To my other GT6 Pages

September 26, 2019

Rear Suspension

The

rear suspension in this GT6 is of the transverse leaf spring type,

where half of the cross-wise leaf spring forms the upper arm af the

two-arm arrangement on each side. The lower arm, despite its

shape, is not really an A-arm, since the apex of the "A" is at the

frame and not at the vertical link. Since neither the upper nor

the lower arms provide any significant fore/aft bracing, an

adjustable radius arm is included to provide positive location in that

direction.

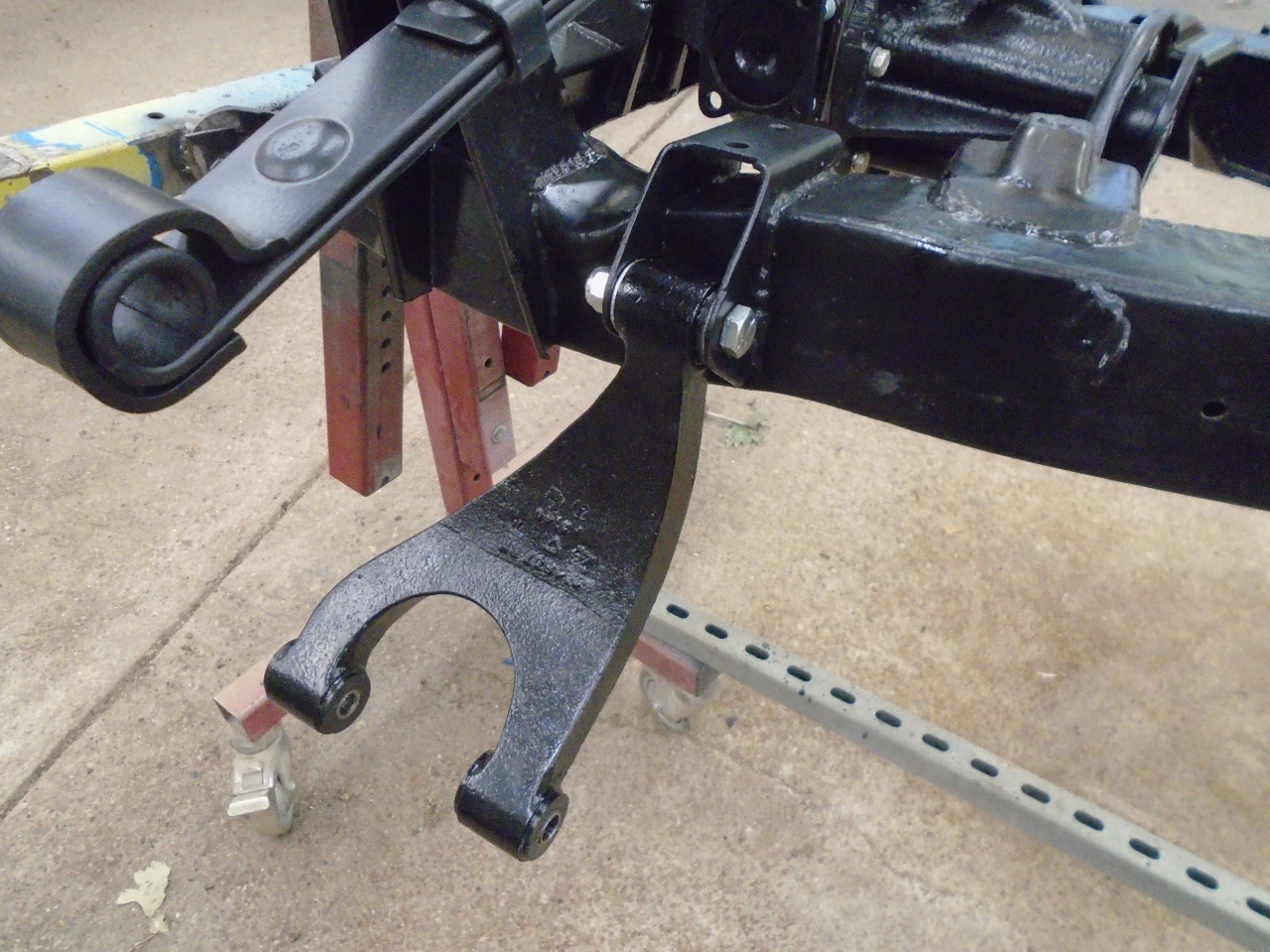

Since my transverse leaf spring

was already installed, I turned to the lower arms. Both of these

had to be cut away from the frame and the vertical links.

Once the remnants of the frozen fasteners and bushes were driven out, the arms cleaned up well...

...and got a nice powder coat.

As

I was ramping up to get the rear suspension parts actually installed,

there was a small setback. When checking frame mounting brackets,

I noticed this wallowed out mounting hole. I'm not sure how this

got by me when I was prepping or painting the frame. There was

also that hole that shouldn't be there.

So I removed the paint and the upset metal from the area...

...welded it up...

...reshaped the holes...

...and patched the POR15.

Now, where was I? Oh, yes, since the vertical lnks and hubs were already assembled, all that remained was to put everything together.

I hauled out the rear "trunnion" kit I ordered.

I'd

always been a little confused about these trunnion joints. It's

not that I didn't understand how to do them--I've done them a number of

times. It's more that I didn't really get why the complexity

was necessary. If it was to try to keep water out of the joint,

they don't even succeed at that very well. I didn't see why a

simpler polyurethane bushed joint as used elsewhere in the front and

rear suspensions wouldn't work just as well.

I

had decided to look into using simple bushed joints at the

vertical links when I ran across a vendor who apparently had the same

idea. They offered a rear wishbone kit that consisted of six poly

bush assemblies that did both sides of the car, so I ordered it.

Three pieces at each point as opposed to nine.

While

I am happy that a vendor is providing this option, the execution may

still need a little tweaking. The bushes at the vertical link fit

perfectly. The bushes for connection to the frame bracket were

slightly longer, but unfortunately, the internal distance tubes were

not.

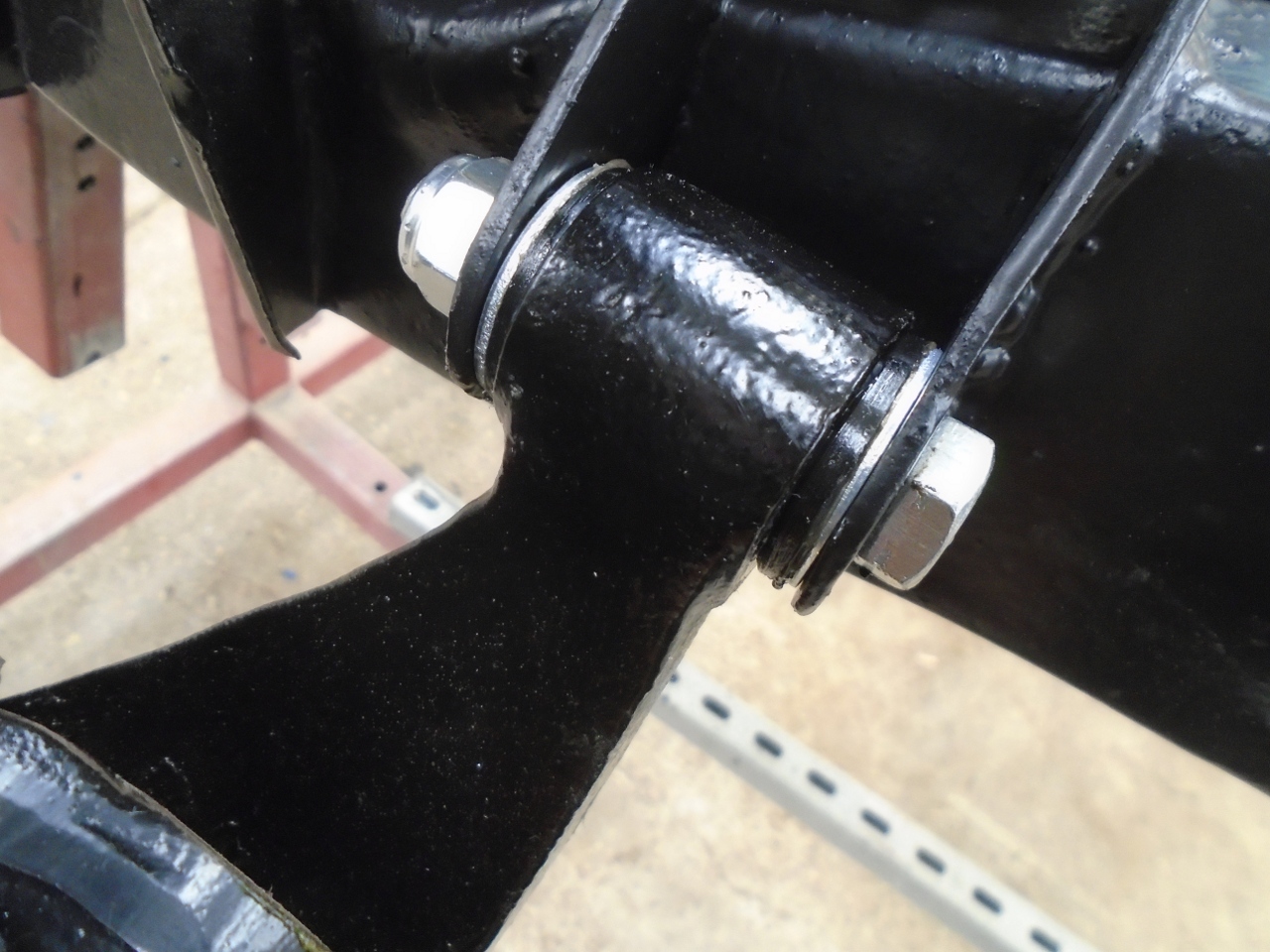

My

understanding of the way these joints work is that the distance tube

should be clamped rigidly in the bracket by the mounting bolt, leaving

a small clearance for the bushes to rotate on the tube. I

considered making new tubes, but in the end, I just trimmed the bushes

a little shorter. This then required a thin washer on either side

of the bush to make up the difference.

The

arms went home fine. The spacer washers are visible. The

arms rotate smoothly, with just the right amount of drag.

In

preparation fot the vertical link, the bushes had to be driven into the

spring eyes. I'm not sure why I didn't get poly bushes for these,

but I didn't. That means I'll have to wait until the suspension

is loaded to tighten the bolts in these bushes.

I

brought the vertical links up from the shop. It seemed easier to

hang the links from the spring eyes first, so that's what I did.

That way the weight of the vertical link assembly was supported

while I fiddled with the trunnion connection.

I

was a little confused by a massive 1/4" gap between the fingers of the

lower arm and the bottom of the vertical link. There was

obviously a part missing. I checked several of the vendors' parts

blowups, and saw nothing. I finally checked some of the pics I

took on disassembly, and saw that there was a pair of thick washers,

one at either end of the bore at the bottom ov the vertical link.

The parts blow-ups don't show them, but I managed to find mine (I

don't throw away anything

until the job is completely done.) They were pretty beat up,

including damage from the saw I had to use to get things apart. I

ended up making the washers (spacers, actually) that actually fit better than the originals.

Here is the lower connection of the vertical link. The spacer washer is visible.

There

was only one last detail for the suspension. There is a long bolt

that goes through the vertical link that holds the lower end of the

damper on one end, and a bracket for the radius arm on the other.

That bolt was frozen in both of my vertical links, and had to be

drilled out. On both sides, I was able to save most of the radius

arm bracket. The original bolts were actually welded to the

brackets. Here are the original brackets, new bolts, and

replacement for the pads and strengtheners I had to sacrifice in the

demolition.

The

heads of the bolts get welded to the square pads, the pads welded into

the brackets, and then the strengtheners welded on. Then the

bracket end is powder coated.

Since

both the radius arms and the dampers connect to the body, they have to

wait, and these assemblies have nothing to do right now. But I'll

put them in place so they don't walk off. I don't think anyone sells these.

The

frame is nearly to the point where I can put the wheels on and get it

off the rotisserie. Putting the axles in will be easier with the

chassis on the ground.

I

had read warnings about how difficult this part of the project might

be. I'll have to say, I didn't see it. Actual assembly only

took maybe an hour or less. Cost was just for the bushing kits,

which I effectively bought twice.

Now, on to rear brakes.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 Pages