To my other TR6 pages

September 1, 2014

Rear Suspension

The

TR6, like some of its ancestors, has an independent rear suspension

using semi-trailing arms. The arms are largish aluminum

castings that carry, in addition to the wheel hubs and brake backing

plates, a recess for the coil springs, and a bracket for a link to

the lever arm shock absorbers.

My trailing arms were dirty, but otherwise in good shape.

The

trailing arms pivot on brackets mounted to the frame. The factory

rubber bushings can be a chore to remove, but a little shop built

persuader helps a lot. I found that running a 3/16 drill bit into

the rubber through the bushing all the way around made it even

easier. There was some corrosion in the bores, but after

cleaning it out they still measured within spec.

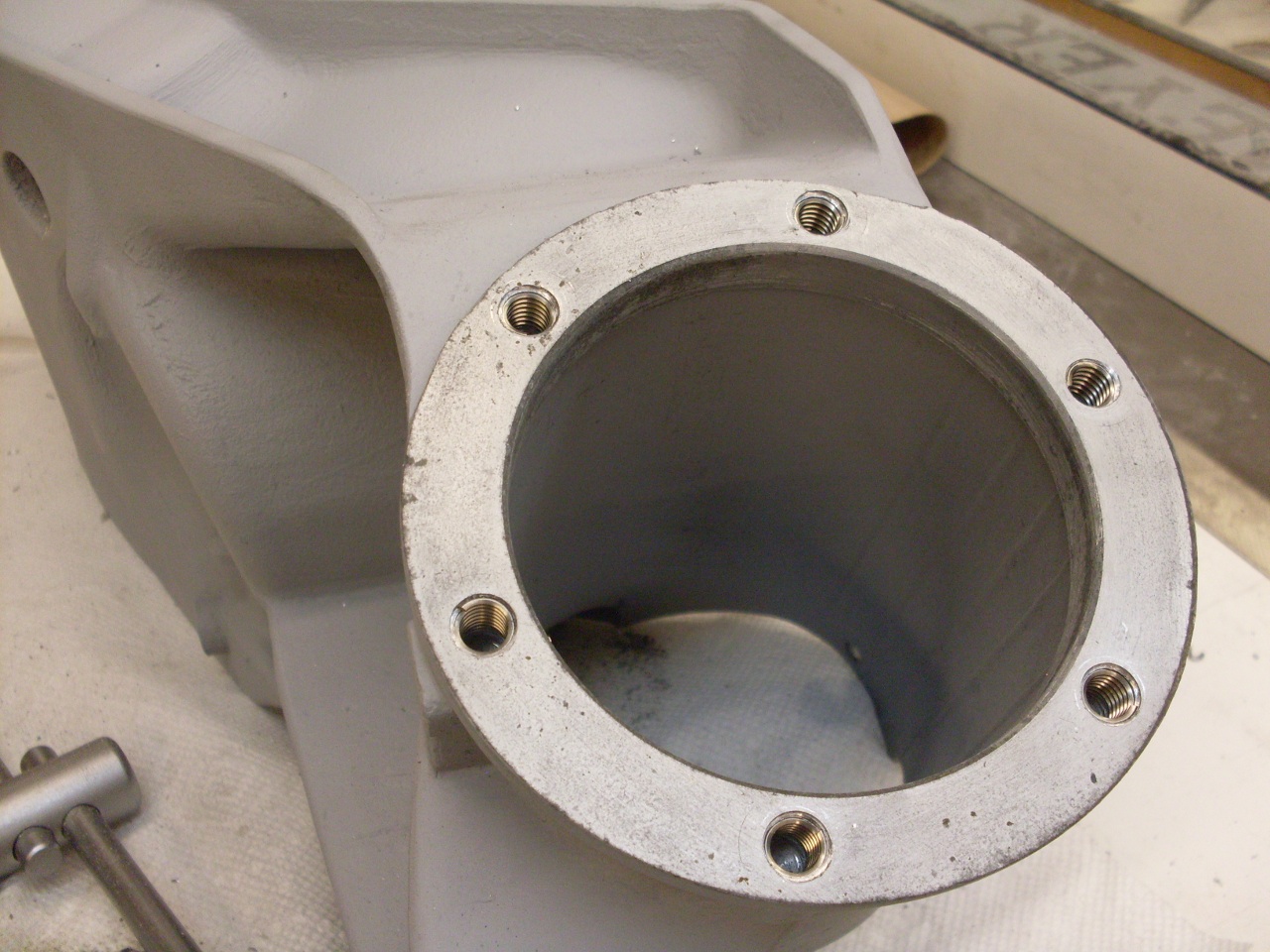

Brackets and bushings removed, ready for cleanup. Also all the rubber bushes and plugs removed from the arms.

I'd

read in multiple sources that the studs that mount the hub to the

trailing arms are prone to stripping. This wouldn't be unexpected

for fairly shallow fine threads in aluminum. A very common fix

(or preventative) is to install thread inserts into these holes.

The threads in my arms all appeared to be fine, but there is no

better time to install an ounce of prevention than when everything is

apart anyway. I decided to proactively upgrade the threads with

Helicoil type inserts.

One often discussed challenge to

installing inserts in the trailing arms is that the arms are such a

large and odd shape, they are just about impossible to mount on a drill

press, and a potential danger of drilling by hand is getting a crooked

hole. I really believe this threat is a little overblown.

There is a straight hole already there, and it only needs to be

enlarged a little, and then tapped. The larger drill bit will try

to follow the original hole, and anyone who has handled a hand drill

before will know how to let it find the path of least resistance.

Likewise with the tap--it wants to go straight down the hole, and

will only go off track if there is some outside force deflecting it.

On

the other hand, these trailing arms are not cheap if they need to be

replaced due to some unforseen problem in drilling or tapping, so some

kind of insurance seemed like a good idea. There are some

guide jigs available commercially to help with this, but they

aren't cheap. If buying the jig were the only option, I'd

probably just do it by hand, and be pretty sure it would come out

fine. In the end I made my own small dril/tap guide. Unlike

at least one commercial offering, mine only guides one hole at a time,

mainly because I wasn't willing to devote a larger piece of stock to

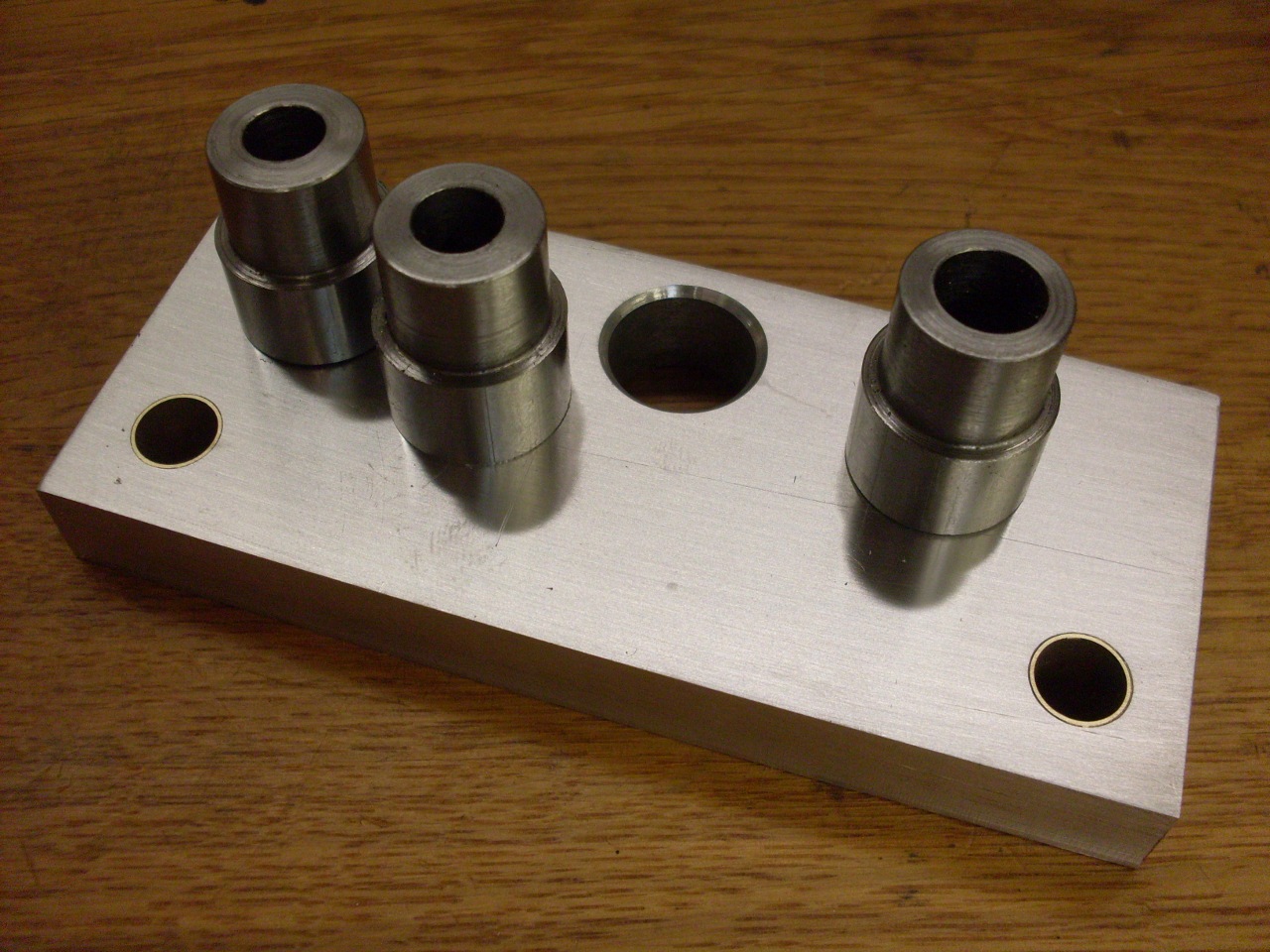

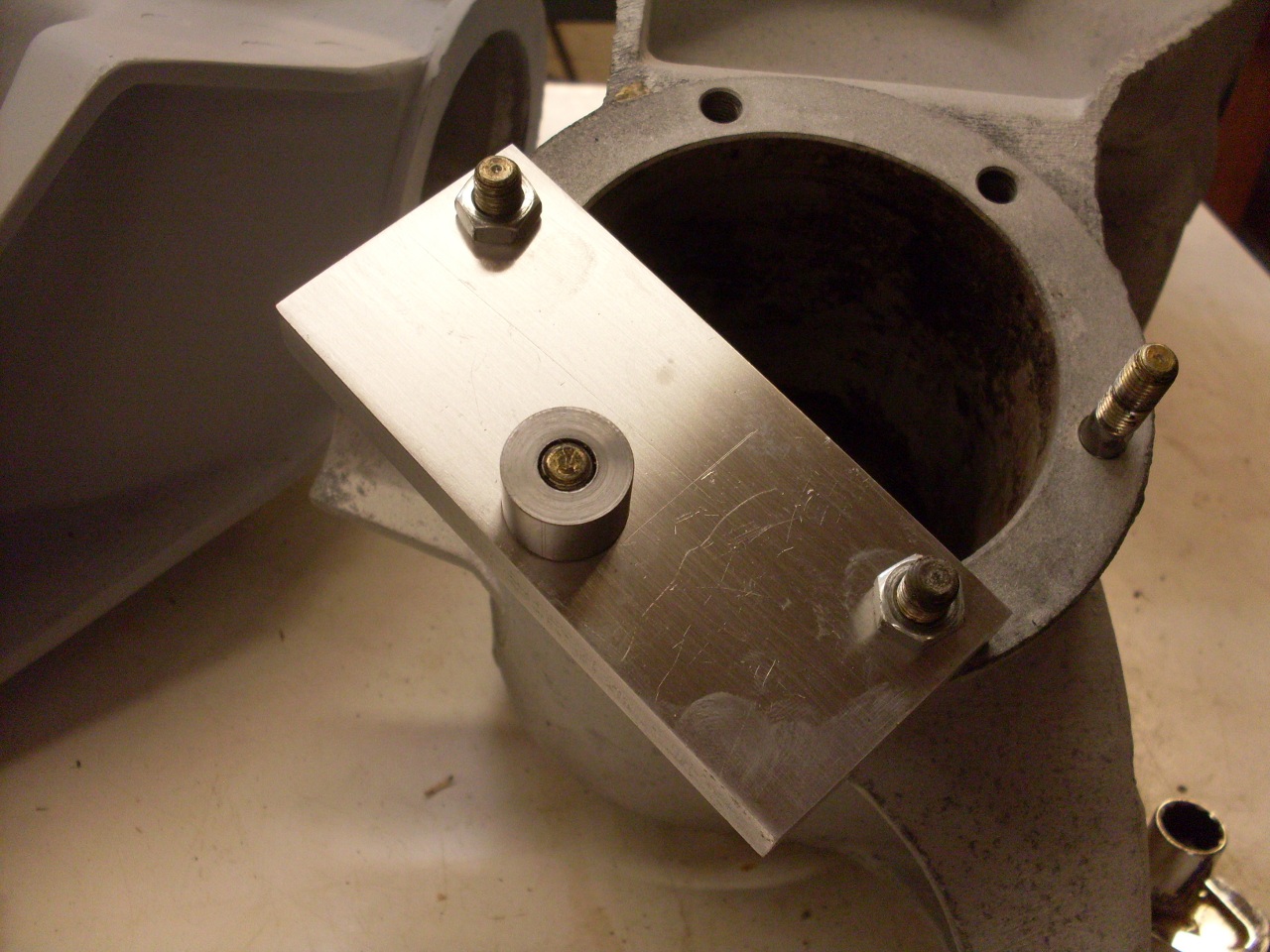

it. Ther jig consists of an aluminum carrier block and three

steel guide bushes--one to go over an original stud to center the jig,

one for the drill, and one for the tap.

I chose to stay with 5/16" studs, but to install inserts for course threads instead of fine.

Here are the trailing arms, cleaned up, painted, and plugged.

The

springs measured a little longer than the spec allows. After a

quick query on one of the forums, it appears that everyone's

springs are longer than spec, so I didn't worry about it. The

pics show the springs after derusting, in the powder coat oven, and

ready to install.

I

planned on using urethane bushes in the trailing arms as opposed to the

original rubber, mainly for longevity. Since urethane bushes,

unlike rubber, need lubrication, I installed grease zerks on the bottom

side of the bush bore. There is already a nice land there in the

casting, as if it was an option the factory wanted to leave open.

Now

comes the interesting part. The original design of the TR6

rear suspension didn't provide any means to adjust wheel camber.

A number of enthusiasts have devised schemes to correct this

omission, and there is at least one popular aftermarket product that

addresses it. A quick look at some of the geometry of the

trailing arm mounting points can help illustrate the challenge of

camber adjustment.

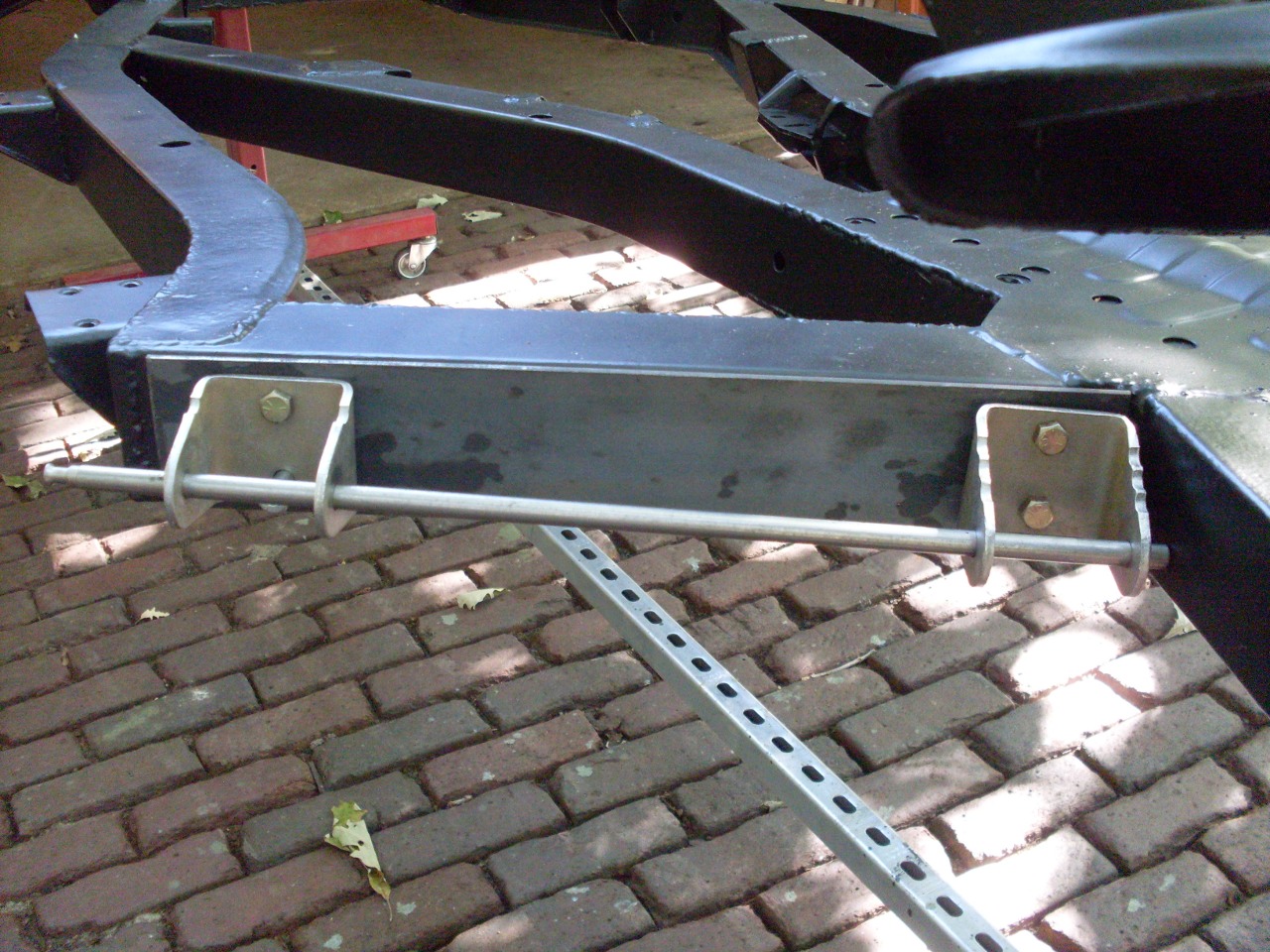

The inner and outer brackets that hold the

trailing arm are different parts. The main difference is the

height of the pivot pin holes relative to the frame attachment points.

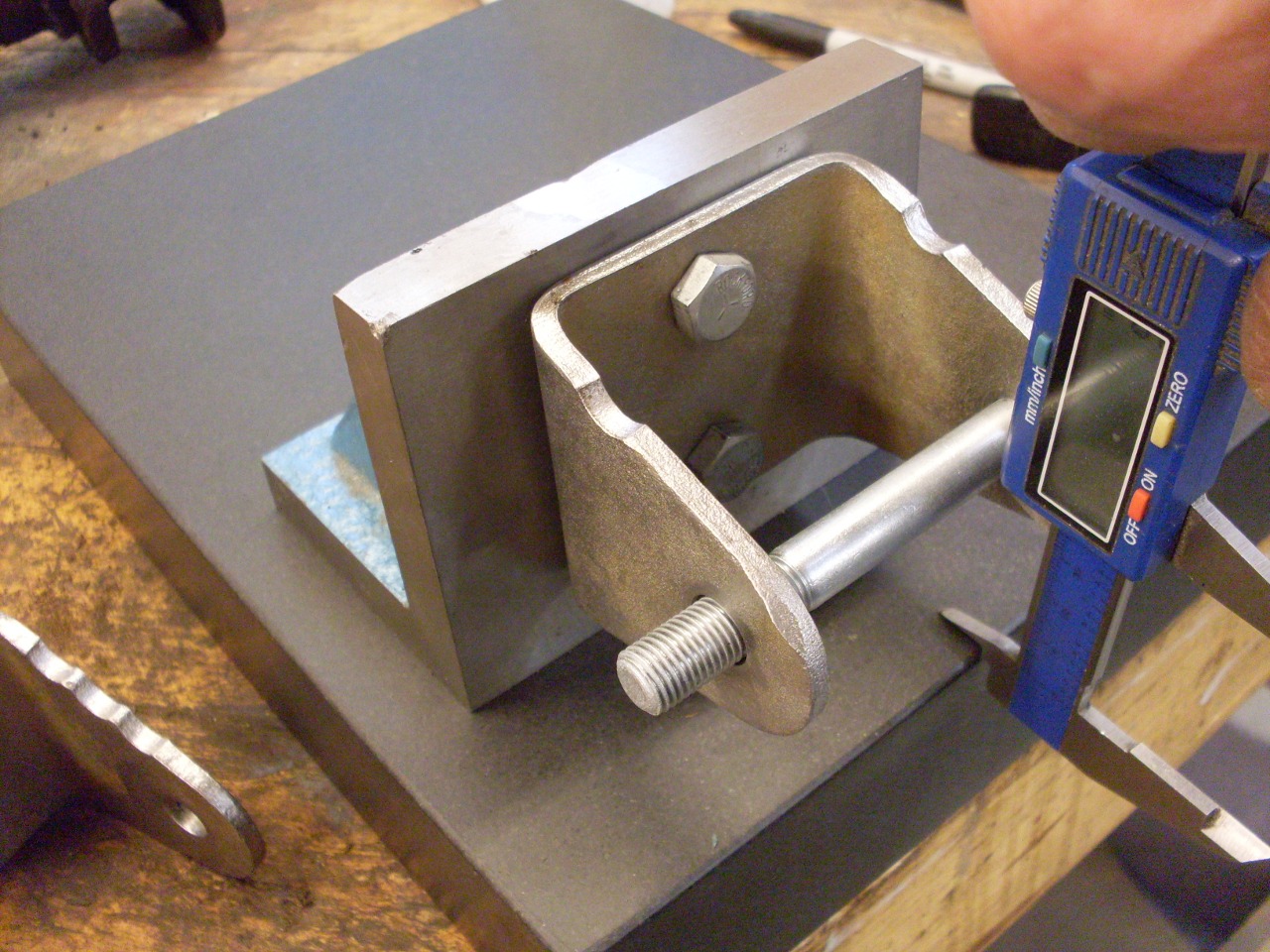

This pic shows a 7/16 rod run through the pivot bolt holes in the

two stock brackets. It is easy to see that the rod is not

parallel to the plane of the chassis rails. A close look will

also reveal that both brackets are slightly cocked to the right to

allow the pivot bolt holes to all be colinear. There is just

enough slop in the frame and bracket holes to allow this.

Measurig

the difference in height of the pivot pins and applying a little trig,

we find that the pivot angle is about 1.8 degrees relative to the

plane of the chassis members. One way to change the wheel

camber is to adjust this angle.

There is a very nice analysis of camber geometry and a method for adjusting it at the Buckeye Triumph

site. The method involves swapping out brackets with different

pivot heights. While I'm sure this approach can be very

effective, swapping brackets is a pretty time consuming task, and

finding the right combination might take several iterations.

There

is also a product available that includes brackets with pivot pins

that can be adjusted vertically to give a range of angles. The

product is popular, and many users endorse it, so I assume it works

adequately. I consider it pretty pricey, though, and it does have

a few quirks that give me at least a little pause. For one, I'm

not sure if the brackets can provide the colinerarity of the pivot pins

through the entire range of adjustment. That is, with one bracket

pin higher than the other, will they be colinear? If not, it

appears that the pivot bolt must be cocked a little inside at least one

of the bushings. If the pins are colinear, then it looks like the

pins must be cocked a little in the brackets, which could affect how

well the bolt holds. I should say that I have not examined these

brackets up close, so it is possible that these things are addressed in

ways I'm not aware of.

In the end, I decided to make up an experimental adjustment system that soothes my worries.

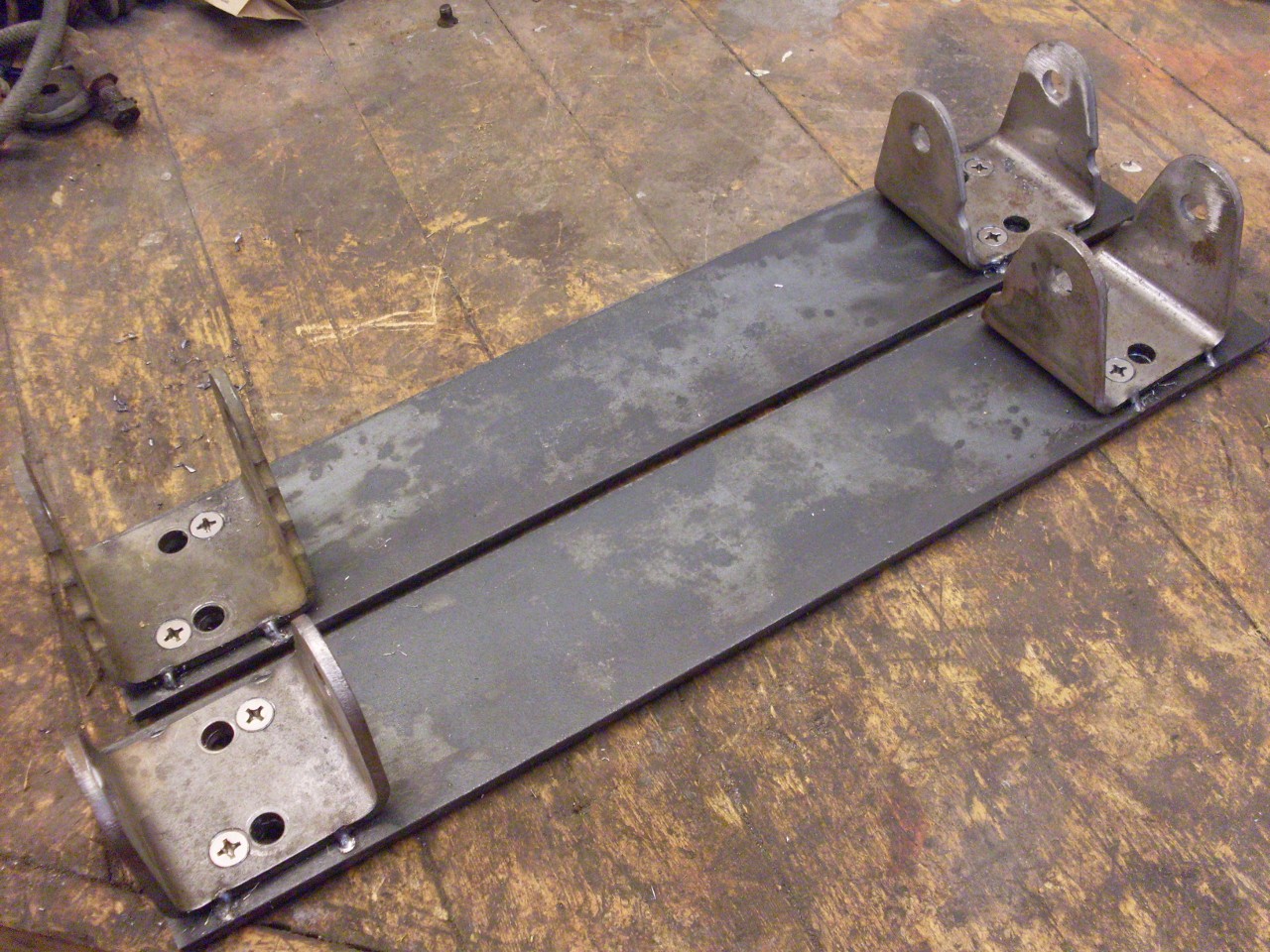

I

got a couple of pieces of 3/16 x 3" steel, and cut them a little

shorter than the trailing arm mounting members on the frame.

These serve as a carrier plate that the trailing arm brackets

will attach to. With the 7/16 rod on place to keep the brackets

lined up, and the carrier plate drilled to allow the bracket mounting

bolts through, I tack welded the brackets to the carrier.

Then

I drilled, tapped the carrier, and countersunk the brackets for flat

head screwas to hold the brackets on the carrier in the aligned

position. I then ground away the tack welds so the brackets and

carrier could be separated.

I

had to weld little extensions to the outboard brackets to allow a

larger adjustment range. It might have been easier just to make

new brackets.

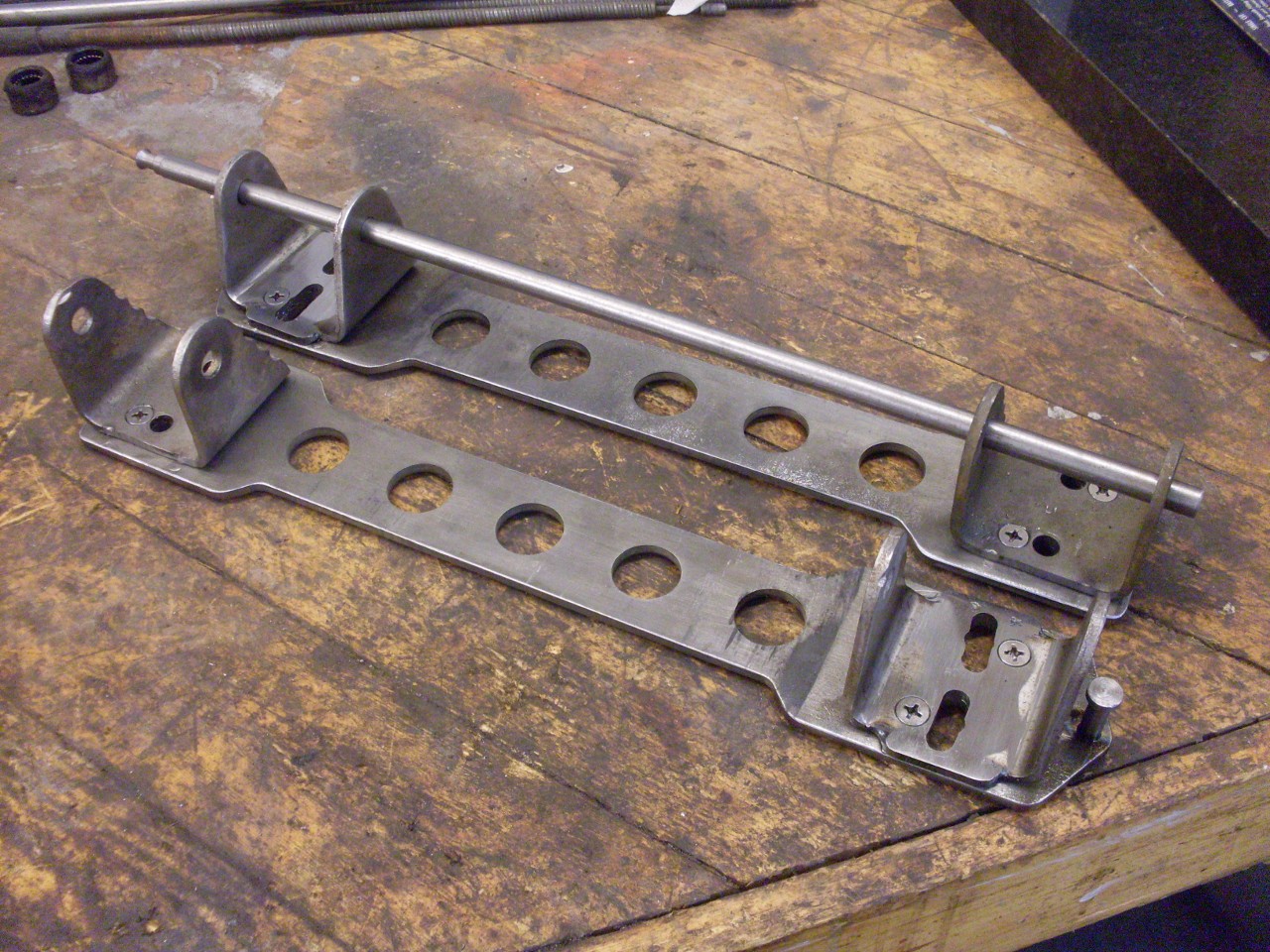

Then

the mounting holes in the carrier plate and outboard brackets were

milled to a short arc centered on the lower inboard mounting hole.

The carriers were also shaped and lightened a little. The

idea here is that the carrier, along with the brackets, can rotate a

few detgrees around the lower inboard mounting hole, but since the

brackets are fixed to the carrier, the alignment of the trailing

arm pivot holes remains constant. The upper inboard mounting hole

also has to be elongated slightly. There is also a little

adjustment pin welded in at the far outboard end of the carrier.

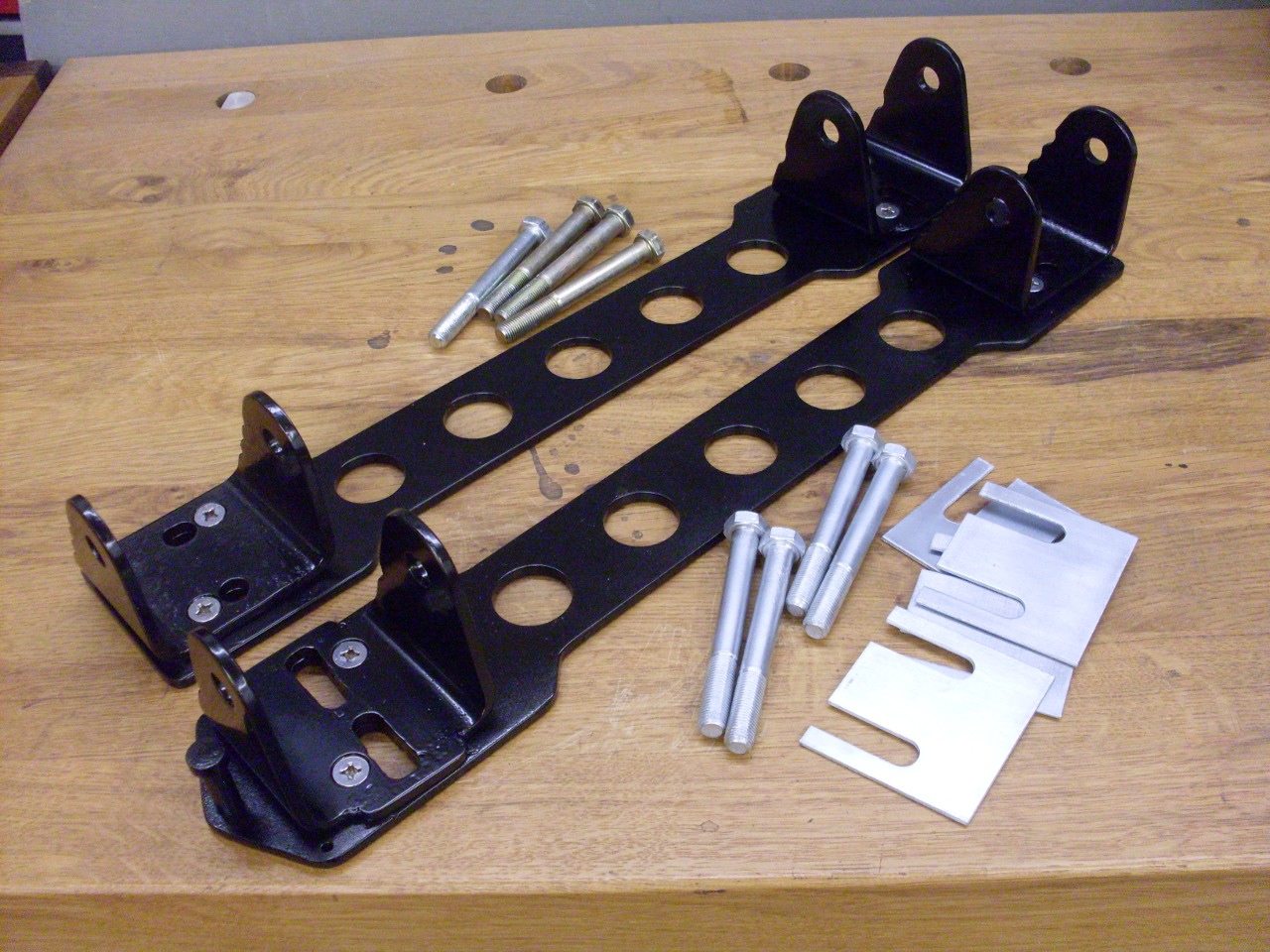

Everything

was then powder coated or plated. All four of my trailing arm

brackets had four shims from the factory. The new carrier does

the job of three of them, so I still needed to install one shim.

The shim also proivided a little space between the carrier and

the frame member.

For an adjustment mechanism, I welded two little ears to the frame at the ends of the trailing arm mounting members.

The

adjustment mechanism itself is just a long bolt, held in place at each

end. There is a little stainlesss block that can be moved up and

down the bolt with a nut above and below. The block engages the

pin at the end of the carrier plate.

With

the parts of the experimental gizmo finiished, I had to turn to the

other pieces of the rear suspension. The shock links are an

integral part of the suspension. They hold the rear end of the

trailing arm up. I noticed on the two links I bought that one had

zinc plated washers, the other had plain washers. The difference

can just be seen in the picture, but it was a lot more obvious in

person. I get a little tired of being the suppliers' QA

department.

Also

the paint was pretty pathetic on the links--it would easily scratch off

with a fingernail. In a few steps that I admit might be a little

anal, I stripped the paint (it didn't take much), plated the lower

parts of the links, and painted with real primer and paint.

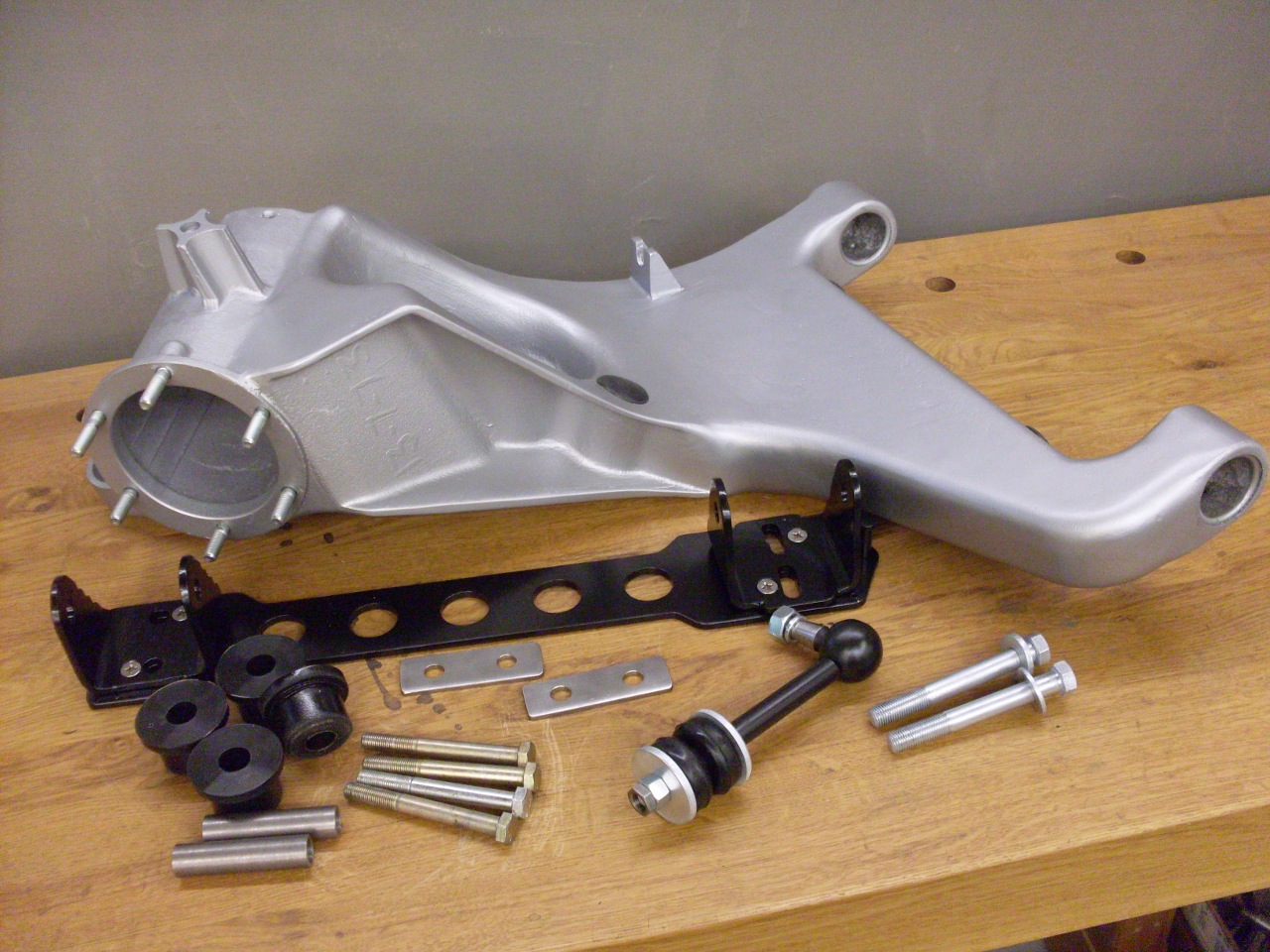

So here are most of the parts for the suspension.

Mounted the lever shocks.

A cargo strap worked OK as a spring compressor.

On the frame. I used a nice hefty stainless washer plate to bridge the arced holes.

A

closer view of the camber adjuster. I've got it set in the

middle--about what the stock brackets would give--until the suspension

is fully loaded.

Getting impatient to get this thing on its own feet.

Comments to: elhollin1@yahoo.com

To my other TR6 pages