To my other TR6 pages

October 16, 2017

Windshield

I

hauled the windshield up from the shed a couple of weeks ago and gave

it a good inspection. Beyond being filthy, the rubber parts were

dry and cracked, the chrome trim strip was discolored, and the paint

was tired. The glass, while intact, was hazy with age. Most

of the attachments, like the sun visors and mirror bracket were in sad

shape.

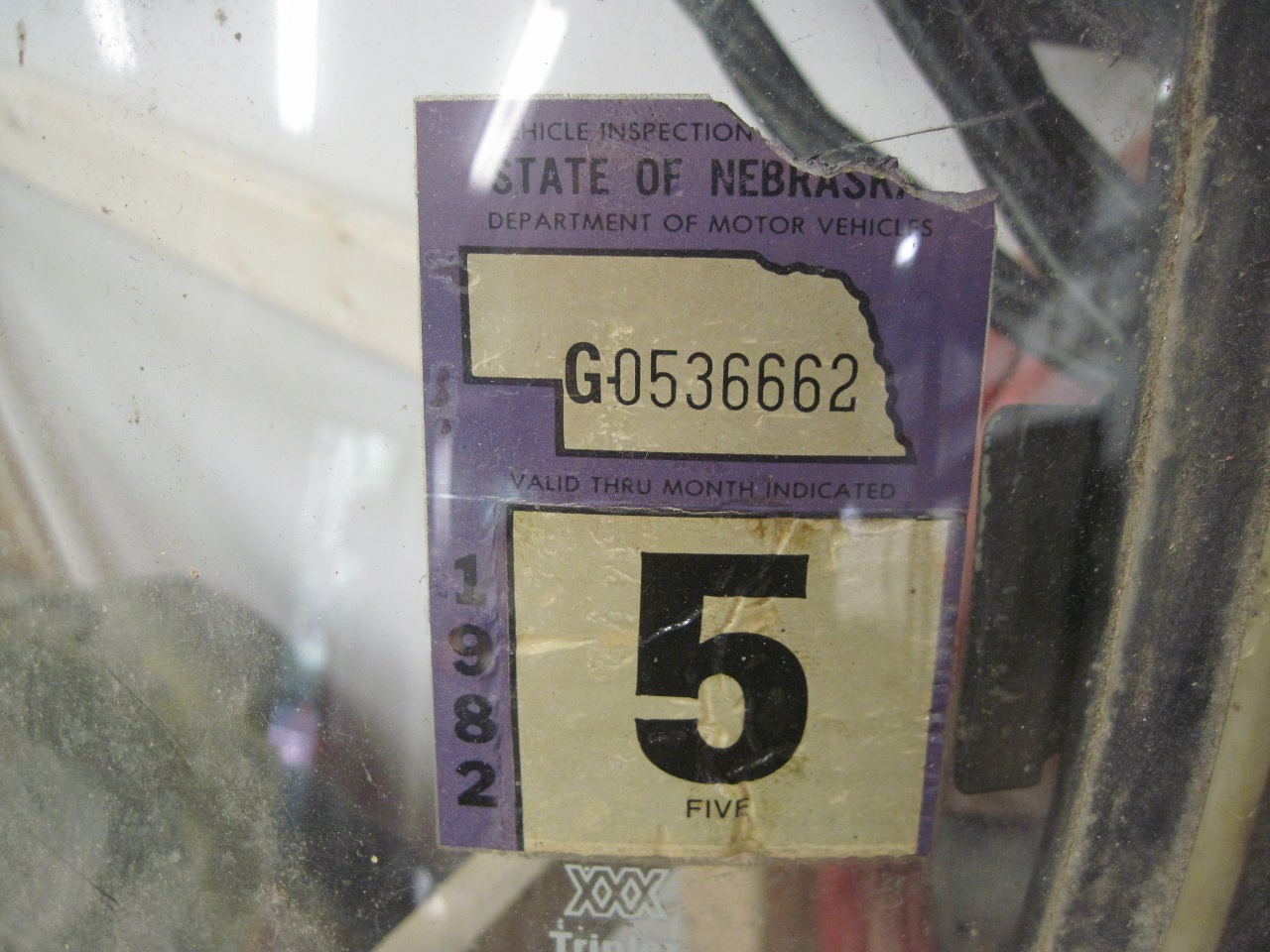

This

is the last time the car was registered or driven--1982! That

means it retired at only 8 years old. I think these cars aged

pretty quickly.

I

stripped everything off the windshield assembly that I could. The

first pic is the visor attachment. The little speed nut thingies

just pop out. Second pic is the windshield to body gasket.

Last pic shows the top of the frame after the aluminum cap was removed.

There was a strip of caulk along the front edge to keep driven

water out.

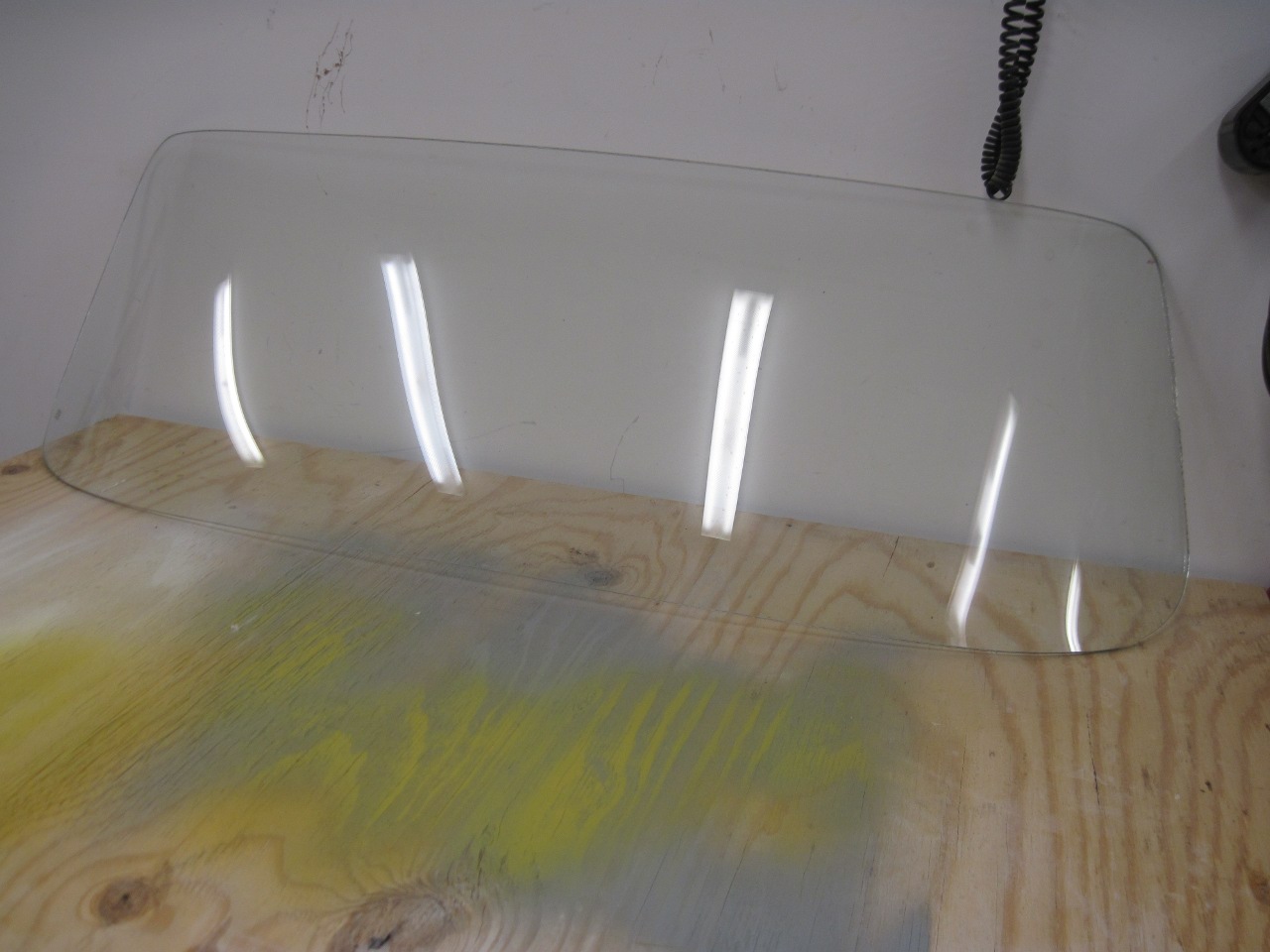

At

last, the glass was removed. There was still a pretty good seal

between the rubber and the glass, so I had to cut the gasket.

With unusual forethought, I rummaged around until I found the windshield mounting brackets.

Then sand blasted the frame and brackets.

Then a couple of coats of two-part epoxy primer, followed by satin black trim paint.

The

inside surfaces of the windshield frame were originally covered with a

grained vinyl material in four overlapping pieces--the bottom, top and

two sides. In my case, the bottom piece came off in a single

piece, but the others were so brittle, they basically came off in

shards.

The

vinyl pieces can be bought as pre-shaped kits, but they seem a little

expensive to me, so I went looking for alternatives. After

cleaning up the intact bottom strip, it looked fine, so I reused it.

It fit perfectly, of course. For the other three pieces I

used a material called "vinyl wrap". It is thin, self

adhesive vinyl material that is very stretchy, especially when warmed

up. It is even used to cover the exterior of entire cars.

The material I bought had a leather-like grain on the surface.

The last pic below shows one of the overlapping joints and

how well the vinyl wrap follows contours.

Next

thing was to mount the frame on the car. Resilient pads were used

between the windshield brackets and the body. I guess you can buy

the pads, but these were home made.

After the frame-to-cowl gasket was fitted to the bottom of the frame, the windshield frame went home.

Beside

the attachment points at the brackets, there are three fixing points

al;ong the top of the cowl. Each one gets a decorative cap and a

black-finished bolt. The black oxide finish on these parts was

tired and faded, so I did a quick powder coat. While not quite as

mechanically durable as black oxide, it should work OK if I am careful

with the wrenching.

I

installed the brass fittings that receive the top cinches, then the

anodized aluminum cap piece with a good bead of 3M strip caulk along

the front edge.

One

thing caught my eye while fussing with the windshield frame on the car.

Seeing that yellow color inside the defrost vent would bug me, so

I blacked it out. Now I feel much better.

At this point, I was ready for new glass.

After one false start involving the wrong glass gasket...

...I finally got the correct gasket installed on the glass.

Then, using the infamous "rope trick", got the glass installed in the frame.

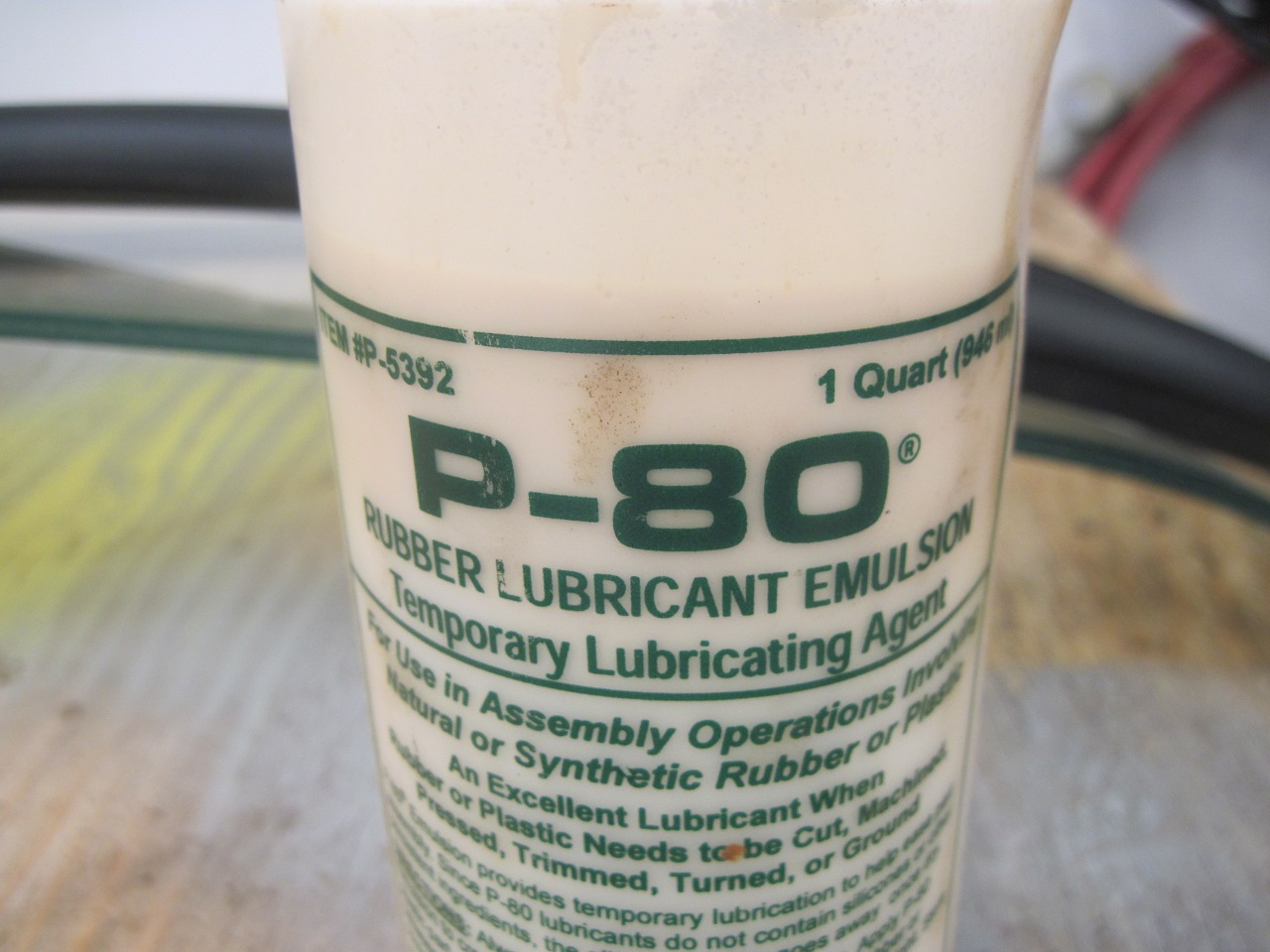

Getting

the gasket to go on the glass and onto the frame is tricky, especially

as a solo act. Some sort of lubricant is a big help. Many

things have been used as a lubricant, but for some reason I had on hand

a true rubber lubricant. It REALLY helped.

Then applied all the various attachments like the rear view mirror and the new trick acrylic sun visors.

The last piece was the commission number tag.

Getting the windshield on really starts to make this car look roadworthy.

I

like projects where I have to learn new skills. I'd never

replaces windshield glass before, nor worked with vinyl wrap.

This wasn't a cheap one. Probably around $250 for the

glass, gaskets and such.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages