To my other TR6 pages

December 21, 2016

Dashboard Pre-Wiring

I

think the wiring on my car was mostly OK, but I had a

few improvements I wanted to make. First, there were some

original devices that I decided to eliminate. For example, the

anti run-on switch, the seat and seat belt sensors, and the ignition

interlock circuits would not be included in the refurbished car.

There were also some new devices--seat heaters, radiator cooling

fan, and some USB power outlets, for example. I also wanted to

re-think the Triumph philosophy of combining many circuits into just

three fuses. One danger of this approach is that with multiple

circuits feeding from one fuse, the fuse's rating must be high enough

to cover all of its loads. I believe it is conceivable that a

partial short in one of the circuits could easily draw enough current

to melt the insulation on its wiring, while still not blowing the fuse.

Further, I wanted to modernize the electrical system by adding

more relays. This would ease the load on dash switches and

eliminate the need for large wires behind the dash.

I also

wanted to improve the grounding on many of the loads on the car.

Using the body as the circuit return path, while common, is not

ideal. Ground joints, many with dissimilar metals and subject to

moisture and corrosion, were a notable weak spot on these cars.

Wherever I could, I wanded to provide explicit copper return

paths from loads to the battery negative.

With these and a few

other enhancements in mind, I decided that rather than trying to modify

the existing harness, it would be easier to just start from scratch.

With it being cold in the garage, I decided to start

with the dash in the shop. I'd like the dash to be electrically

as self-contained as possible. Ideally, I'd like to be able to

remove the entire dash along with most of its wiring by just

disconnecting the speedo and tach cables and the oil capillary, and a

few electrical connectors.

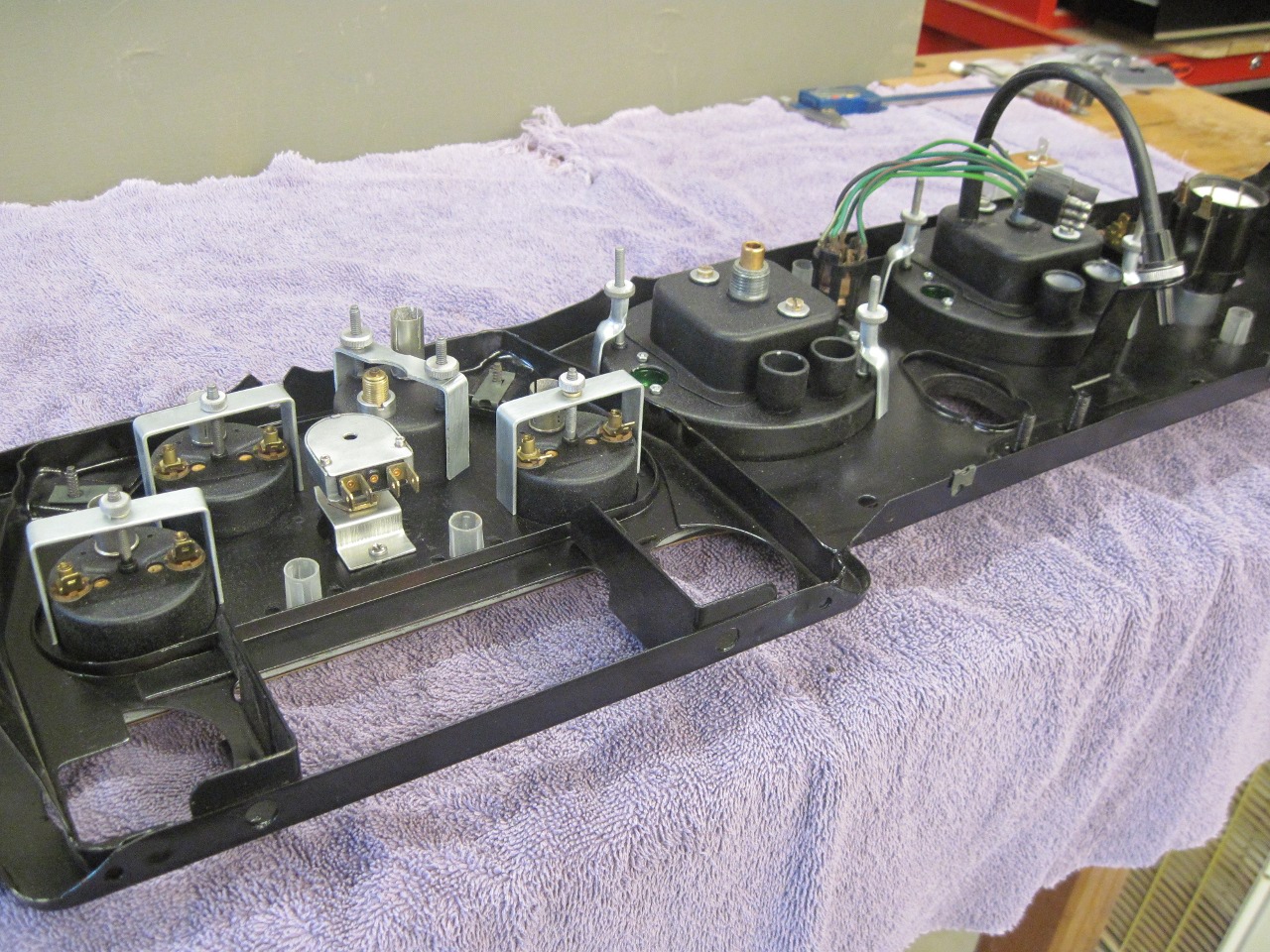

So, first, I populated the dash with

all its gauges, lights and switches, then flipped it over so I could

work easily on the back side.

For

wire, I harvested good wire from the harness. I tried to stick

with the original Triumph color code for the most part, but with many

more fused circuits, this was not always possible. I also took

all of the dash lamp sockets from the harness to determine which ones I

could re-use.

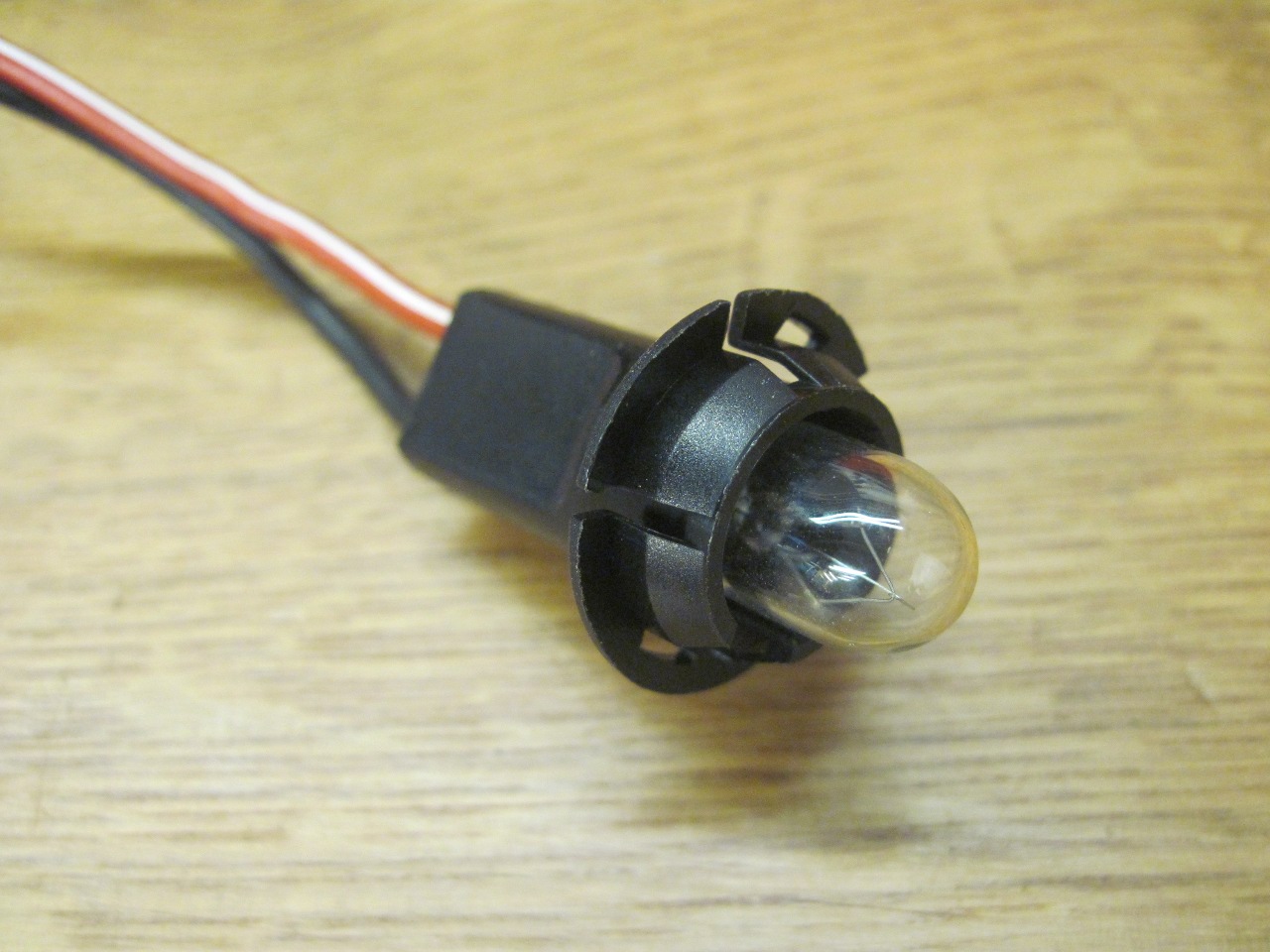

The

speedo and tach illumination lamp sockets were simple one-wire units,

and I didn't see a good way to add a ground wire to them other than

just soldering it to the side of the socket. Rather than do that,

I found these two-wire sockets that snap- fit perfectly into the holes

in the instrument cases. These sockets take modern wedge-base

bulbs of similar wattage to the originals. I also used these

sockets for the oil, ignition, hi-beam, and turn signal lights in the

tach and speedo.

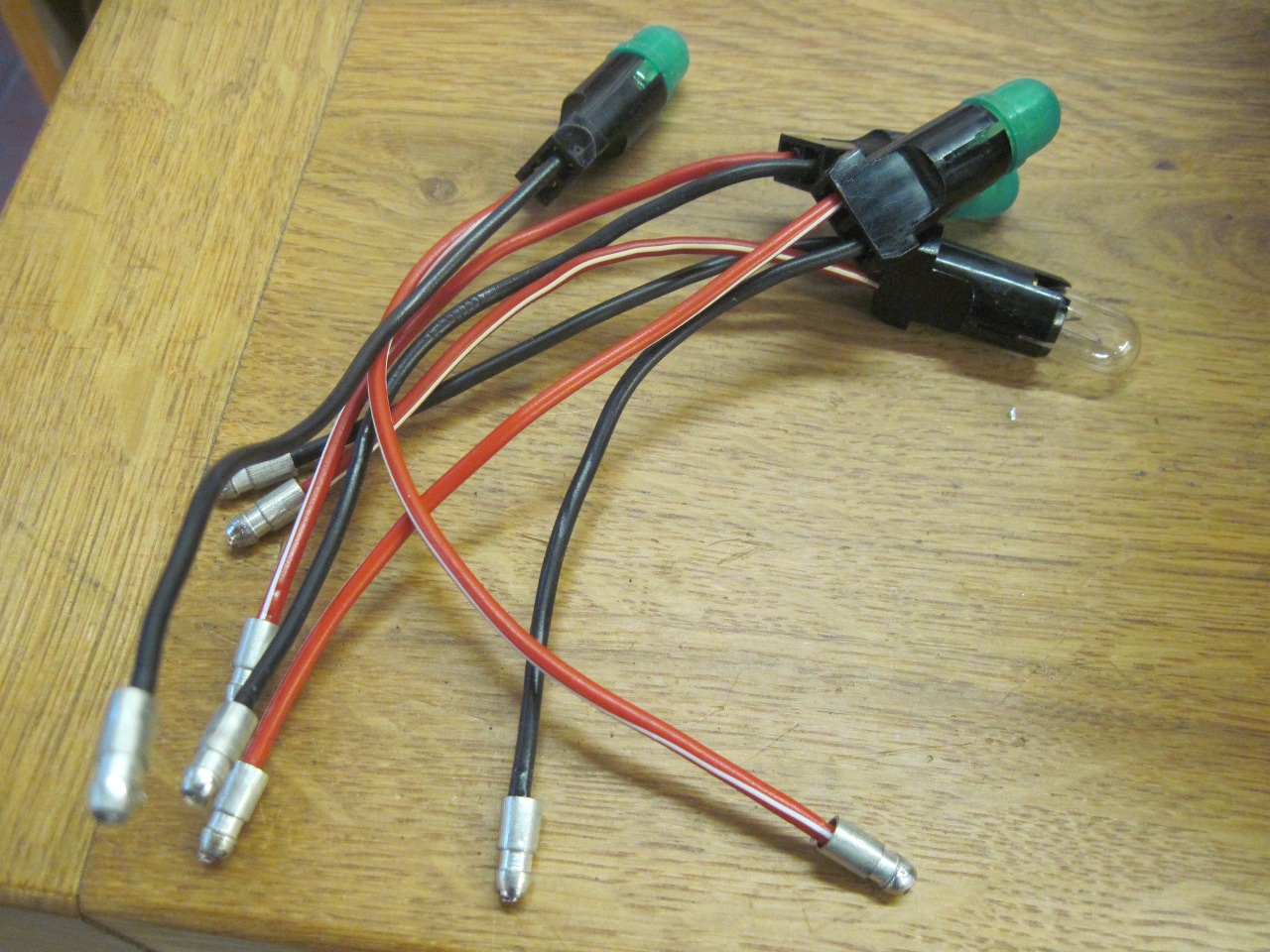

The

illumimation of the smaller gauges used a similar socket that would

slide into the smaller hole, but taker the same bulb. Since none of the internal green

filters in the gauges survived, I used the little green covers.

Red with a white stripe was the correct wire color for the lamps

on the dash dimmer circuit.

For

the wipe/wash and hazard switch marker lights, which also connect to

the dimmer circuit, I was able to clean up and re-use the original

sockets with their small BA7 bulbs.

.

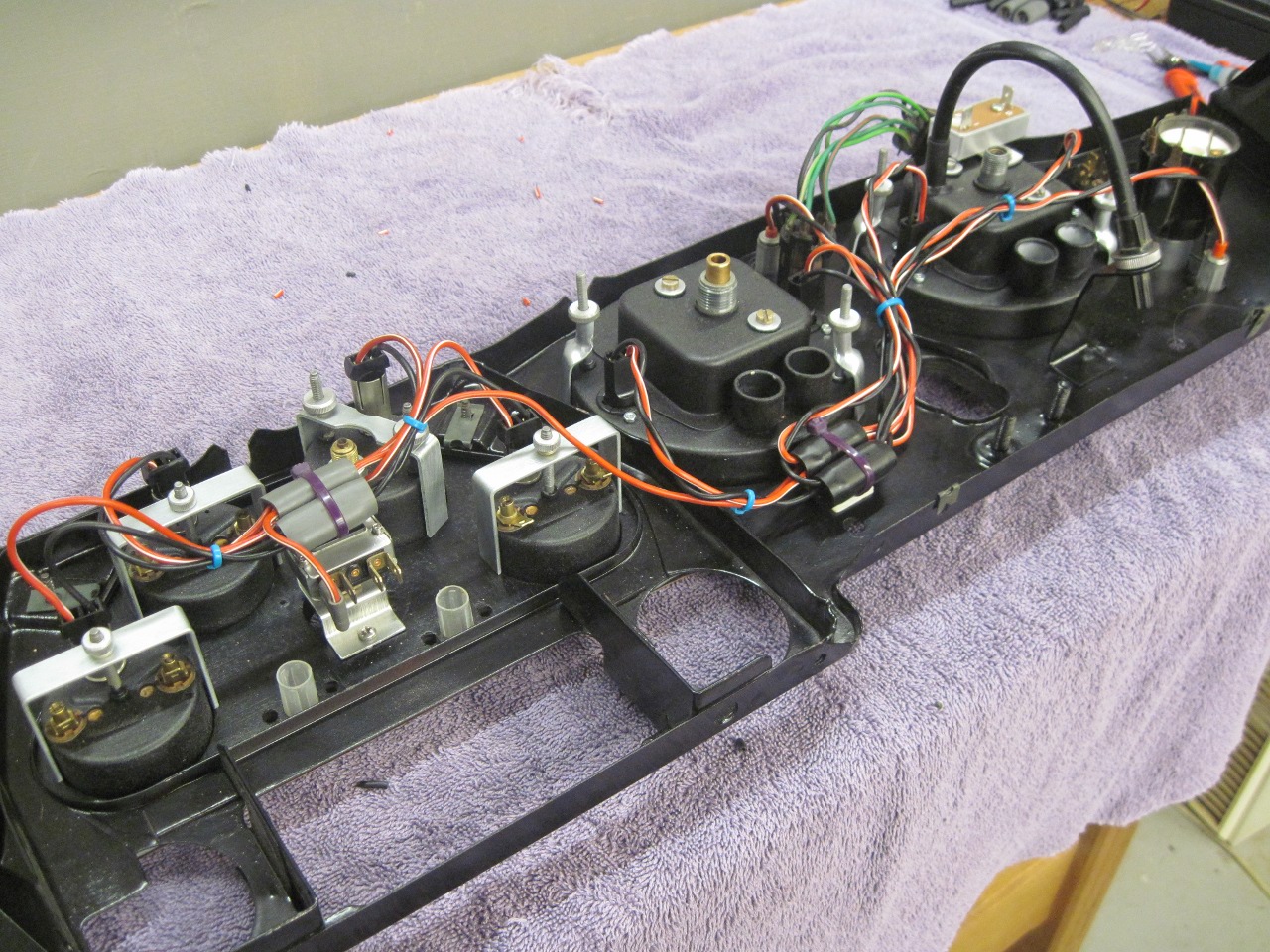

So here is the dash with all the bulbs on the dimmer circuit wired.

Before I went any farther with the wiring, I wanted to find a final place for the new gauge voltage stabilizer. It seemed to make more sense to mount it near the gauges rather than its stock location on the back of the speedo.

Now,

on to some other indicator lights. The BRAKE (PDWA) and the

new PARKING BRAKE warning lights also use the small BA7 sockets, which

I could re-use, but I had to change the wire colors.

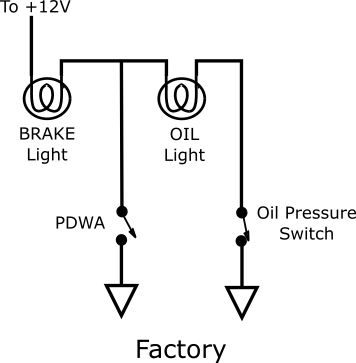

Speaking

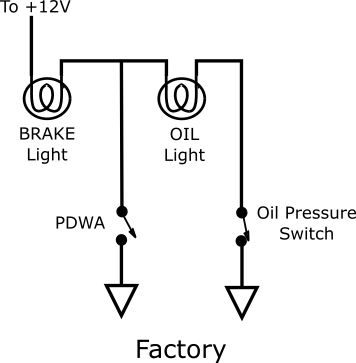

of the PDWA light, this is an area where I (and many others) consider

the wiring design a little funky. The PDWA light and the oil

pressure warning lights were wired such that when the oil pressure

switch was closed (signifying no oil pressure), the two lamps were in

series, so each would light, but dimly. When the PDWA switch was

closed, the BRAKE light would light to full brilliance. This

apparently served as a simple bulb test function on startup with the

ignition switch on, but the car not running.

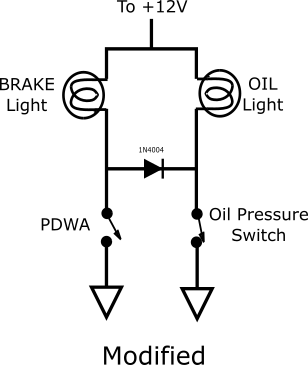

I've seen

some ingenious improvements in this area involving relays, but I just

applied a simple diode mod that allows both lamps to show full

brightness during the lamp test (and also on oil pressure failure).

.

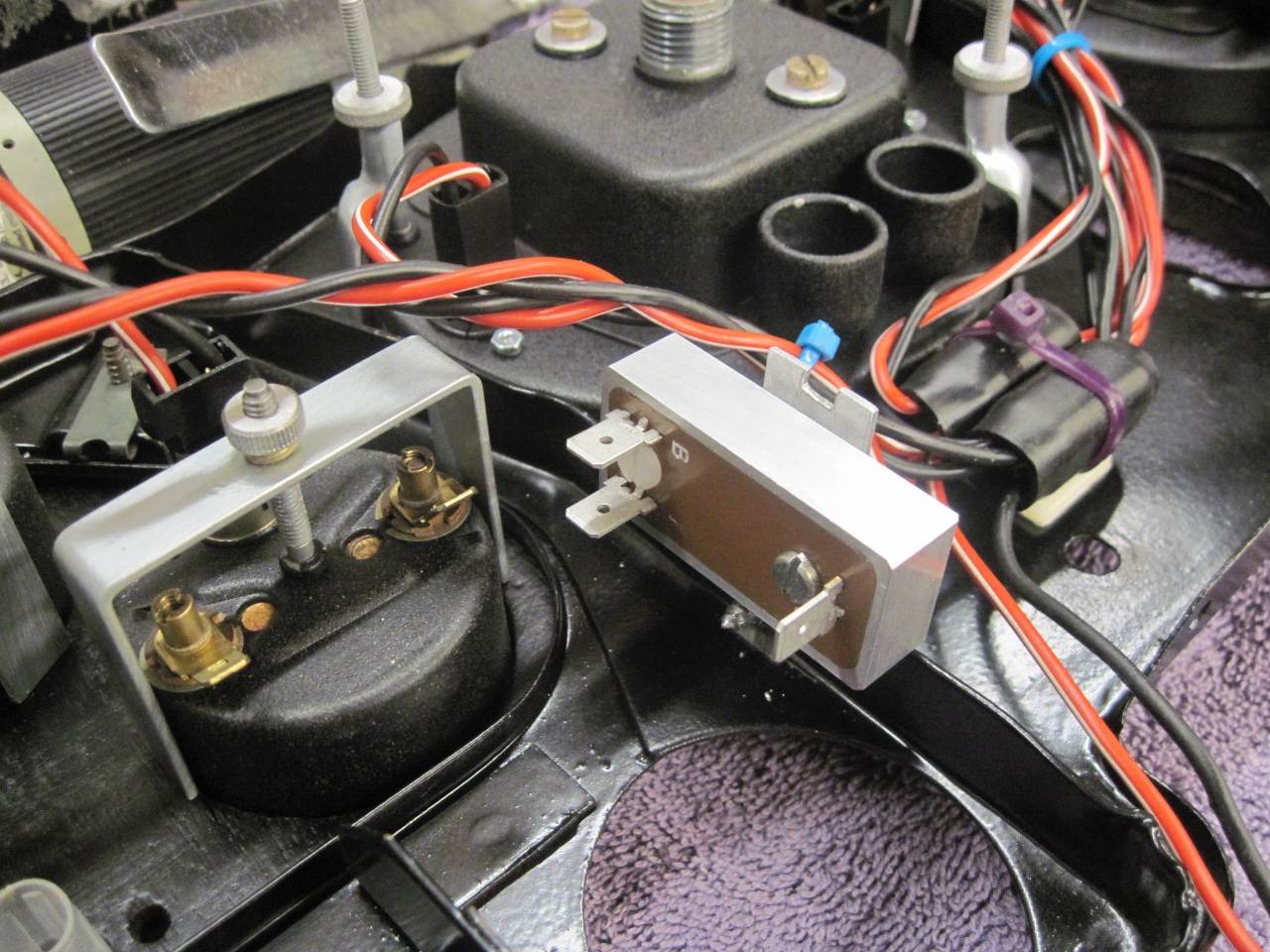

The diode was just soldered to a couple of bullet-terminated wires of appropriate color, and protected by heat shrink.

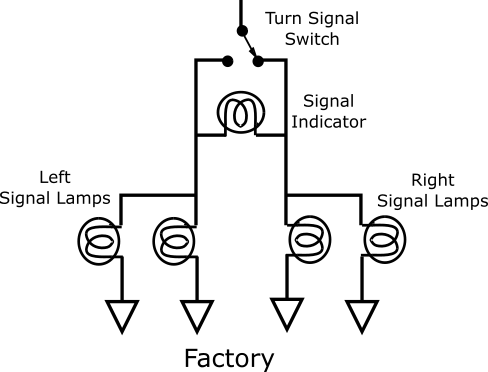

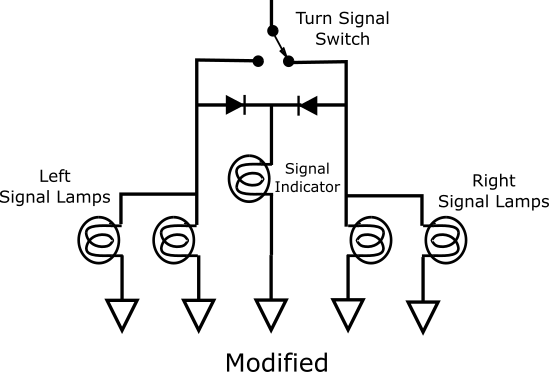

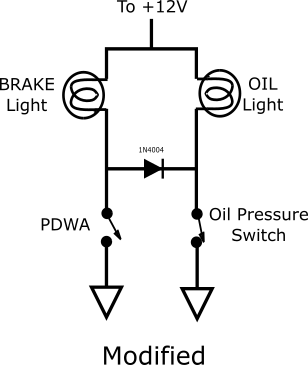

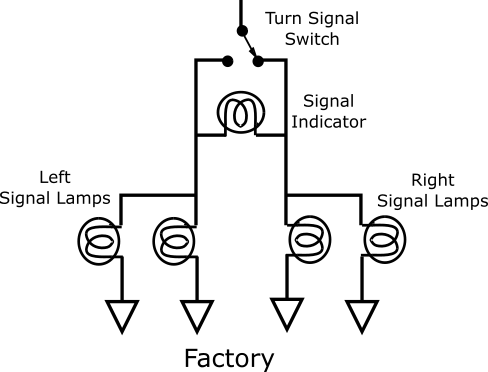

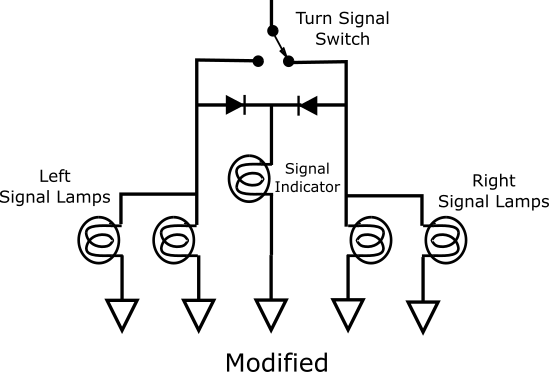

A

couple more diodes were used to modify the operation of the turn signal

indicator lamp on the dash. The factory just wired this lamp

across the two wires going to the outside turn signals. This in

effect puts the indicator in series with the signal lamps that aren't

flashing. Since the indicator is a much lower wattage than the

outside signal bulbs, the currrent that flow is enough to light the

indicator, but not the signals. This works fine for a stock

setup, but with LED lamps for turn signals, it may not. The

modified circuit should work regardless of the type of signal lamps.

The diodes were assembled into a pluggable module.

Incidentally,

having to insert so many of those ubiquitous Lucas bullet connectors

made me look into buying a proper insertion tool. All the ones I

found appeared really cheaply made for their price, so I improvised by

grinding a slot into the jaws of a pair if inexpensive slip-joint

pliers.

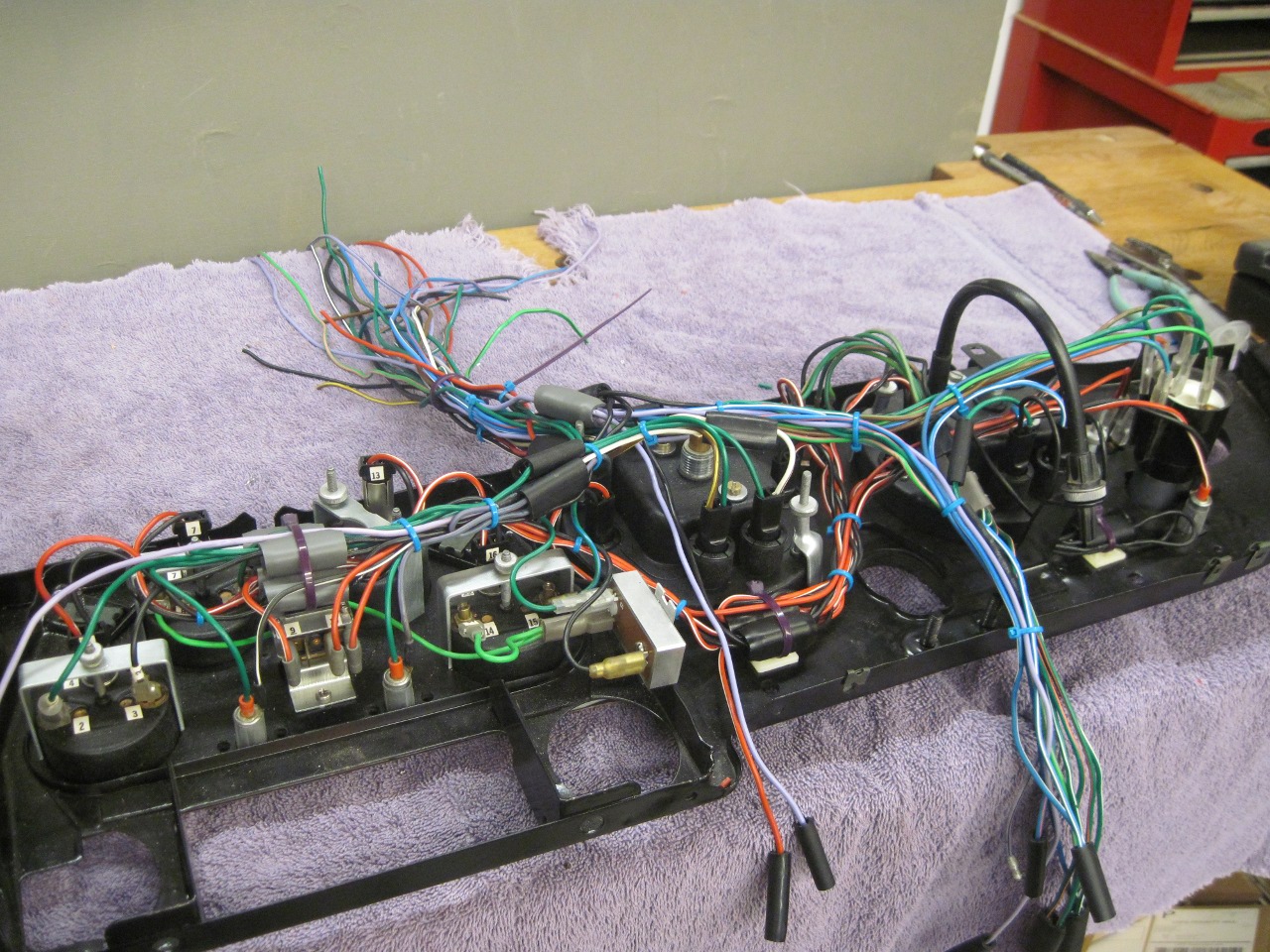

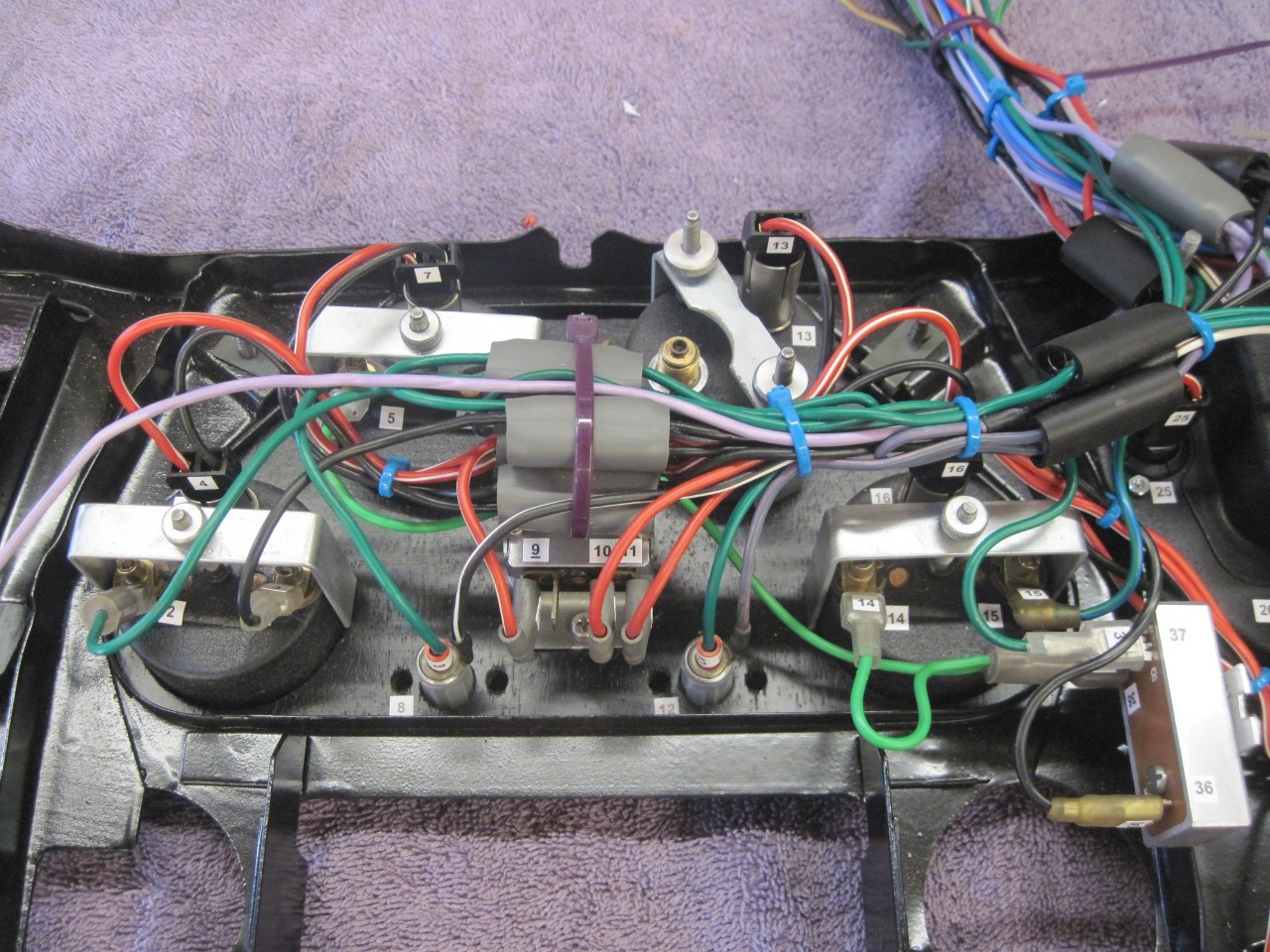

I

then proceeded with the rest of the wiring. The wires trailing

off near the lower right connect to the wires from the steering column

controls. The other two wires coming off the bottom of the dash

are for the plinth light, and for power to the courtesy lights.

The wires coming from the top of the dash go to various other

parts of the car.

To save heartache in the future, I numbered all the connections according to the appropriate facia diagram.

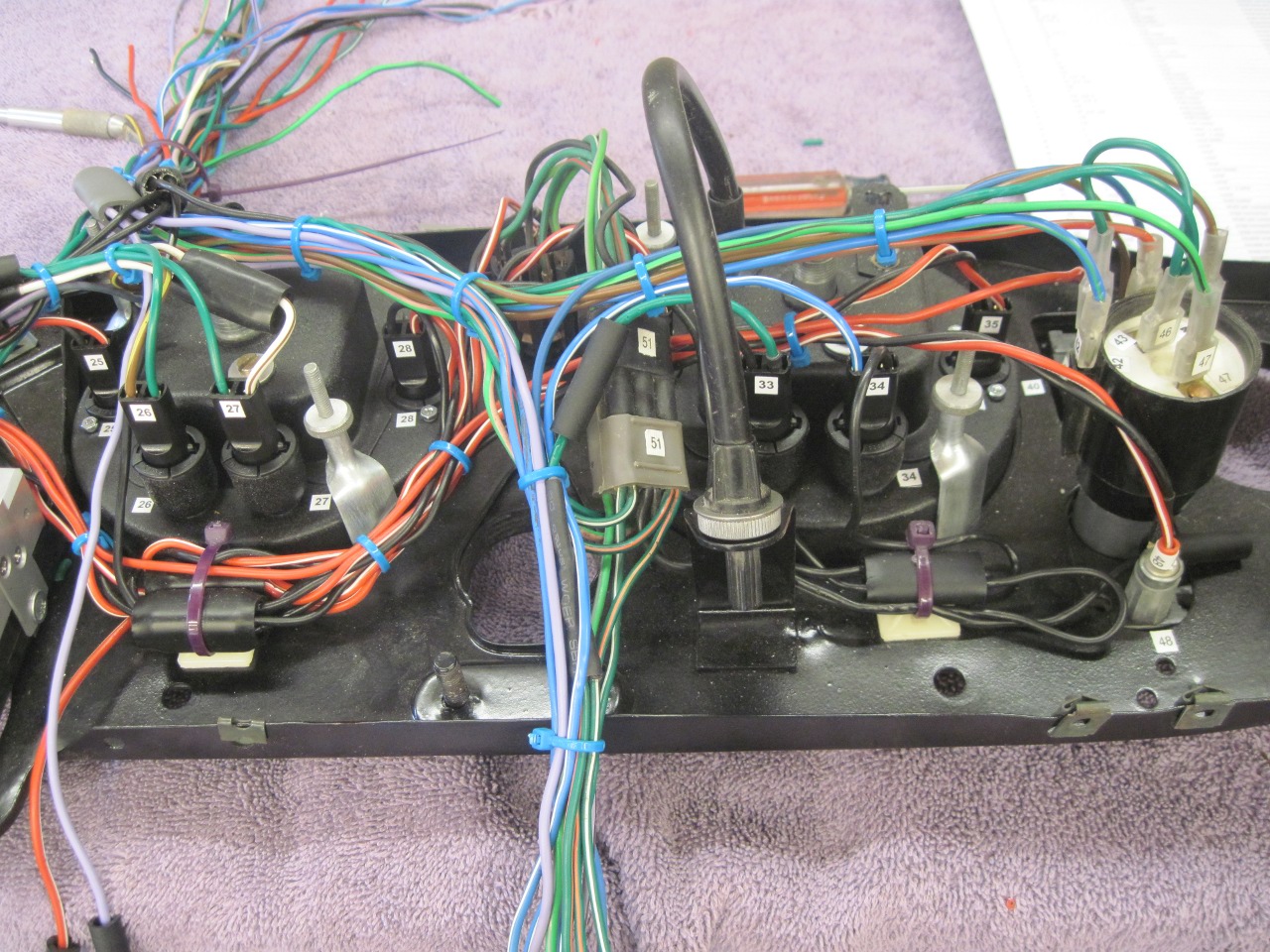

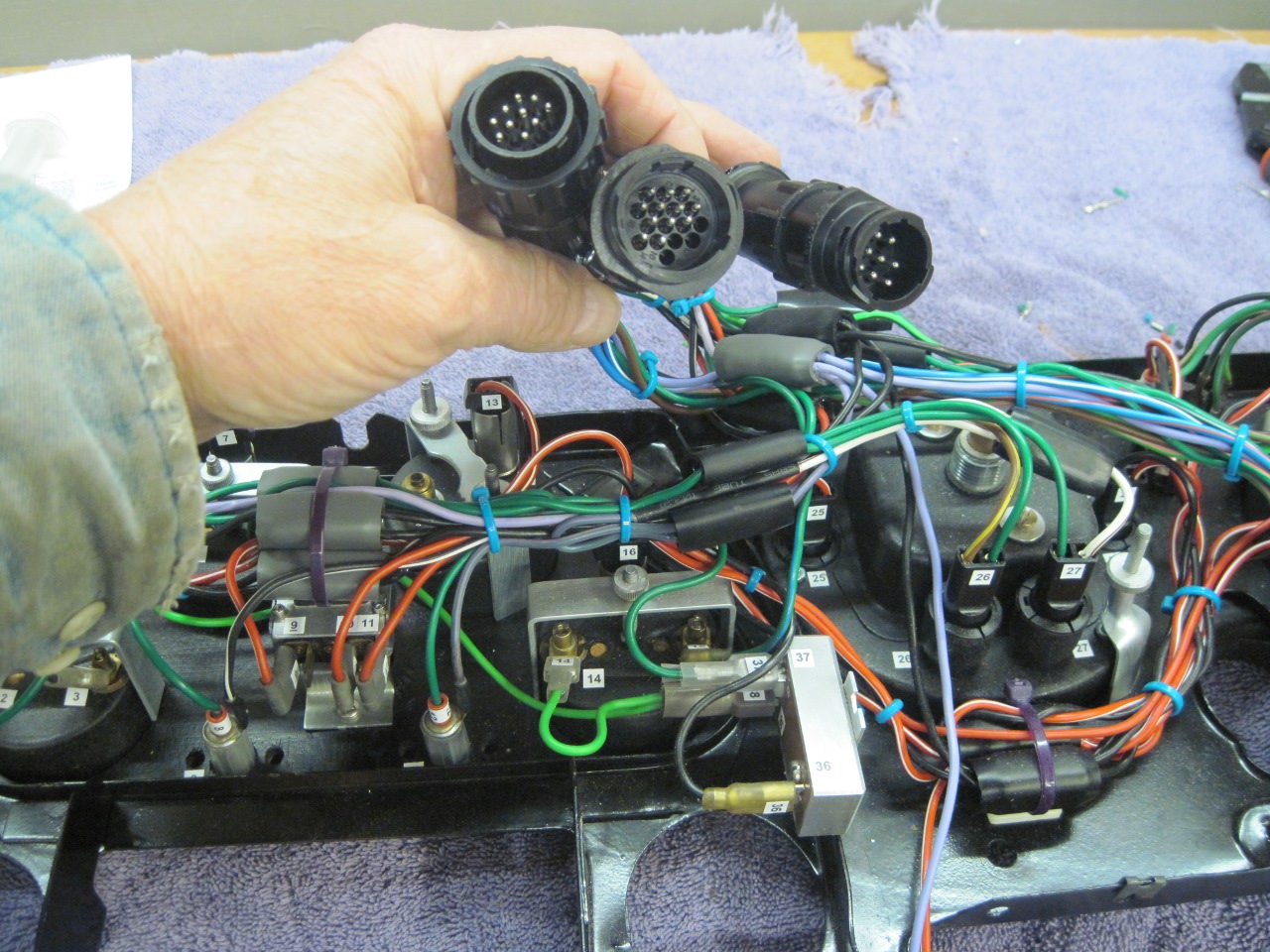

Then

terminated all the wires going elsewhere into three circular

connectors-one each for the cables going to the new power module, the

front of the car, and to the rear of the car.

I'll make up some dummy mating cables for testing, but I need to get busy on the power module first.

This

was by far the task on this car that took the most planning. I

have more hours in working out schematics and cabling diagrams than in

actual wiring. The cost wasn't low, but not too bad. I was

able to use all original switches and instruments, and even wire, but

there were quite a few new lamp sockets and connectors. I

still have the option to go to LEDs for the dash lamps, with a

changeout of the dimmer, but the power savings isn't nearly as

high that for the outside lights, so at this point I'm not seeing

a huge advantage.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages