To my other GT6 pages

June 20, 2022

Bonnet, Doors, & Gaps

Last Fall, I painted the body shell and the bonnet. I painted them separately, on different days, and while the body came out pretty good, I wasn't happy with the bonnet. It

had dozens of little fisheye-like divots, some going down to the

primer. Fisheye defects in paint are often blamed on silicone

contamination, but I think in this case it was more likely due to

condensed water droplets. It was pretty humid that day, and while

do use a desiccator for the air, I think the media was a little too

water logged. So, I resolved to paint the bonnet again.

This time, I made a little wheeled cradle for the bonnet. The

padded supports go into the wheel wells, and hold the bonnet at a nice

height for sanding and painting.

So I spent maybe half a day wet sanding the paint with 400 grit

paper. The cradle allows the bonnet to be tipped forward or

backward, which helped a lot.

It came out much better this time. In the past, I've set up a

"tactical" paint booth in the garage, but I don't find it worth the

trouble now. I'm not a good enough painter to expect a perfect

finish out of the gun, so I just plan to cut and buff everything.

This means that a little dust, dirt, and even the occasional small

insect in the paint isn't a crisis.

After a respectable waiting period, I wedded the bonnet to the body. Since I'm a solo act, I regularly use sky hooks.

Shortly after that success, I turned to the doors. The doors

had already had quite a bit of rust repair, and one had been

reskinned. Before final paint prep, There was one other job to

do.. The reskinned door had no cut out for the door handle. I

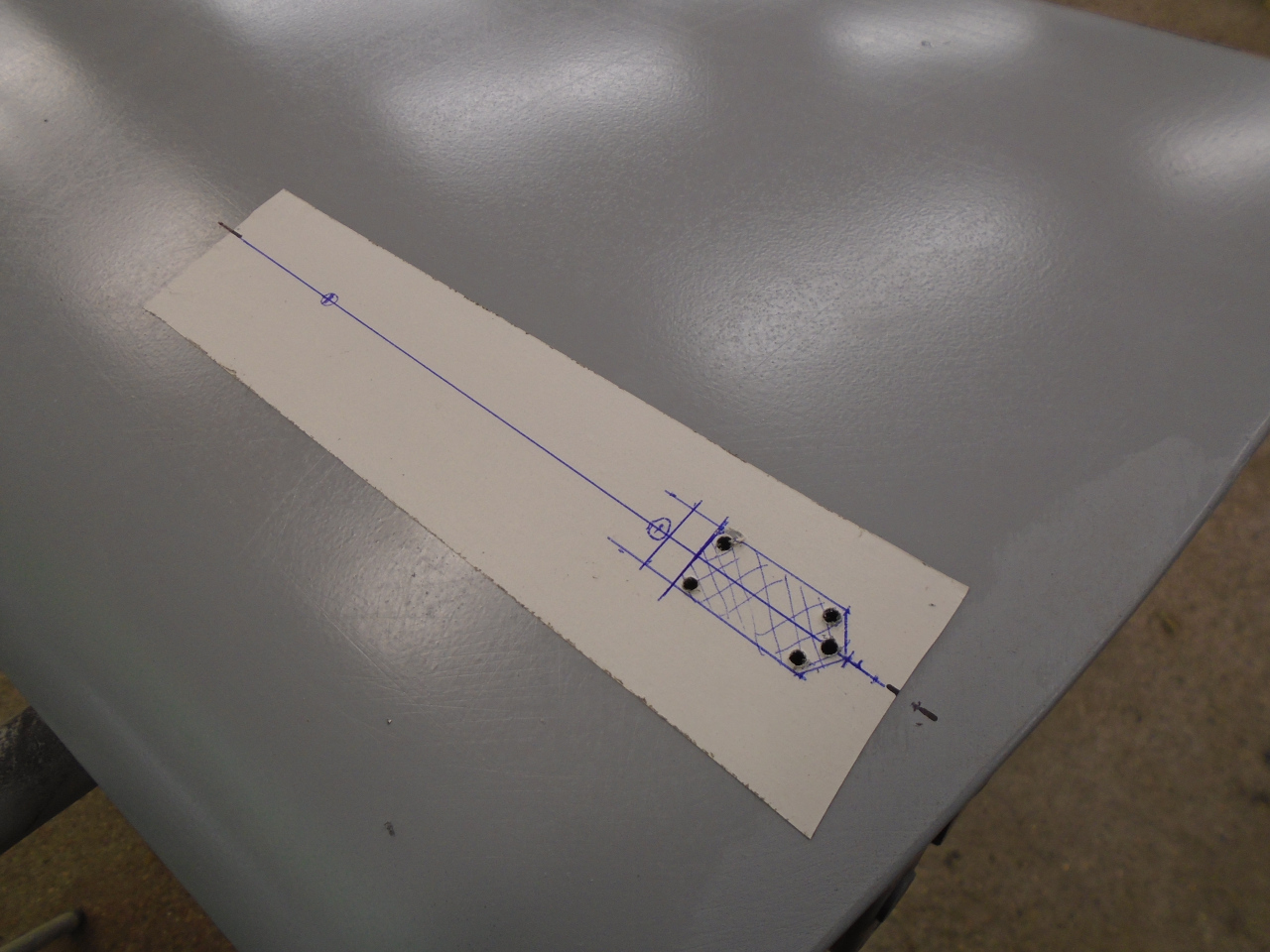

took measurements from the other door, and laid out for the holes.

I thought the original hole was unnecessarily big, so my new one is more of a bespoke fit for the handles.

I think mine is stronger. The re-skinned door is on the passenger

side, and I've decided to not put an exterior key lock on that side.

A few rounds of primer-filler and block sanding, and shot them with color.

While waiting for the door paint to cure, I turned to some of the door attachments necessary to mount them.

Found first in the box were the strike plates. They had patches of

rust, and some scuff marks where the latches rubbed, but they appearedd

to be serviceable.

Most of the zinc plating was intact, so I used a zinc-friendly chemical

to remove the rust. This left some visible pitting where the rust

was, but nothing that would impair performance. A fresh layer of

zinc was applied to cover the pitted and scuffed areas.

Then a dip in a chromate bath to protect the zinc, and to give the parts that iridescent yellow color the original parts had.

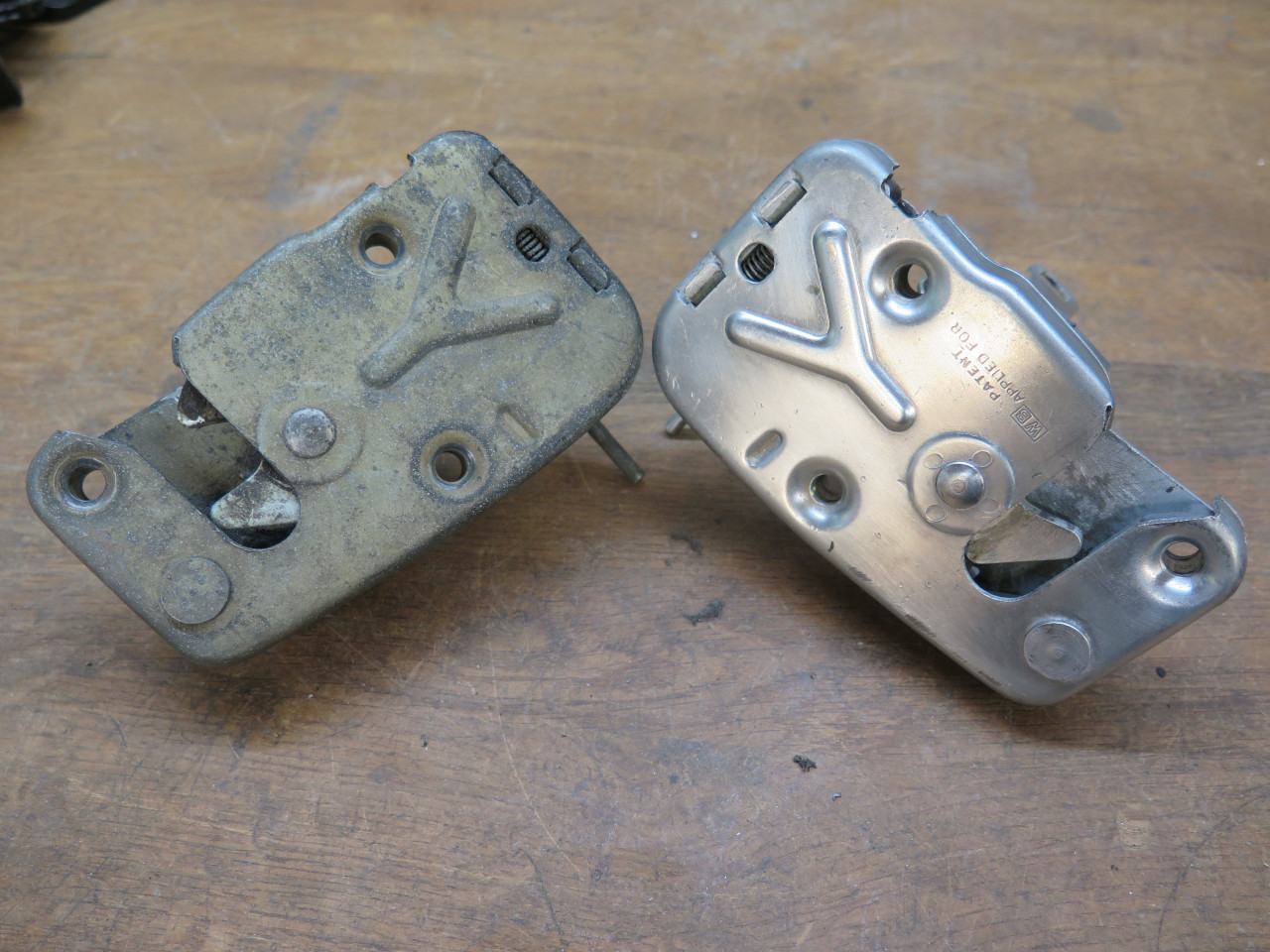

Then there were the lock/latches themselves. They seemed to sort of work, but were kind of balky.

I resisted my inborn urge to open them up, and just rinsed them with

some solvent, which freed them up pretty well. I believe the

crusty surface appearance of parts like this is usually just dirty zinc

and zinc oxide, so a quick dip in something that eats those two things

brightens them up quite a bit.

Then a chromate dip. The chromating process is very sensitive to

the amount of time in the bath, and I left these a little too long, so

the color on the latches is a little stronger than I really wanted, but

I'll live with it.

At this point, I had everything I needed to mount the doors. I neglected to order the pads for the hinges or the strikers, so these are home made from thick gasket material.

Bolting things up...

Looking more and more like a proper motorcar.

While futzing around with the door gaps, I realized that the door

handles would really be helpful,. so I paused that operation to see to

the handles. They were dirty but functional.

Took them apart, cleaned everything up, replated the fasteners and

replaced the washers. I usually only do one side at a time, in

case there is any question about how it goes back together.

Ready for install, except I then realized that there were a couple of

gaskets for each handle to go between the handle and the painted

doors. I didn't want to wait a week for an order to arrive, but I

also didn't want to scratch up my new paint. I also wasn't too

sure what they actually looked like, bit I could imagine how I wanted

them to look. It was a quandary. But, 3D printer to the

rescue!

I drew up a couple of gaskets that had shallow little pockets for the

chrome handle to seat in. This gave a little lip around the

chrome. I'm not sure if the factory gaskets were made that

way. It took a few iterations with gray PLA, because it's easier

to print, then the final pieces in black ABS. I considered using a

softer, rubbery material, but was afraid it might just extrude out of

the joint under pressure. With these thin sections, the ABS is

actually pretty flexible and resilient.

They should do the job.

Gaps look OK, but I'm still fiddling with them.

This feels like another milestone, but pretty soon, I have to begin to tackle this vast expanse.

For the first time in a while, this car is only consuming a single

car-sized space in my garage. There is finally some room to move

around.

All of this work was fiddly and took some time, but other than the paint, there wasn't much cost.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages