To my other TR6 pages

January 22, 2014

Voltage Stabilizer

[Click the images for a bigger view]

The

fuel gauge and the coolant temperature gauge on my TR6 are electrical

instruments that respond to the current flowing through them. The

current is controlled by a varying resistance in the appropriate

sensor--the fuel tank float in the case of the fuel gauge, and a

resistive temperature sensor in the coolant stream for the temp gauge.

This arrangement works well, but it depends on a stable voltage

for the gauges to work with. A changing voltage will also vary

the current through the gauges, and affect their readings.

Unfortunately

for the gauges, the system voltage on this and most other cars can vary

pretty widely--from less than 12 volts to nearly 15. For this

reason cars of this vintage have a voltage stabilizer included solely

for use by the electrical gauges. On my TR6, it was mounted on a

bracket on the back of the speedometer.

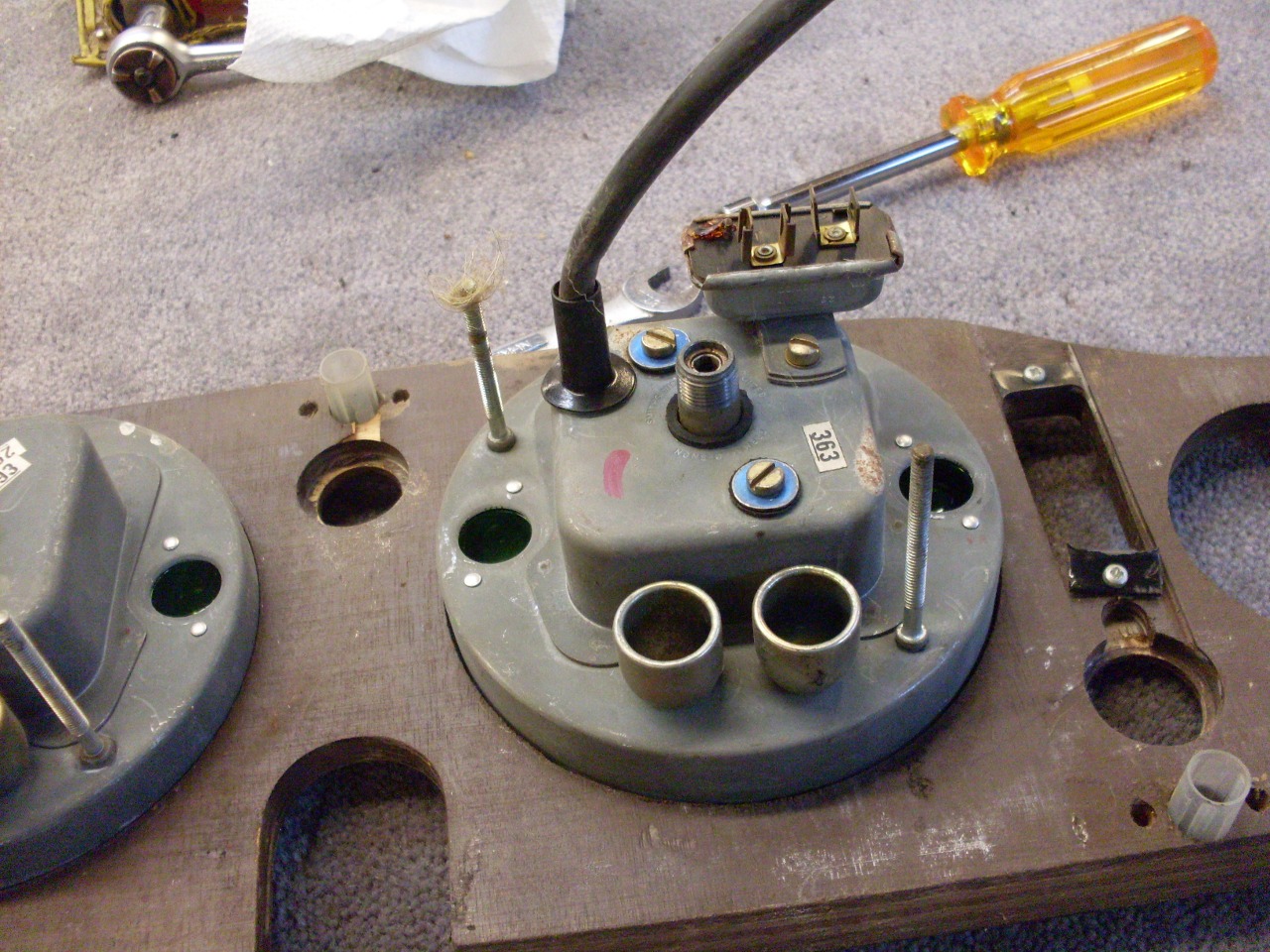

This

stabilizer is a pretty standard type used on many cars for decades

before and after the TR6. It works by putting the input voltage

across a coil of resistance wire wound around a bimetallic spring.

Current through the coil heats the spring, causing it to flex.

The spring moves a contact that disconnects the input voltage

form the coil and also from the output terminal. When

disconnected, the spring cools, eventually to the point where it again

connects the input to the coil and to the output. The result is

that the output alternates between the input voltage (which is the

system voltage) and zero volts. The higher the input voltage, the

faster the spring heats, so the faster the alternation between on and

off.

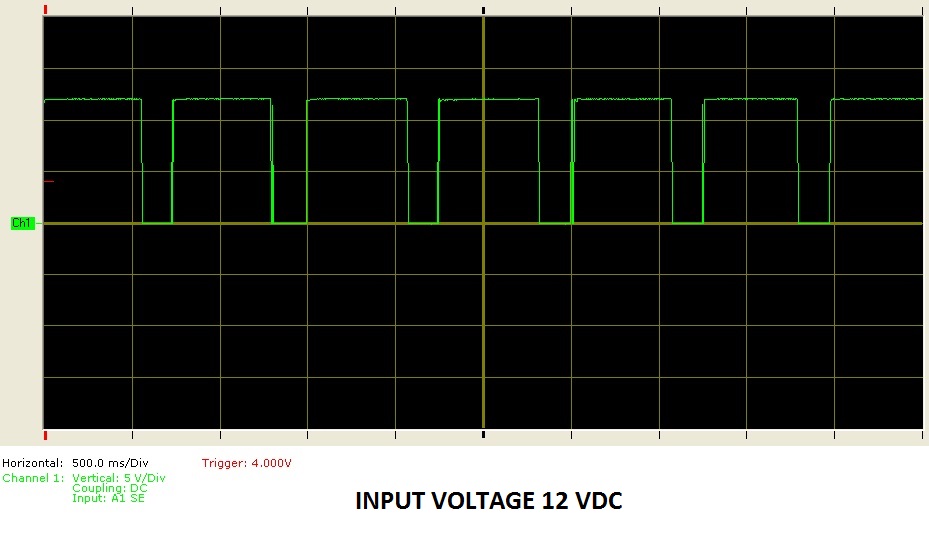

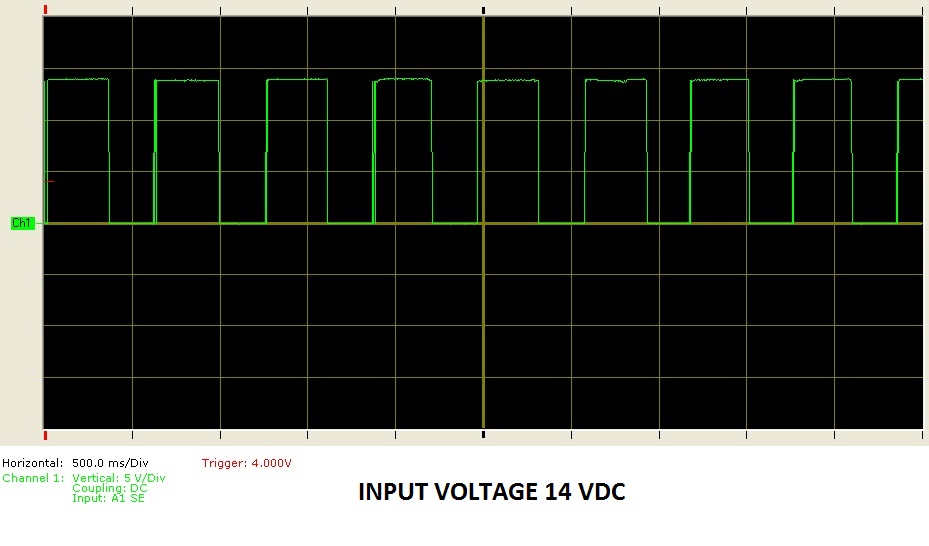

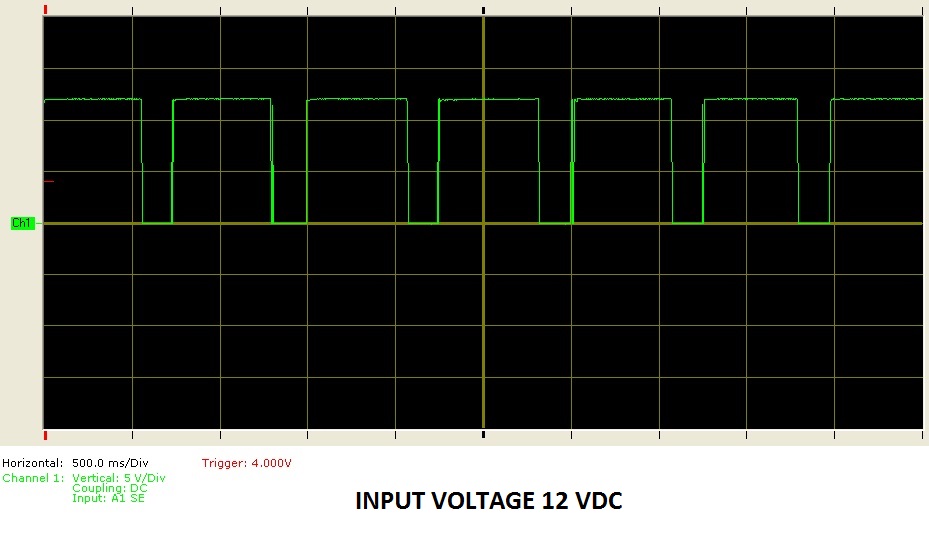

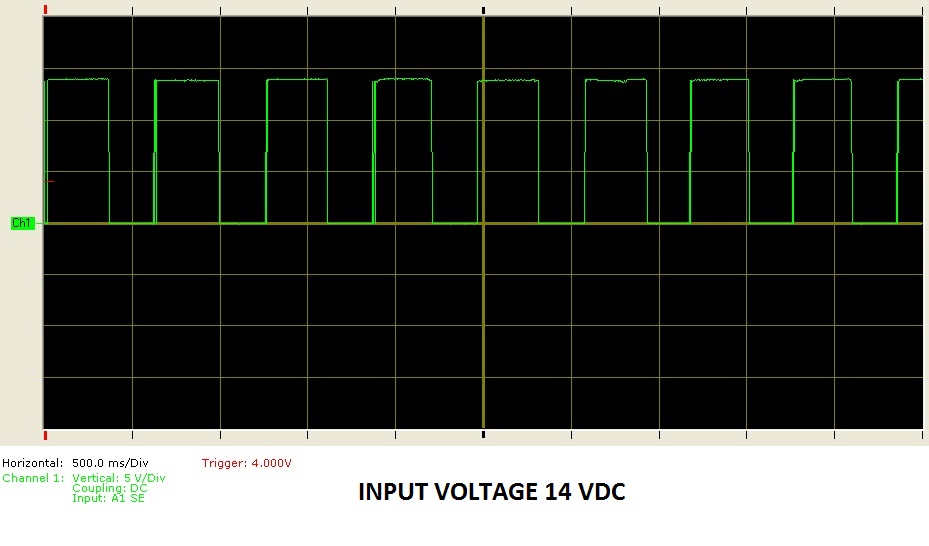

The

graphs below show what the output waveform looks like for input

voltages of 12 and 14 volts. Each graph shows five seconds worth

of time on the horizontal axis, and they show that the switching

frequency of my device was between one and two cycles per second.

Even

though it may seem a little funny to call something that does this a

"stabilizer", it does do the job. The fuel and temp gauges also

work with a resistance coil around a bimetal spring, but they are

designed to react very slowly to changes in current. They are

sluggish enough that they can't respond to the individual pulses from

the stabilizer, but settle on a reading that represents the average

current that they see. In both of the graphs above, the average

voltage coming from the stabilizer is about 10 volts. When the

input voltage is higher, the output has to spend relatively more time

at the "off" level to keep the average at 10 volts.

While

I concede that this is a tried and true approach, it is ancient

technology, pretty much unchanged since at least the thirties or

forties. Being a sort of a techie by nature, I'm not really able

to leave this Neanderthal device alone. An upgrade to a solid

state regulator is cheap, simple, and quick. There are multiple

places to buy modern drop-in replacements, and even at least one web

site that explains how to roll your own. Since this is the kind

of thing I do (did, actually) for a living, it seemed like a good place

to apply some of that expensive education.

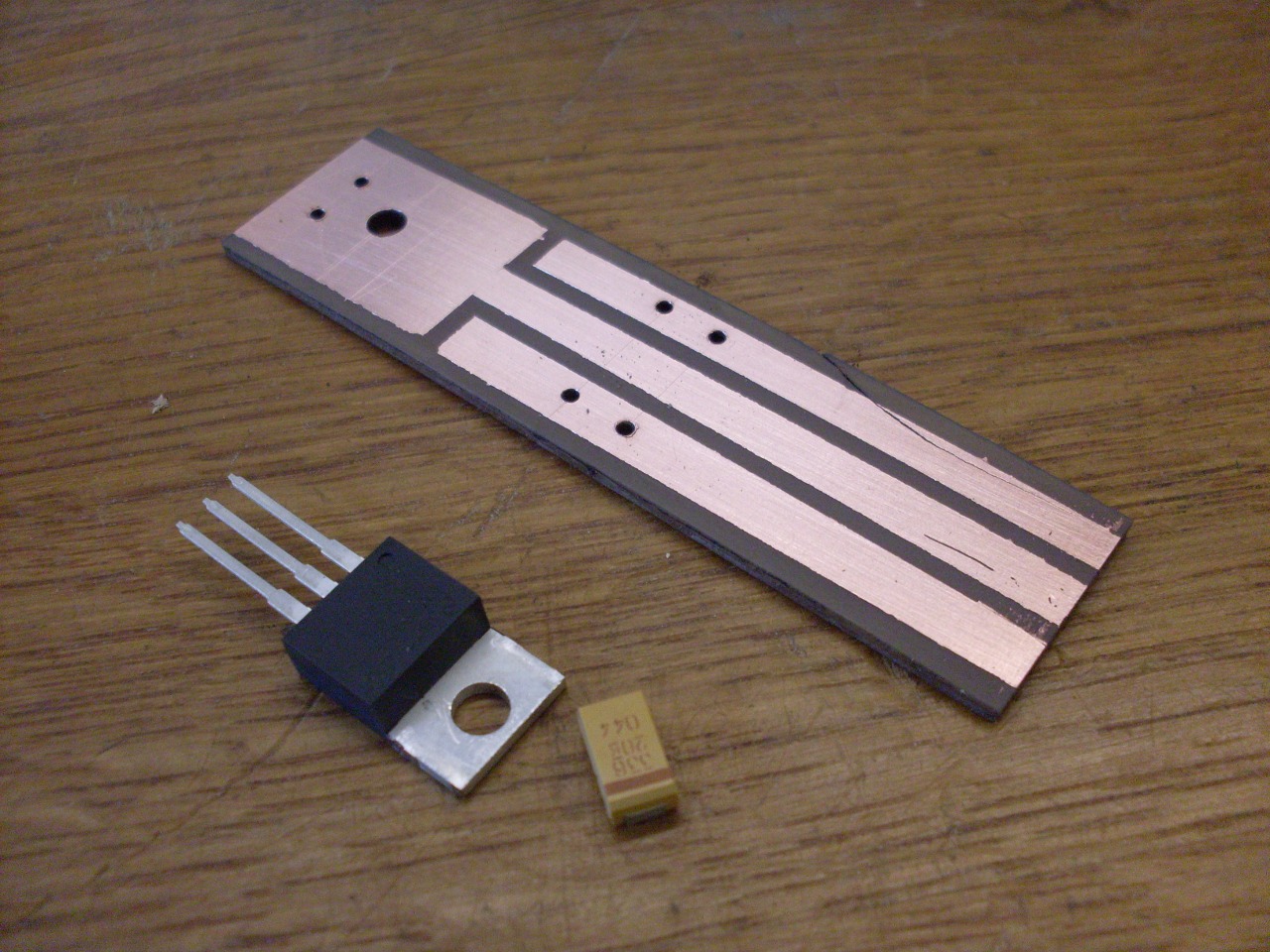

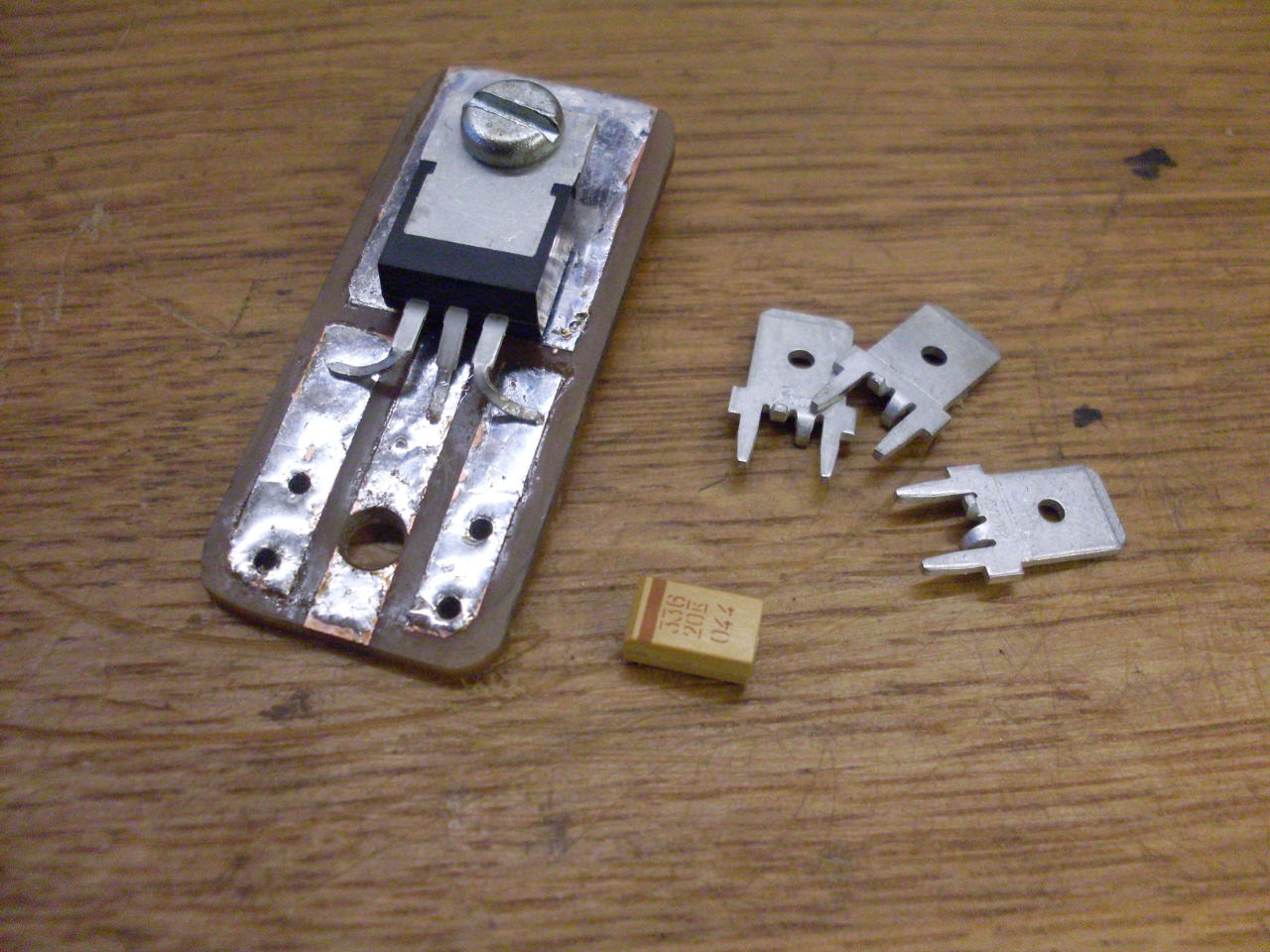

There

are a number of three-terminal voltage regulators on the market that

can be used for this application. I chose an LM2940 device

because it was the first one I came to in the catalog. The

manufacturer recommends a capacitor on the output to ensure stability.

What this means is that without the capacitor, it's possible

under certain load conditions to get some high frequency oscillation of

the output. Oscillation wouldn't affect the gauges, but it could

conceivably interfere with the radio, so I included the cap. The

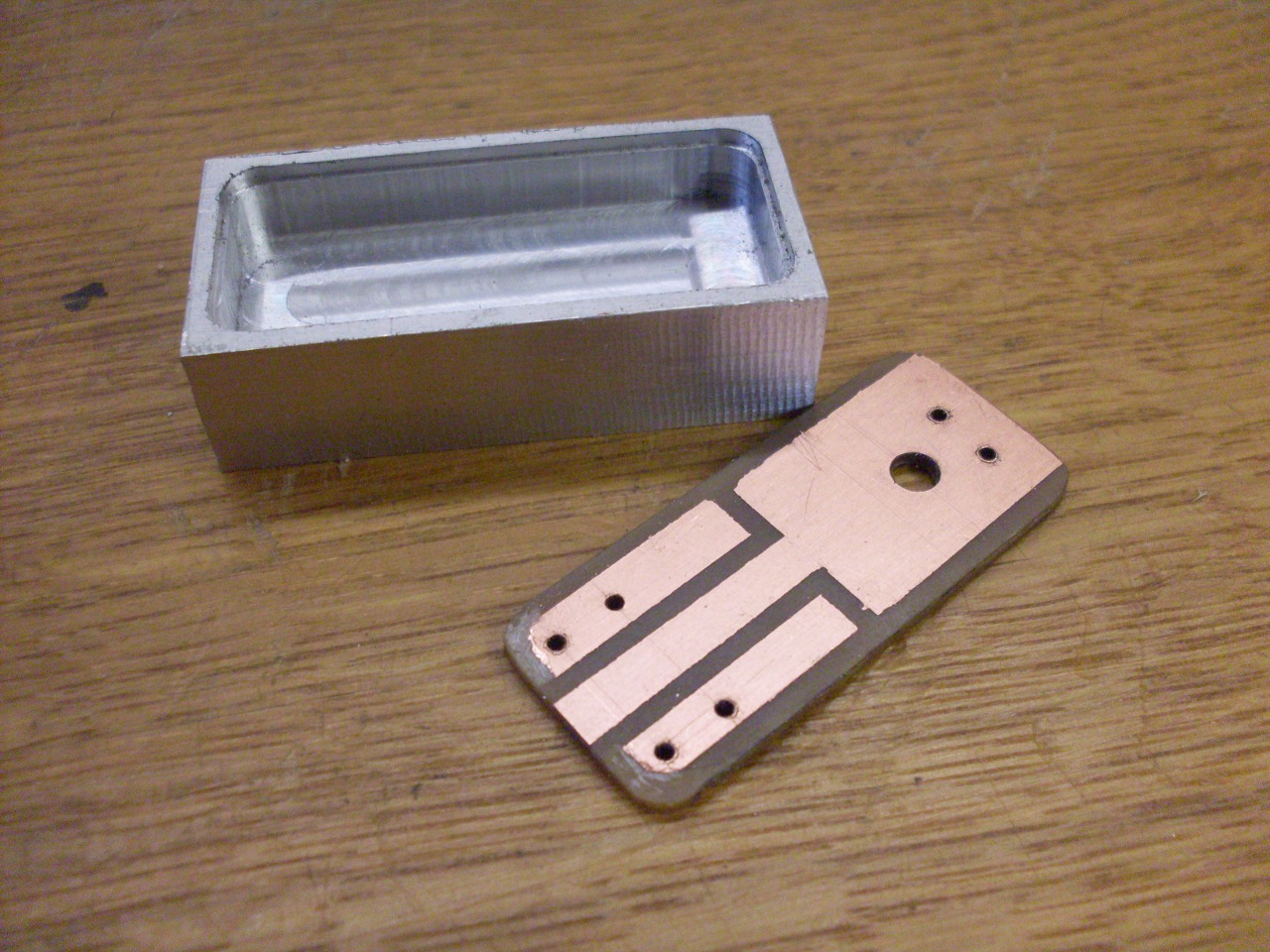

circuit board is a hand-done home brew.

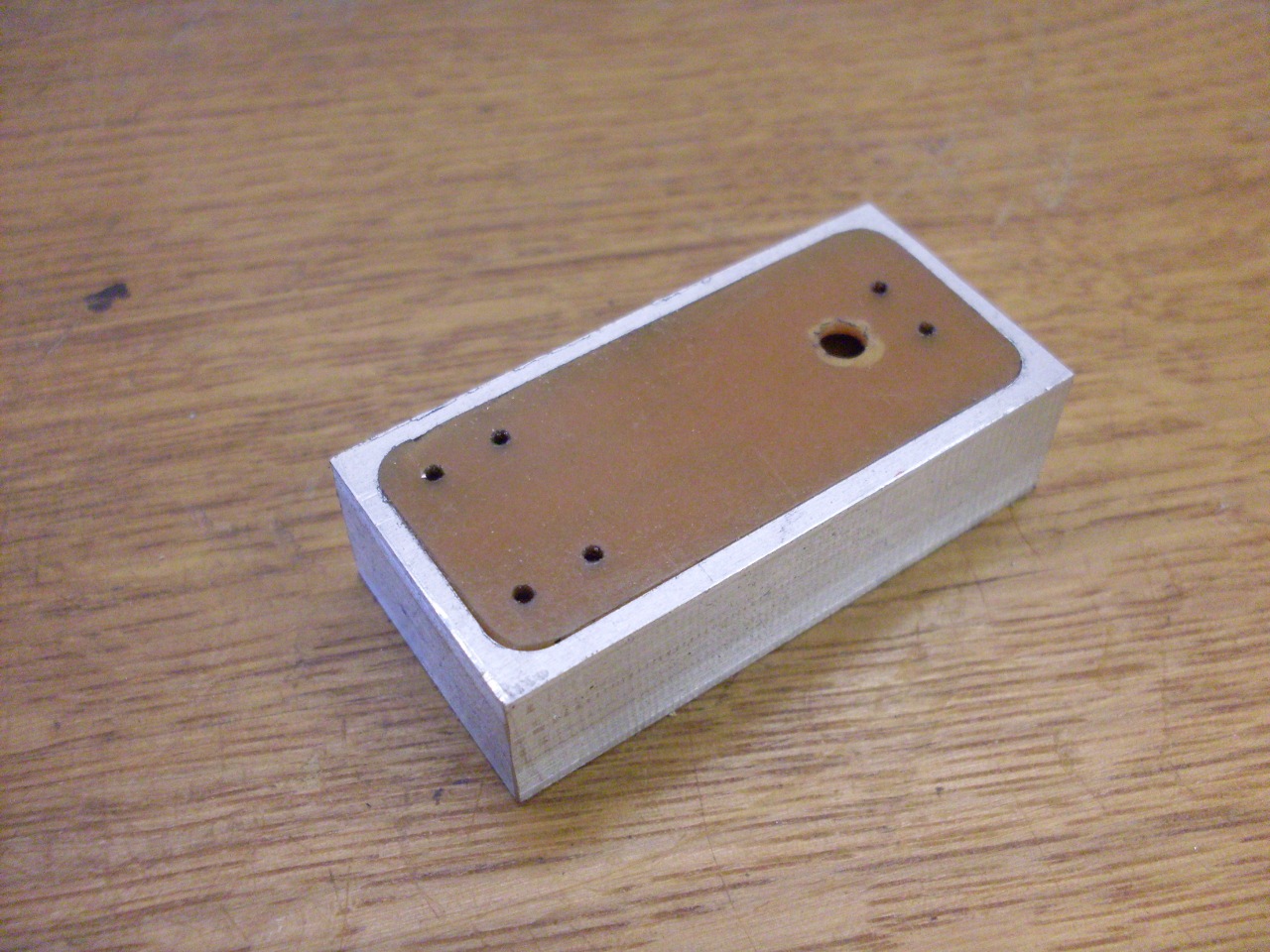

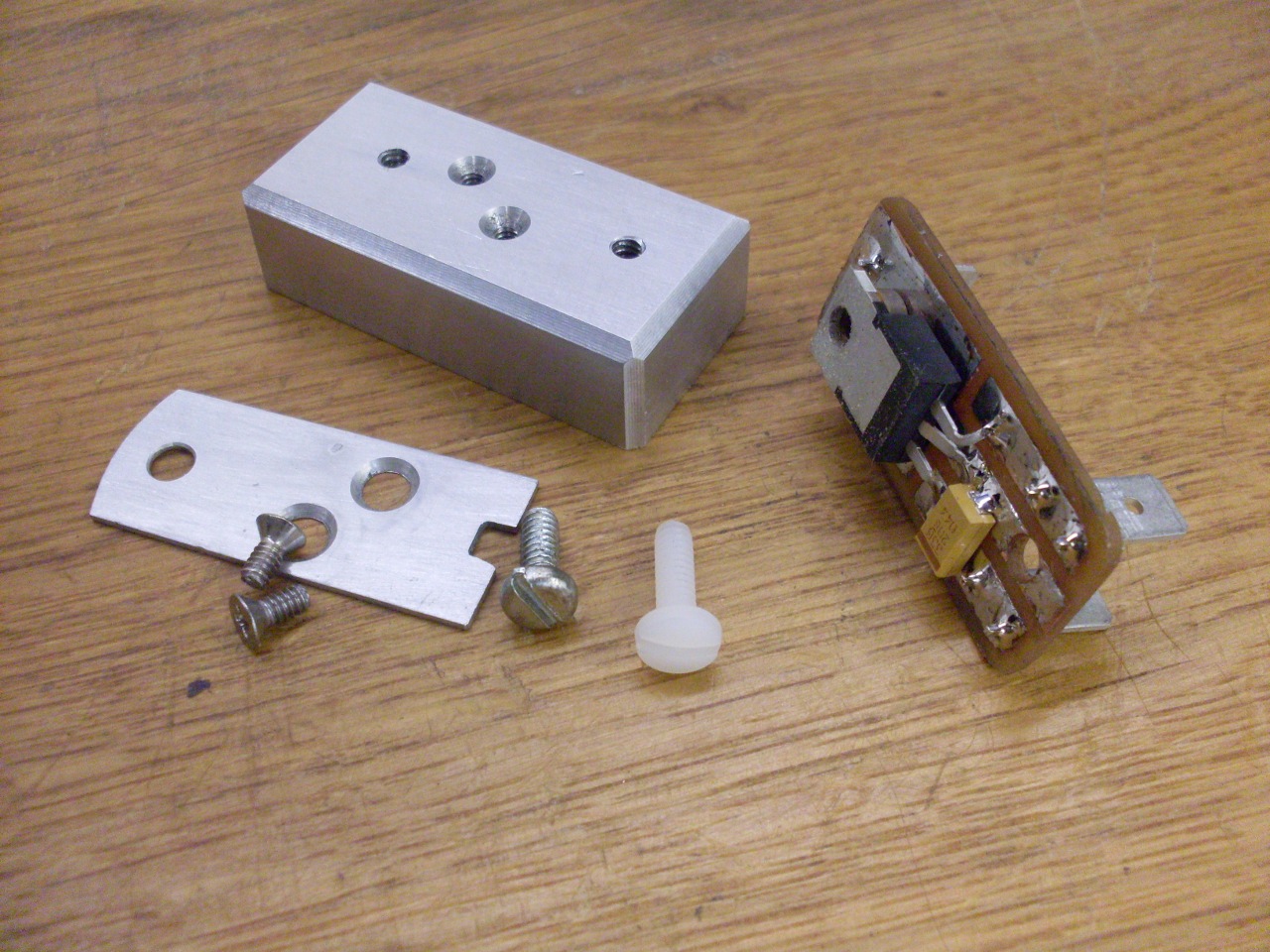

Made a little aluminum case to make mounting easier.

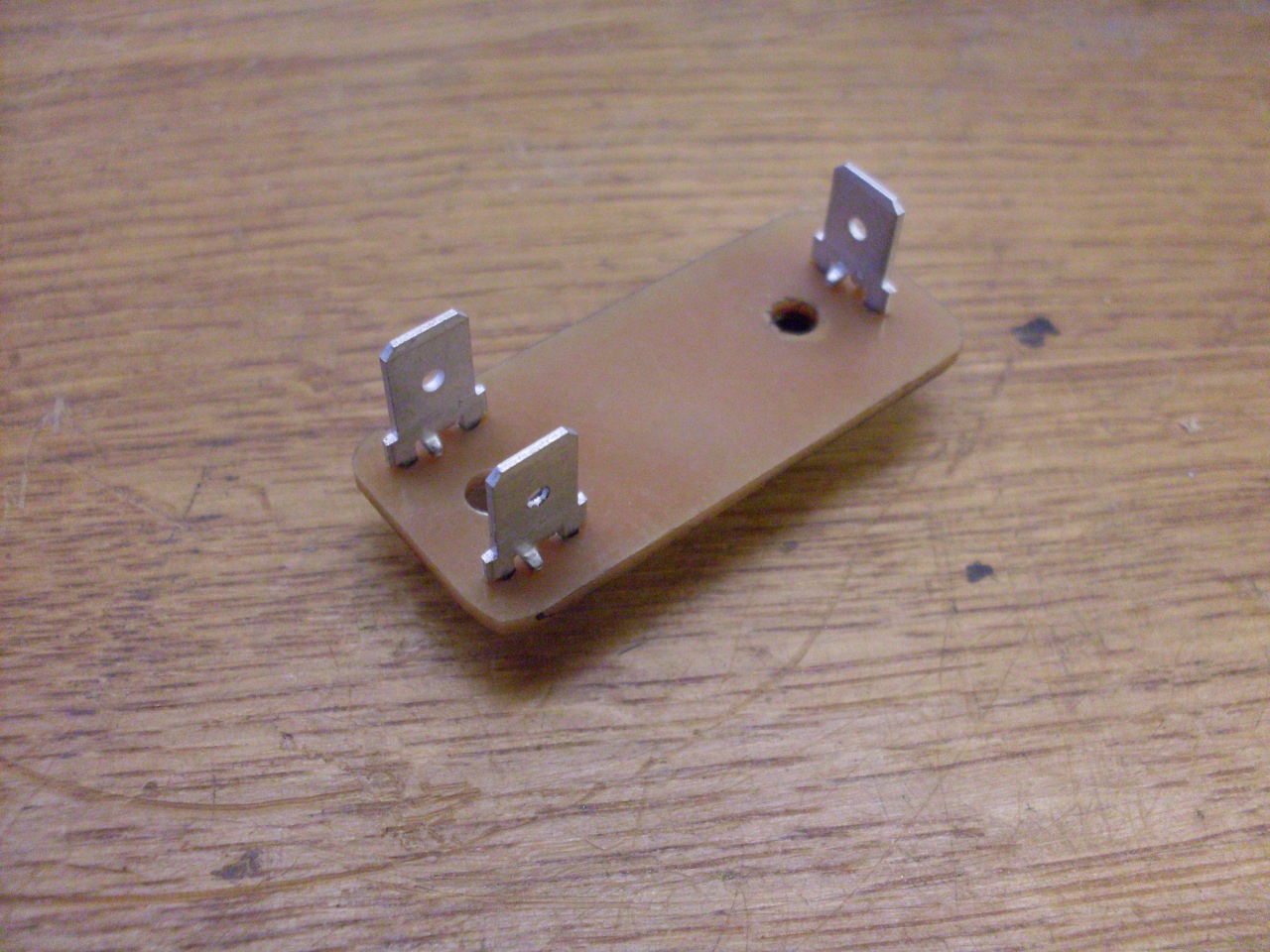

There

are only two electronic components and a few terminals. Unlike

the original device, which was grounded through its case to the case of

the speedometer, I included an explicit terminal in for ground.

Bad grounds are one of the most common causes of electrical

problems in cars, especially older ones.

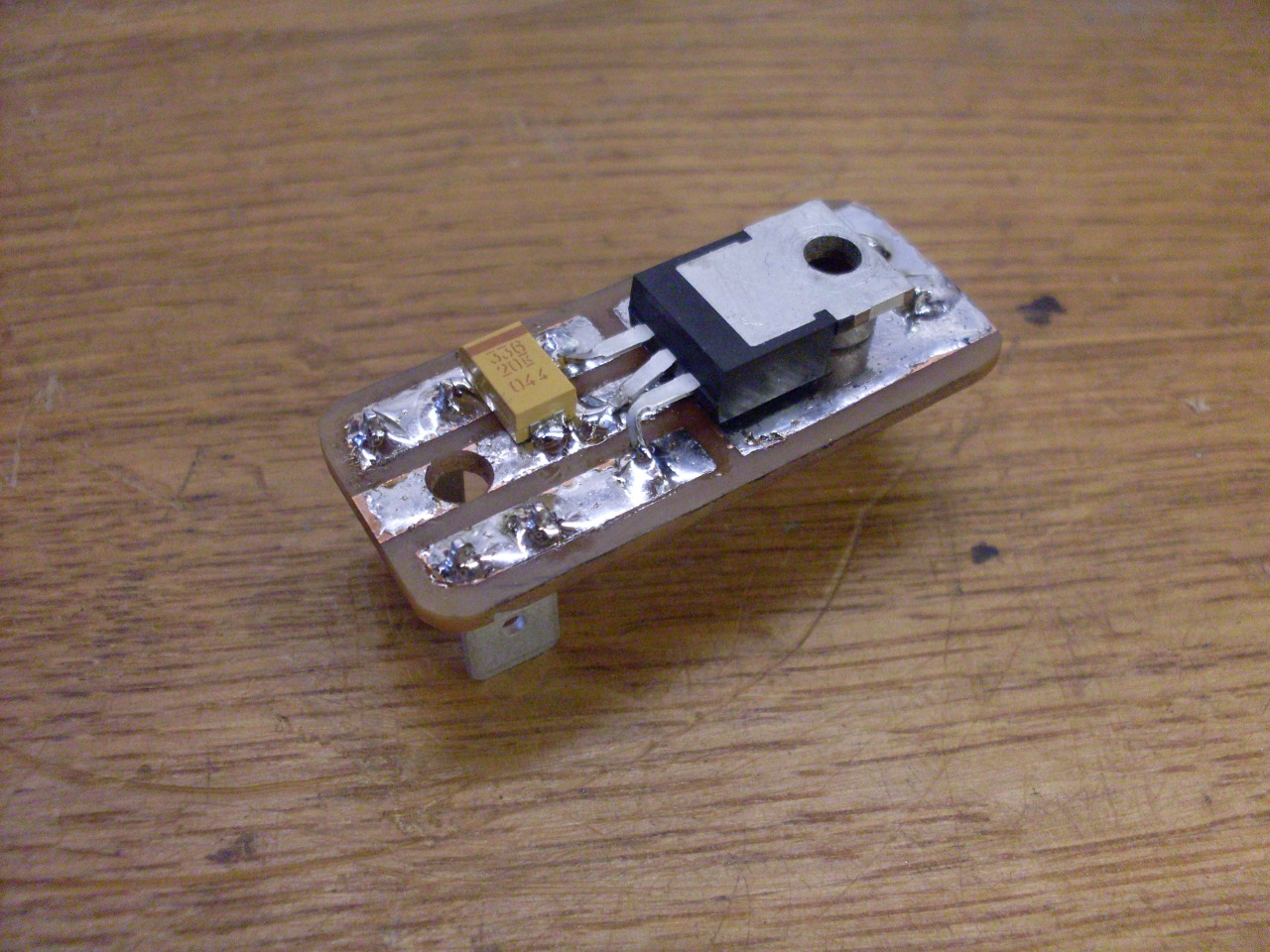

The

regulator is surface mounted on the foil side of the board.

It is facing the board so that its back side can seat against the

aluminum case for heat sinking (though at the voltages and currents

involved, heat sinking might not be necessary).

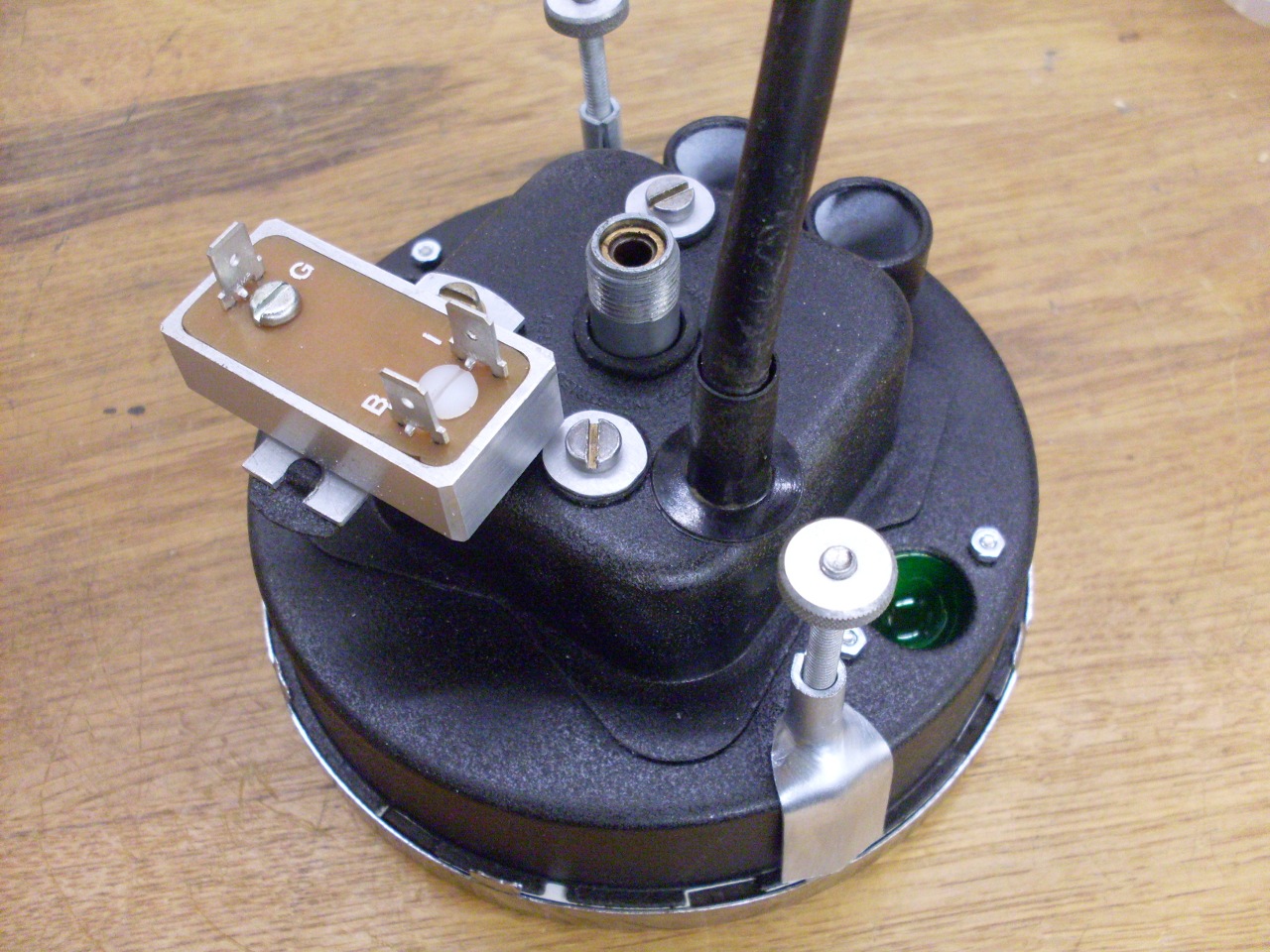

Made a bracket to match the original. I used a nylon screw on one side because of the proximity to the terminals.

The finished product.

Guess I should at least test it!

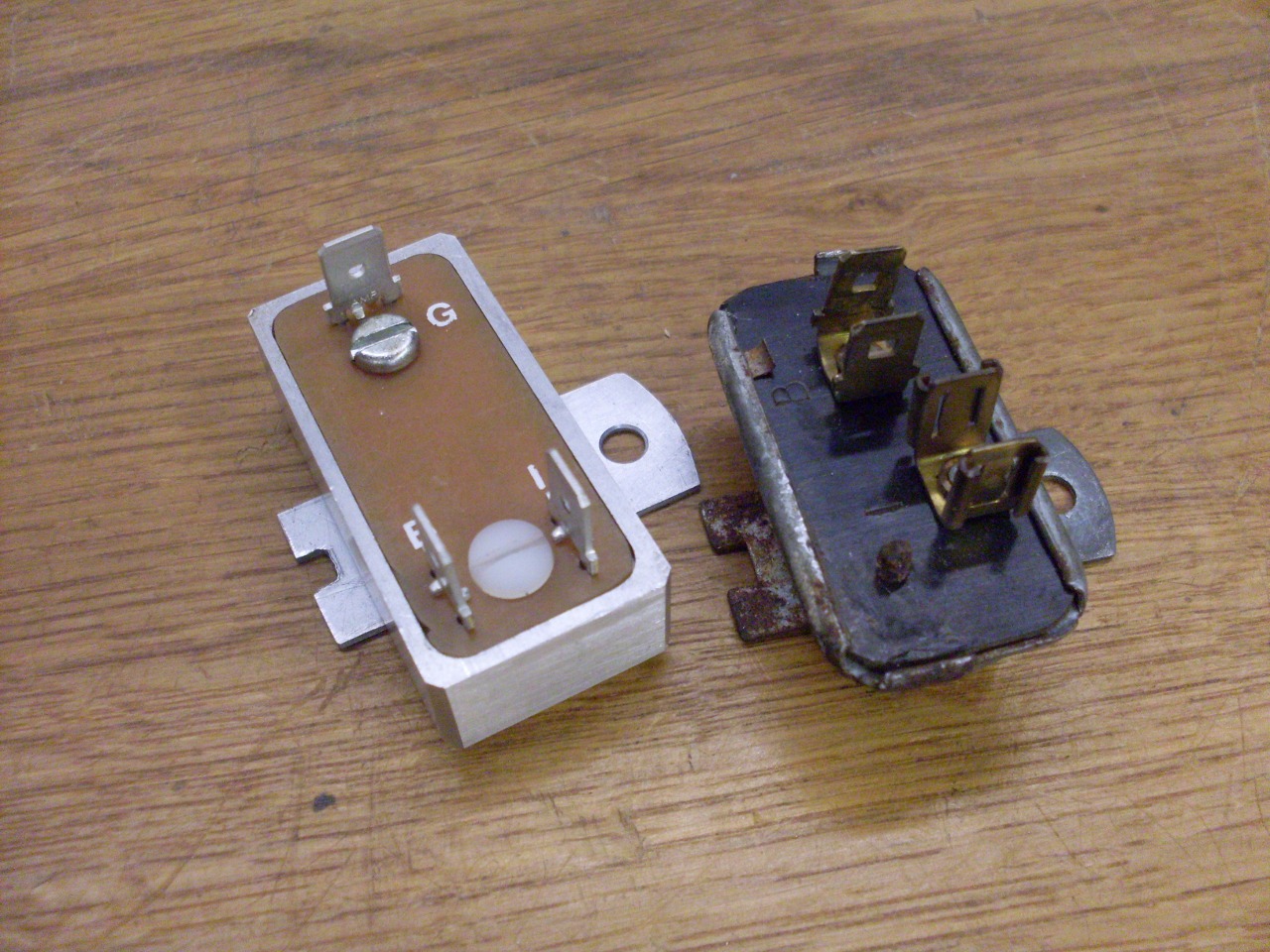

Installed it in it's new home. I keep the original for nostalgia.

So

is this an upgrade? An improvement? I don't know.

Reliability might be a little better, but I wouldn't expect to

see any noticable difference in gauge performance. I don't think

I'd pay the $15-$20 for a commercial replacement, but for about $3 in

parts and a pleasant afternoon in the shop, it seems like a good deal

to me.

Comments to: elhollin1@yahoo.com

To my other TR6 pages