To my other TR6 pages.

March 27, 2014

Coolant Return Tube

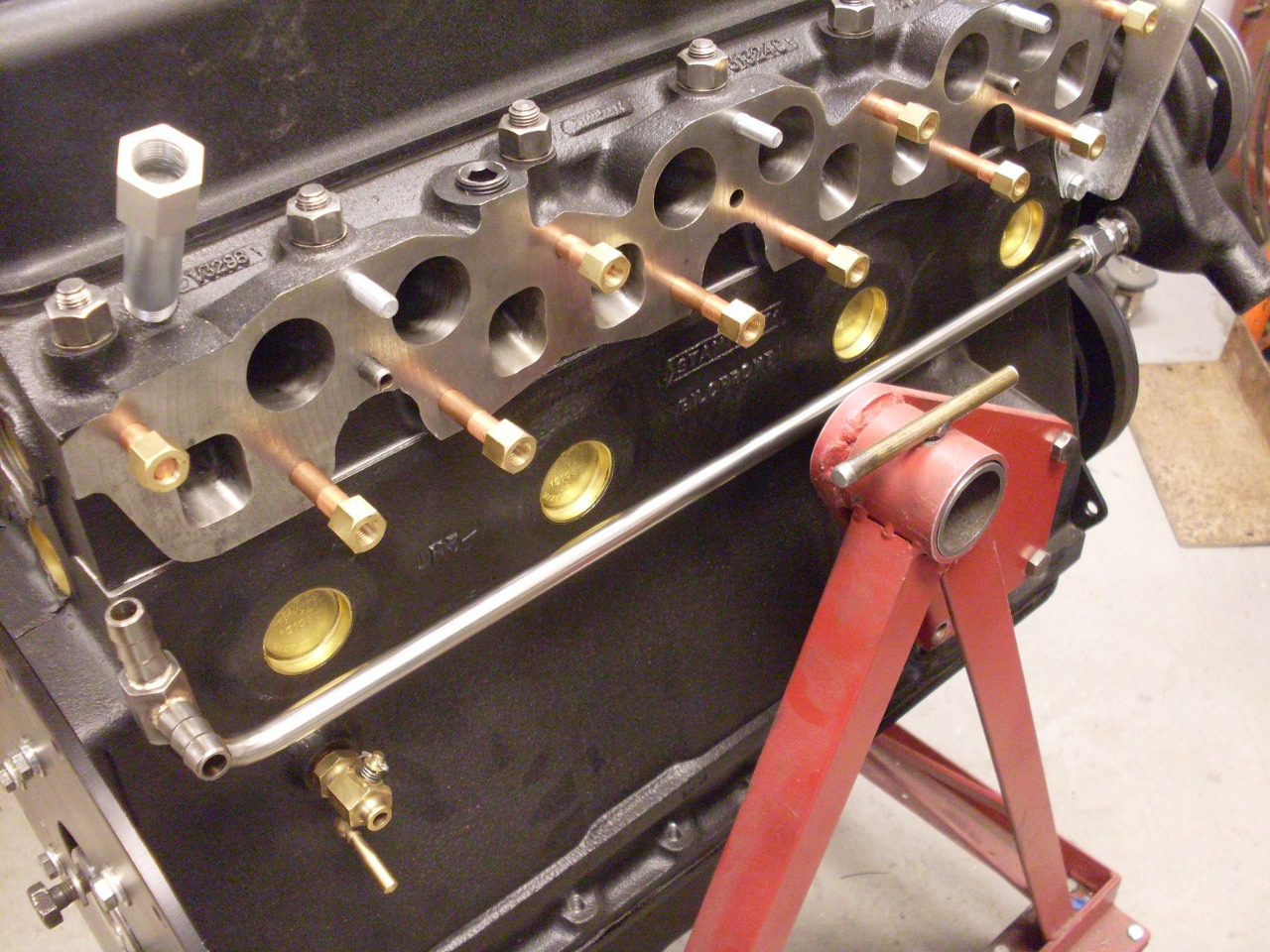

The

TR6 engine has an external 1/2 inch steel tube that returns coolant

from the heater core and the intake manifold heater at the rear of the

engine to the water pump housing at the front. It runs under the

exhaust manifold, so it's exposed to pretty harsh conditions, both

inside and out.

The

tube on my car was pretty severely rusted on the outside, and totally

clogged on the inside. After derusting, there wasn't much left in

some places. The passage in that little stub pipe is open only

because I drilled it out.

I

considered the tube toast. There are aftermarket replacement

tubes available, even stainless ones, but considering the probability

of disappointment with the quality of aftermarket parts, the return

tube seemed like a good candidate for a home-made replacement. I

determined that whatever the replacement turned out to be, it should be

made of some more durable material, like stainless steel.

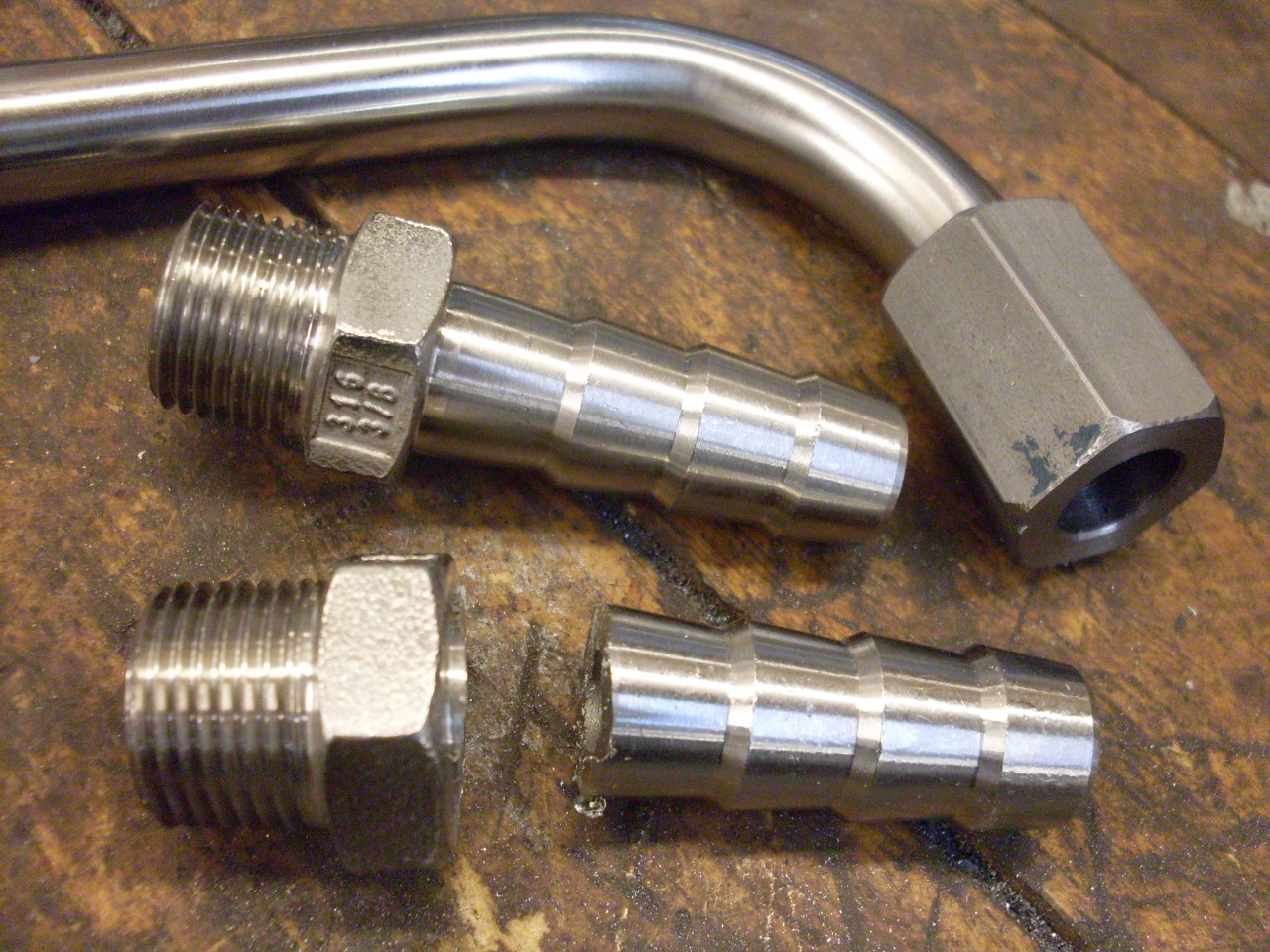

My first attempt at making a replacement consisted of a stainless tube (left over from the replacement of the intake manifold heater pipe)

and stainless plumbing fittings. When it was finished, I thought

it looked kludgy and clumsy, and it didn't reproduce the positions of

the tube connecting points very well.

One

of the reasons I wimped out and used a plumbing elbow is because I

didn't have a good way to bend stainless tubing to the necessary

radius. I took a day or two to modify a bender I had, and started

on a new, more encouraging path.

I

now had a pretty good bend, but I still didn't have high confidence in

my ability to make a good looking weld for the stub pipe.

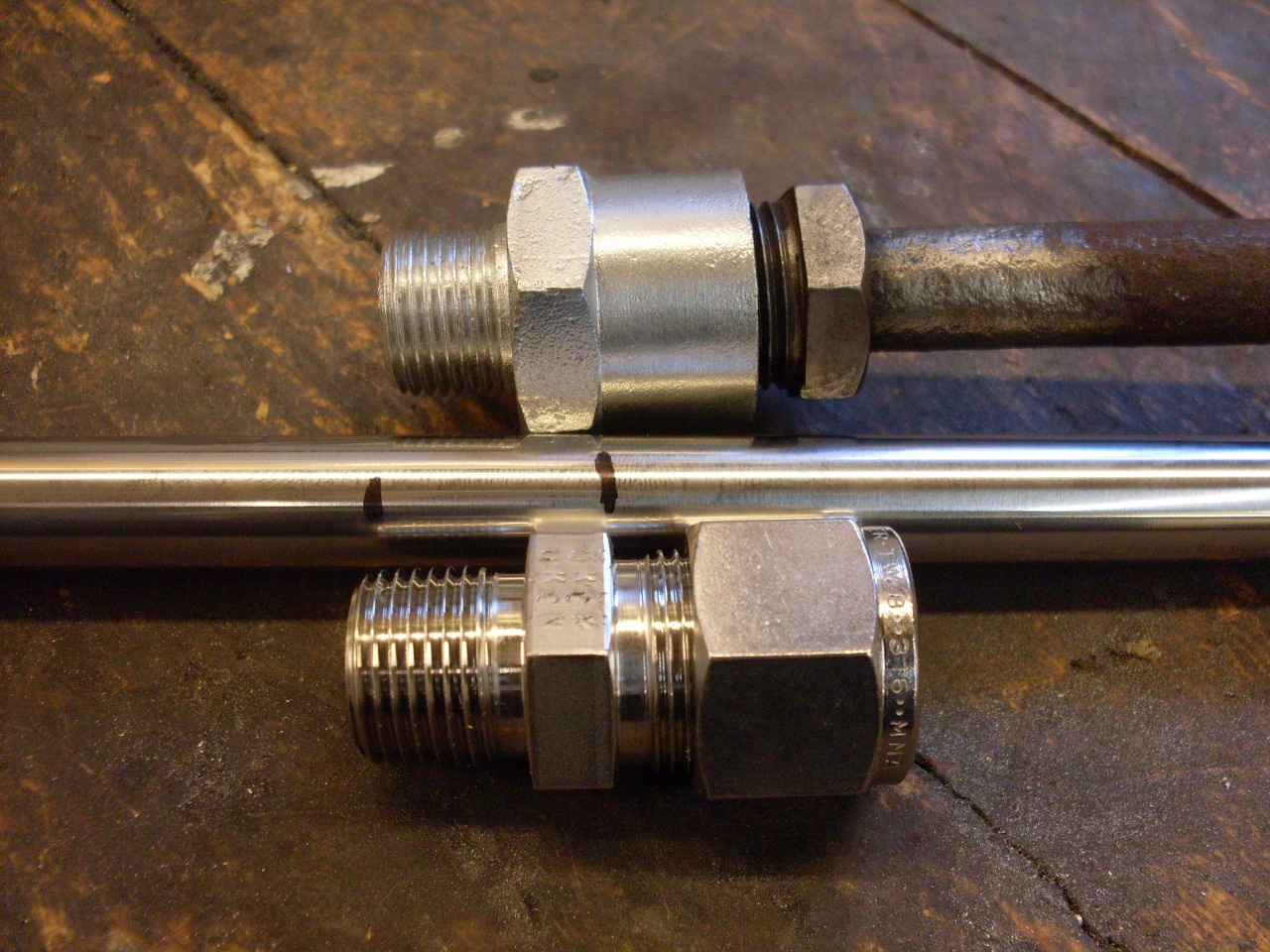

Instead, I found a piece of 3/4" hex stainless to make a "T"

junction.

I cut off the hose barbs from the fittings from the previous attempt and adapted them to fit into the drilled hex.

Then silver soldered the T block together.

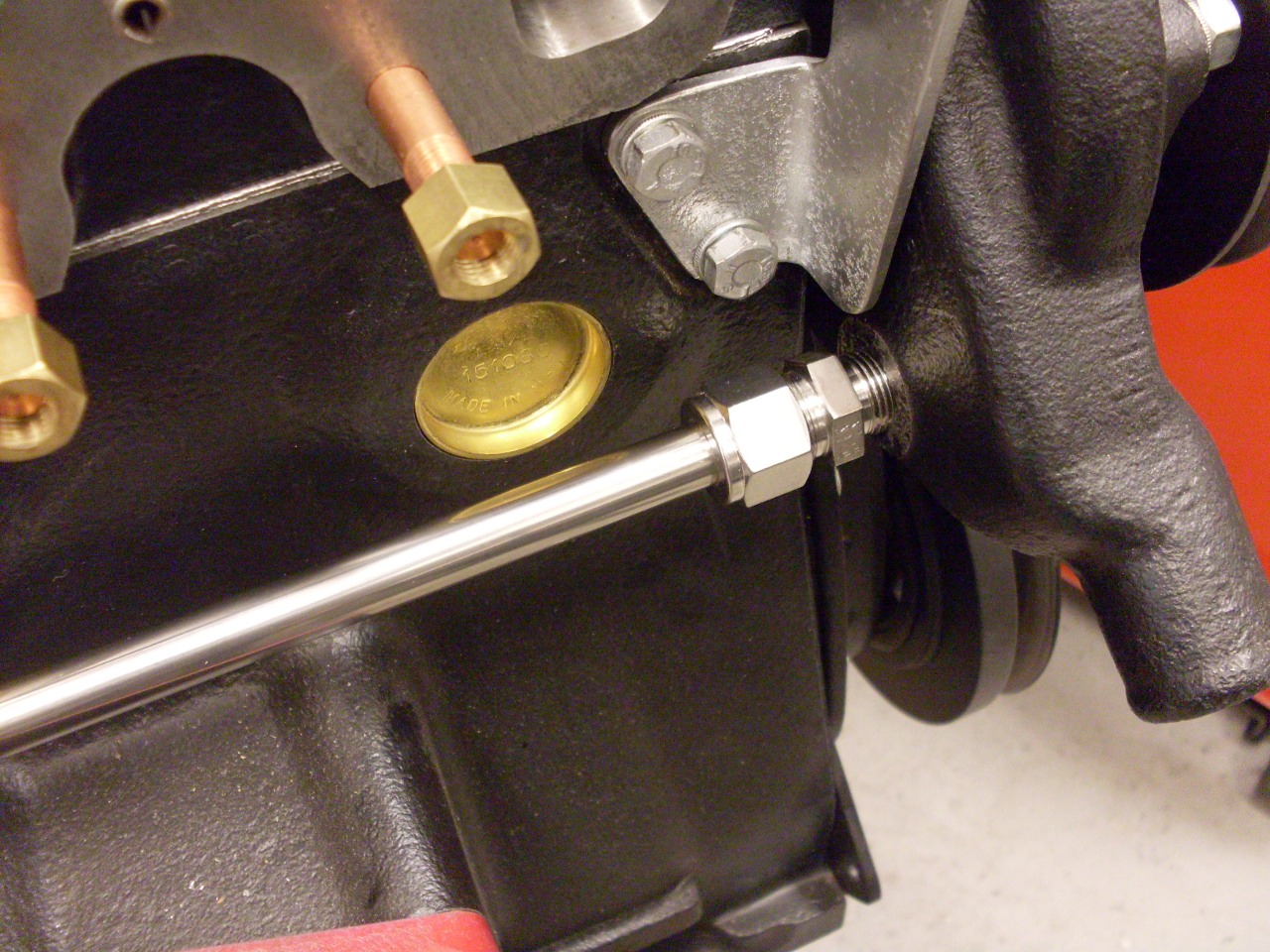

I cut the other end of the tube to length for a new stainless compression fitting.

I like this approach much better.

Now

to make the little support bracket for the rear of the tube.

Another reason for the hex T junction was to give a place to

attach the bracket to the tube assembly. I wasn't sure I could do

a good weld directly to the tube. I got a piece of 1/16"

stainless sheet and after making a cardboard template, cut out the

bracket, bent it, and drilled it.

I attached the bracket with an old surplus spot welder I have, but silver soldering it might have been cleaner.

The tube came out pretty well, and looks nice. Too bad it's mostly hidden.

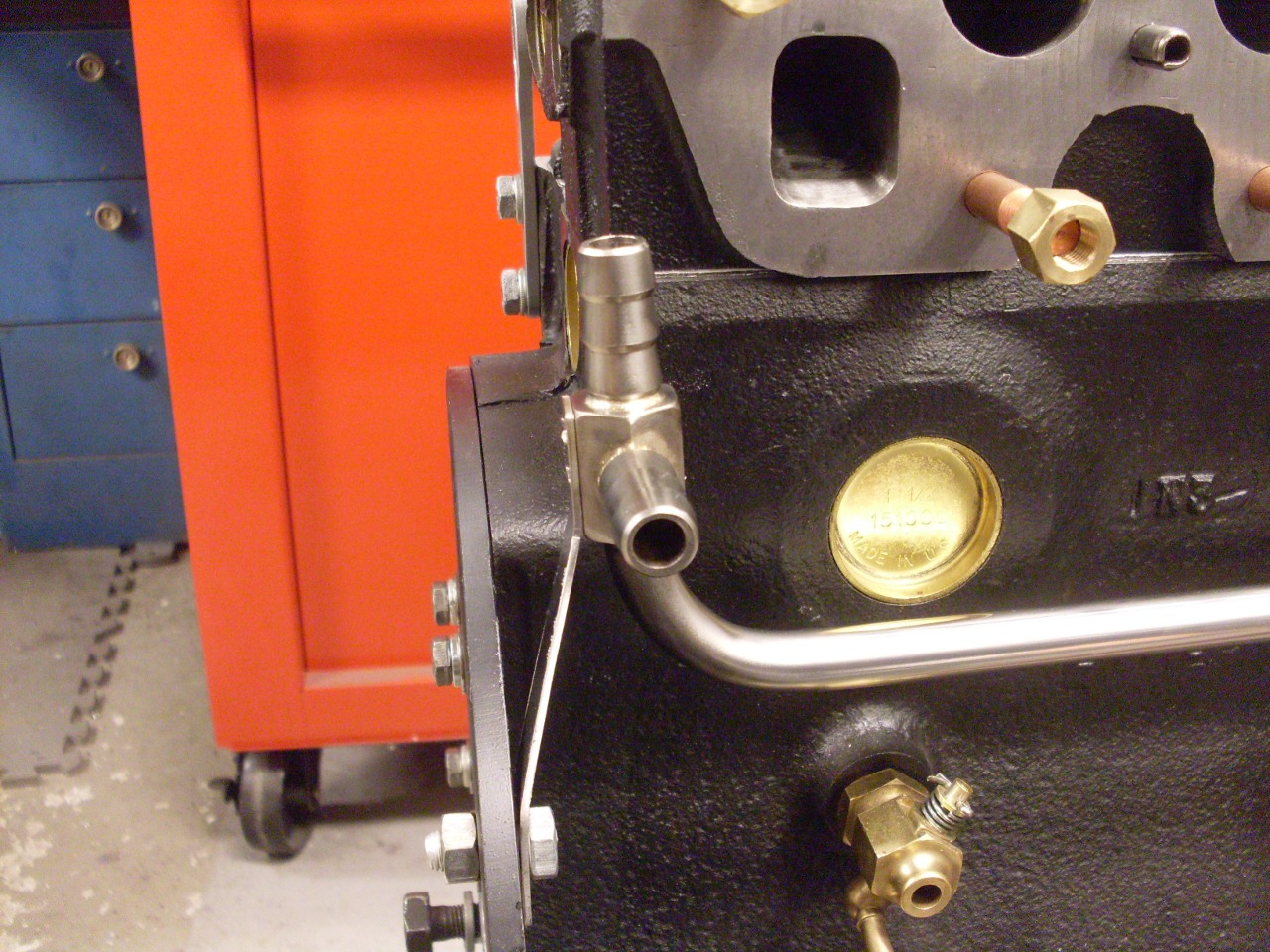

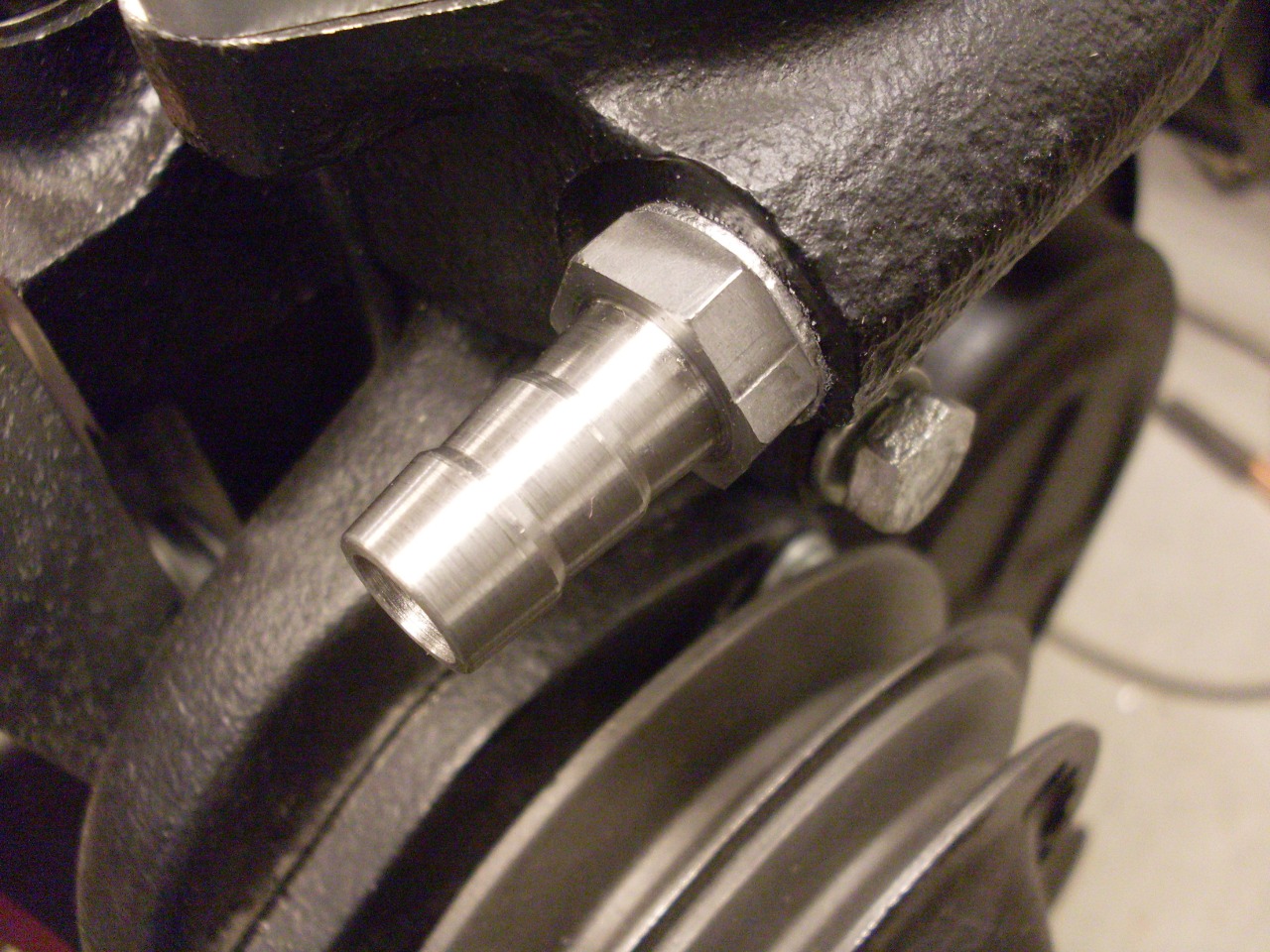

I

had a little of the stainless hex left over, so I made a barb fitting

to replace the one at the top of the water pump housing. I'd

already zinc plated the old one, but it still looked pretty sad.

Comments to: elhollin1@yahoo.com

To my other TR6 pages.