To my other GT6 pages

January 23, 2023

Sun Visors

A standard fitment in most cars is some sort of adjustable shadowing

device to block bright sun and glare for the driver and front

passenger. These are almost universal in the way they work. A

flap is mounted on an arm fixed at one end above the windshield.

The flap can be stowed up against the headliner, or flipped down to

block sun. The arm can also typically swing outward to block sun

from the side.

Called "sun visors", the ones in the GT6 are totally unremarkable.

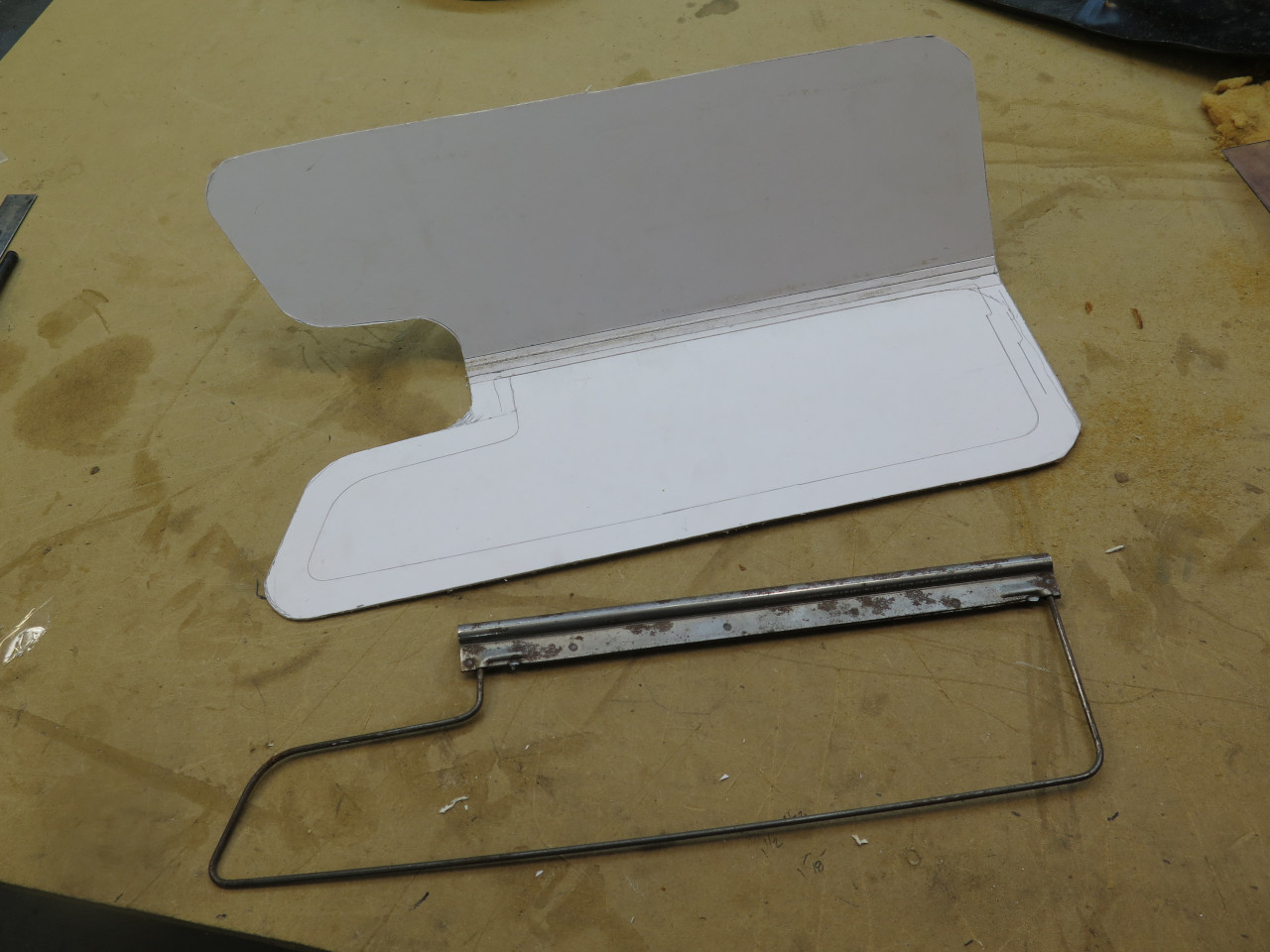

They consist of a light metal framework covered with foam padding and

thin vinyl. Mine were dirty and misshapen, but all there.

Though I could tell that they were once padded, they were now saggy and

crunchy when squeezed. The vinyl appeared to be heat welded around

the perimeter, then trimmed. Cutting one of the visors open

confirmed that the foam was deceased. It turned to crumbs when handled.

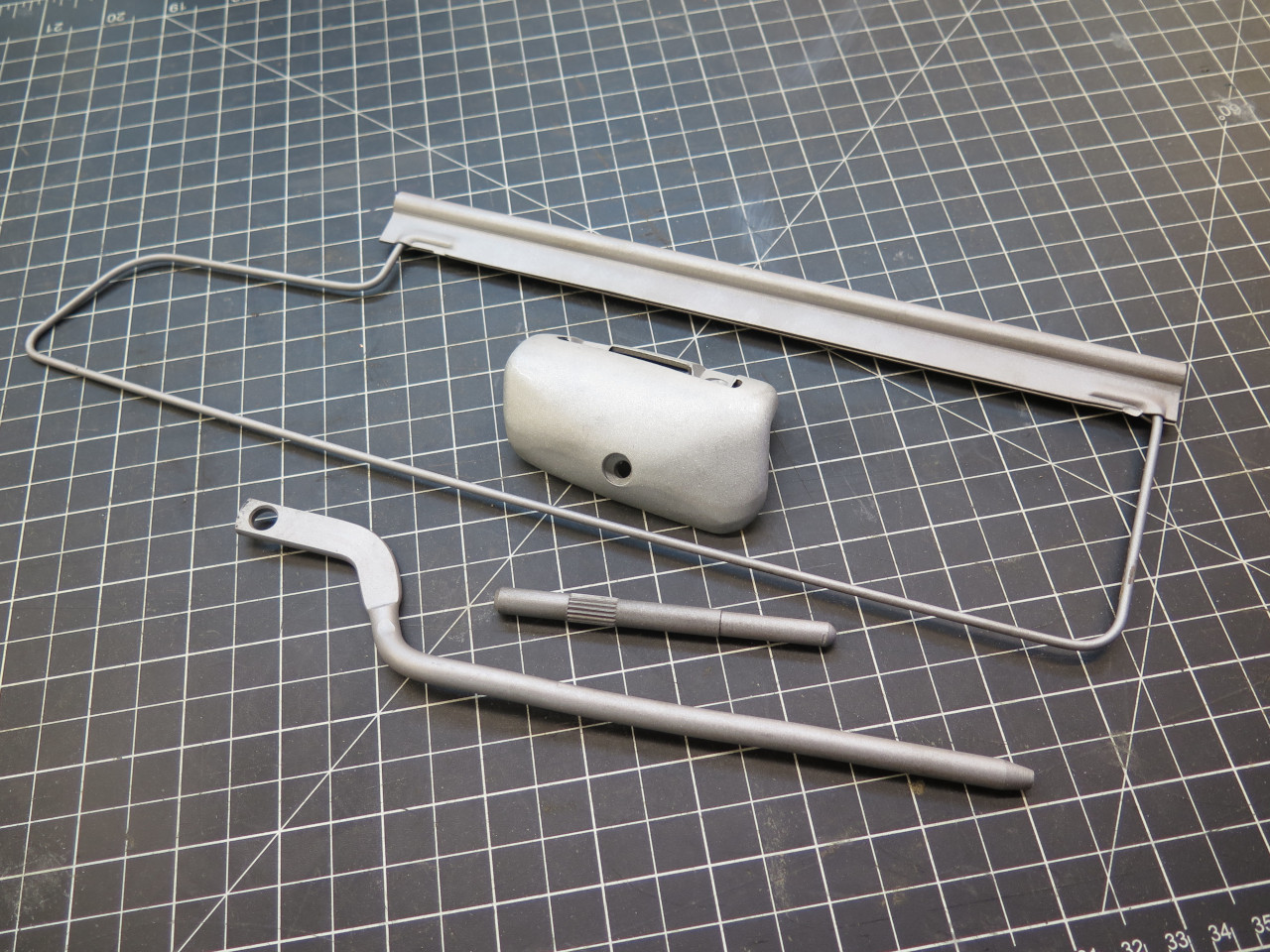

The only real structure inside was a wire frame attached to a metal

tube. It's likely that the construction and materials used in

these devices was influenced by US safety regulations of the time.

More substantial innards might risk slicing off the top of someone's

skull in a front collision.

There was a rod friction fitted into each end of the tube. The

longer rod is the arm that the visor can rotate on. The shorter

rod clips into a little holder on the windshield frame to support the

loose end of the visor.

Now, aftermarket replacements are available for these visors. and they

aren't all that expensive. On the other hand, it seemed to me an

interesting challenge to try to refurbish the ones I had. It fits

the spirit of the overall project, and I didn't have much to lose in

trying.

A little research taught me that modern visors are often have more of a

clamshell construction, and this seemed like a better DIY

approach. In keeping with the use of relatively weak, collapsible

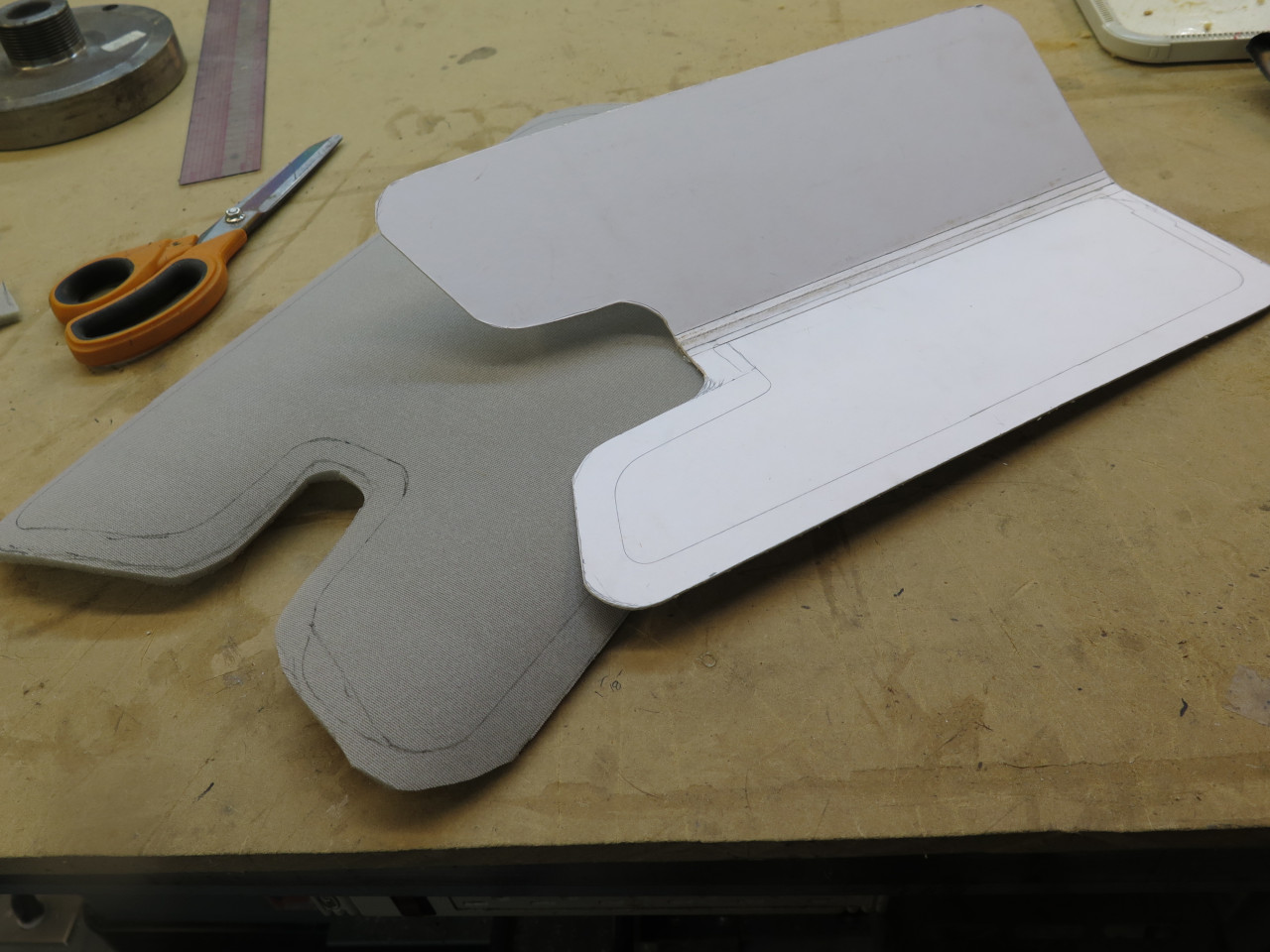

materials, I decided to try some card stock for the body of the

visor. This is basically poster board, about 1 millimeter

thick. It was cut to match the shape and size of the original

units. It is designed to wrap around the original wire frame to

form the clamshell.

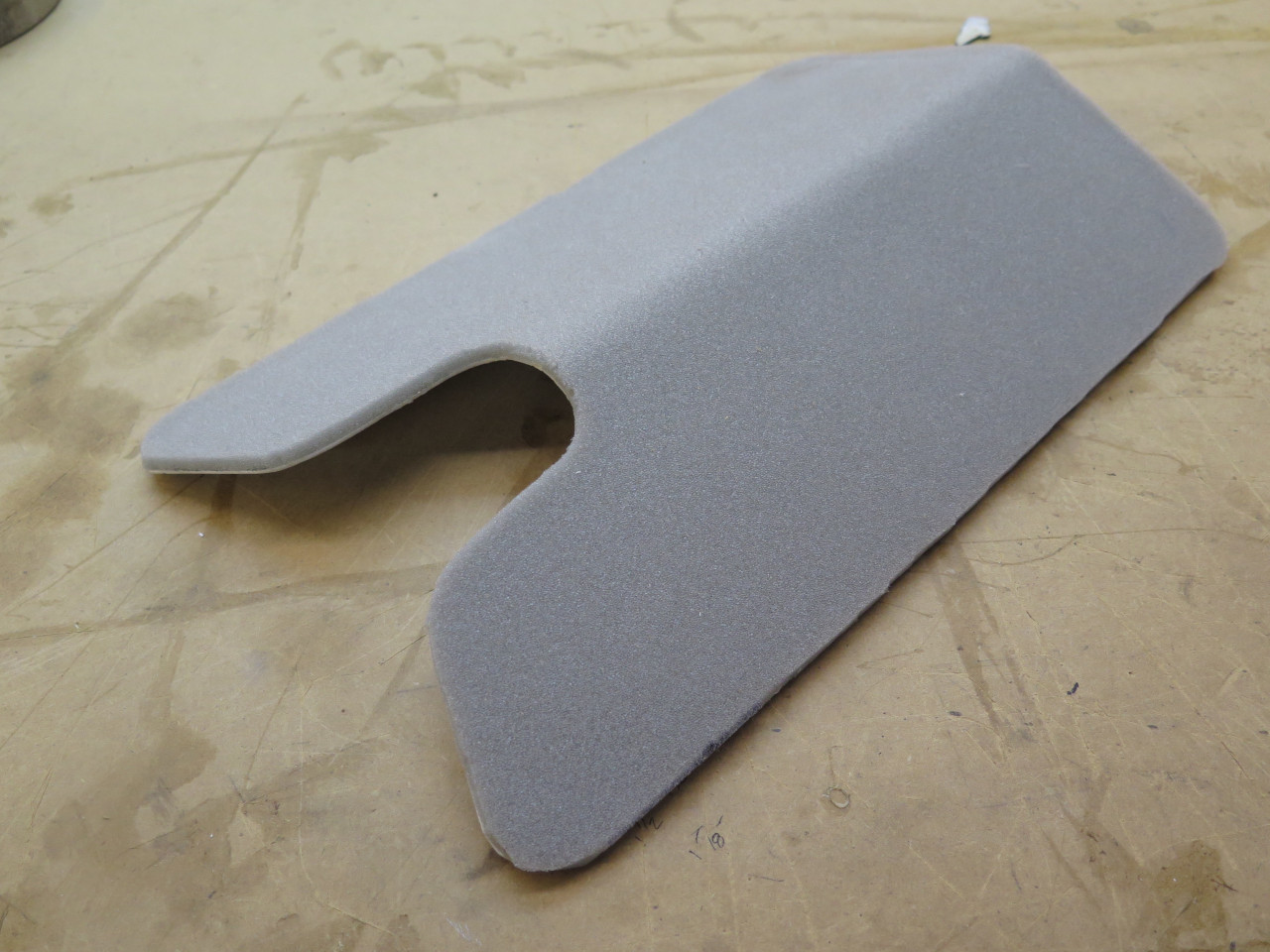

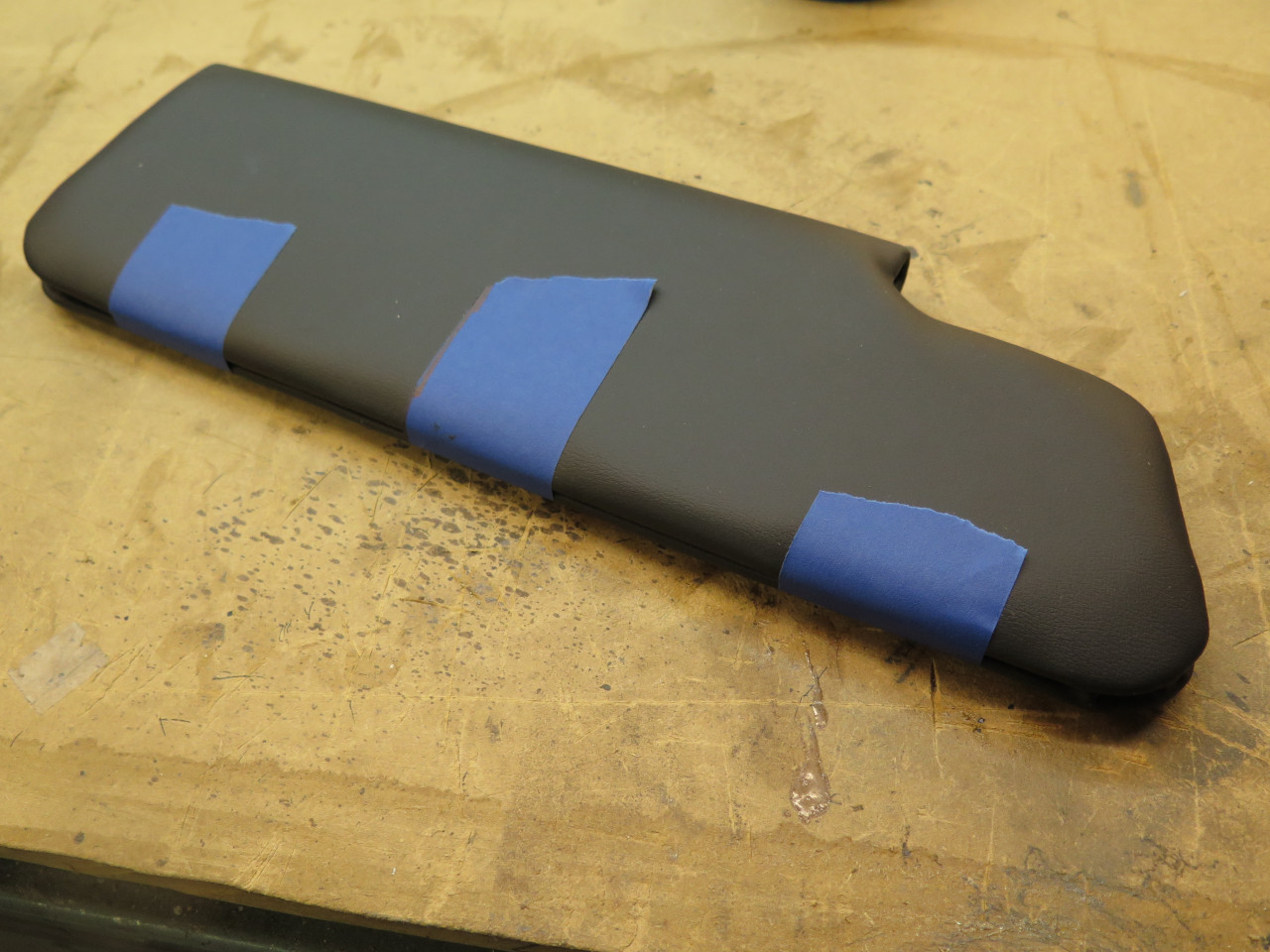

For some bulk and a little plushness, 1/4 inch upholstery foam was then glued to the card stock.

Then the assembly was wrapped with some nice black automotive vinyl.

Before I could go any further, I had to get the metal parts ready, first blasting all the paint and rust off.

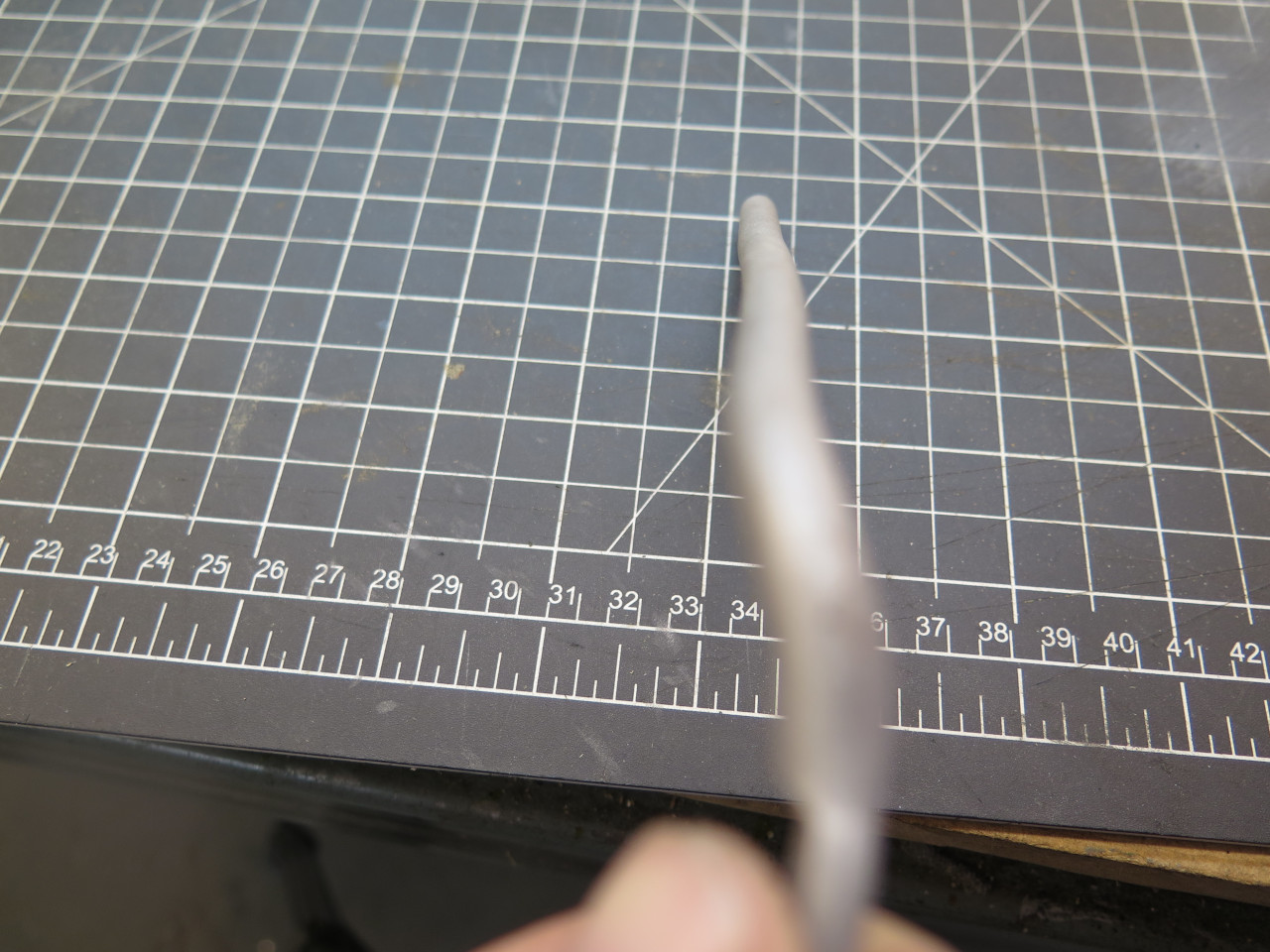

An interesting note is that the stiffness of the visor rotating on the

swing arm rod was accomplished by distorting the rod slightly so that it

binds in the metal tube by just the right amount. The rods on

both visors have identical kinks.

Then a nice powder coat.

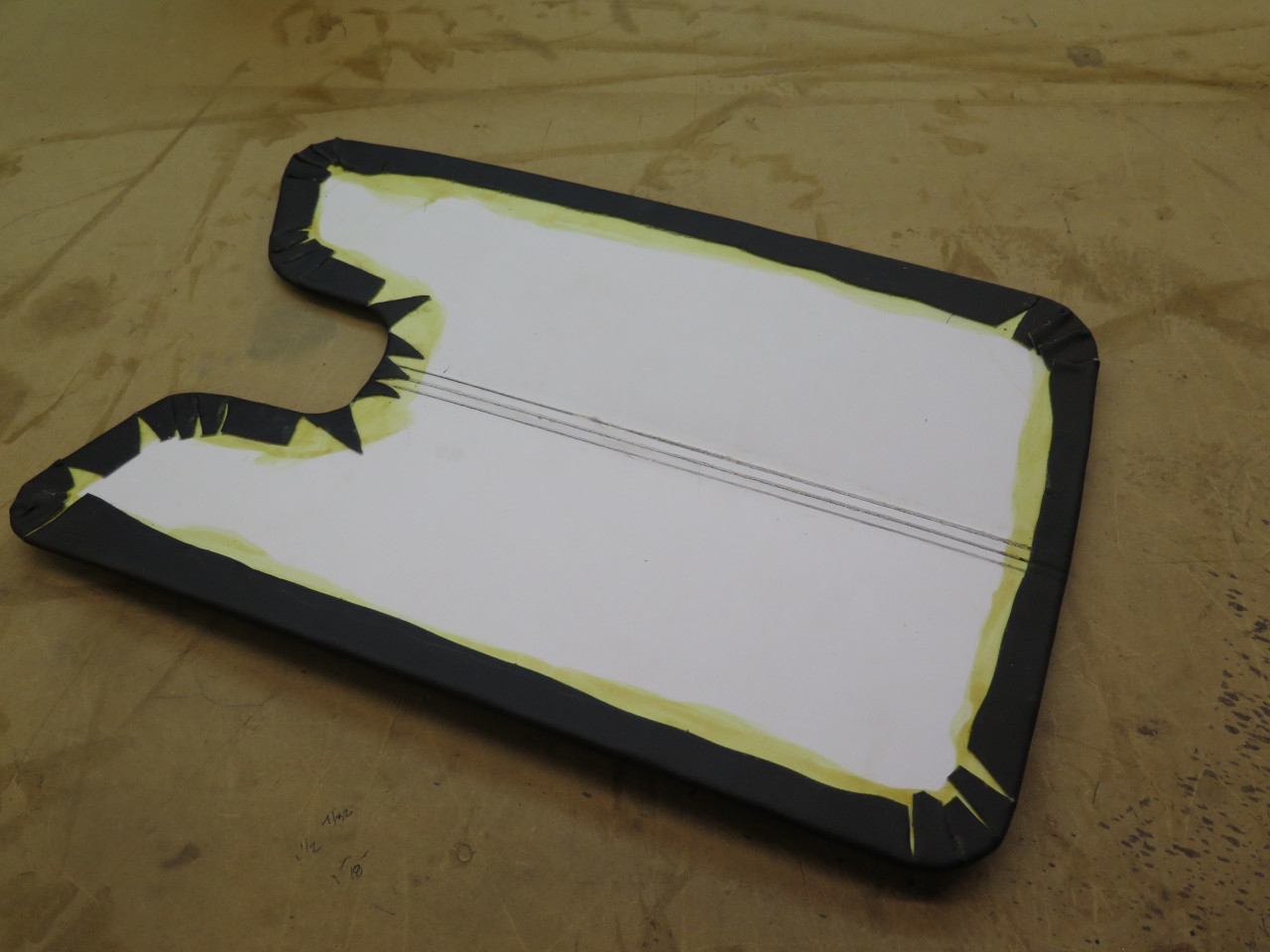

The wire frame is positioned and taped in place.

Then the clamshell is folded closed.

After some thought, I decided I wasn't really that fond of the blue

tape, so I considered other ways of securing the clamshell closed.

Some modern visors are sewn shut, so I decided to try that. The

main issue is that at the edges that need to be sewn, the assembly is

around 1/2" thick, and my sewing machine didn't like that one bit.

It moaned and groaned about it, but it did manage to sew the

seam. The stitching is not as regular as I'd like, but I'll see if

I can live with it.

Then applied the metal parts.

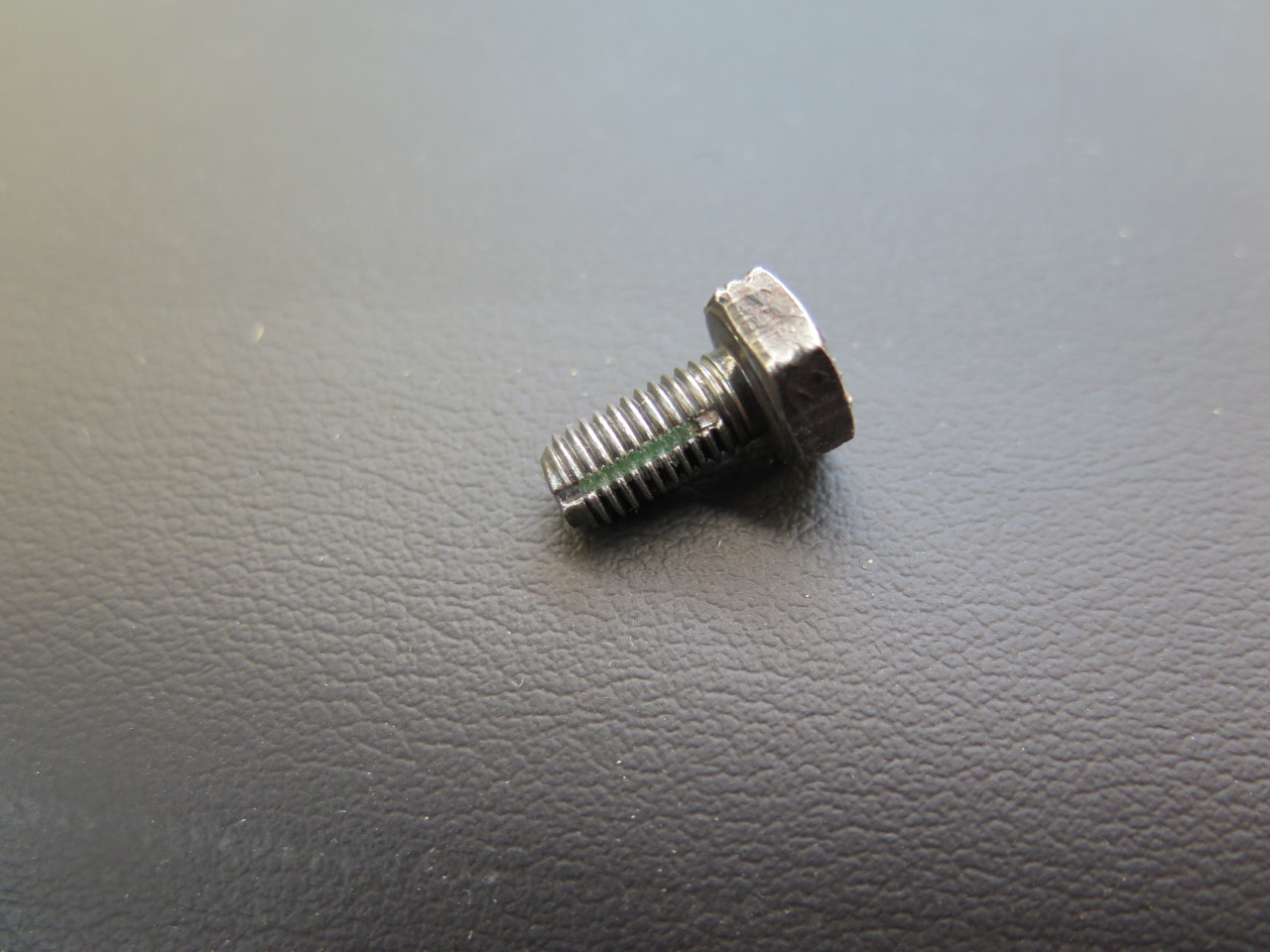

This is the bracket that holds the swing arm to the windshield

frame. One interesting thing is that the bolt that acts as a pivot

is actually a lock bolt. It has a little nylon insert that

distorts to bind the bolt against loosening.

As with most things that come in pairs, I usually do one at a time in case I have to refer back to the untouched one.

The passenger side visor included the obligatory vanity mirror.

The design was problematic though, because the mirror was behind a clear

vinyl window. This made it impossible to clean the actual mirror,

and any crud that got between the mirror and the window was

unreachable. I decided to defy tradition and not include a vanity

mirror.

On the shelf with these dudes.

This was a sort of fun project. It was one of those happy projects

where I had everything on hand, and didn't have to buy anything, so

there was no explicit cost.

I think the visors came out fine, but I'm not totally satisfied with the

stitching. My machine could handle the layers OK, but the

thickness threw off the geometry, and it wasn't feeding

consistently. If it bothers me too much, there are always

the aftermarket ones available.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages