To my other TR6 Pages

January 22, 2019

License Plate Plinth

Well,

I've ordered license plates for the this TR6. In preparation for

getting the plates, I perused the mounting locations on the car.

I realized that since I'd replaced the rear valance, there were

no mounting holes for the plates. OK, I guess I can handle that

somehow.

Then

to the front. I couldn't exactly remember how or where the plate

mounted to the front, so I referred to some of my "before" pictures.

There were two rusty little tabs hanging below the bumper.

"Is that really how it was?" I asked myself. "Looks kind of

cheesy."

I

checked some Internet pictures, and sure enough, at least in '74, that

was the factory offering for the US plate attachment. I also

found that in later years, maybe starting in late '74, the factory (or

US dealers, maybe) began supplying a more proper mounting arrangement

for the front plate. It was a metal plinth that hugged the front

bumper, and looks way better in my opinion.

"OK, no problem", I reasoned. "I'll just get one of those."

Well, it

didn't take long to find out that no one makes or sells new ones these

days, and that used ones are rare and are all apparently silver plated.

I guess it's not too surprising. The part was only used for a couple

of years, and only for US cars. Also, not all US states even require a

front plate.

So

I pawed around in the box or two of what few parts weren't already on

the car, and came up with the original brackets. I cleaned them

up, but I just couldn't do it. I couldn't put those brackets on

this car. They just look too much like a shade-tree hack to me.

I

also didn't want to pay a couple of hundred dollars for a used plinth.

The remaining options are few. I started to think about how

I might mount the front license plate.

In the mean time, I busied myself with the rear.

I

like these little plastic push-in nuts for license plates. They

don't rust, don't sieze, and can be easily replaced when they wear out.

But,

they take a square hole. Unless a suitable punch is available,

this is a pain in the backside. I don't have a suitable punch.

I started by marking out the position and shape of the holes, then drilled them round, and filed them square.

Removed the tape, and pushed in the nuts.

Dug up an old plate for a trial fit.

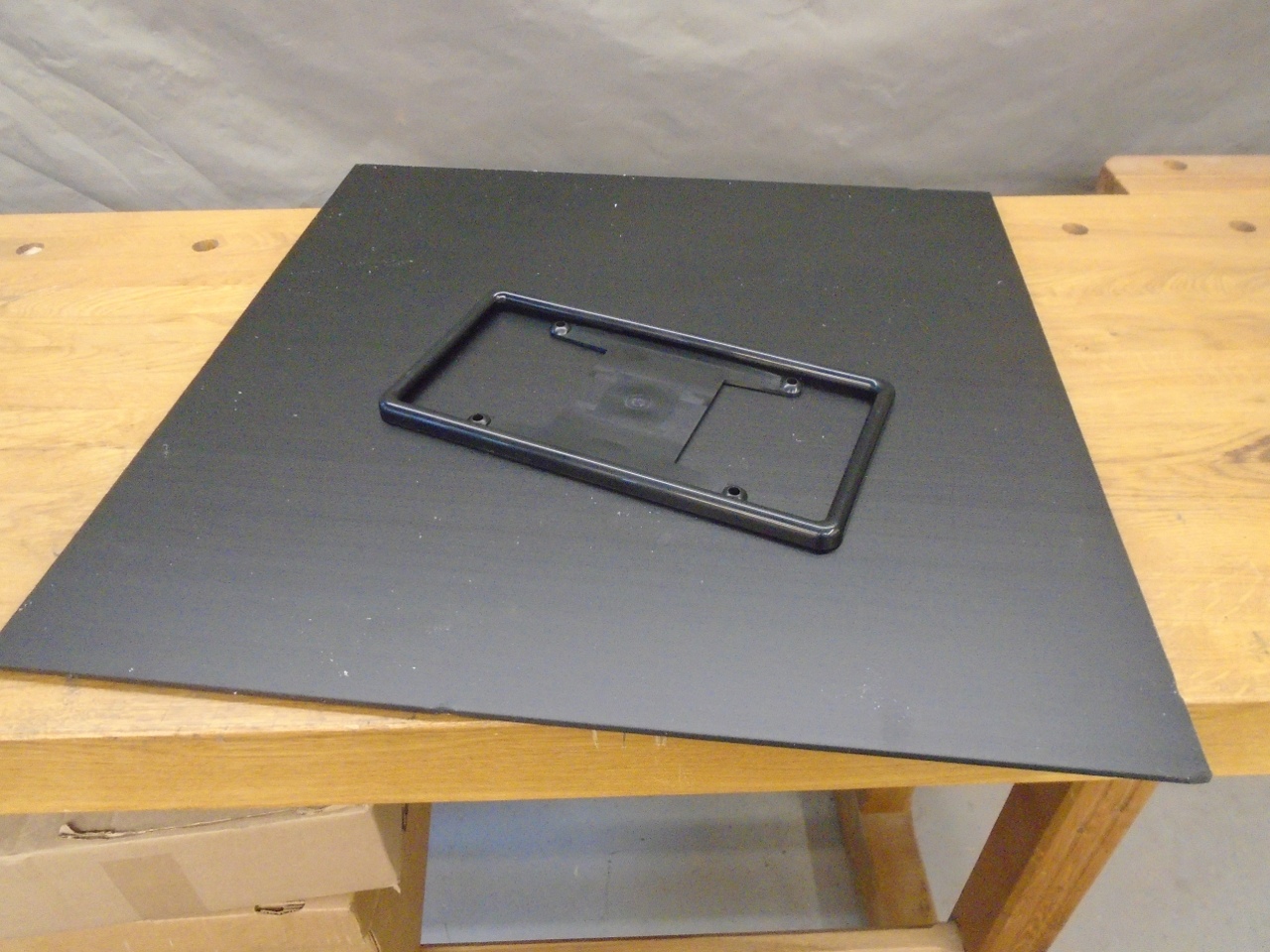

By

this time, I had sort of a plan for the front. I started with a

nice license plate frame just like the one in the rear. This

would give me the overall size for the plinth and also provide a

pleasing profile around the plate so my construction wouldn't have to.

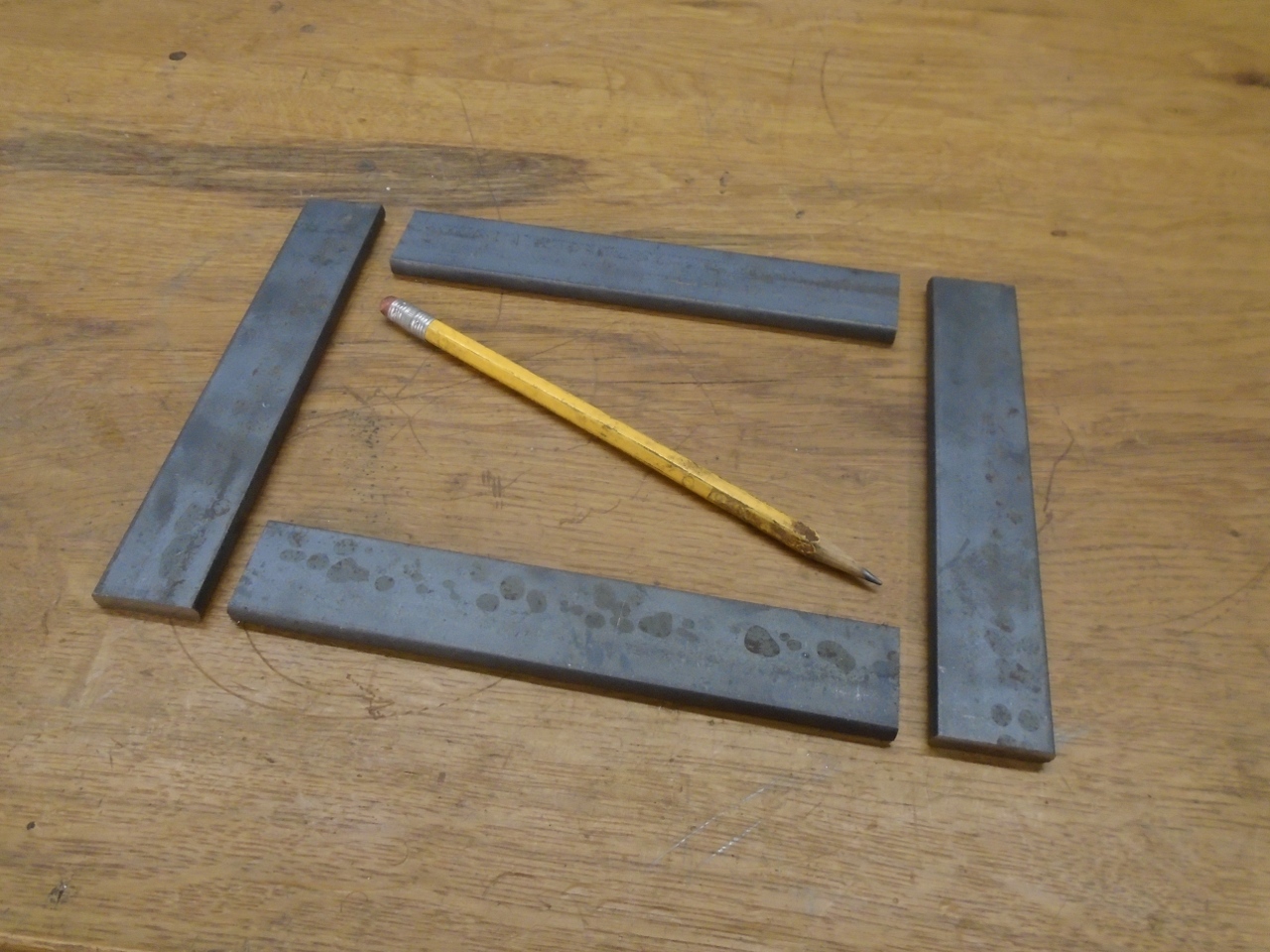

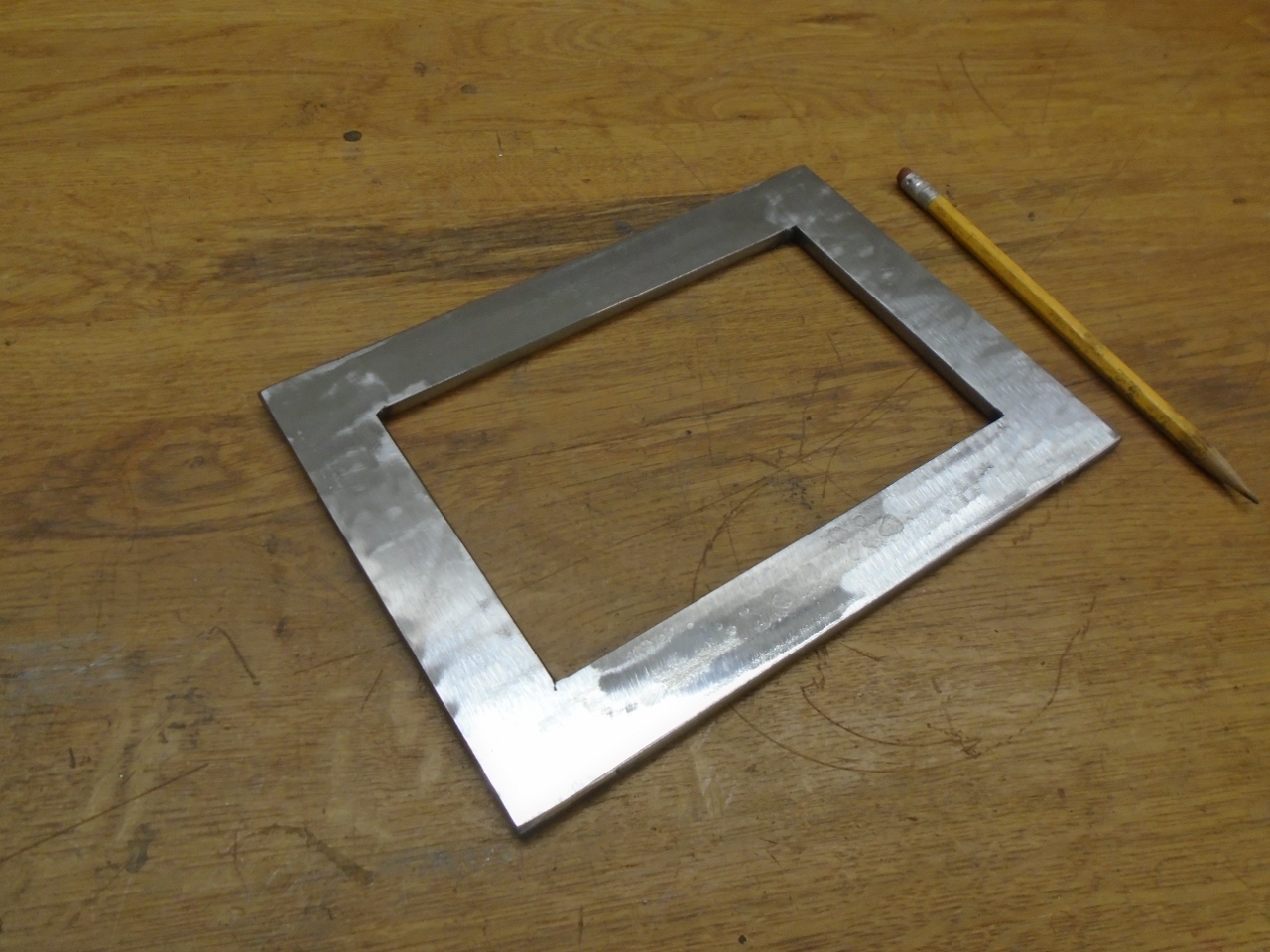

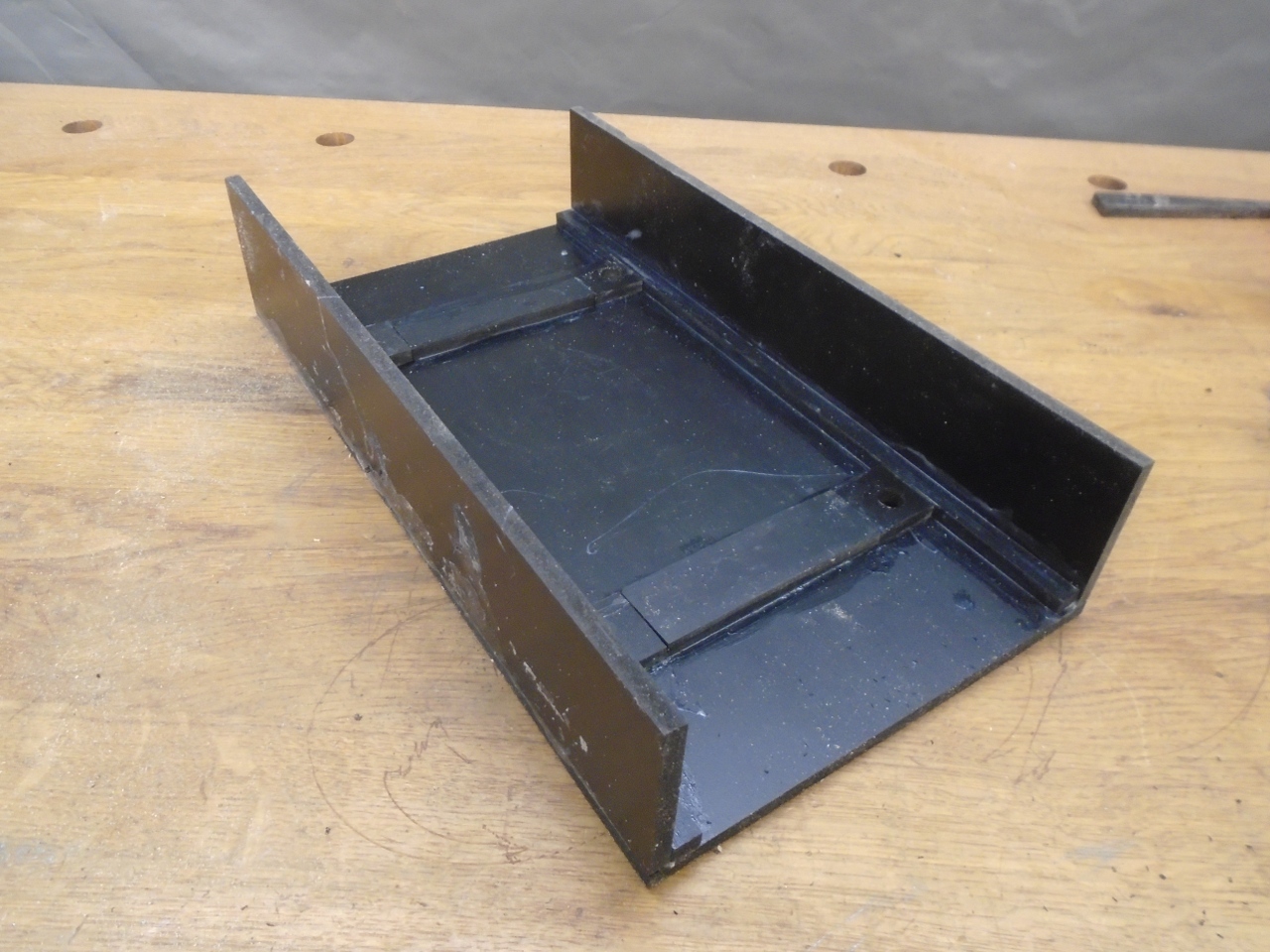

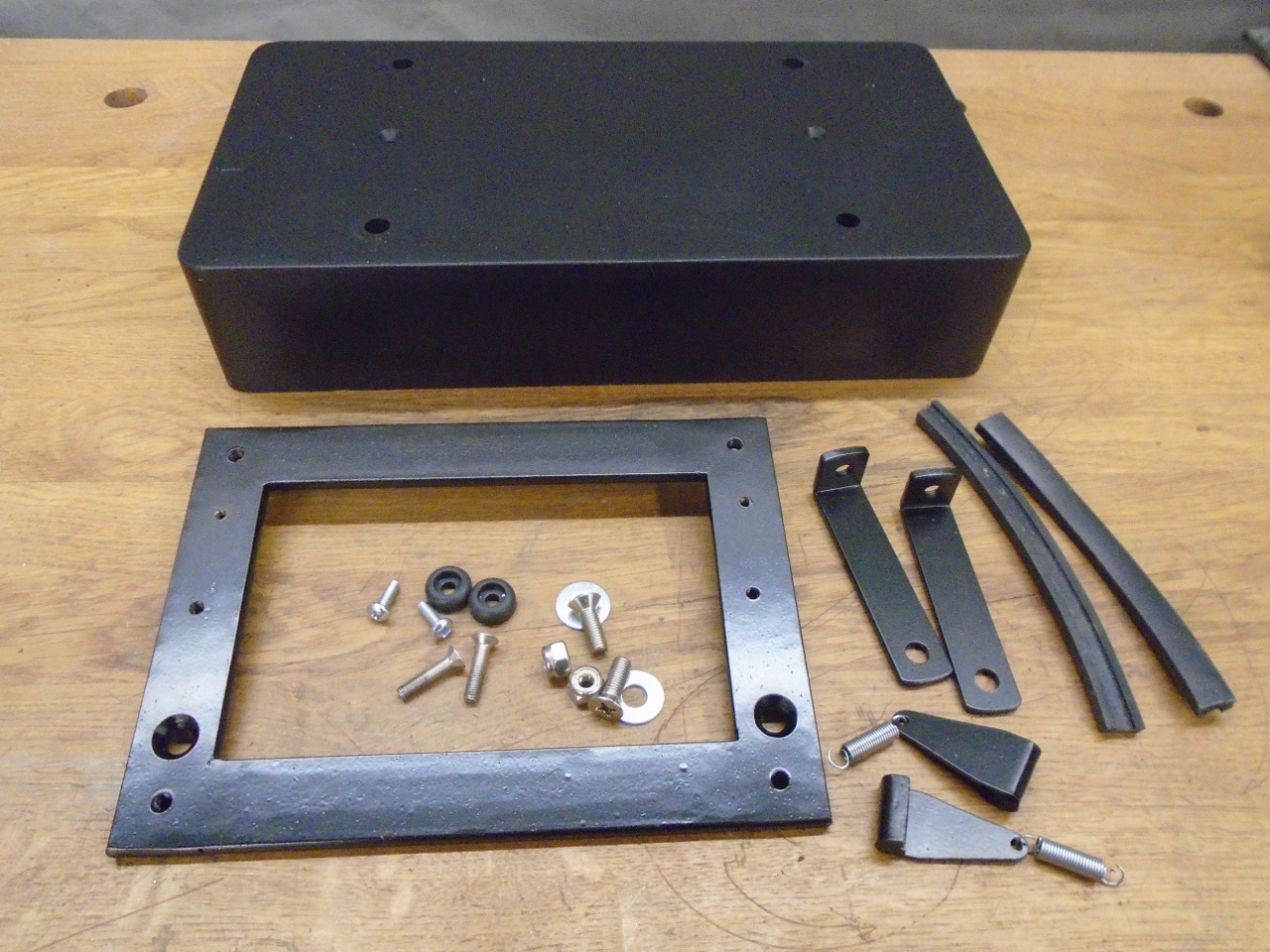

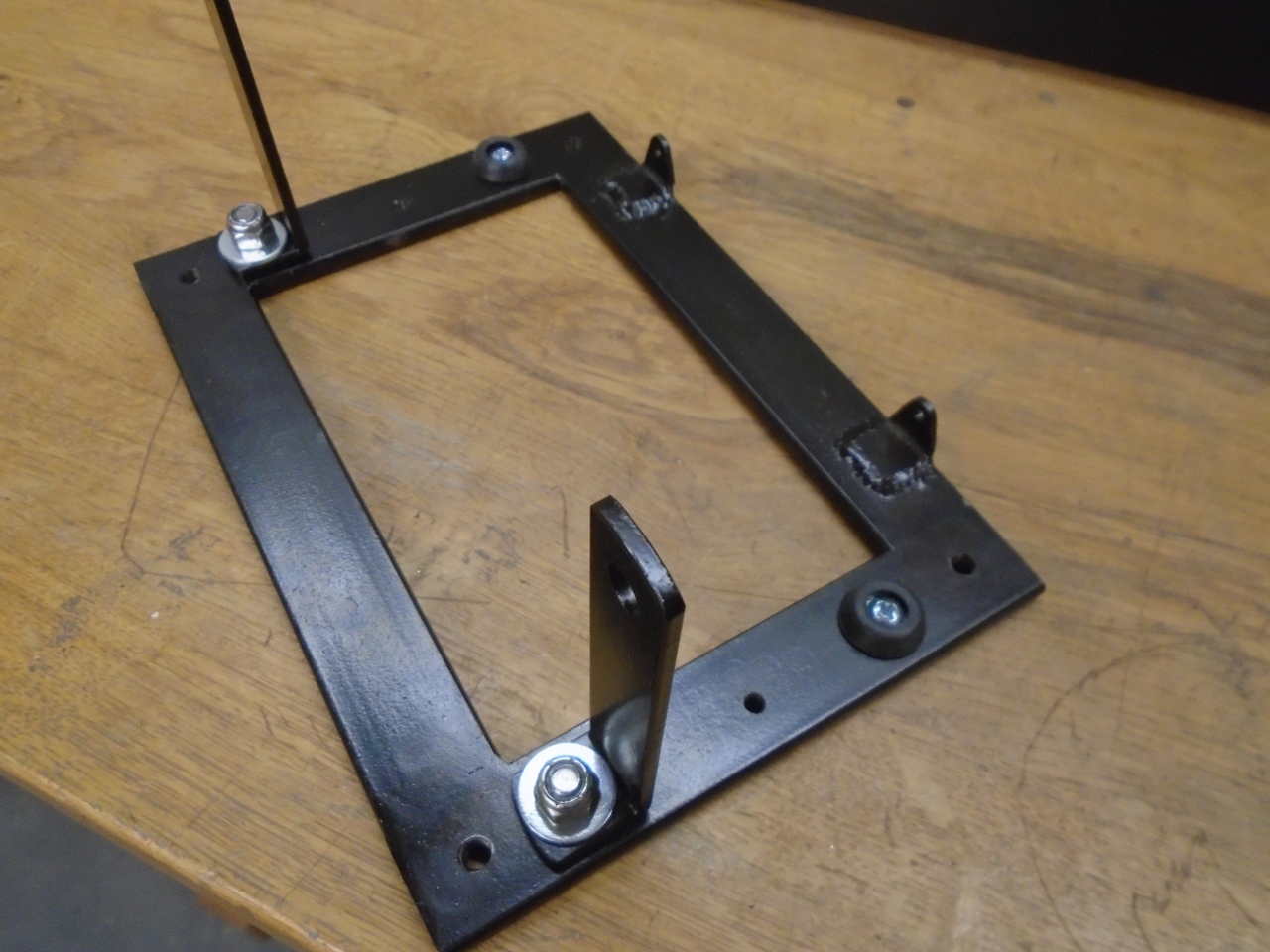

Using

the plate mounting holes and the bumper dimensions as a starting point,

I worked out a substructure bracket for the plinth.

The

braqcket has two little struts to connect to the original plate

mounting holes on the lower lip of the bumper. Oddly, the

original plinth apparently had struts that went all the way to frame

members. The bracket rests on the bumper through some 1/4" thick

rubber pads.

The top of the bracket ties back to the upper rear lip of the bumper with a couple of stiff springs.

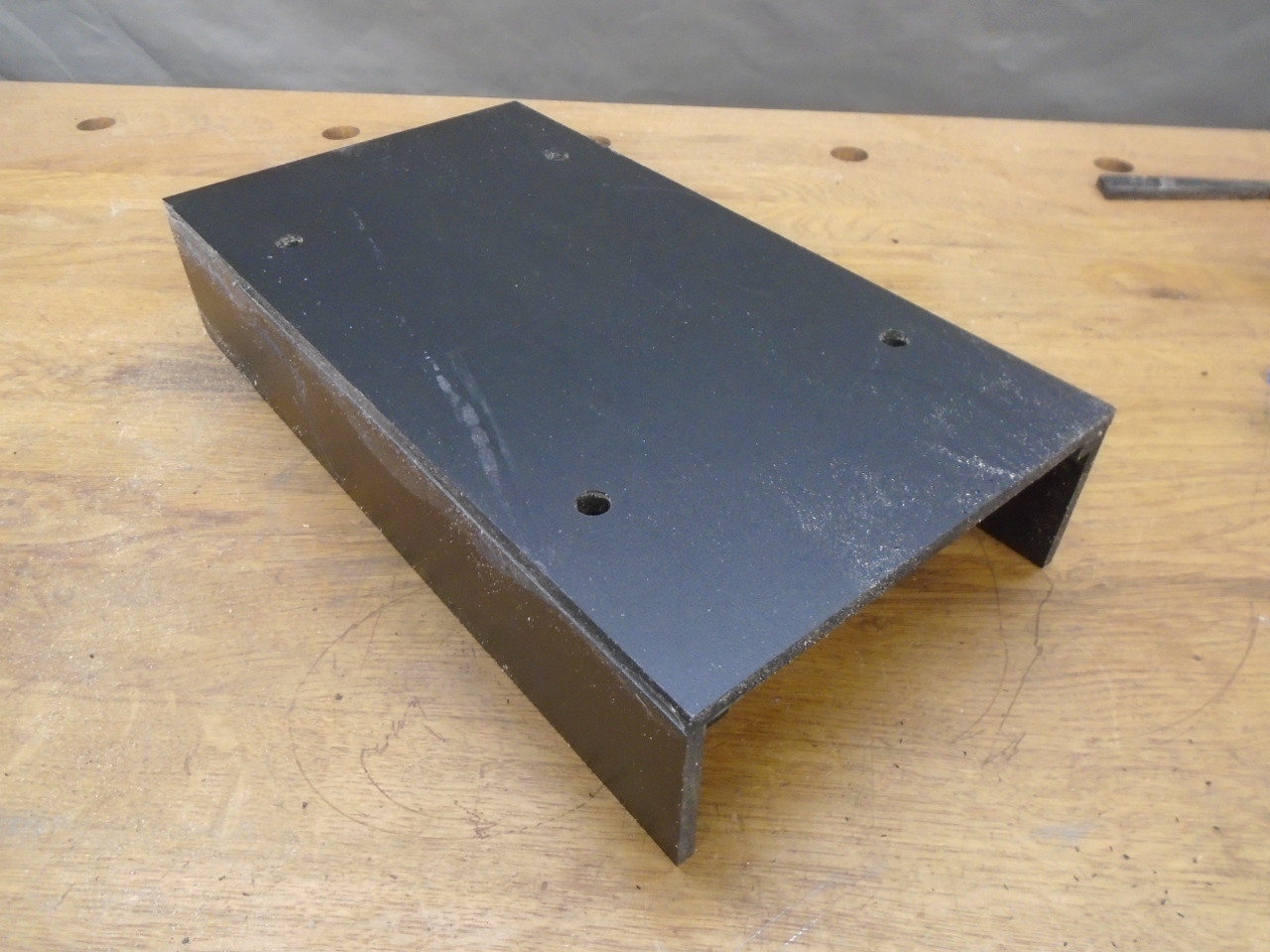

This

bracket is covered with a box-like piece about the same size and shape

as the original plinth. I decided to make the box out of the same

PVC foam board I used for the center console.

The material is strong, light, rated for outdoor use, and cuts

and glues well. I made up the box, except for the right and

left sides. The material is doubled up in the corners and around

where the fasteners go.

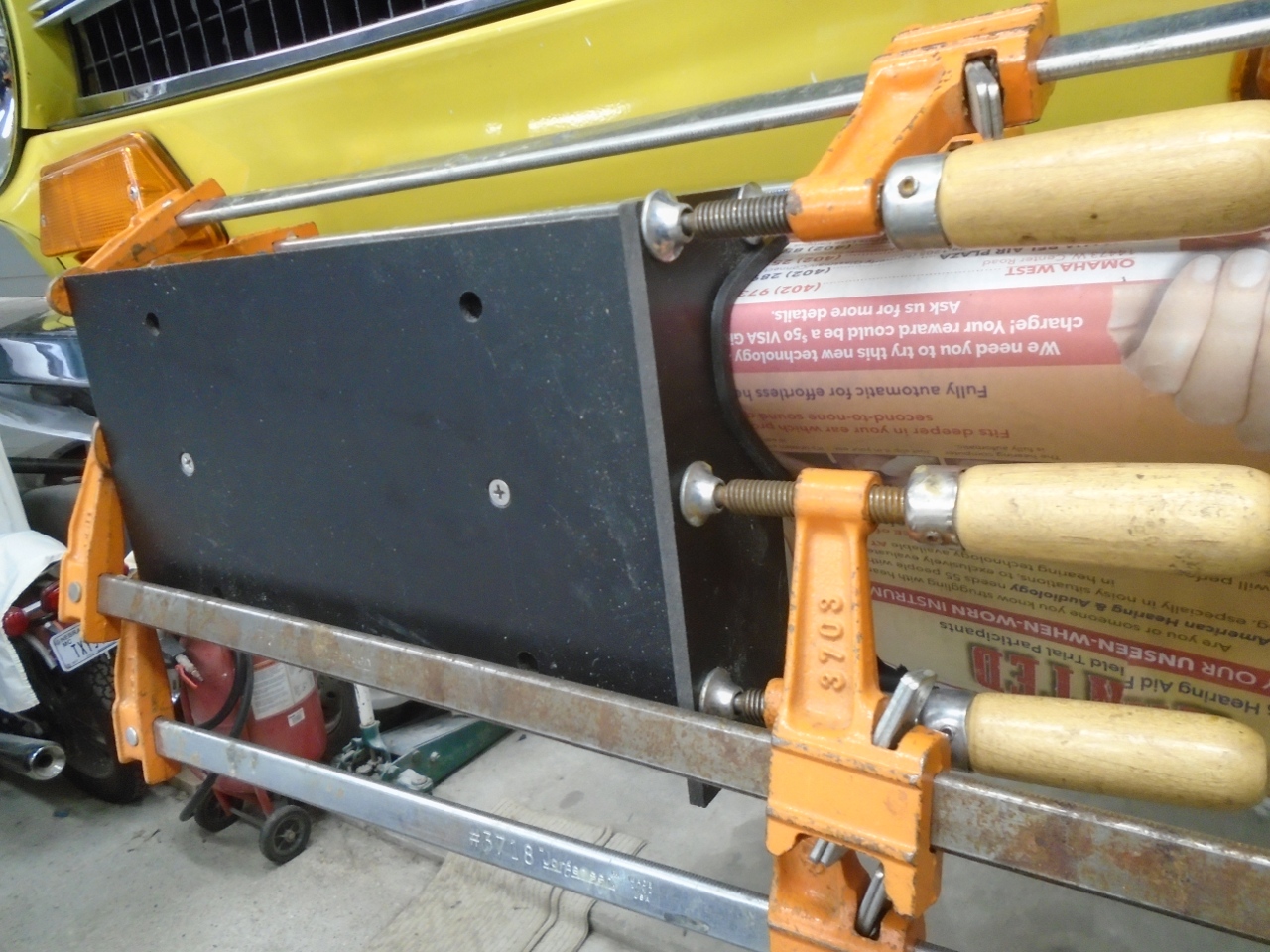

The

two sides, which had to have cutouts to fit the bumper profile were

made last and adjusted to fit the bumper well with the rubber gasket in

place. They were left large everywhere else. When the

bumper fit was good, they were glued to the box while in place on the

bumper.

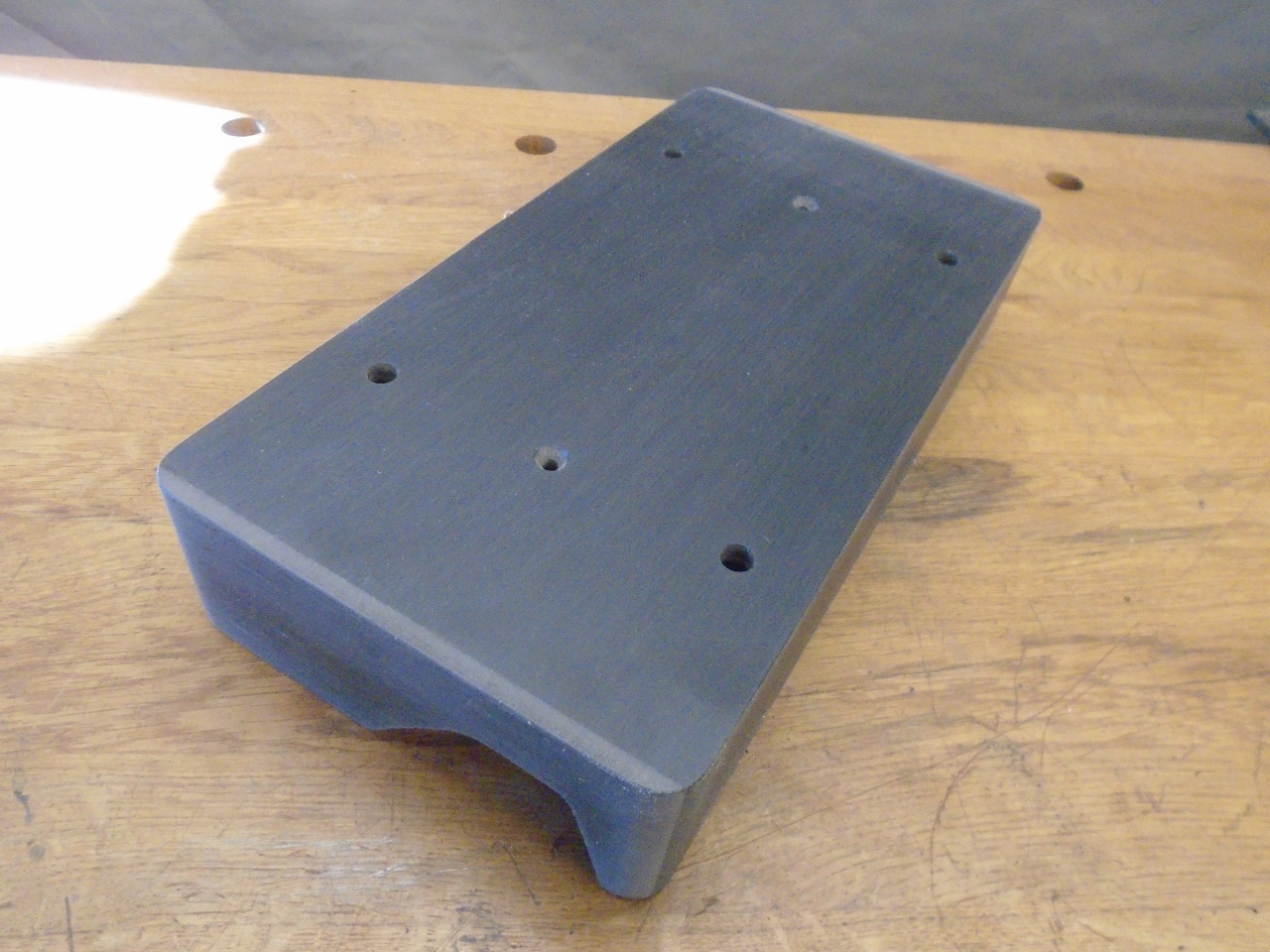

When

the glue was set, the box was moved to the bench where the excess

material was removed from the sides, and the corners were

reinforced.

Then

the corners were rounded, the whole thing sanded, primed with a

plastic paint, and topcoated with trim paint to match other windshield

frame and rear valance.

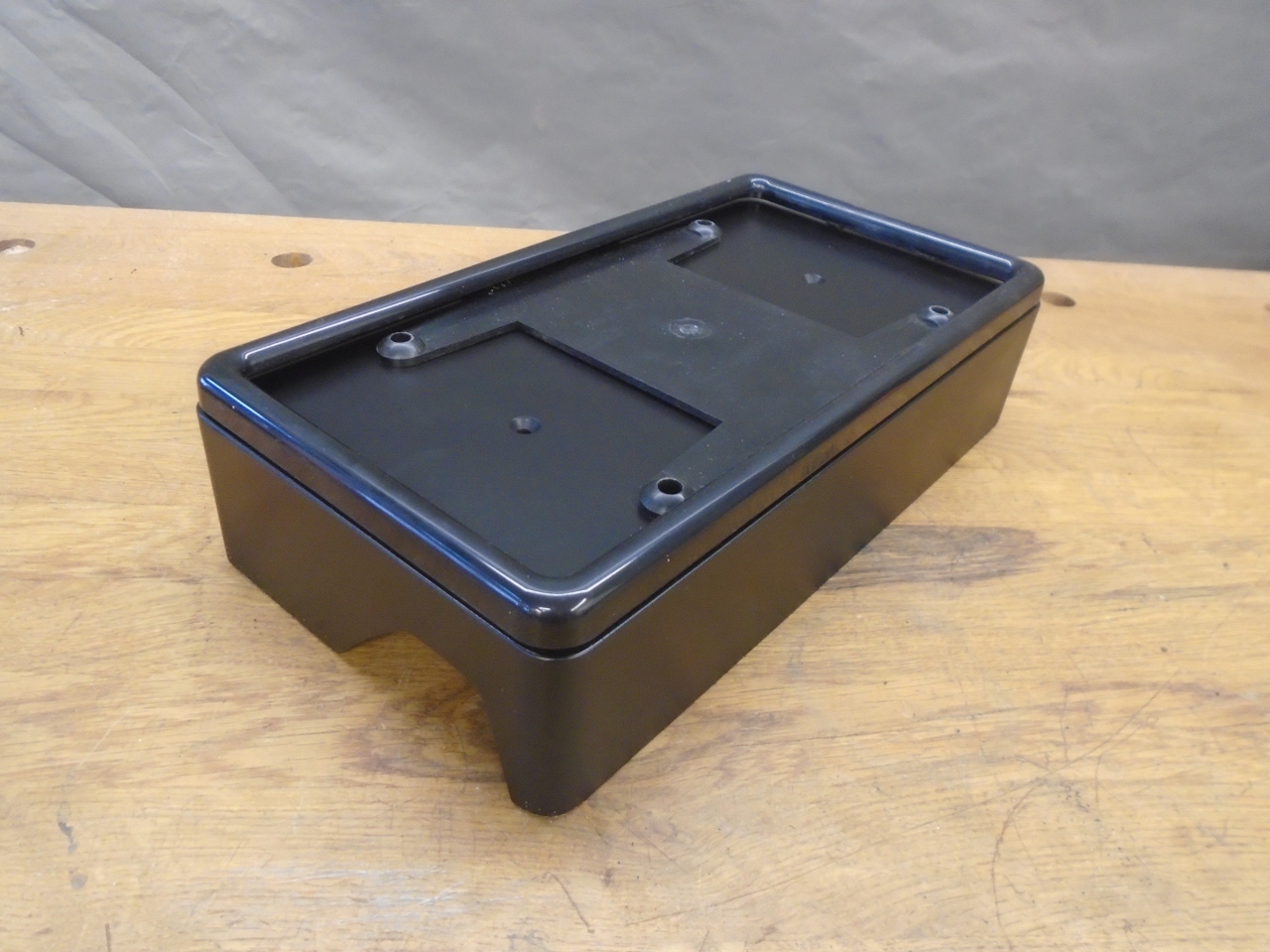

So,

with everything ready, I powder coated the metal parts and put it

together. Little rubber feet took the place of the rubber pads.

The little hooks for the rear bumper lip got lined with rubber to protect the chrome.

Then the box went on.

I don't have the plates yet, so this will have to do for now.

If

this seems like a lot of work for a trifle, it is. The cost was

pretty low--just the plastic and some hardware, but it took some time.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 Pages