To my other GT6 pages

June 25, 2024

Odds & Ends

With this project essentially finished, I turned the the "punch list" of

final jobs to be done. Some of these were done a few weeks ago,

but didn't seem to warrant their own page.

To skip ahead:

Seat Belt Install

Wing Molding

Side Reflectors

Sun Visor Install

Rear View Mirror Install

Battery Terminal Cover

Body Ground

Body Plugs

License Plate

Wiper Arms

Seat Belt Install

Before I took the first actual drive, I wanted to have seat belts.

I'm not really that much of a safety wonk, but they had to go in

anyway, and why not then?

I dug out the refurbished belts from their storage bin.

First job seemed to be to install the attachment fittings.

There are three attachment points on each side. I had to go looking for the one behind the seat near the inner sill.

The one for the shoulder belt is on the wheel well.

The last one is on the tunnel, and accessible through an opening in the

tunnel trim panel. The belts hook onto eye bolts on the lower

points. The retraction reel goes on the outboard side.

I'm not really fond of these belts. I'd forgotten the hassle that

most 60s seat belts were. The shoulder belt component was

relatively new back then, and it had to be manually connected to the lap

belt. The retraction reel was strictly to stow the belt out of

the way, and didn't really tighten the belt. That was manual,

too. There was no inertial activation.

I looked into modern 3-point inertial replacements. They exist,

and claim to fit the GT6. However, all of the ones I saw put the

inertial activation and retraction reel at the base of the wheel well,

with a fitting higher up on the wheel well to change direction of the

belt. This arrangement won't work on GT6 cars with the larger rear

deck like mine.

I suppose I could cut a passage in the deck, but for now, I'll just deal

with the original system, and try to enjoy the nostalgia.

Wing Molding

I went to the shed to retrieve the stainless wing moldings that cover

the pinch seams at the top of the wings. I was pretty sure there

should have been four of them, but I could only come up with

three. I don't really remember it, but one must have been damaged

in removal. So I ordered a new front trim piece. The one

second from the right is the new one.

First thing I noticed was that the new part has a lot less curve than

the original. This seemed like it might be a problem.

With a little artful encouragement, I did manage to get the new piece to

better imitate the old one. This was tricky, because bending this

shape "the hard way" consistently threatened to just buckle and bend

the "easy way".

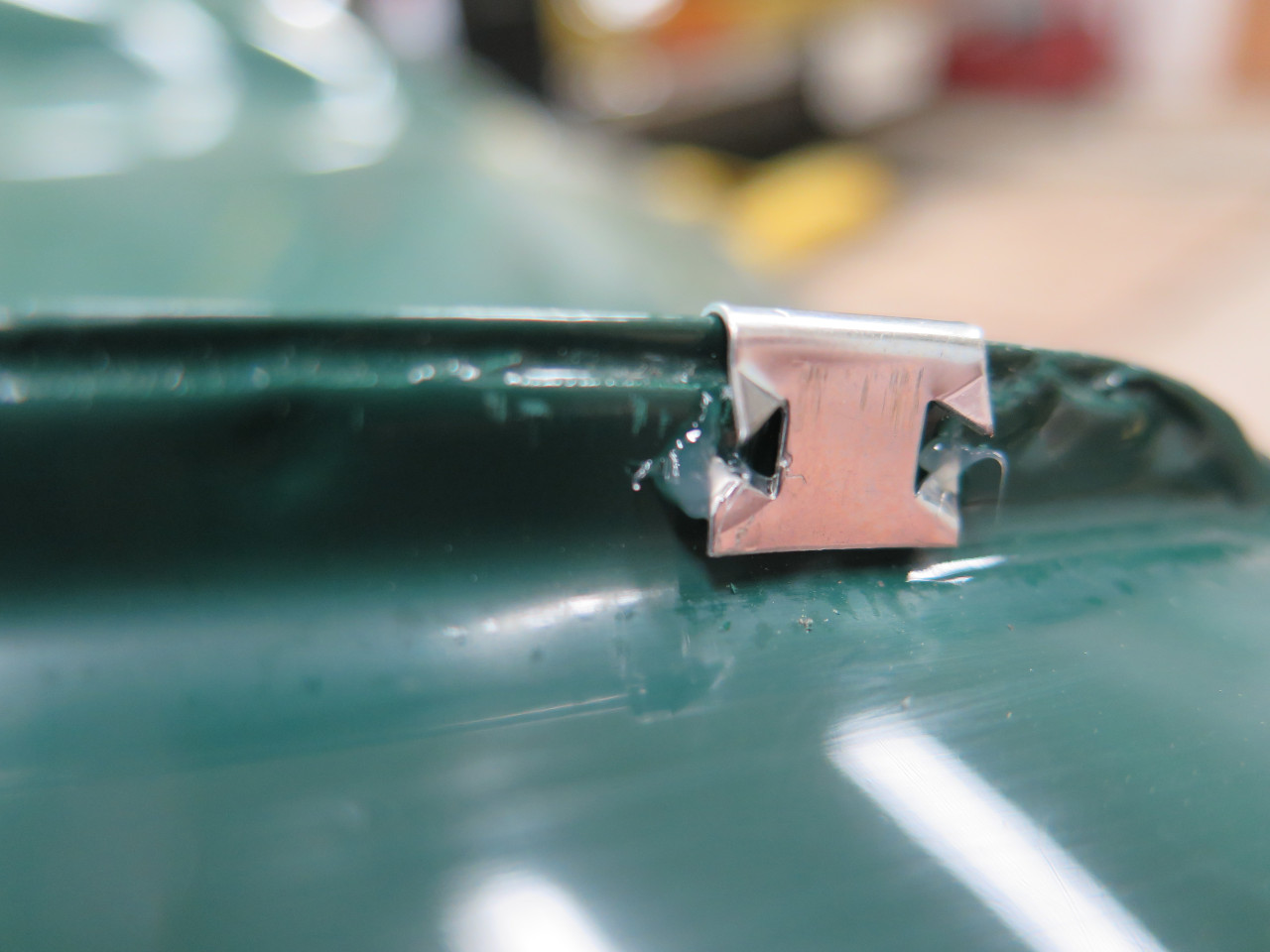

The stock method of retaining these trim pieces is with little barbed

gizmos that straddle the wing seam. A common objection to using

these clips is that the internal barbs breach the paint, which could

give rust an inviting place to start. So some folks opt instead to

glue the trim on, using RTV or some similar adhesive. I decided

to use the original clips, but then try to mitigate the paint

damage. I basically squirted some heavy bodied grease onto the

places where the barbs contacted the paint. I tried to spread the

clips a little on install so they didn't scratch the paint going home.

Well, I'm happy to say that the three original trim pieces seated with a nice, convincing amount of pressure.

The new one, not so much. It just wouldn't stay put. The barbs

wouldn't bite into it properly. It did seem that the legs were spread a

little wider than on the originals, which might cause the problem. My

first inclination was to just whack it with a hammer down its length,

but when some better judgement clicked in, I set up my bead roller to

compress it in a more civilized operation.

This helped, but didn't cure the problem. It seems that the

material of the new piece is harder than the originals, so the barbs

can't grab it as well. I added more clips and actually carefully

bent some of the barbs out a little. This gave me a trim piece

that is staying on, but still comes off way easier than the

others. I may end up gluing it.

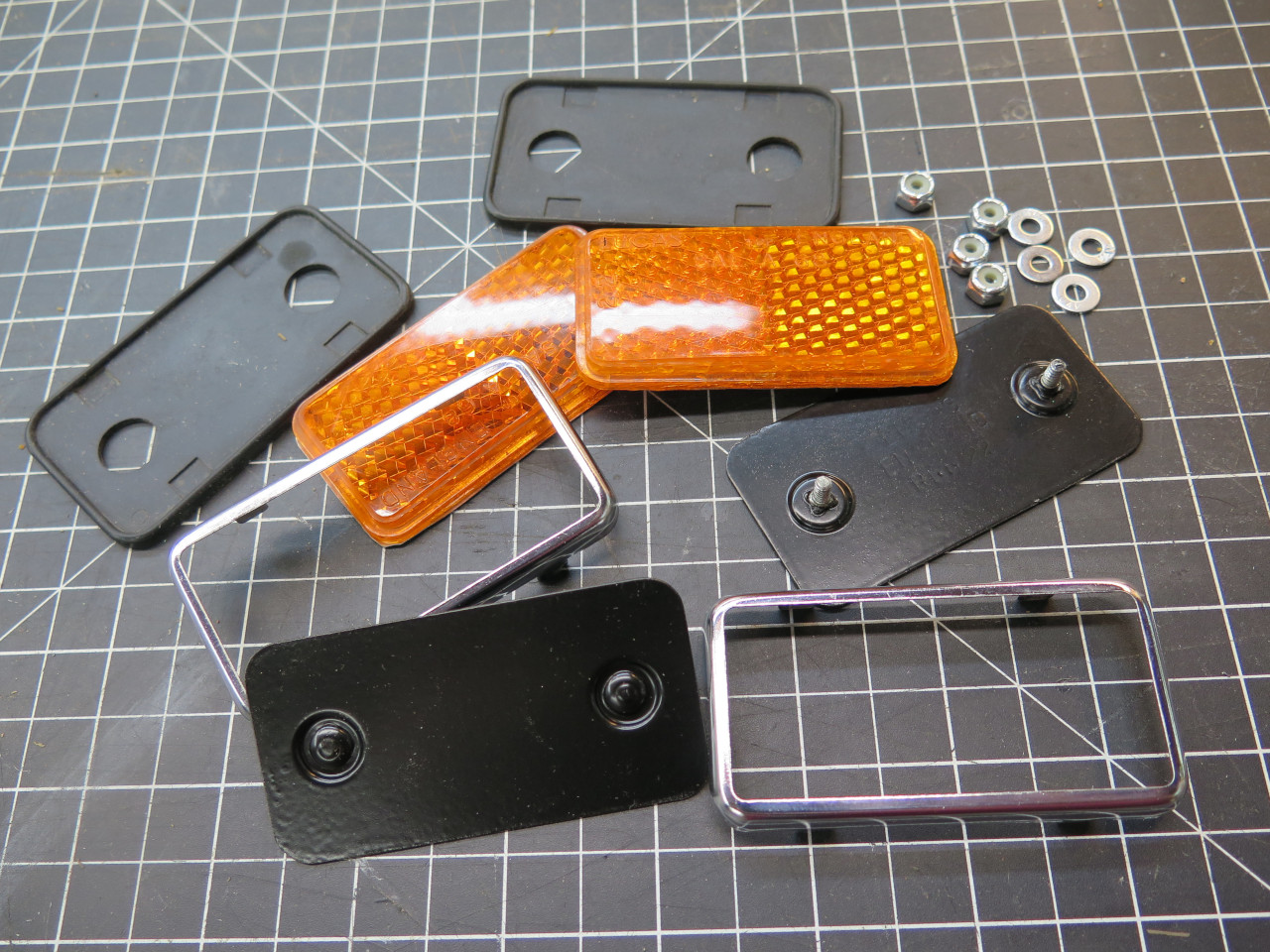

Side Reflectors

Just about the only little bag o' parts left in the parts box

contained the four side reflectors. Two of these went on the front

wings, and two on the rear wings. Many folks don't re-install

these, for a "cleaner" look, I guess, but since I had neglected to weld

up the mounting holes on the front wings, I just about had to use

them. On the other hand, since my rear wings were new, and I had

neglected to drill mounting holes, and didn't want to drill them now, I

just about have to leave them off. It's funny how neglect can have

many different consequences.

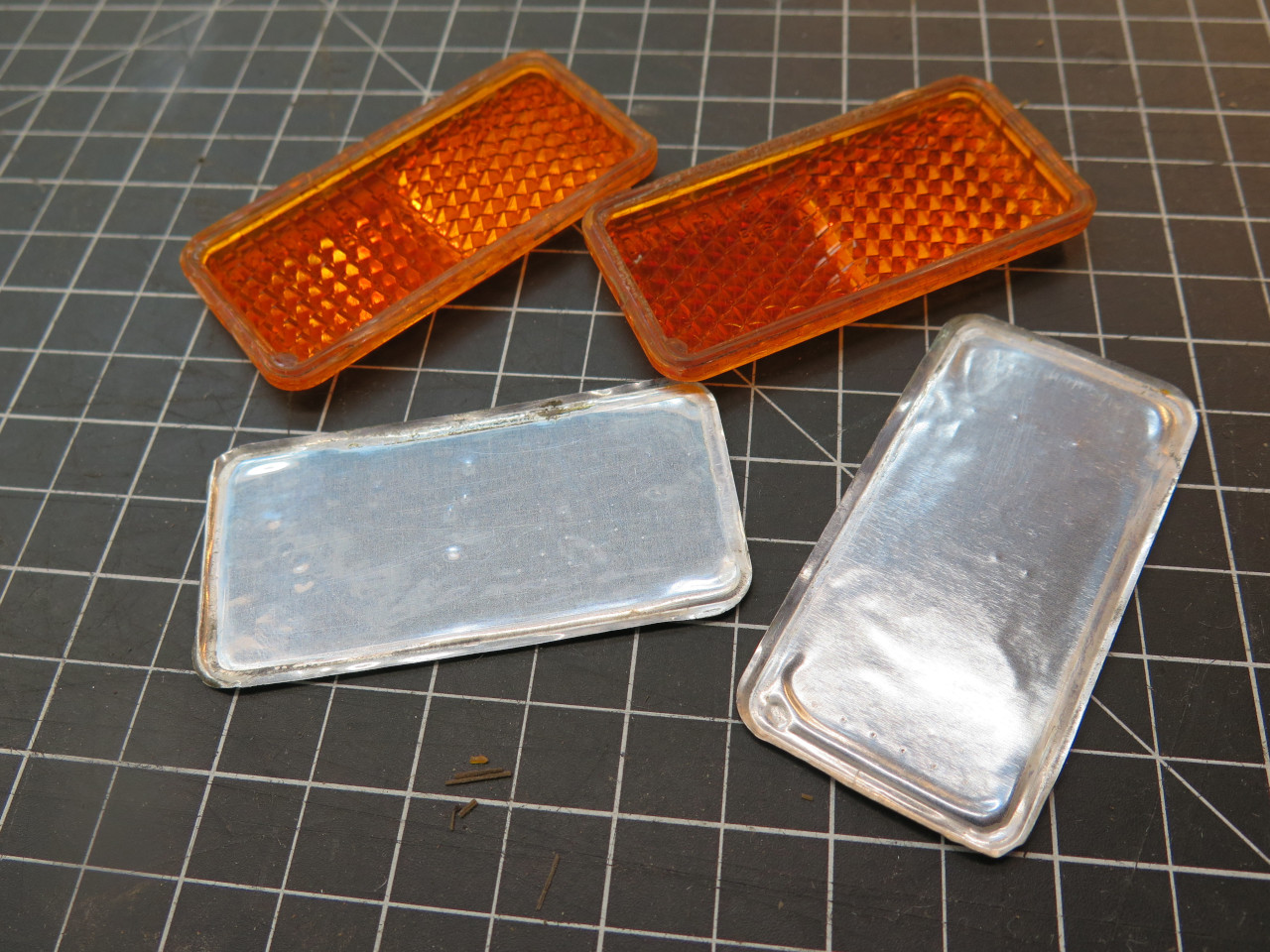

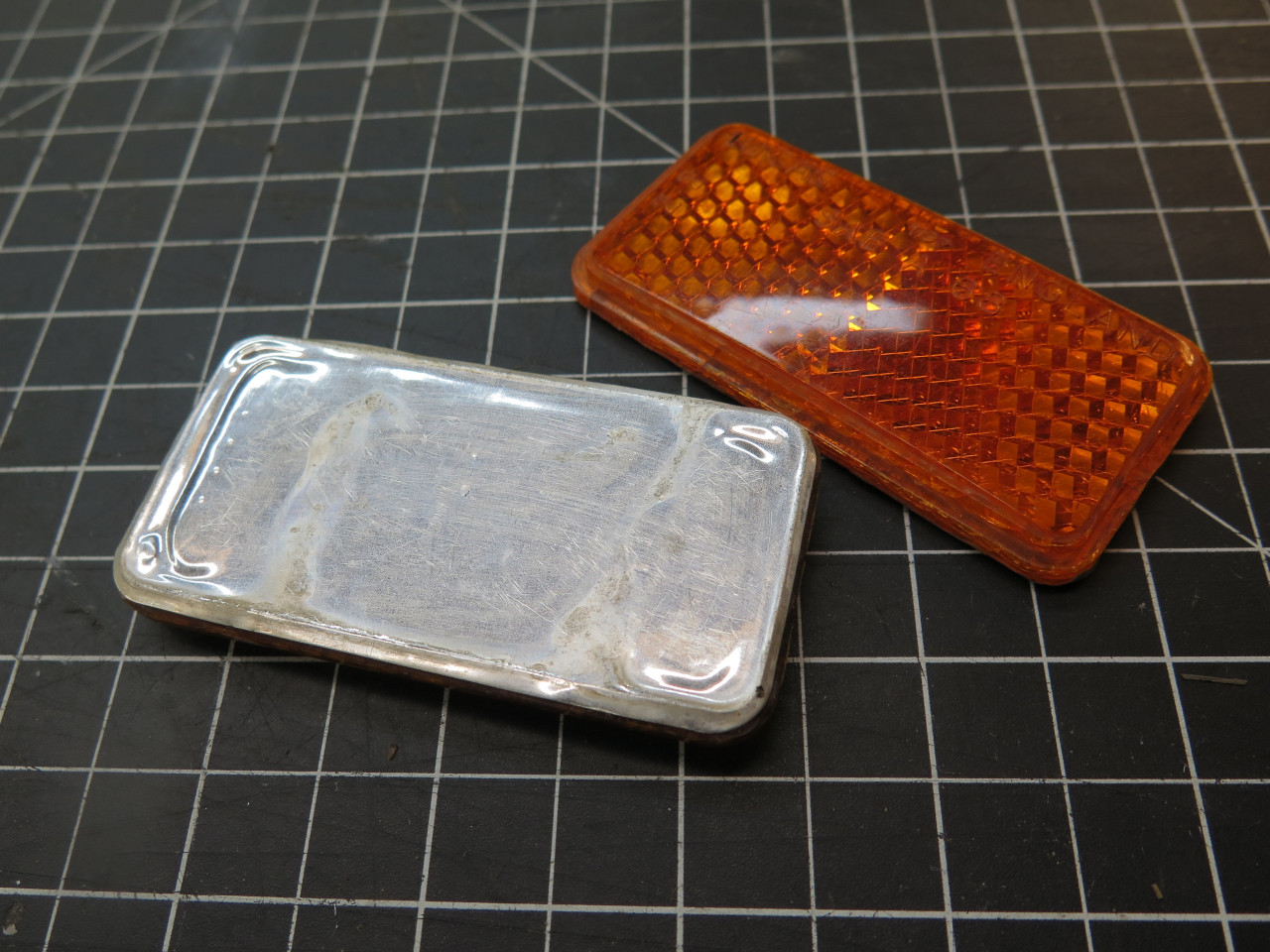

A little research suggested that it was the amber reflectors that went on the front.

These are properly called "retroreflectors", which means that they

reflect light back in the direction it came from, no matter what the

angle (within limits, of course). Each reflector consists of a

plastic lens with lots of small angled surfaces on its backside that do

the "retro" magic, a thin foil reflector that returns any light that

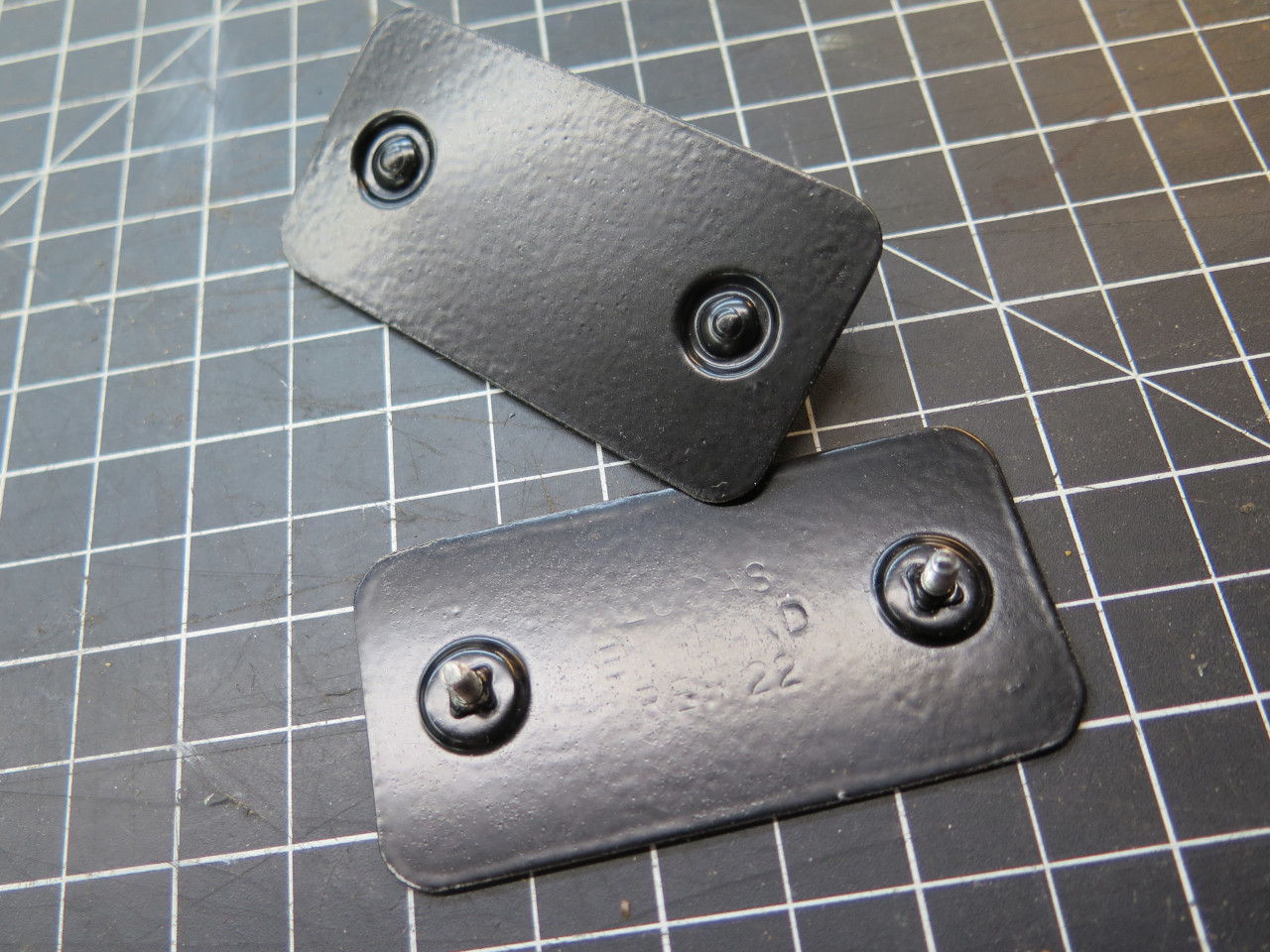

makes it through the lens, a steel backing plate with mounting studs,

and a chrome plated bezel that holds everything together.

The backing plates were pretty corroded, so I stripped off the remaining

zinc and replated them. Then, since these plates will be exposed

to weather and probably trapped water I powder coated them too.

The lenses were cleaned up and polished on the outside. The foil

reflectors were just cleaned, flattened, and glued to the lenses.

The rubber pads that go between the reflector and the car body were in

excellent shape after some cleaning, so I reused them. I'm often

amazed how some old British rubber ages so well.

Then took them home.

I might prefer the car without these, but I really don't mind them.

Sun Visor Install

I took the re-made sun visors off the shelf, where they've been waiting patiently for 17 months.

Then had to locate and open up he clearance and mounting holes under the headliner.

By some miracle, I still had the original fasteners and speed nuts.

The mounting plates went on without a hitch.

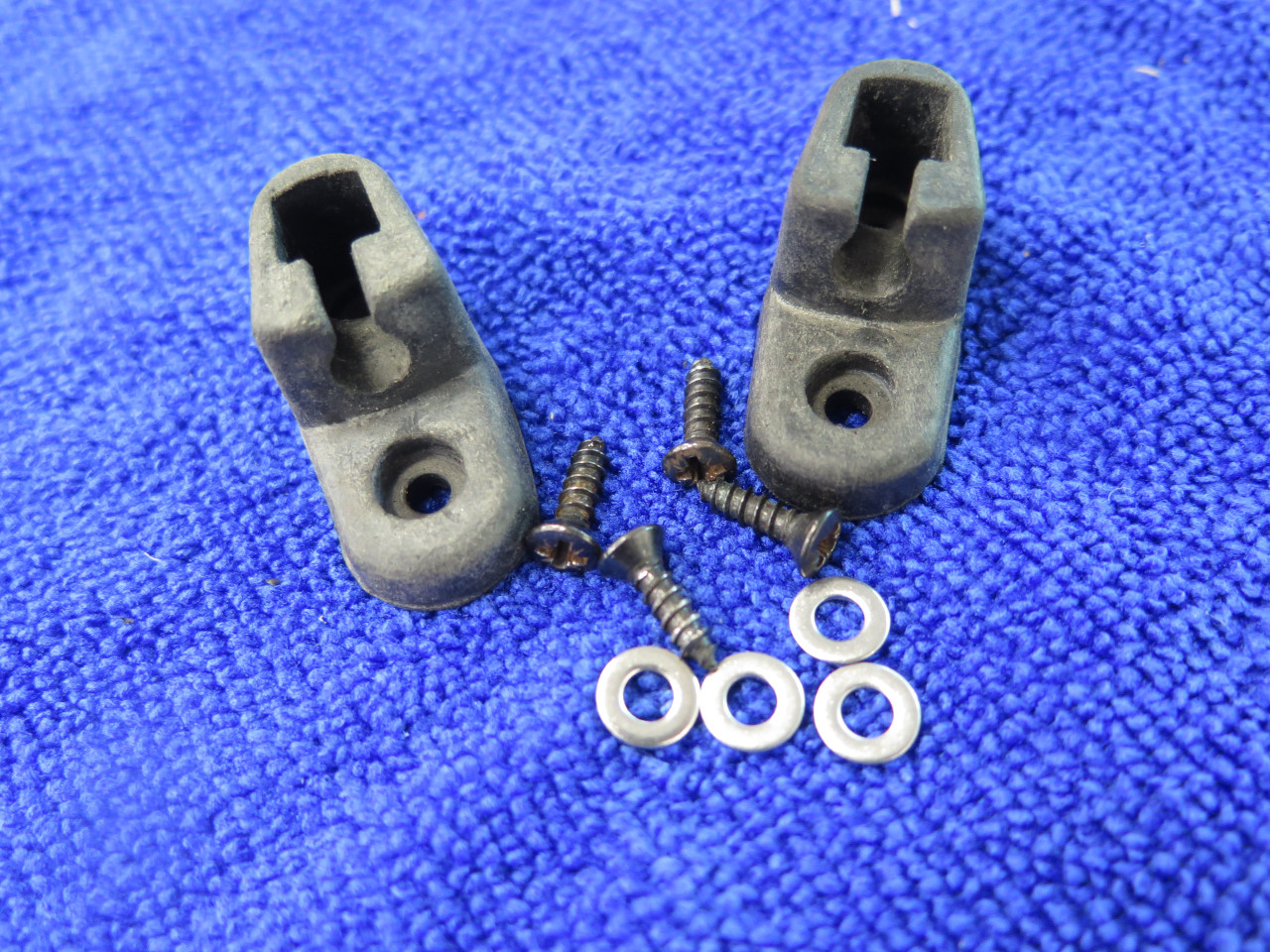

Then there were the little inboard keepers. Originals were the

ones on the right in the first pic. They were stiff and

brittle. The ones on the left I actually ordered for my TR6, but

they proved to be too soft and wimpy to hold the visors against wind

buffeting. I 3D printed some stiffer ones for the TR, so these are

hand-me-downs for the GT.

There was some adjustment involved to get the visor end tip to fit into

the keepers. It mainly involved shifting the visor and end tip in

the outboard direction.

They seem to work just fine.

Rear View Mirror Install

Dug out the refurbed rear view mirror.

It went in without any drama, heartache, or adult language. Why can't all jobs be like that?

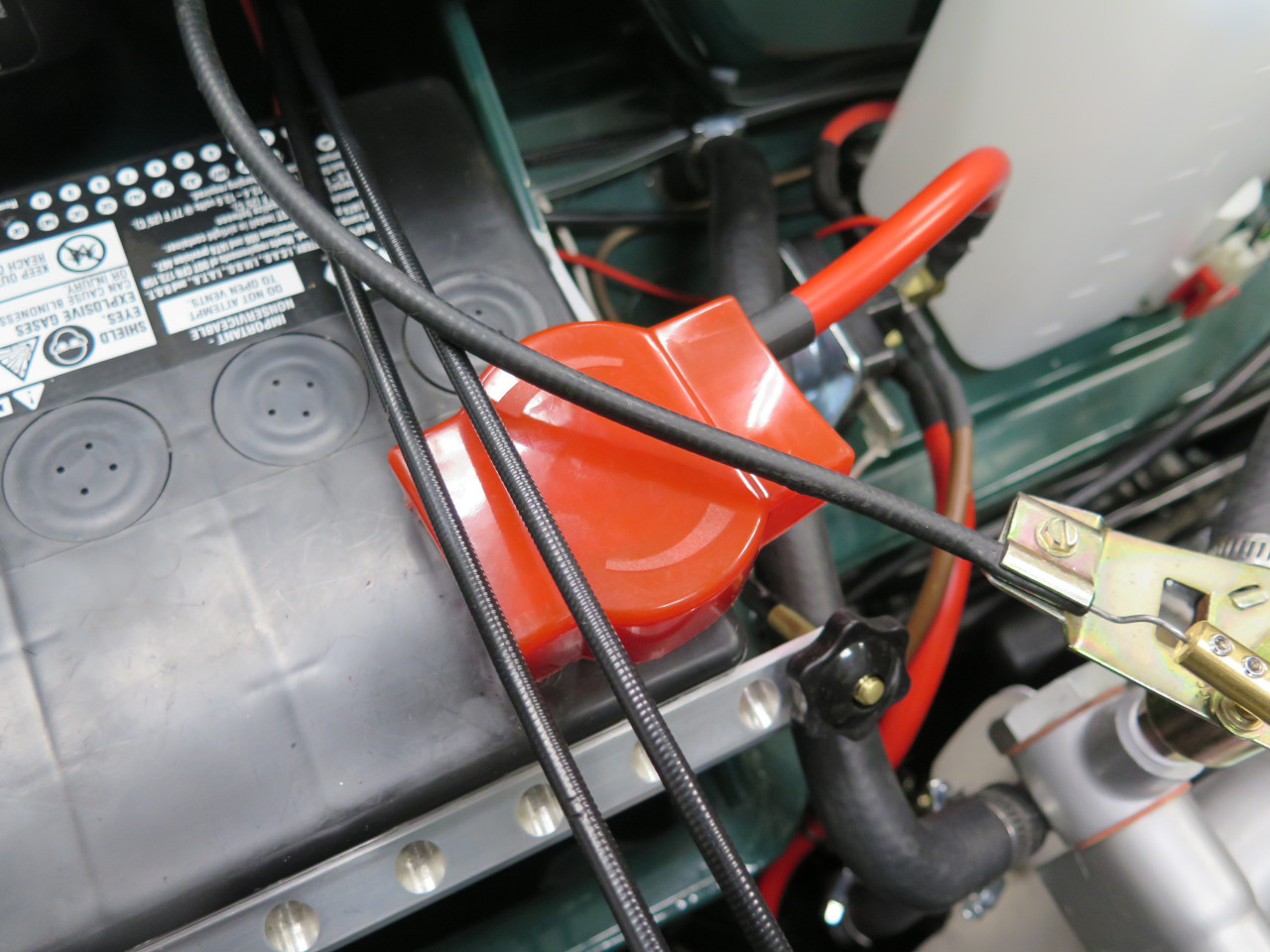

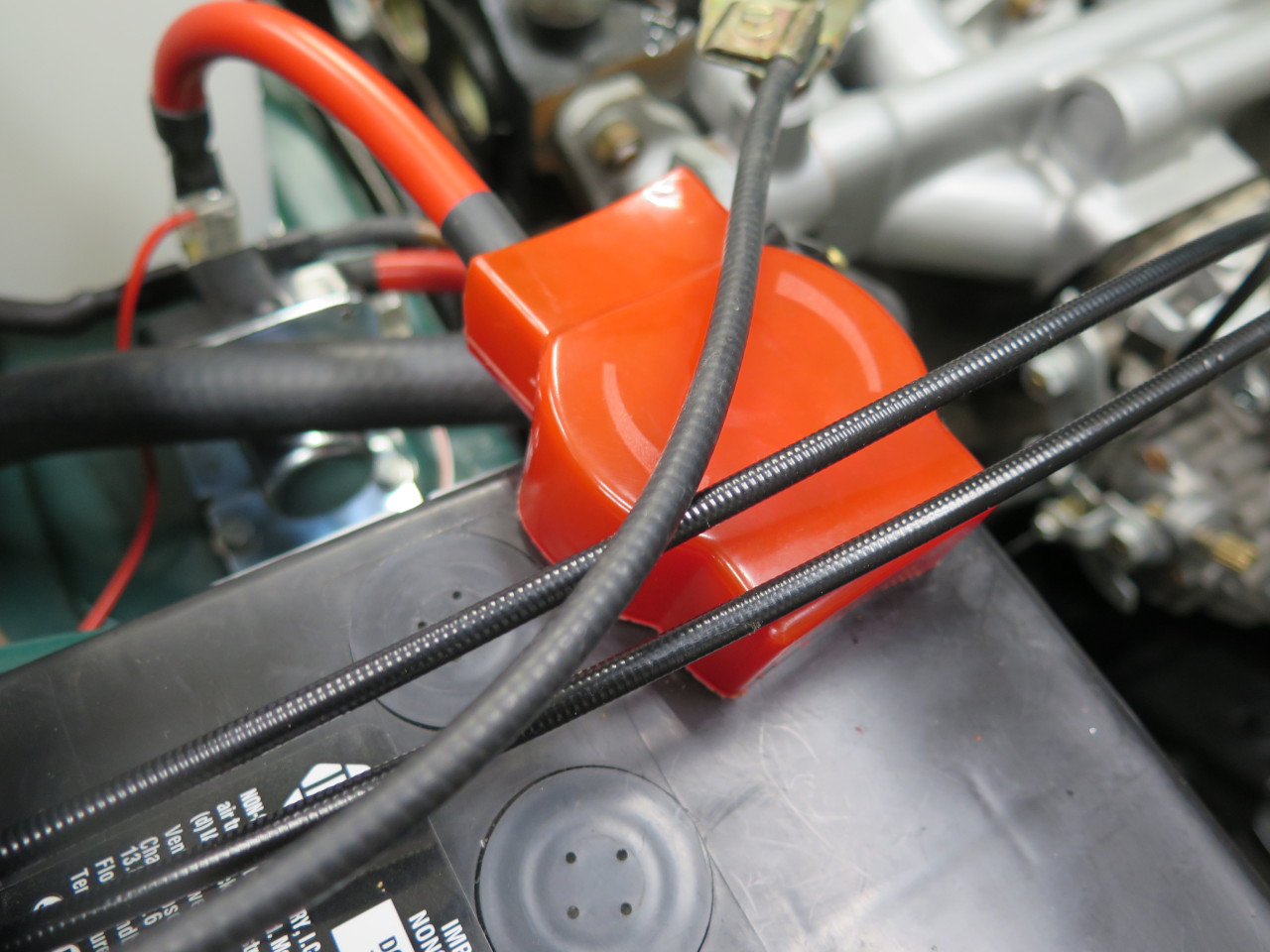

Battery Terminal Cover

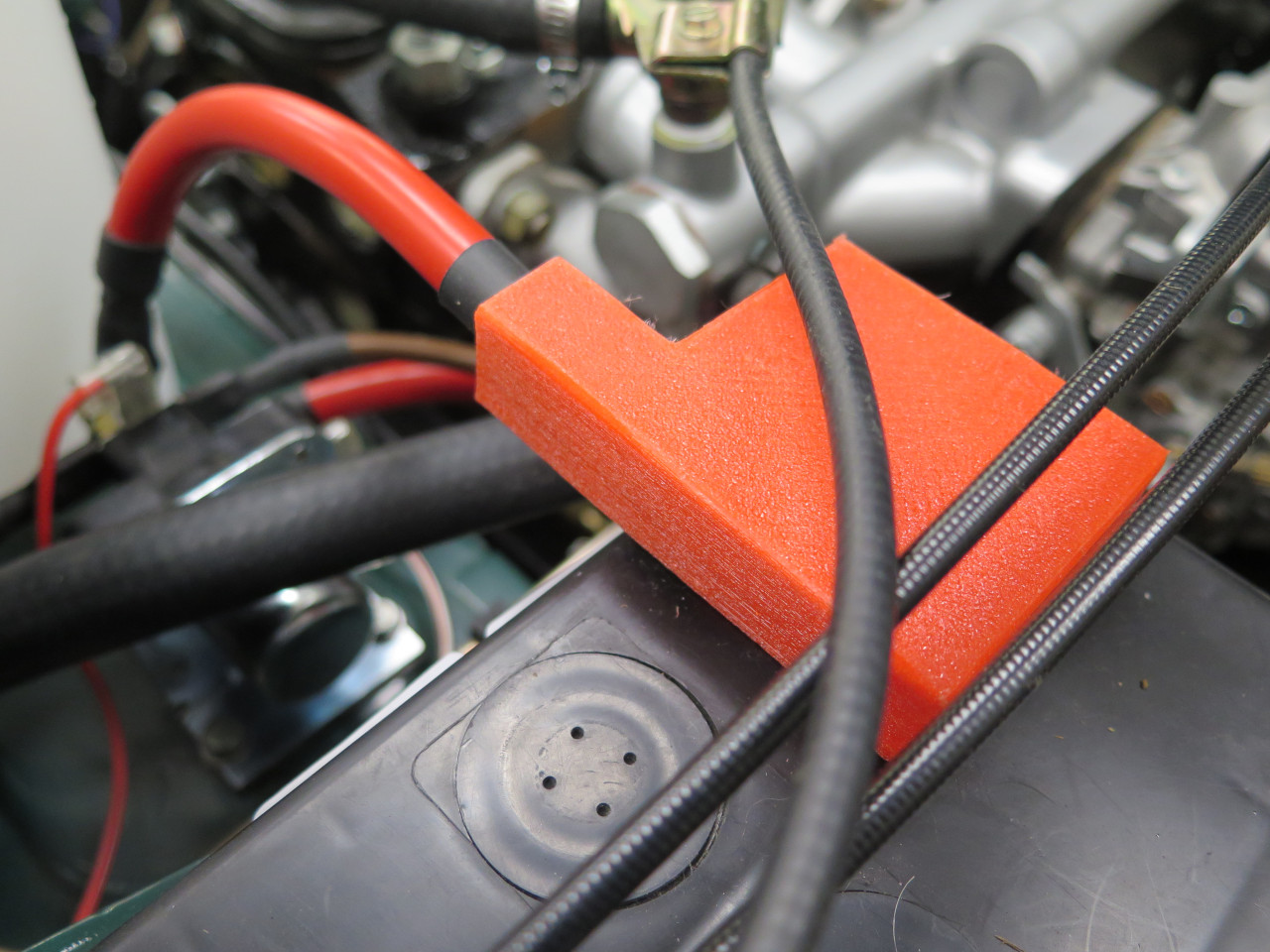

Perusing the engine bay, my eye always seemed to stop at that big

oversized battery terminal cover. I think it came with the cable

terminal.

I thought something a little more form-fitting would look better.

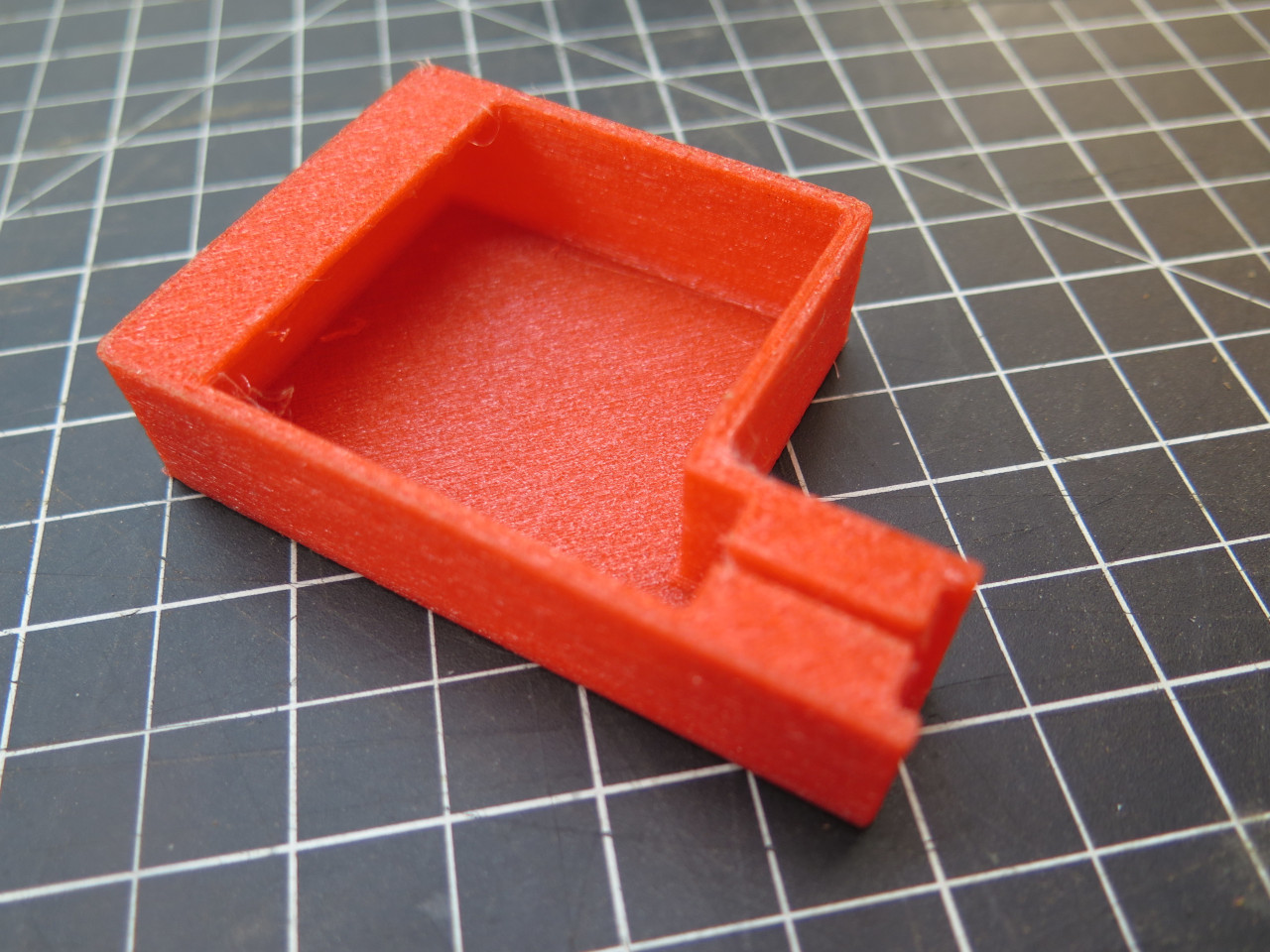

This is a 3D printed cover. It's made from TPU, a soft, rubbery

material. This allows it to be snapped on and removed without

undoing the terminal.

Looks a lot better, I think.

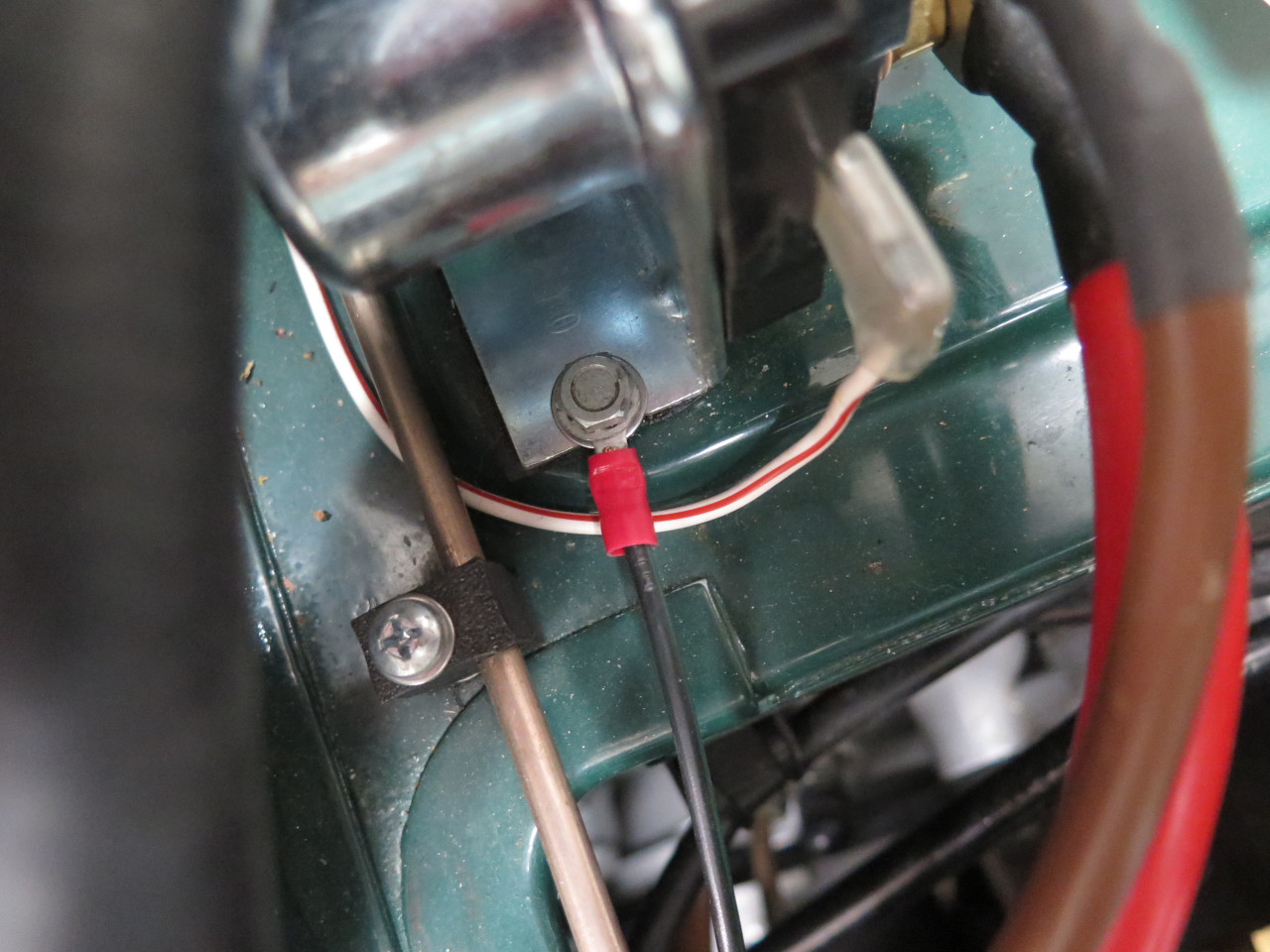

Body Ground

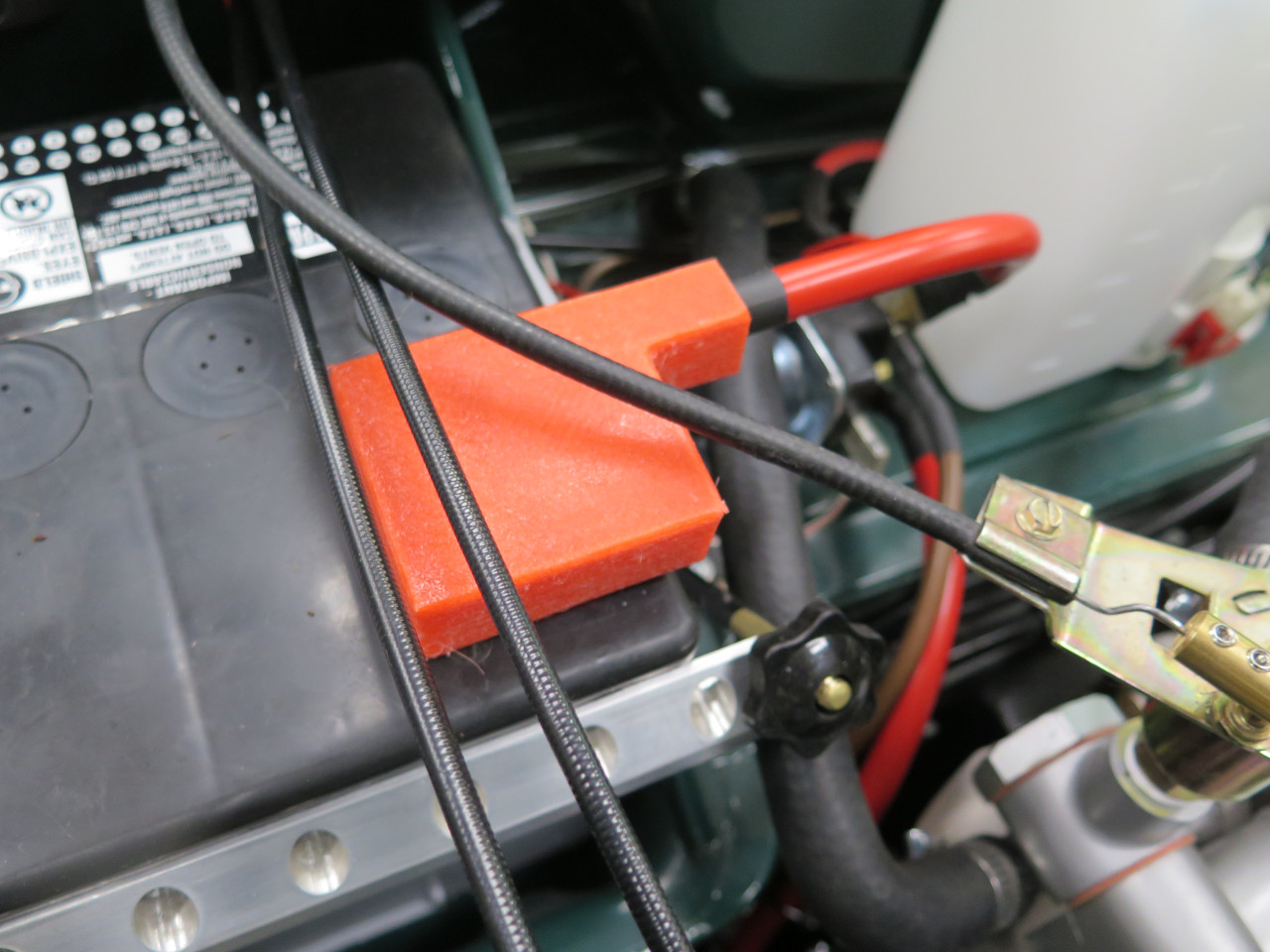

When doing the electrical system for this car, I resolved to provide an

explicit ground wire for all loads so that the body would not be part of

any electrical circuit. There turned out to be a few electrical

devices where this wasn't really practical--namely the distributor, the

coolant temperature sensor, the starter solenoid and the PDWA. The

two engine mounted devices still have their ground through the engine

block, since the starter frame is connected directly to the battery

negative.

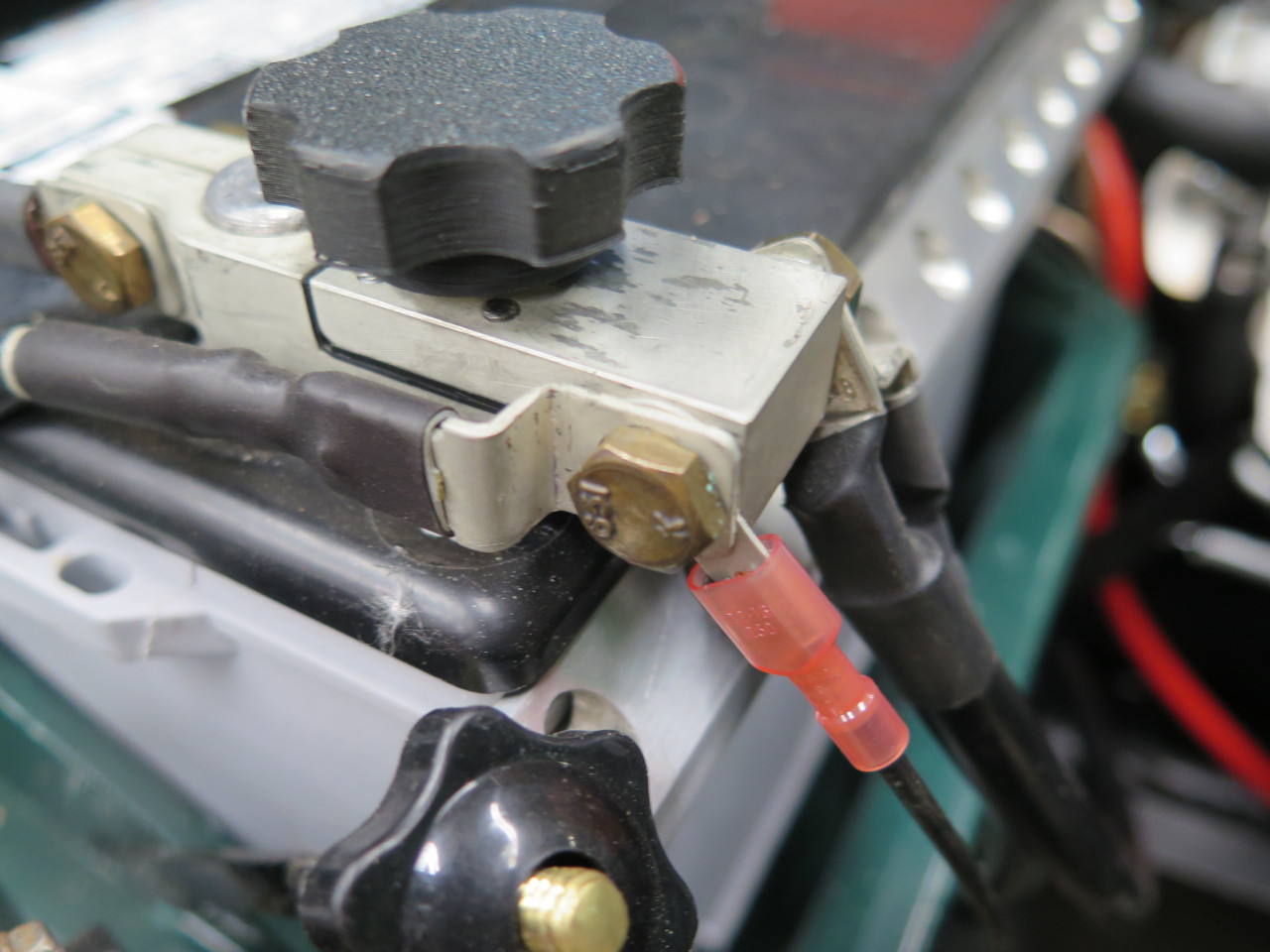

But the solenoid and PDWA still each have one electrical connection to

the body, and the body is not explicitly grounded. Both devices

still work because of opportunistic ground connections--I think it's

just the choke and heater valve control cables.

This didn't seem like sound design, so I capitulated, and agreed to add a

real ground connection to the body for exclusive benefit of the

solenoid and PDWA.

I made up a little quick disconnect tab for the negative battery terminal, and a short cable.

One end goes to the battery, the other to one of the solenoid mounting

screws. The PDWA still gets its ground through the firewall deck

from the solenoid. This irks me a little, but I'll get over it.

The body still provides an electrical path for most of the other loads

on the car, but none of them depend on it. It's just a redundant

secondary path now.

Body Plugs

I went through quite a lot of trouble to eliminate the front

bumper on this car, for aesthetic reasons. I've more recently

decided to delete the rear bumpers also, at least for now. I don't

really object to the look of the rear bumpers, but like it a bit better

without them.

Both of these decisions leave some loose ends in the form of unused

mounting holes. Each front wing has a 5/8" hole on its side, near

the headlight. The rear valance has a pair of 1/2" holes under the

tail lights. Since the rear wings are new, and I didn't drill any

holes in them, there are no other holes.

I found these little plastic blanking caps. They snap into holes

of the appropriate size, and have a very low exposed profile.

Looks more finished to me. From any distance they aren't noticeable at all.

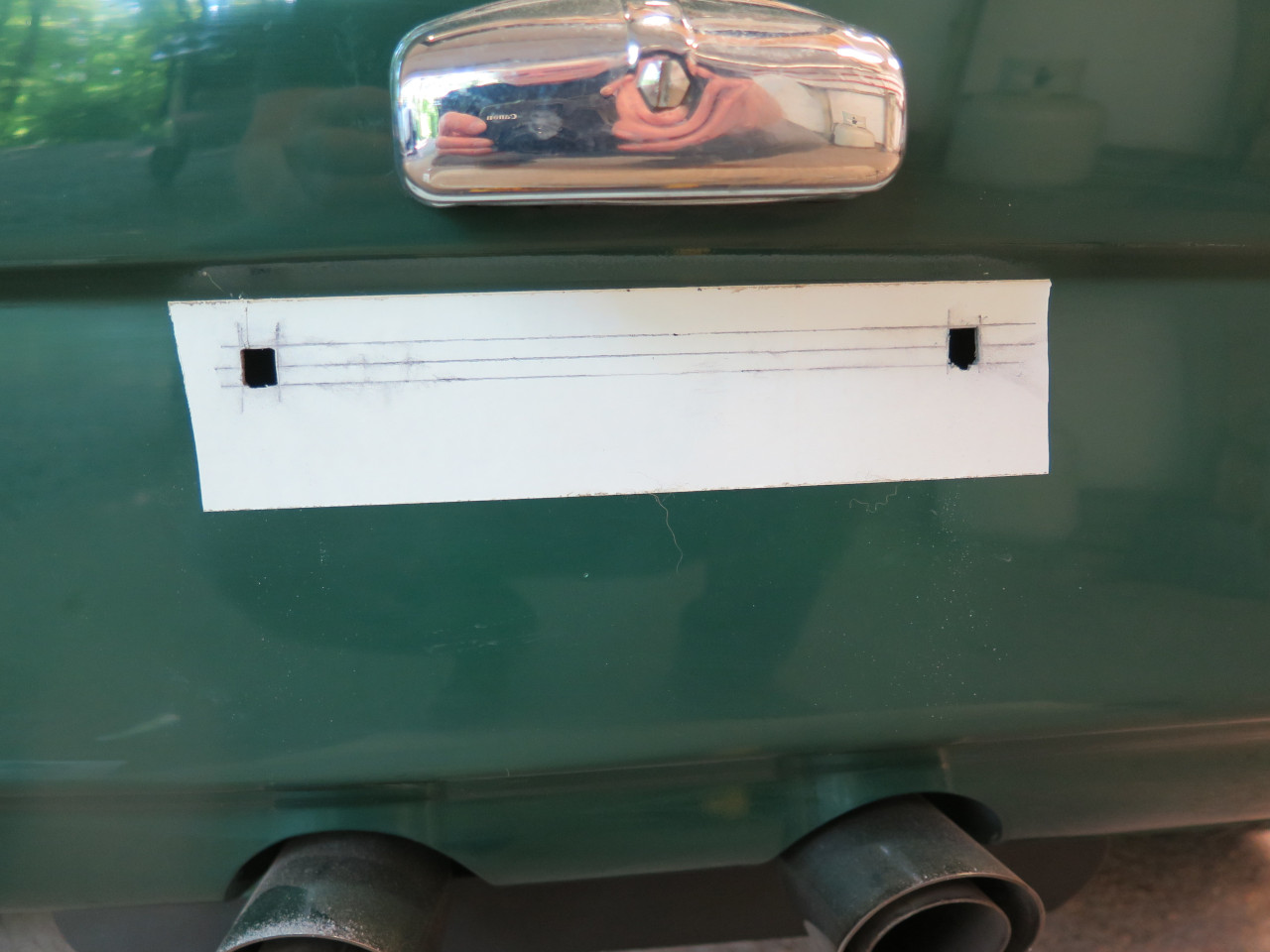

License Plate

It's always seemed funny to me that, knowing that probably 90% of these

cars were going to the US, the designers still designed the rear valance

to take a European shaped license plate. Mounting a US plate on

that long rectangular space looks awkward and mismatched. But we

have to do it anyway.

I wanted to install some of these plastic license plate nuts. They

won't weld themselves to the mounting screws with corrosion, and if

they get buggered up, they can be easily replaced.

The problem is, they take a rectangular hole. I marked out the

position and size of the holes. Notice how one of the original

(from the dealer, maybe?) plate holes is nearly 1/4" lower than the

other one. Luckily, my new holes will correct that.

The nuts slide in. it's actually the screws that expand them for a snug fit.

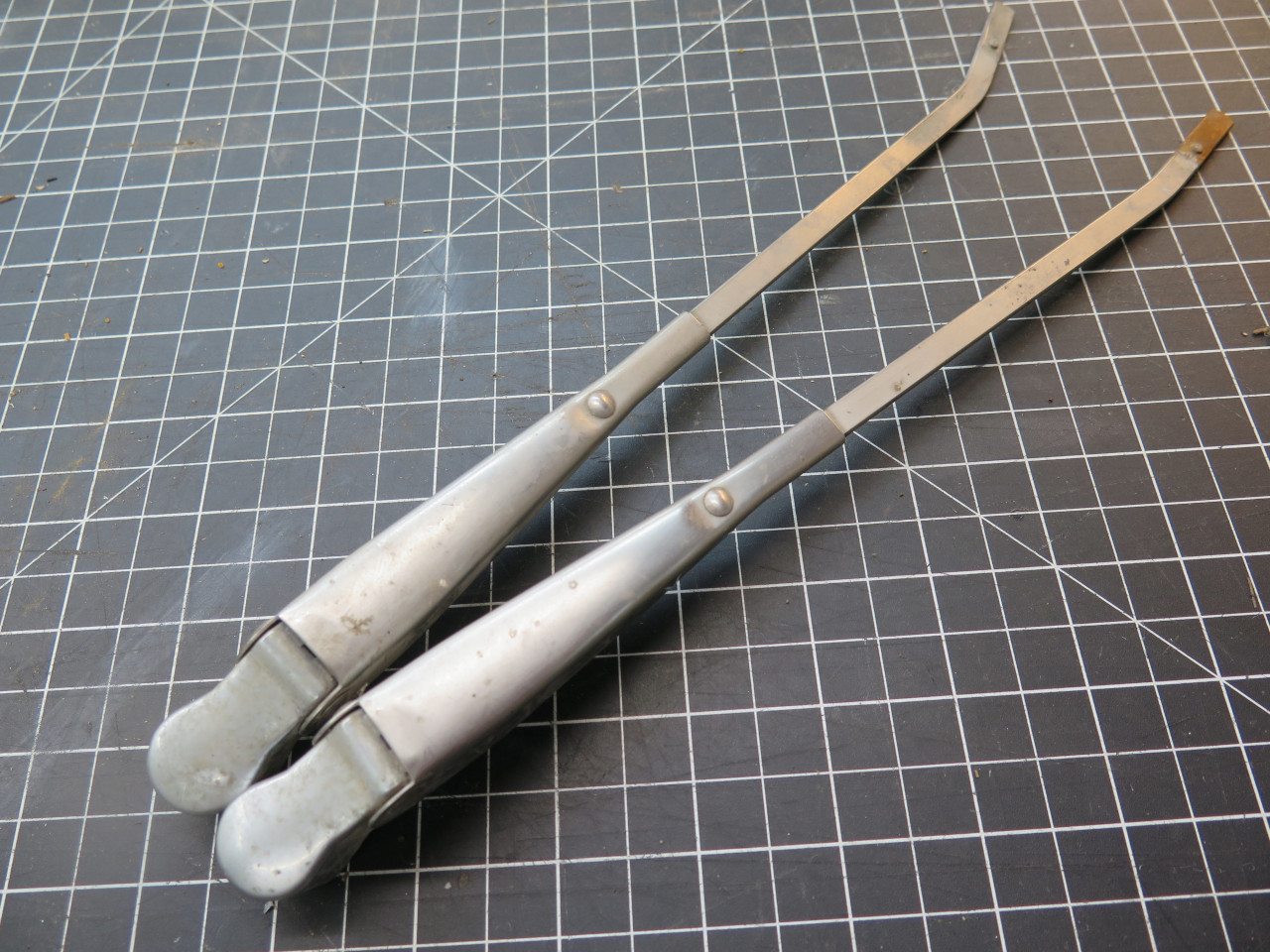

Wiper arms

Wiper arms were dirty but in OK shape. The blades were of course, toast.

The arms are stainless steel, and respond well to a little cleaning and polishing.

New blades.

I think this is how they go.

That concludes the current punch list, but I think there will be a few more items that pop up.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages