To my other TR6 Pages

November 4, 2016

Heater Install

So I dragged out the refurbed heater, which has been on a shelf for nearly two years.

The

first thing I noticed, other than the unit being covered with dust, was

that the foam cowl seal had let go. This seal, as supplied by at

least one of the big three, comes as a short length of closed cell

foam weather stripping that can be bought at any big box home store.

The 1000% markup aside, the adhesive isn't good enough to hold

the strip to the tight curve for very long. If I had installed

the heater right away, the story might have been different.

In

the end, I thought a better solution was to duplicate the original foam

ring. I removed what was left of the old adhesive on the

overpriced foam strip, put some contact ahesive on its ends, and joined

them to a ring that would snugly slip over the heater's inlet opening.

I

wasn't sure if the heater would interfere with installation of the

bulkhead hose connectors, so I looked at that next. The original

was in pretty bad shape, with rust perforations in a few places.

The new one I bought looked a lot better, but I wish I'd been

able to find a stainless version. Note that in the last pic below, the unit is installed upsidedown. I didn't catch that until I tried to hook up the hoses.

Before

actually hanging the heater, I wanted to apply a panel sound deadening

treatment to the firewall behind it while I still had access. I

was a little na´ve about this at first. I assumed that the only

way to deaden a panel was to increase its mass and reduce its

springiness. This was the thinking behind the bituminous pads

applied to various panels of the TR6 at the factory. The pads are

relatively dense, and fairly limp (at least when new). The extra

mass lowers the resonant frequency of the panel, and the soft material

absorbs the energy of flexing. I learned that a more modern

answer to vibration and sound deadening is Constrained Layer Dampening

(CLD). A CLD system consists of two metallic layers and a

so-called "visco-elastic" material, which is constrained between them.

This material is like a very soft, almost gooey rubber. In

an automotive application, one of the metallic layers is a panel in the

car, and the other is typically a thin layer of aluminum.

Vibration or sound frequencies distort the soft material which

absorbs the energy, turning it into a small amount of heat. A CLD

product can allegedly give the same amount of sound and vibration

damping as a bituminous or similar pad with less weight and less

thickness. I was skeptical at first, but the anecdotal

evidence is strong, and the science seems solid.

The

downside, however, is cost. Premium brands of these products can

approach $10 per square foot in smaller quantities. I bought a

few square feet of a slightly cheaper offering just to try it out.

This

product came in one square foot sheets, and the gooey constrained layer

also serves as a pretty effective adhesive. It is probably less

than 1/16" thick, and is pliable enough to fit to moderate countours.

Because of the way it works, it's important that the sheets have

as complete and intimate contact with the steel panel as possible.

It reportedly isn't necessary to cover 100% of a panel to reduce

its vibration. In fact, one source claimed that covering just a

third or so of a panel gets most of the damping effect. I assume

which third makes a difference.

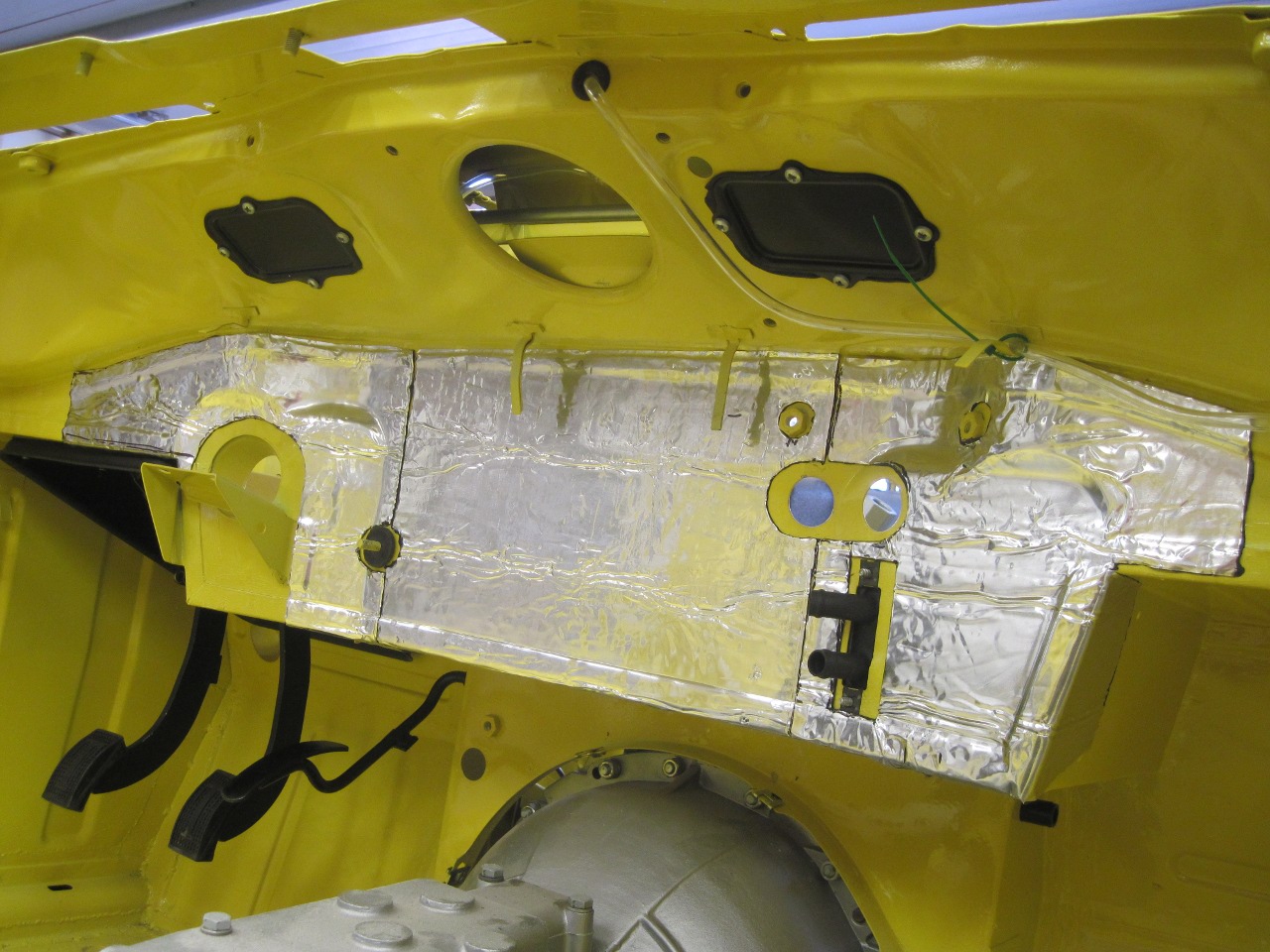

Here is the firewall panel behind the heater with the sound mat applied.

I'll

add to the record of anecdotal evidence. In a subjective before

and after test, and comparisons with treated and untreated panels, I

can say that the treated panels definitely have a "deader" sound when

thumped.

Finally, the heater was offered up and bolted in.

I'm

convinced enough of the effectiveness of these CLD products for sound

deadening that I'll probably use them in other areas of the car.

One other claim made by some of the purveyors of these products

is that they also have high resistance to heat transmission.

This, I'm still skeptical of.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 Pages