To my other TR6 pages.

November 20, 2018

Odds & Ends I

Even

though I've got the car started now, and have even driven it up

and down the driveway, I realize there are still dozens of loose ends

to attend to. Here are a few of them.

Rocker Trim

The

rocker panels on at least some TR6 cars were black. I'm not

certain whether all cars were that way nor whether the black was paint

or some textured coating. Either way, I think the black rockers

make the car look a little longer and lower. I like the look, so

I set out to recreate it.

There

was a polished stainless strip that spanned between the wheel wells at

the top of the rocker panels, just beneath the doors. This strip

marks the transition from body color to black below. My trim

strips were really dirty, but other than one sizeable dent, they

cleaned up pretty well.

I got the dent pretty much out by using rollers and wooden dollies. It looked good enough that I decided I could use it.

Next

was to mark out the locations of the fasteners for the strips.

There was a surviving hole on the bottom of each of the

rear wings, but everywhere else was new metal. There were seven

fasteners for each strip, so I just laid them out on a straight line

pretty much equally spaced.

Then masked a line through the holes.

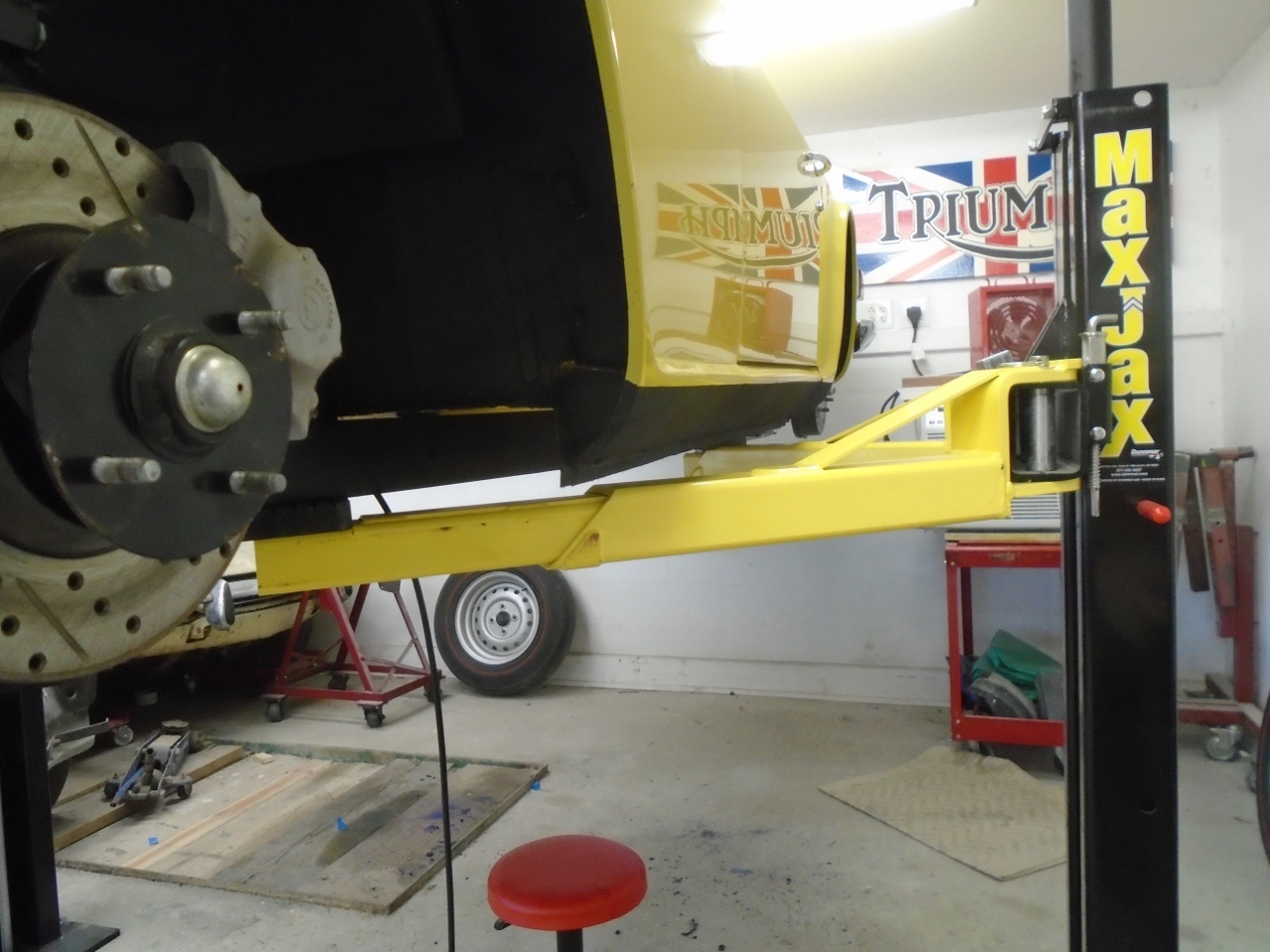

I

decided to use the same 3M Schutz product that I used as undercoating

in the wheel wells. It sprays from a special gun and builds up

fairly quickly. There is a version of this product especially for

rockers, but I believe the only difference is that it is paintable.

Since I'm leaving it black, I think this product will work fine.

I

found that the Schutz can tend to splatter everywhere, and isn't easy

to remove, so I masked the rest of the car and also my brand new lift.

And a few minutes later, it was done. I used nearly a quart on both sides.

The fasteners for the strips are just little steel buttons blind riveted to the body panels.

The strips just snap on to the buttons.

Side Mirror

Side

mirrors on TR6 cars were apparently dealer-applied items, and

there were reportedly several kinds used. I'm not sure my mirror

is dealer original since there were several sets of mounting holes in

the door. It certainly is period correct though, since it was on

the car when I bought it in '78 or so.

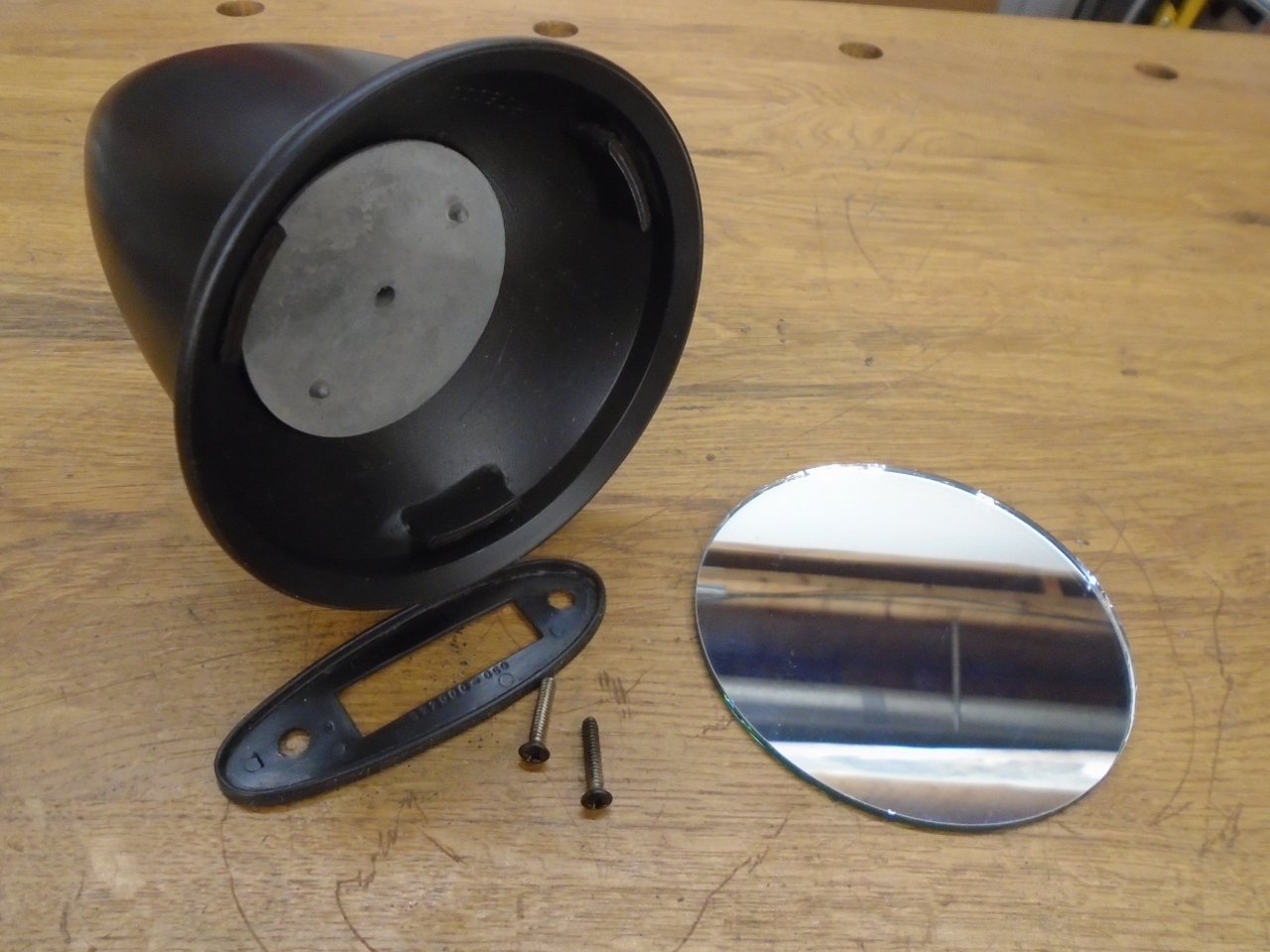

The mirror assembly looked pretty worn and dirty, but it didn't appear to be damaged, except for the mirror glass itself.

It came apart pretty easily.

The pot metal castings were generally OK, but showed some casting flash on some of the edges. These were easy to clean up.

One

thing that sort of bugged me about the mirror is that it was designed

to be mounted with sheet metal screws at a pretty pronounced angle.

I consider this sort of a sloppy design, but I guess the price

point dictated some of these details. I did a little reshaping of

the base mounting holes so that I could use parallel machine screws.

The paint came off a little too easily. Also got a new 4" mirror form the hobby store.

Epoxy primer, and a top coat to match the windshield frame and the rear valence.

Finally, glued in the mirror.

I

was hoping to mount the mirror on that flap of metal that extends out

over the A post since, using machine screws, I'd have access to the

nuts on the backside. There just isn't enough room for this

mirror, though. That curved line is the location of the body of

the door underneath.

So I had to move the mirror back so that the rear fastener would go inside the door.

I

didn't really want to remove the handles and door card just to get to

that one fastener, so I used a rivet-nut in the rear hole, though

I apparently don't have a picture of it.

This is where I discovered that angled fasteners would have made mounting a lot simpler, but I persevered, and got 'er done.

Seat Belt Install

In

preparation for mounting the seatbelts, I located the mounting holes

under the wheel well vinyl, nervously cut relief holes, and tested the

hardware.

I dug out the rebuilt original Kangol

Reflex seatbelt assemblies from the store room. There were some

little bent metal tabs with them. I included them with the

restoration, but didn't really know what they were for. Well

after installing the seatbelt reels, I now believe that those plates

serve to hold the reels parallel to the floor. Since the reels

are based on a internal hanging weight, they must be installed level.

Otherwise, since there is just one mounting bolt, the reel might

become cocked, and would not work properly.

To round out the seat belts, I gathered up the new "parkers". I think the entire time I drove this car, I either never noticed these little things, or never knew what they were for.

I'm not sure exactly where these were placed originally, but back near the door opening buttress seemed a logical place.

Should have made them brown.

Wiper Arms

I

of course assumed that the wiper blades would be shot, but I wasn't

sure about the wiper arms. They were certainly dirty and beat up.

After

some cleanup and inspection, they seemed to be working OK. The

only issue was that the right side arm was missing a little clip in the

hub that attaches to the wheel box spindle. I guessed this was

some sort of retainer, and I didn't see a good way to make one, so I

ordered a new right side arm. The new one varied slightly from

the original.

Now,

to make the left arm look as good as the new right one, I stripped it,

epoxy primed it, and then shot both arms with paint to match all the

orther black trim on the car. Then added new blades.

Not sure they are adjusted optimally, but they work.

Update:

It was gently suggested to me by a kind member of one of the TR6

forums that I might have in my enthusiasm inadvertently swapped the

wiper arms. He was right, of course, and that is why the arms in

the picture above look ill-fitting.

Luckily, fixing it was trivial:

None

of the tasks here cost very much, but they seem to take a lot

of time. I've got a long list of little things that need to

be done on this project in order to truly call it done. I expect

it will take the rest of the winter to get to them all.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages.