To my other TR6 pages

August 11, 2014

Rear Lever Shocks

[Click the pics for a better view]

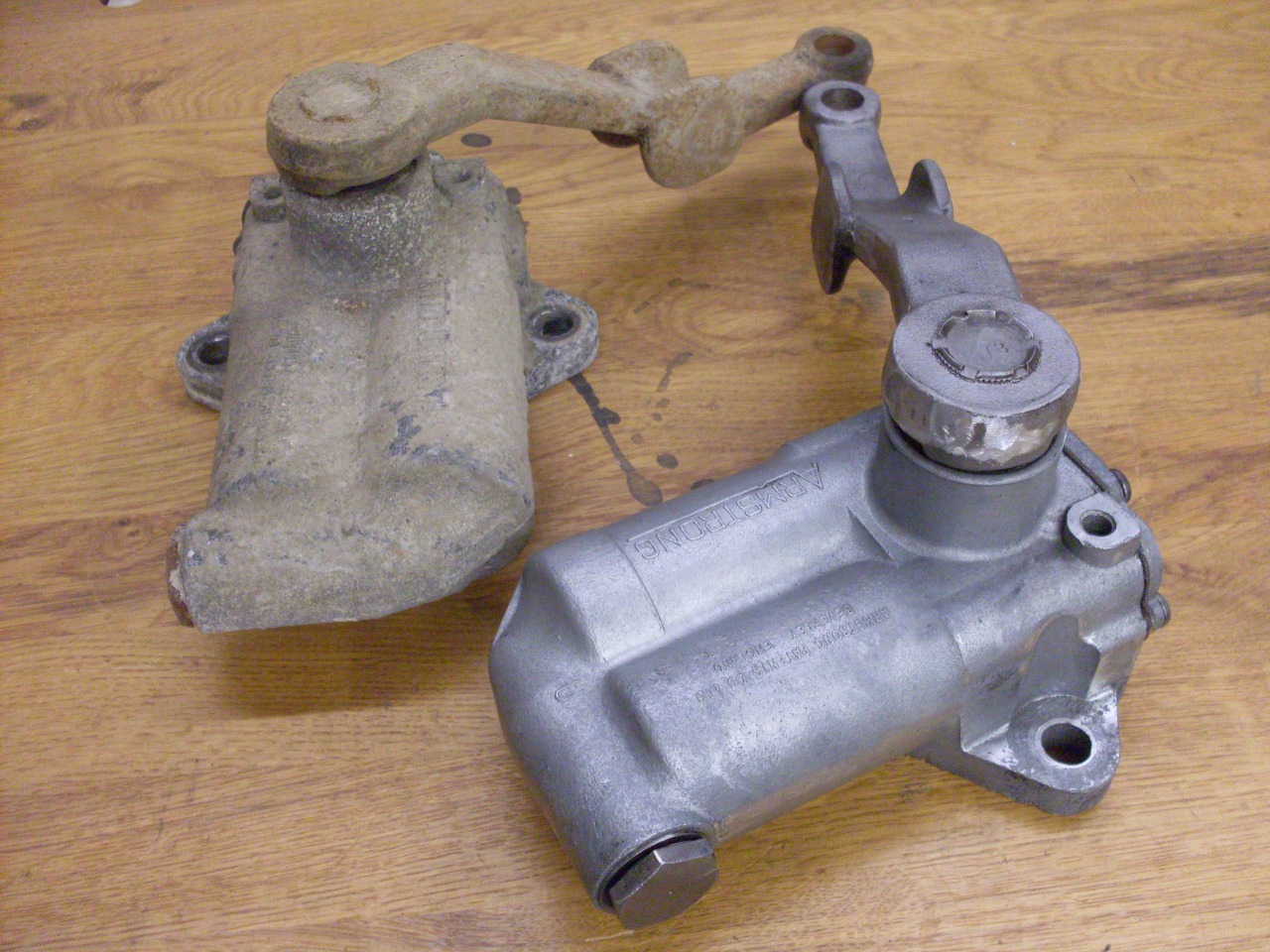

In anticipation of assembling the rear suspension soon, I dug out the rear shocks.

The

TR6, like many British cars of the era, used Armstrong lever type

dampers (shock absorbers to us Americans). These units use two

adjacent cylinders with pistons that move in a see-saw fashion

controlled by the lever arm, which is in turn attached to the trailing

arm of the rear suspension. Hydraulic oil is pumped back and

forth between the cylinders, but is restricted by a metering valve.

The metering valve is seperately adjustable for each direction of

oil flow, thus allowing for independent setting of damping stiffness

for jounce (bump) and rebound motions.

The

shocks were grimy and dirt-caked, but the main thing I was looking for

initially is evidence of leaking from around the lever arm shaft.

I didn't really see any, but I delayed any celebration until I

could look at them more closely. There was no doubt that the links were deceased, though.

After

some

cleanup and bead blasting, I checked out the action of the lever

arms. Firm but smooth motion throughout the 90 degree arc of the

arms told me that these units might just be serviceable. The

units may not be originals, but early 80s replacements. If so,

they didn't have many miles on them. When I removed the caps, I

was really happy to find both shocks still filled to the top with oil.

Though

these shocks are not considered DIY repairable, I was prepared to give

it a try anyway if necessary. A typical failure mode is leaking

around the arm shaft, which apparently has a rudimentary bearing and no

real seal. Commercial rebuilders often machine the body to accept

a better bearing and a true oil seal, which is what I would have

attempted. This was moot, though, since the shocks apparently

didn't need any repairs.

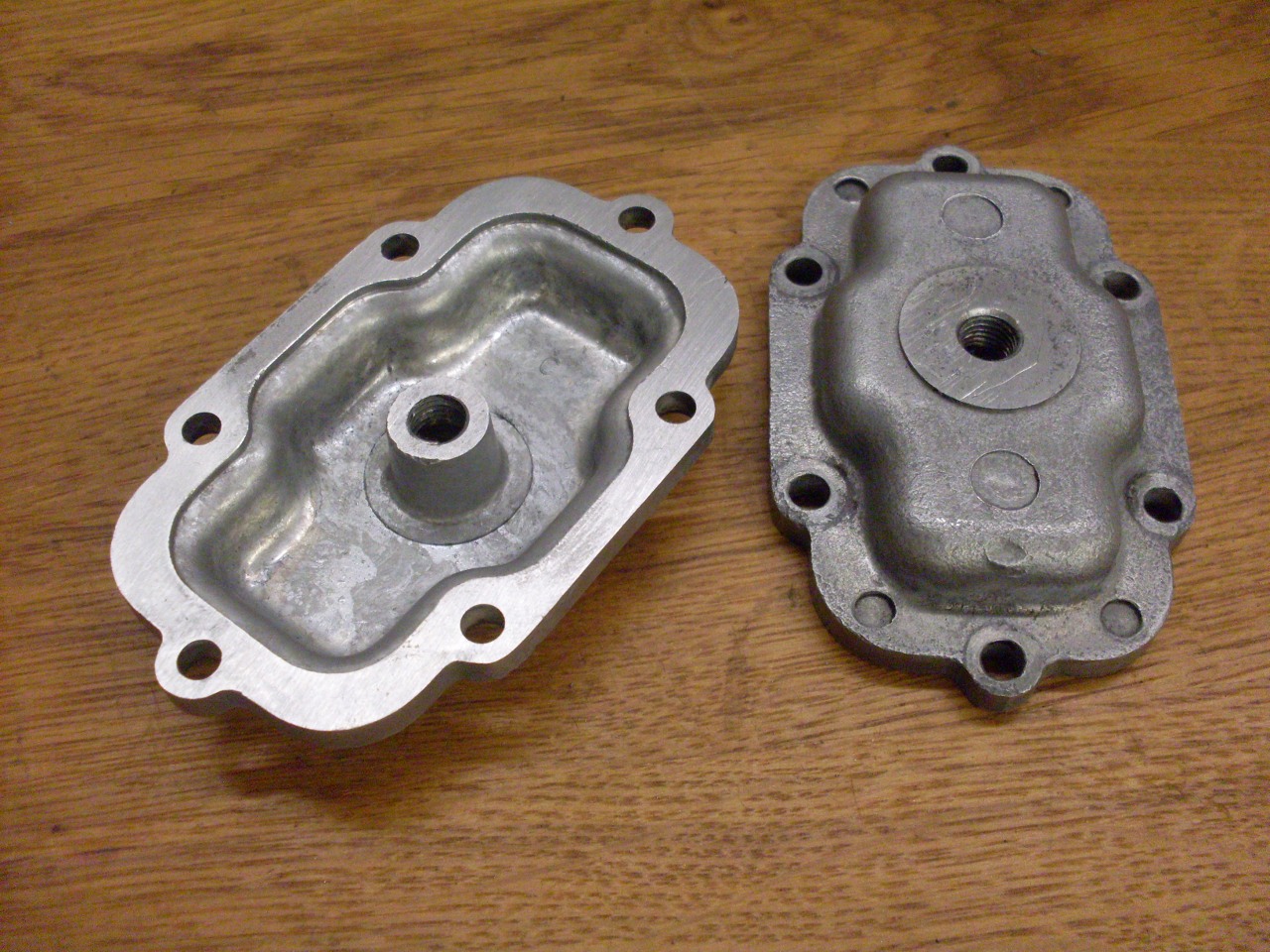

I

did decide to flush out the units and replace the 30+ year old oil with

fresh fluid. It would also make sense to replace a few rubber

parts along the way. The fluid gets drained by removing the body

cap and the valve assembly and pumping the arm over a catch basin.

The body caps get a routine linishing to maks sure they are flat.

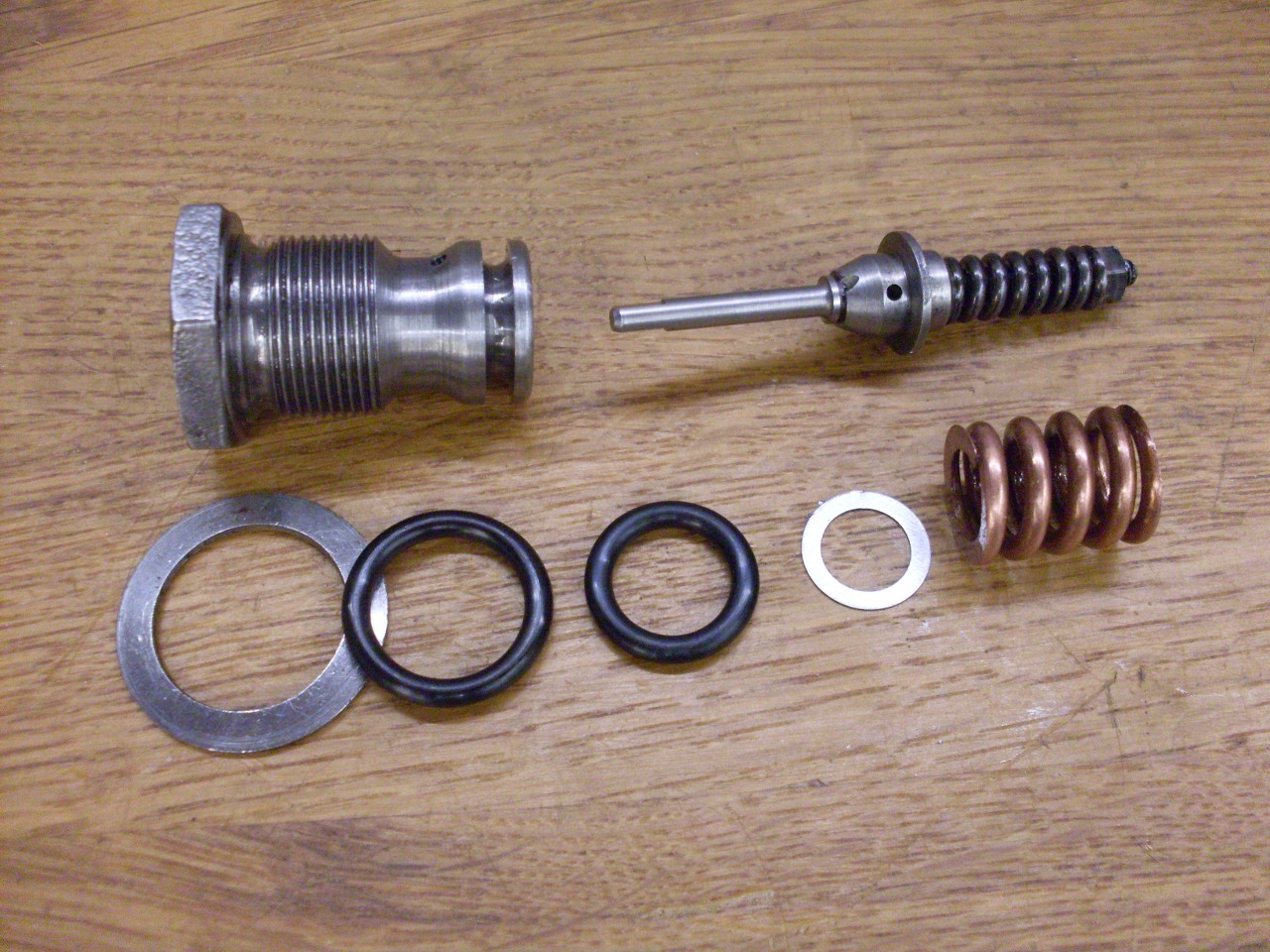

The

valve assembly has two O rings--a smaller one to make sure the flow

from one cylinder and the other goes through the valve and not around

it, and a larger one to seal the valve assembly in the body. The

O rings are industrial sizes -111 and -113, respectively. I

didn't do any adjustment of the valve at this point, but if I had, the

jounce damping is controlled by the shims under the large copper

colored spring. while rebound stiffness is set by turning the nut at

the top of the smaller, longer spring. The pic shows the assembly

with new O rings. The one shim was from the factory. This

must vary, since the valve on the other side didn't have any shims.

After

draining, and flushing a few times with mineral spirits, I primed and

painted the bodies, replated the hardware, and made new cork gaskets

for the body caps.

These are the units ready for refilling.

I

found the quickest way to refill the shocks is to fill the cylinders

first through the valve cavity. With the shock mounted sideways

and the valve removed, oil is put into the valve cavity, and the arm

pumped. This is repeated until the level of oil in the cavity

doesn't fall with movement of the arm, and no more bubbles are seen.

The movement of oil from one cylinder to the other can be plainly

seen in the cavity. The valve assembly is then inserted and

tightened.

Lastly, the reservoir is filled.

Now it's on the shelf for these dudes until I need them for the rear suspension build.

Comments to: elhollin1@yahoo.com

To my other TR6 pages