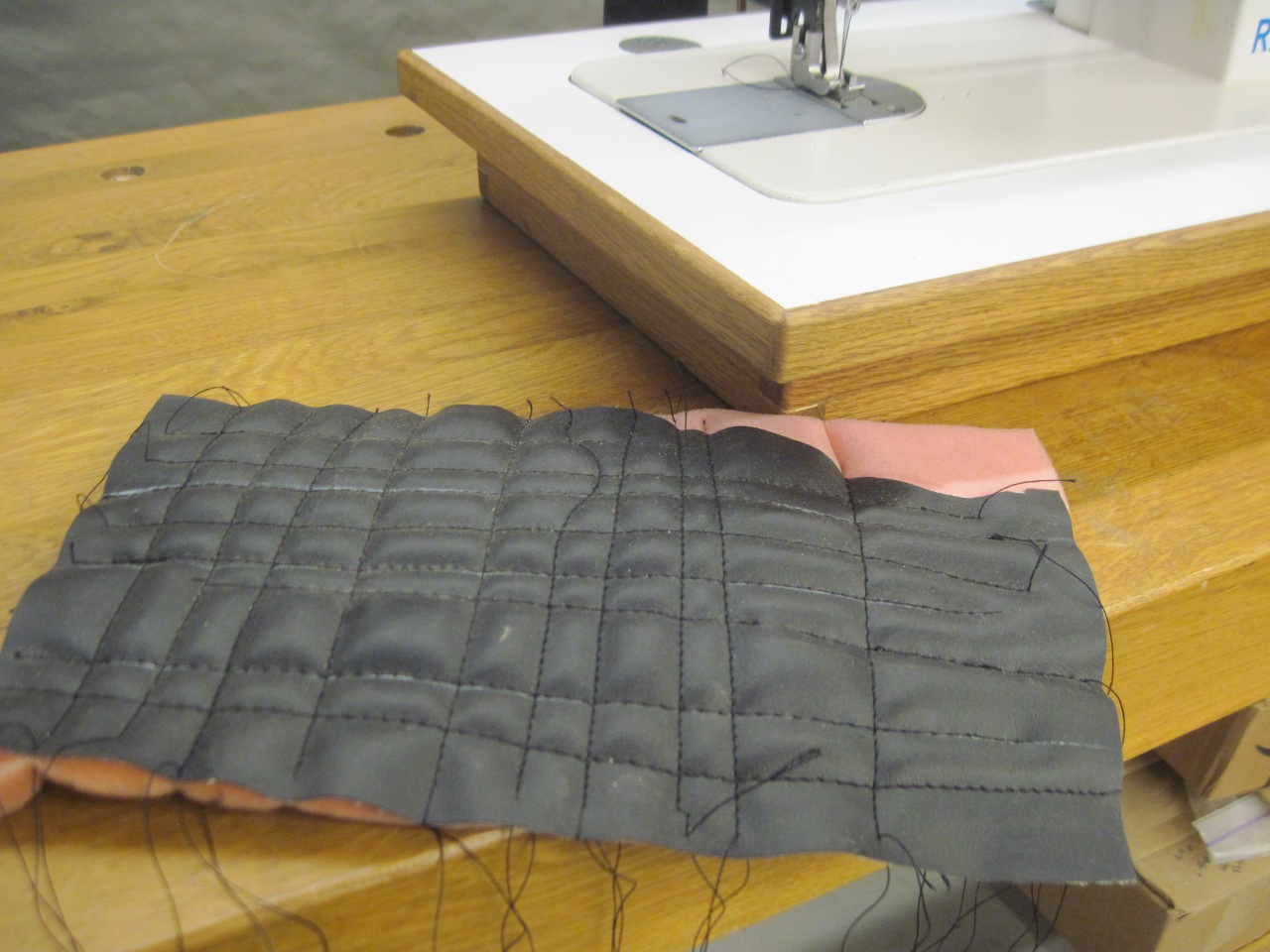

Sewing

machines capable of handling heavy fabrics need to have something

called a walking foot--an arrangement that pulls the fabric through the

machine from both the top and bottom. This is a lower-end walking

foot machine. To the right are rolls of black automotive vinyl,

and some 1/2" "scrim foam" that has a fabric on one side so that it

will hold stitches. The machine is pretty basic, and doesn't come

with a base, so the one in the pic is home made.

Also,

being a rank novice at machine sewing, I was intimidated by the speed

of the machine. The speed control on the machine was a

little notchy at the low end, and I had trouble maintaining

a speed slow enough for my rudimentary fabric-guiding skills. My

solution was to put a bigger pully on the balance wheel to cut the

speed in half. This worked great for me.

After a few familiarization runs, I felt a lot better about my ability to sew a straight line..

I transferred the panel shape to the foam, cut it out, and lightly glued it to a piece of cut vinyl

Then sewed a few straight pleats.

Then

lightly glued the assembly to the hardboard panel, trimmed the

wrap-around, and glued it on the backside. Then poked the hole

for the front mounting screw.

Then

did the other panel. Even though I included a power circuit and

fuse for an audio system in my Power Module, I'm not sure I'll install

a radio. At least not right now. Speakers would be pretty

simple to add later. I haven't tried it, but the larger panels

might accept larger speakers.

They

seem to fit pretty well. I'm toying with the idea of putting

black piping at the joint between the panel and the H frame.

This was a fun one. I learned a new skill, and now have a better sewing machine than my wife does.

Cost was pretty low (except for the sewing machine, that is).

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages.