To my other TR6 pages

January 22, 2018

Battery System

With the wrap up of the wiring,

the only piece of the electrical system left to do was the battery and

its associated parts. I didn't think there was much to change in

the battery system untill I got down to some of the details.

First,

I dug out the battery cables. The positive cable looks to be

about 6 gauge wire with a crimped tap along its length with four spade

connectors. This is where the alternator connects to the battery, and

where all of the electrical loads except the starter source their

power. The battery terminal connector was roughly cast or forged

brass or bronze.

The ground

cable was heavy tinned copper braid that ran from the battery negative

terminal to a bolt on the rear plate of the engine. Crimped and

soldered along the way was a tap that was bolted to the firewall to

provide the return path the the body. The tap on my cable was

missing.

I

thought I could replace and maybe improve the battery cables by making

my own. I started by looking for battery terminal connectors.

I bought a set of these, based mainly on the glowing marketing

copy, plus the fact that liked the idea of all connections being

made directly to the connector, thus eliminating those taps on the

cables. The description of these items implied, or maybe I just

assumed, that they were made of tinned copper or brass. I was

disappointed to find that they are actually made of a coated pot metal.

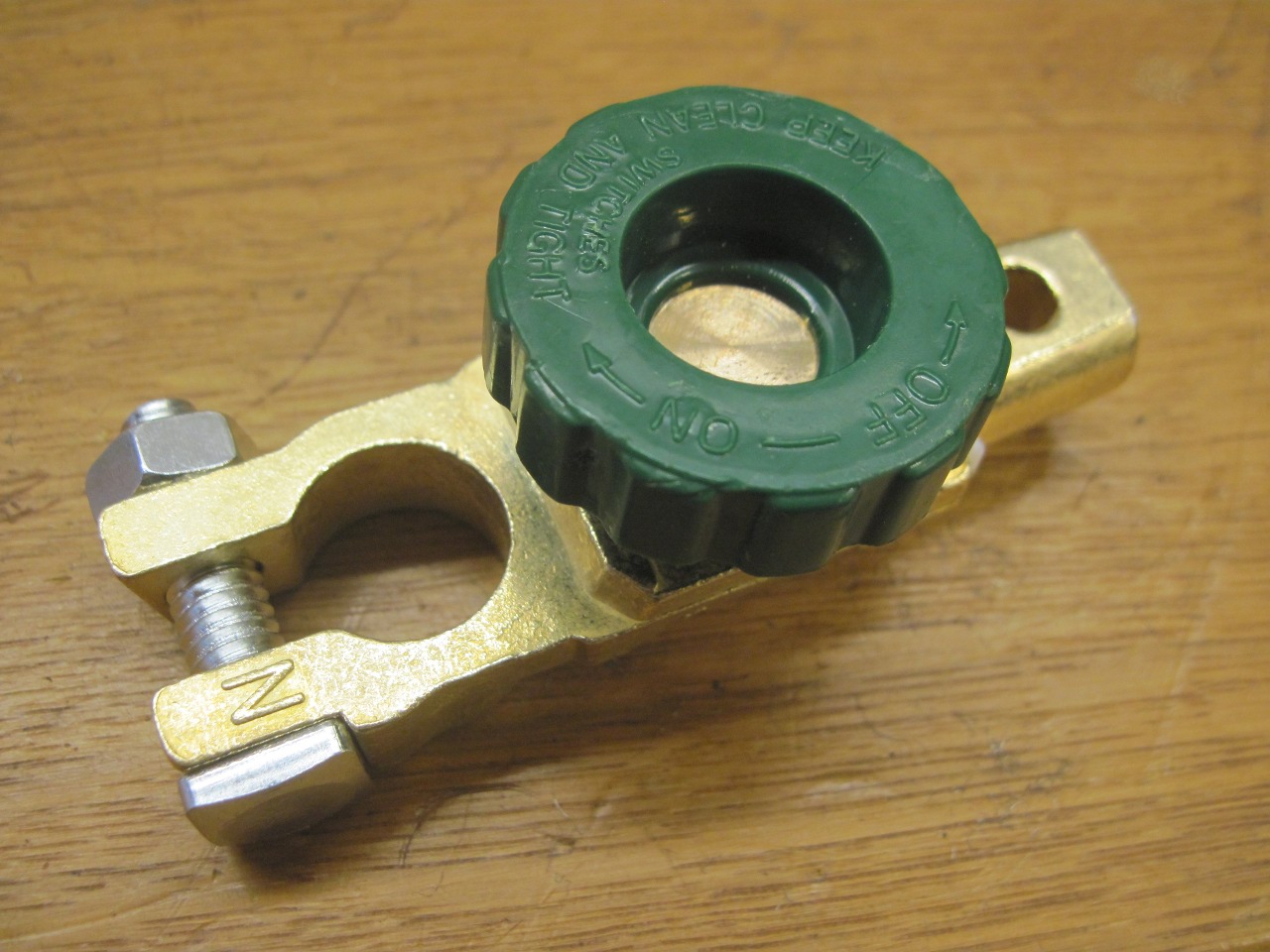

I

also wanted a main battery shutoff. I ordered one of these, and

was disappointed to find that under the nice but misleading brass color

was more pot metal.

Now

when I started this little project, I had no earthly intention of

making my own battery terminal connectors, but as I continued my

search, I really couldn't find exactly what I was looking for.

Then, while I was pawing through my scrap metal bin looking for

something else, I hit on this sizable chunk of copper and,

well, the deal was sealed.

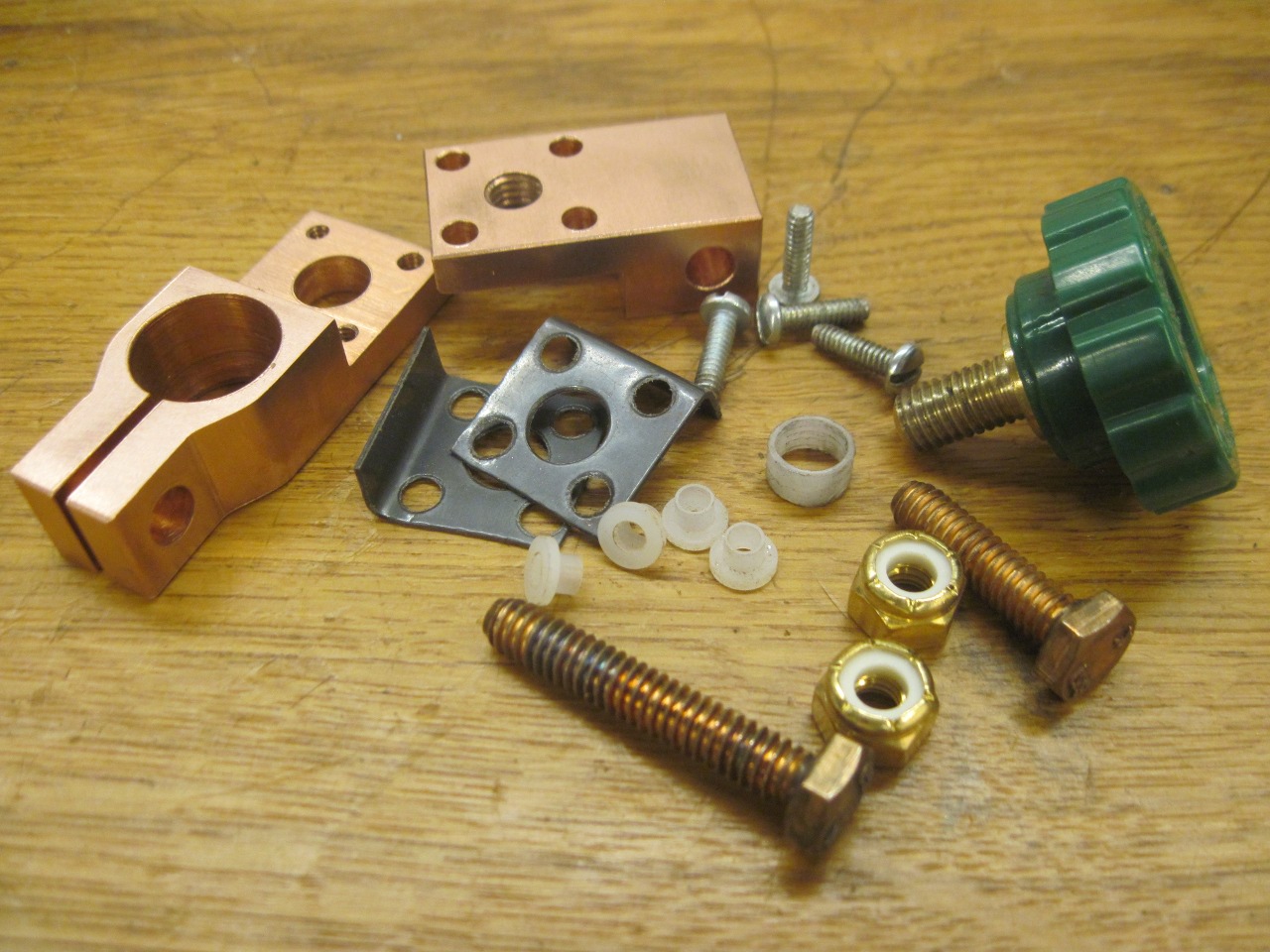

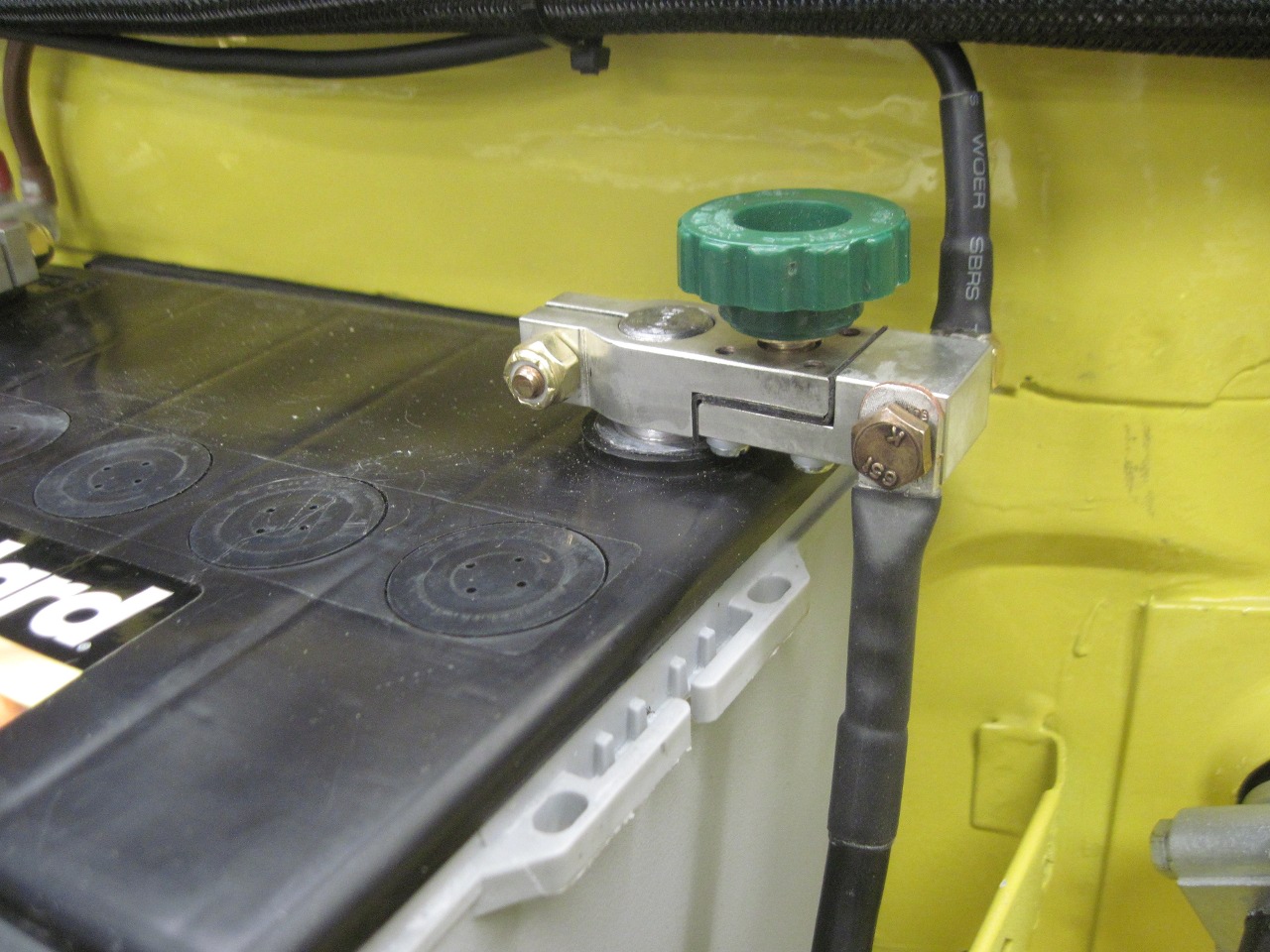

For

the negative terminal, I sort of copied the design of the

shutoff I bought, but with improvements. On the store-bought

piece, it is just the shutoff knob that holds the parts together.

In my design, the two conducting parts are held together with

insulated screws, so the knob can be completely removed and the unit

stays solid. Also. the battery cable connects directly to the

piece with a terminal lug, instead of using another barttery clamp as

in the store-bought unit. I robbed the green knob from the

commercial unit to use in mine.

Foir

the positive terminal, I moved the connection points for the alternator

and system loads to the terminal body, instead of a tap on the cable.

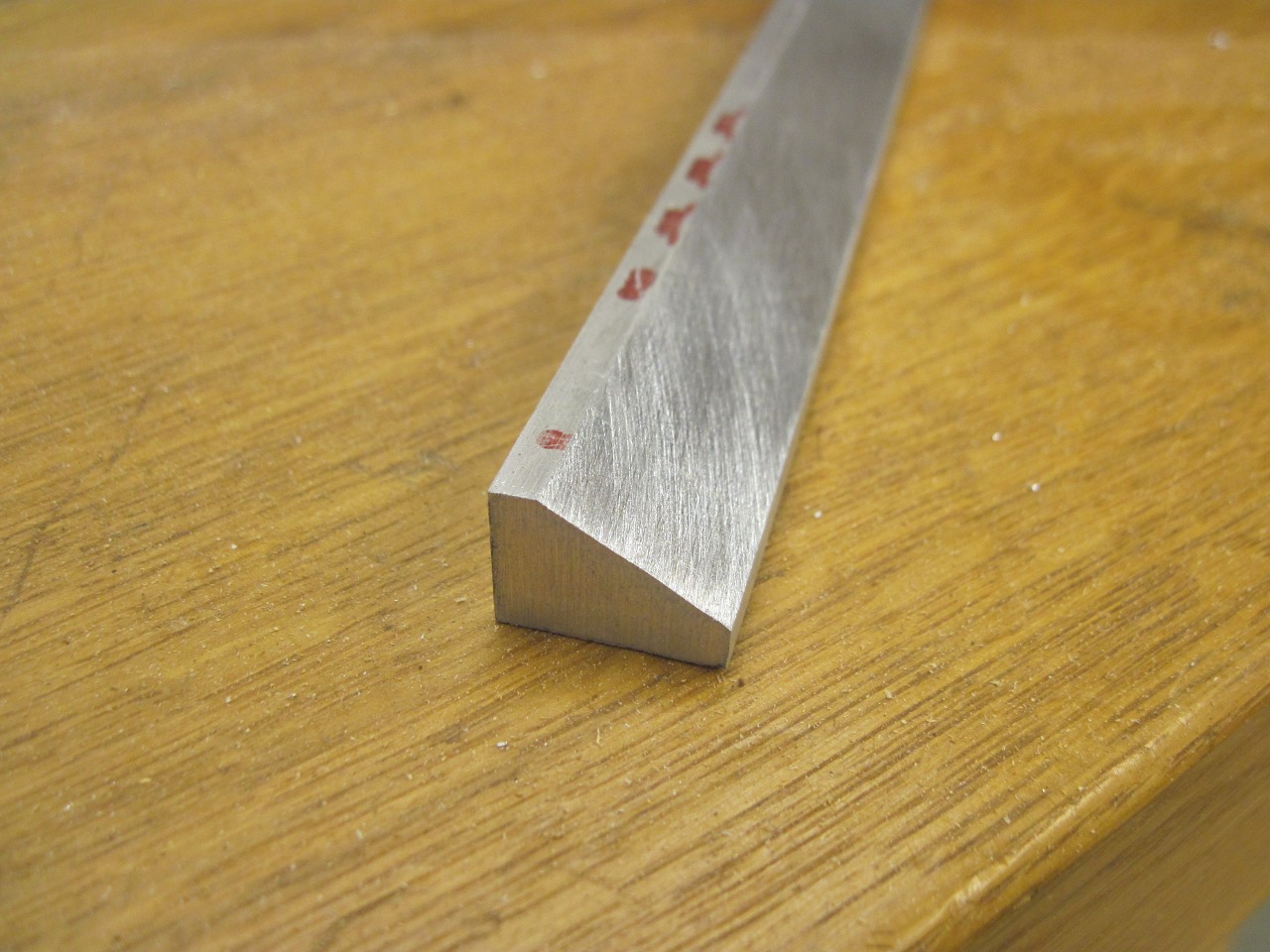

The terminals look silver colored because they are coated with

tin to prevent copper oxidation.

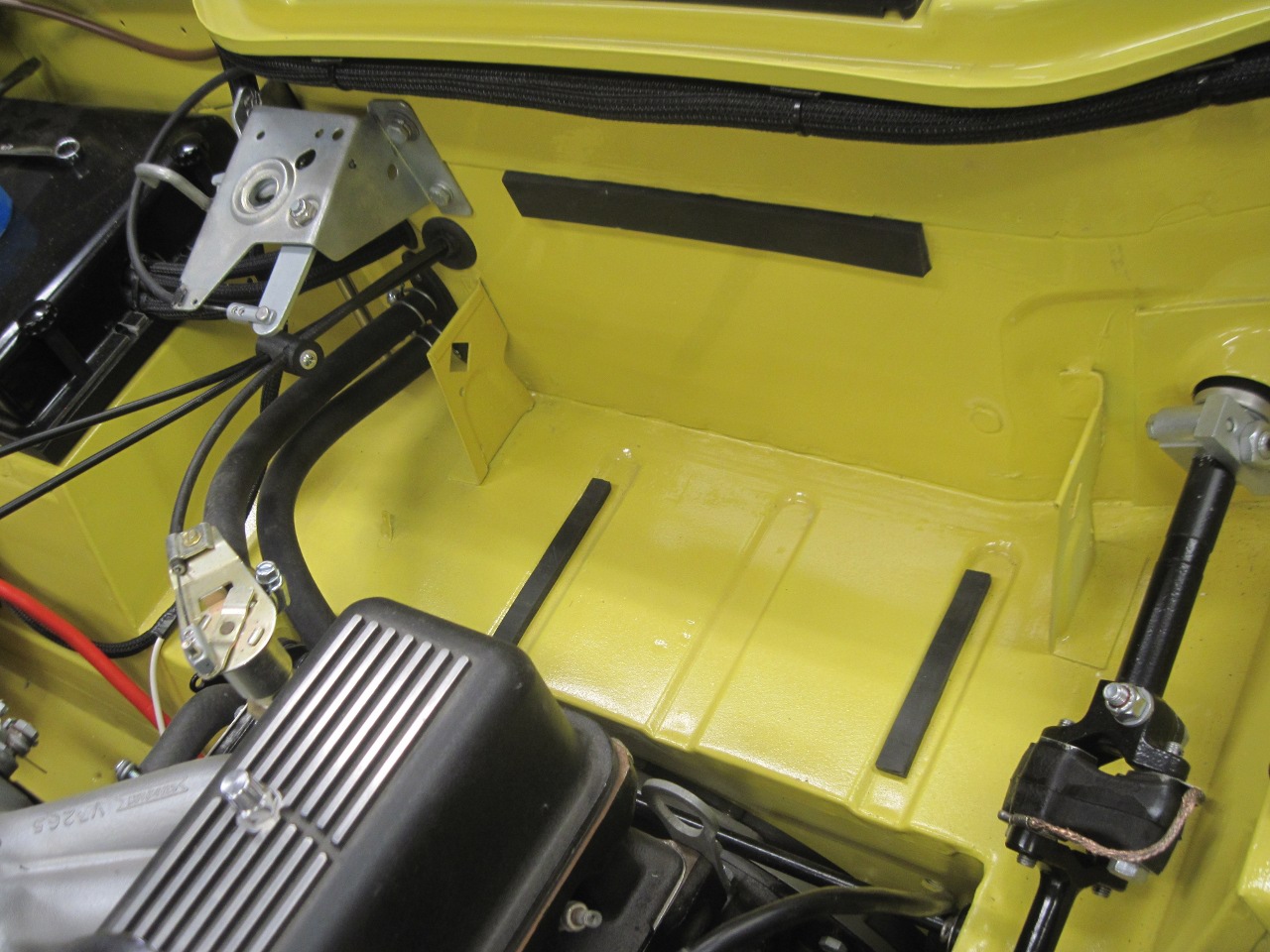

OK, now for the battery itself.

The

battery for the TR6 was nowhere to be found, but I believe the stock

TR6 battery is a group size 24. To do some mock-ups, I stole

a battery out of one of the other cars, but it was smaller, so I jhad

to make up the difference with spacers. During these trials, I

decided that I'd really like the battery terminals to be at the rear of

the battery, sort of under the cowl. To me, it looked a little

more tidy that way, but it would require that the positive and negative

terminals be reversed. Group 24 batteries can be had with reverse

polarity, in which case they are designated Group 24F. The

problem then became that the 24F battery is pretty tall, and the

clearance to the cowl was uncomfortably close. My solution was to

move to a Group 34 battery, which shares the footprint of the 24

battery, but is an inch shorter. Luckily, the 34 battery is also

available in a reversed polarity version called, inexplicably, Group

34R. After finally convincing the guy at Sears that I really did

want a 34R battery and not to worry about what car it was going into, I

got the battery.

This is an AGM (Absorbent Glass Mat) battery.

AGM batteries are more expensive than flooded cell lead acid

batteries, but are lower maintenance, and much less leak-prone.

The rubber strips hold the battery off the paintwork.

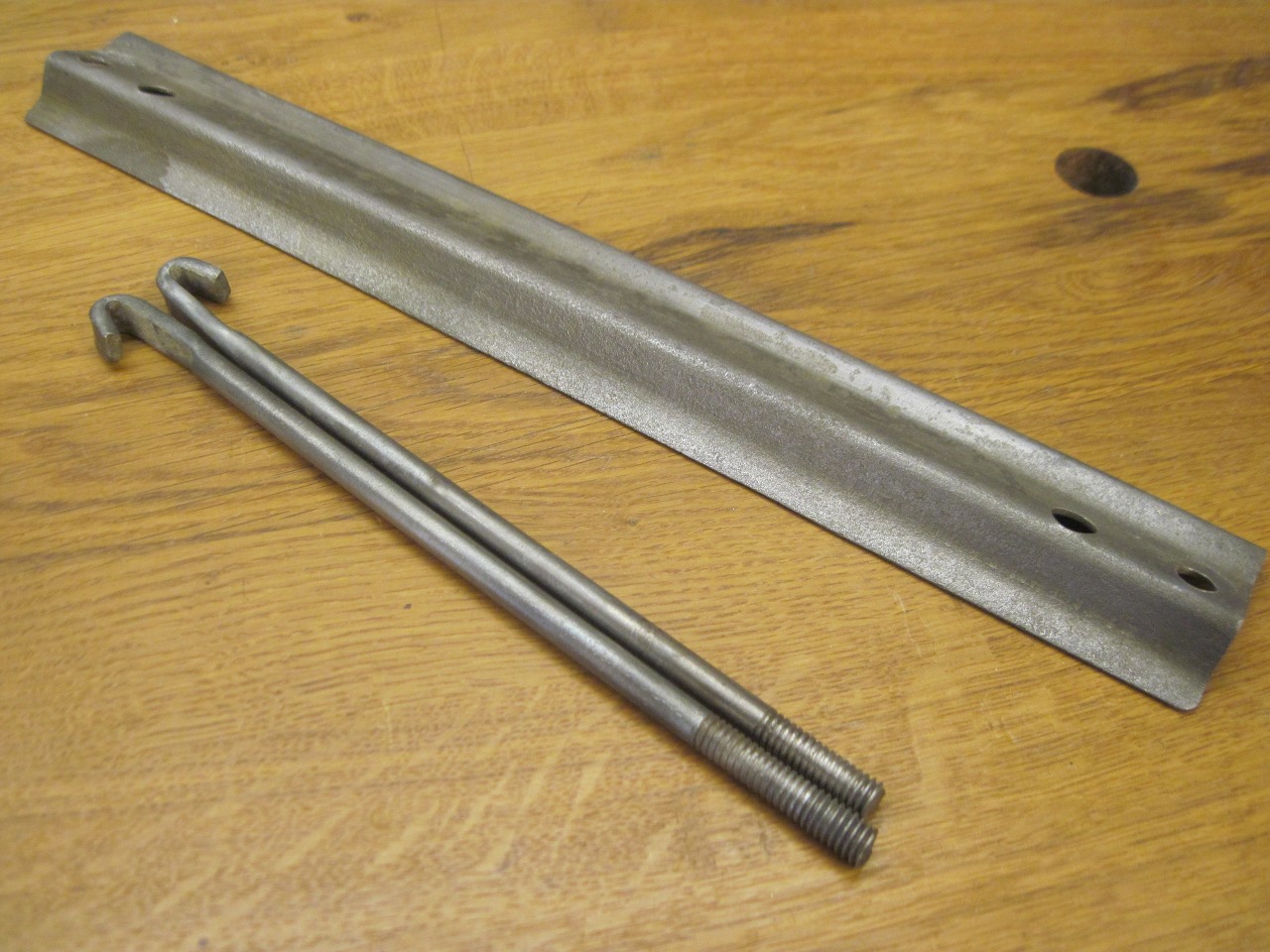

I

knew there must be some sort of battery hold down arrangement in one of

my boxes of assorted parts, and I finally found it. It looked

pretty acid-eaten, and even after I cleaned it up, it wasn't pretty.

The cross bar was severely pitted and the tension rod threads

looked to be just about stripped.

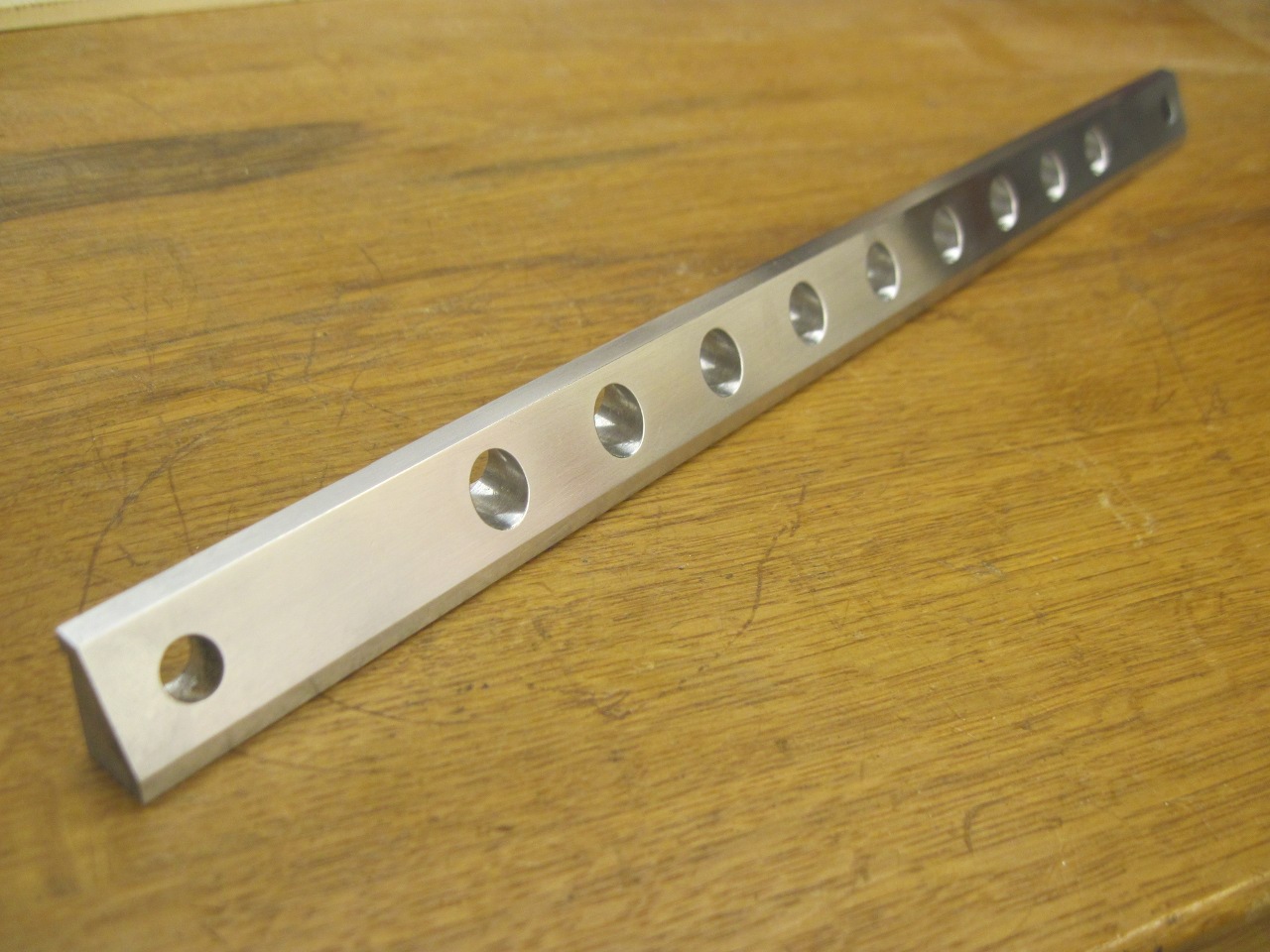

I made a new crossbar out of aluminum, but it looked sort of--I don't know--plain, I guess.

That's it! Some go-fast racing holes!

Some new tension rods and some nice plastic knobs.

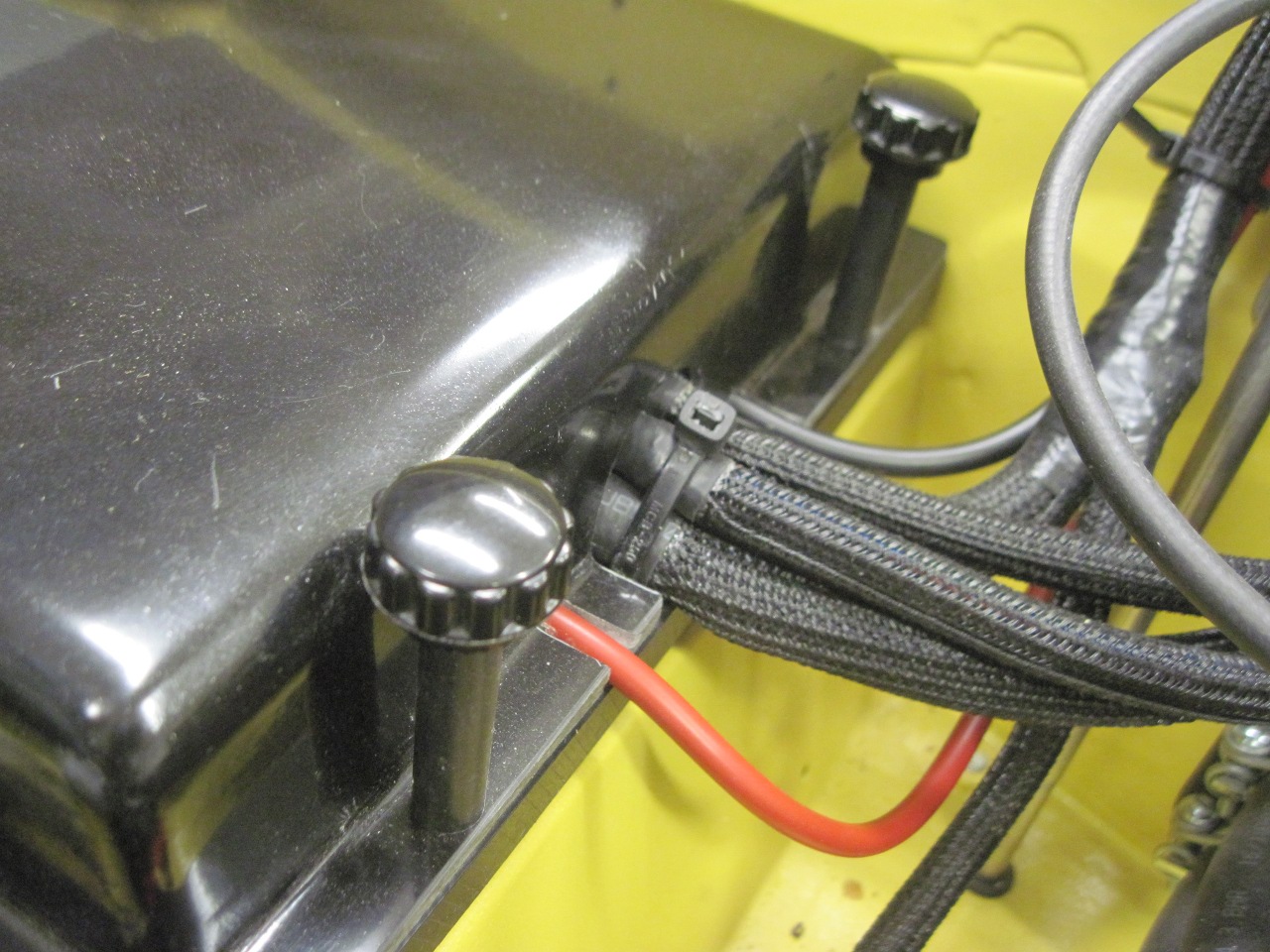

Finally

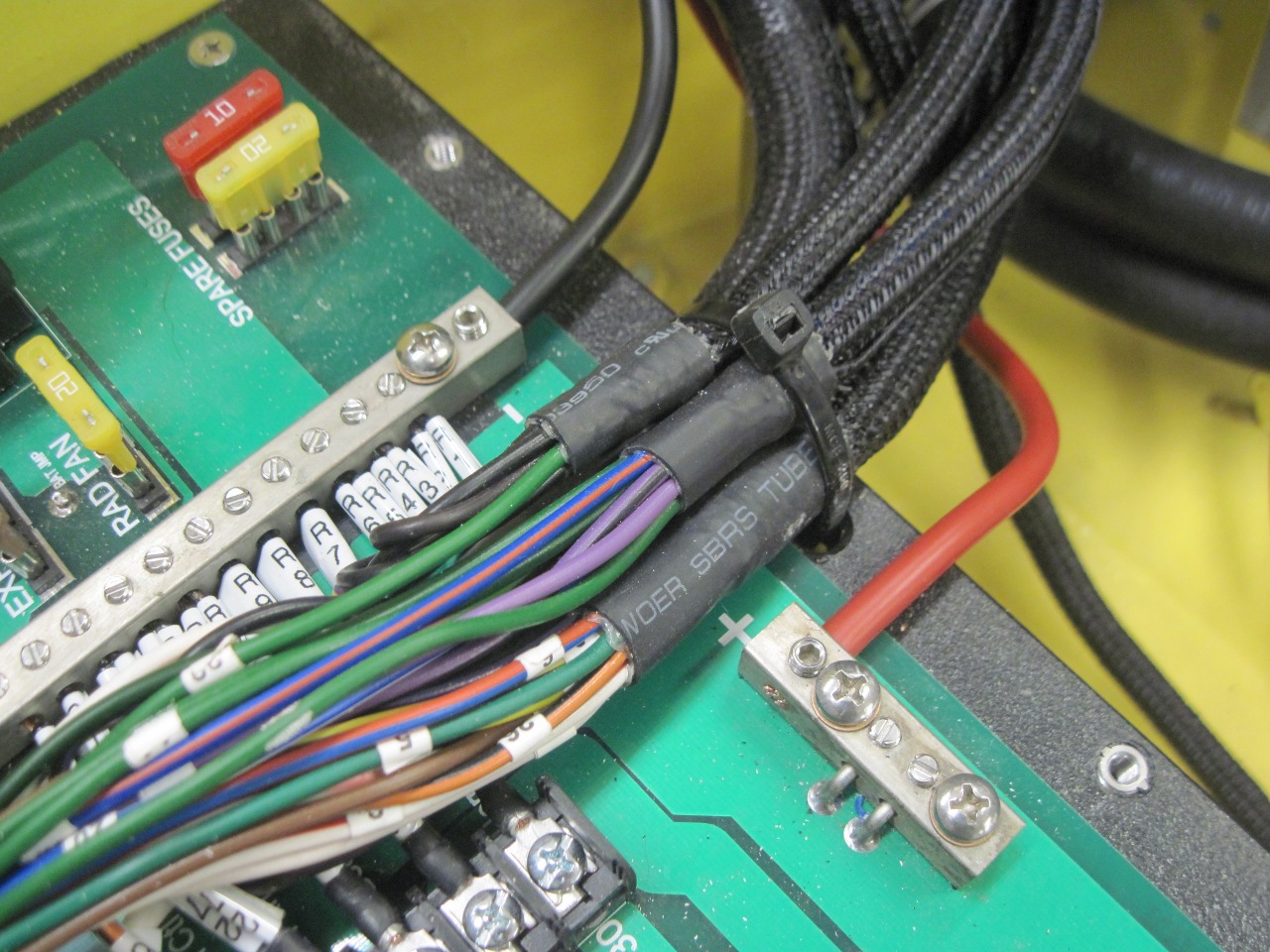

putting everything together. On the positive terminal, the

smaller red wire is 8 gauge to the Power Module. The brown one is

120 strand (approximately 8 gauge) to the alternator. The large

red is 4 gauge to the starter. On the negative, black 8 gauge to

the Power Module, and black 4 gauge to rear engine plate. No need

for a connection to the body since it is no longer used for any ground

returns.

The Power Module get its input power connections.

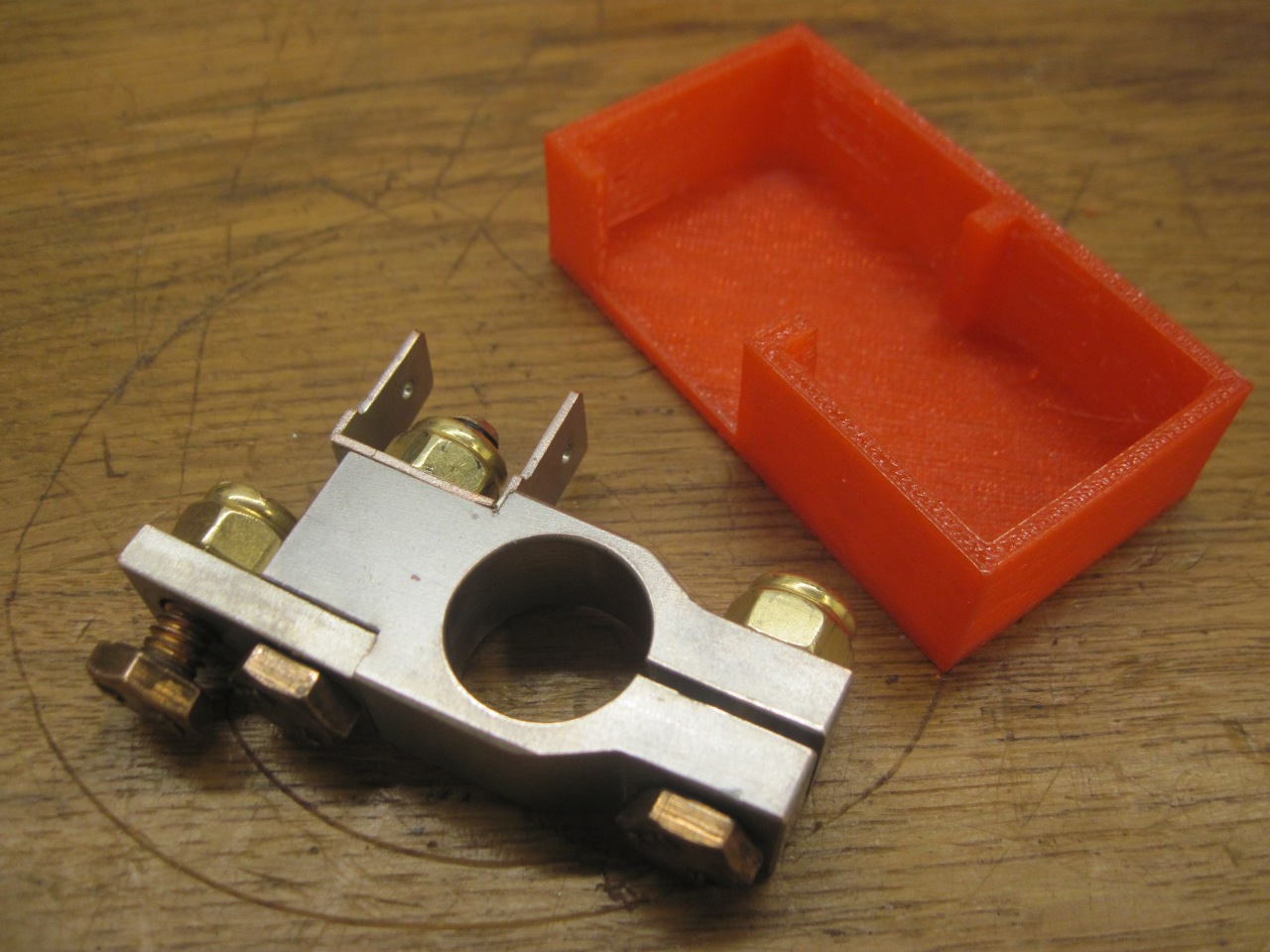

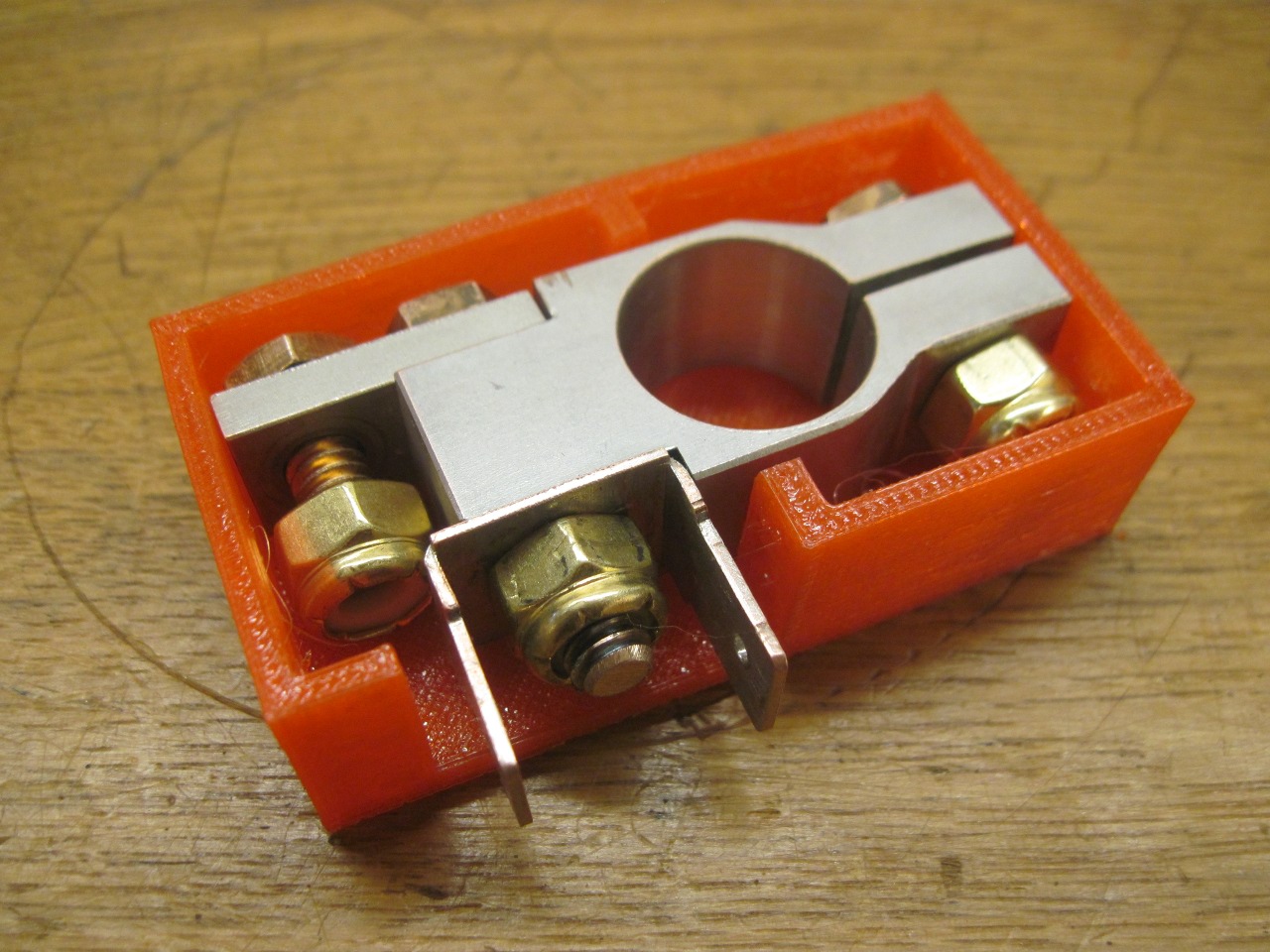

The last touch. I love this 3D printer!

All done.

Before

I closed the shutoff switch, I thought it prudent to put an ammeter

across the switch to see if there would be any current flow. It

read a couple of hundred milliamps. I didn't understand.

Everything on the dash was switched off. I studied the

wiring diagram. Where could this current be going? Long

story short, my doors are not installed, and the door switches were

closed. The interior lights weren't bright enough to se in the

daylight. That was good for over an hour. Glad I didn't

start taking things apart.

This was a fun one. Even the

obsessive part with the battery terminal connectors was enjoyable.

In principal, with a little more plumbing, I could try to start

her up. I'll probably wait until Spring, though.

Comments to Ed at: elhollin1@yahoo.com

To my other TR6 pages