To my other GT6 Pages

September 11, 2022

PDWA & Plumbing

By '69, all new cars, at least in the US, had a dual-circuit hydraulic

braking system. The master cylinder actually had two pistons, each

drawing fluid from its own fluid reservoir. One piston fed the

brakes at two wheels, while the other fed the other two.

Typically, it was front brakes/back brakes. This redundancy was a

boon to safety, but by itself, it had a down side. If one circuit

failed, the brakes would still stop the car, but with reduced

effectiveness, especially in a panic situation. Thus the provision

of a device to detect and report the failure of one of the circuits.

This device, on our cars called a "Pressure Differential Warning

Actuator" or PDWA is a mechanical gadget that both brake hydraulic

circuits pass through. The PDWA has no effect on the operation of

the brake system. There is a shuttle piston inside that sees

hydraulic pressure of one circuit on one end, and the pressure of the

other circuit on the other end. In normal operation, these two

pressures should be close to equal, so the shuttle is unaffected.

If one circuit fails, the difference in pressure forces the shuttle to

one side. This actuates an electrical switch that turns on a

warning light on the dashboard.

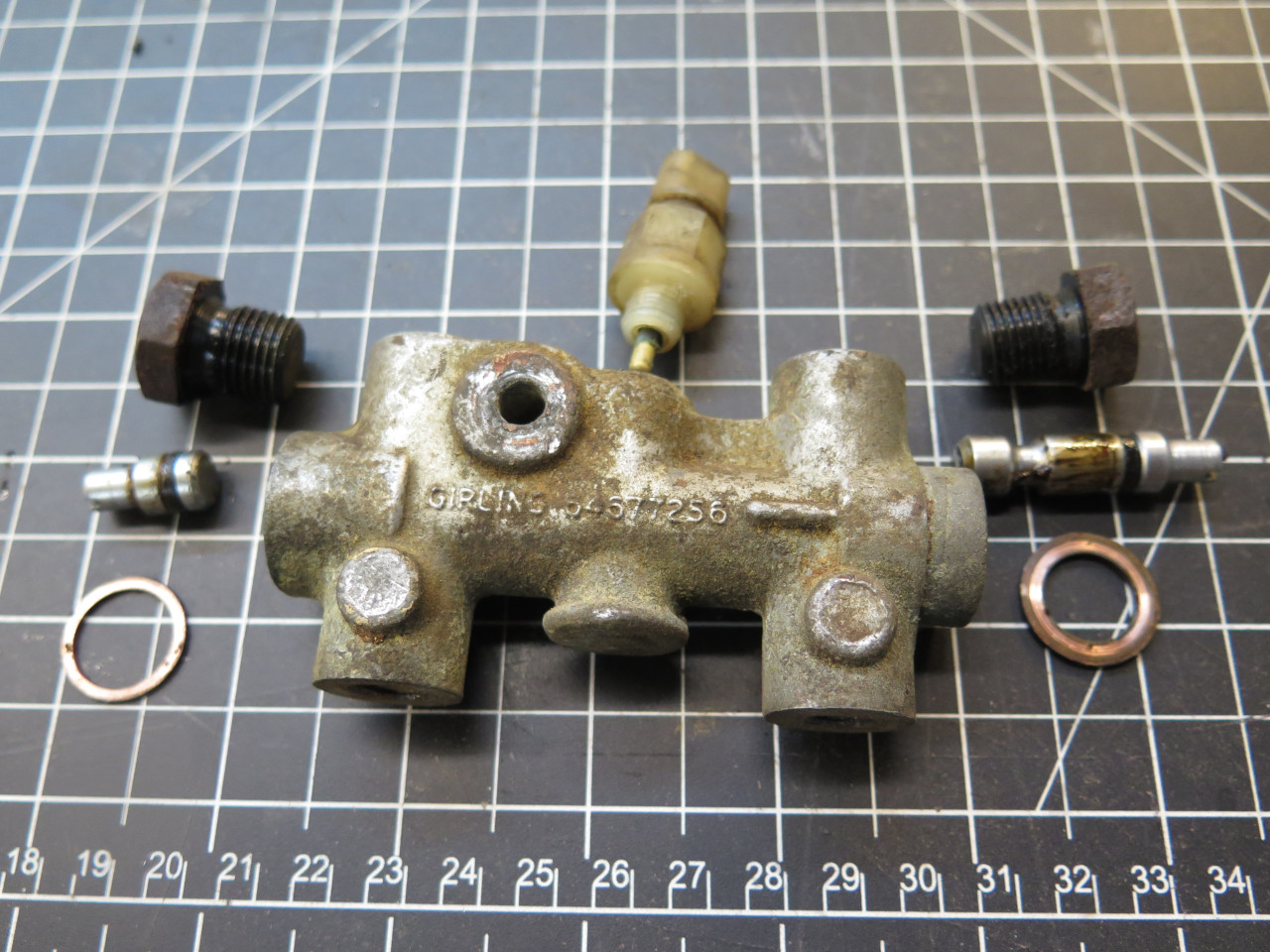

Triumphs used a number of PDWAs over models and model years. Mine was an aluminum body type.

There are quite a few documents and videos on the web that show how to rebuild a PDWA, so I guess I'll just add one more.

The plastic switch screws out of a hole in the center of the

device. Once the two end plugs come off, with their copper sealing

washers, the two-piece shuttle can be drawn out. There is also a

small ball bearing which at this point was still stuck in the body.

Each part of the shuttle has a square section O ring seal. They

are a common industrial size -010, but you have to be mindful of the

material they are made from. These new seals are Viton.

Viton is compatible with DOT5 silicone brake fluid, which is what I use

in my old cars.

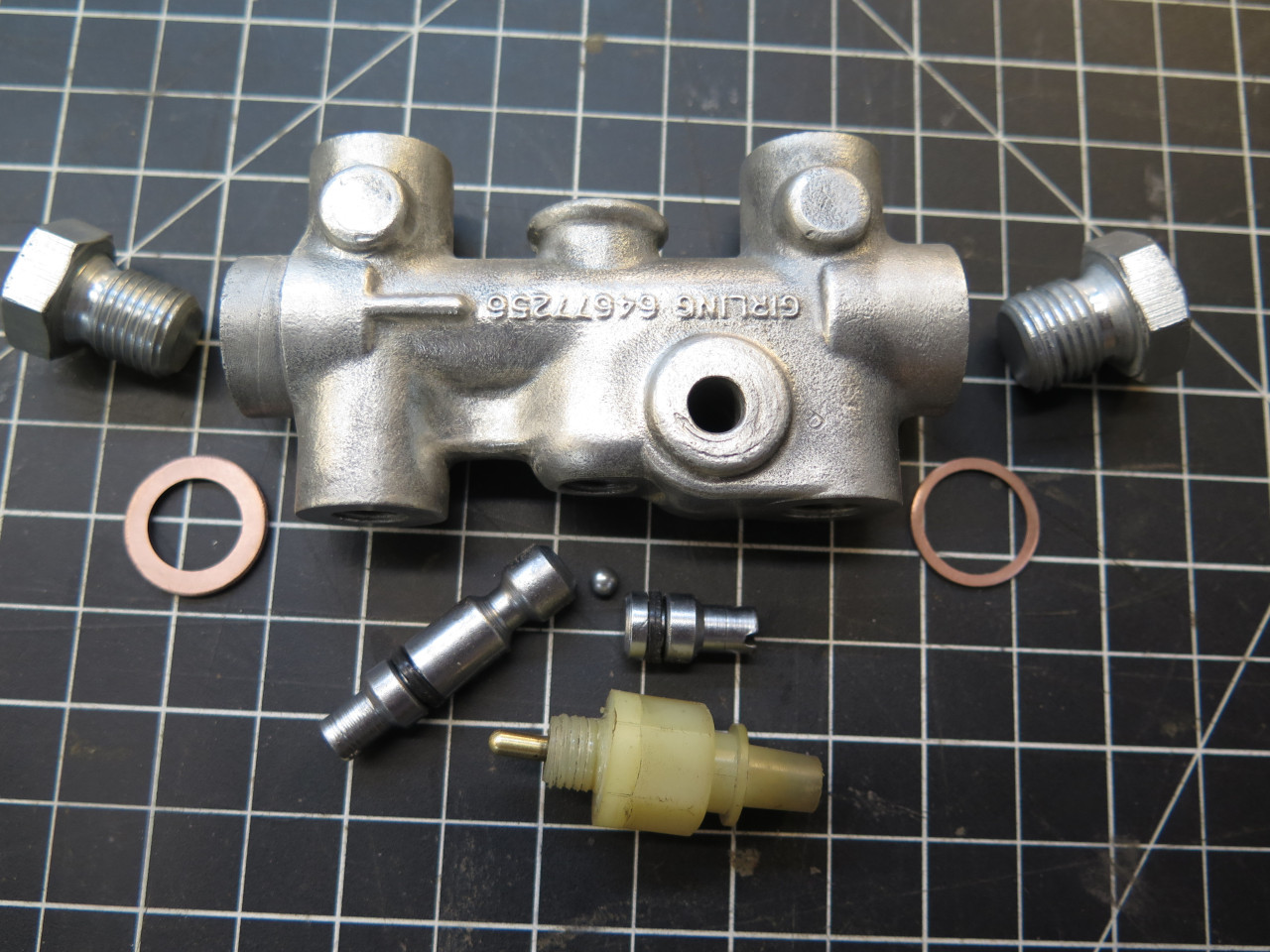

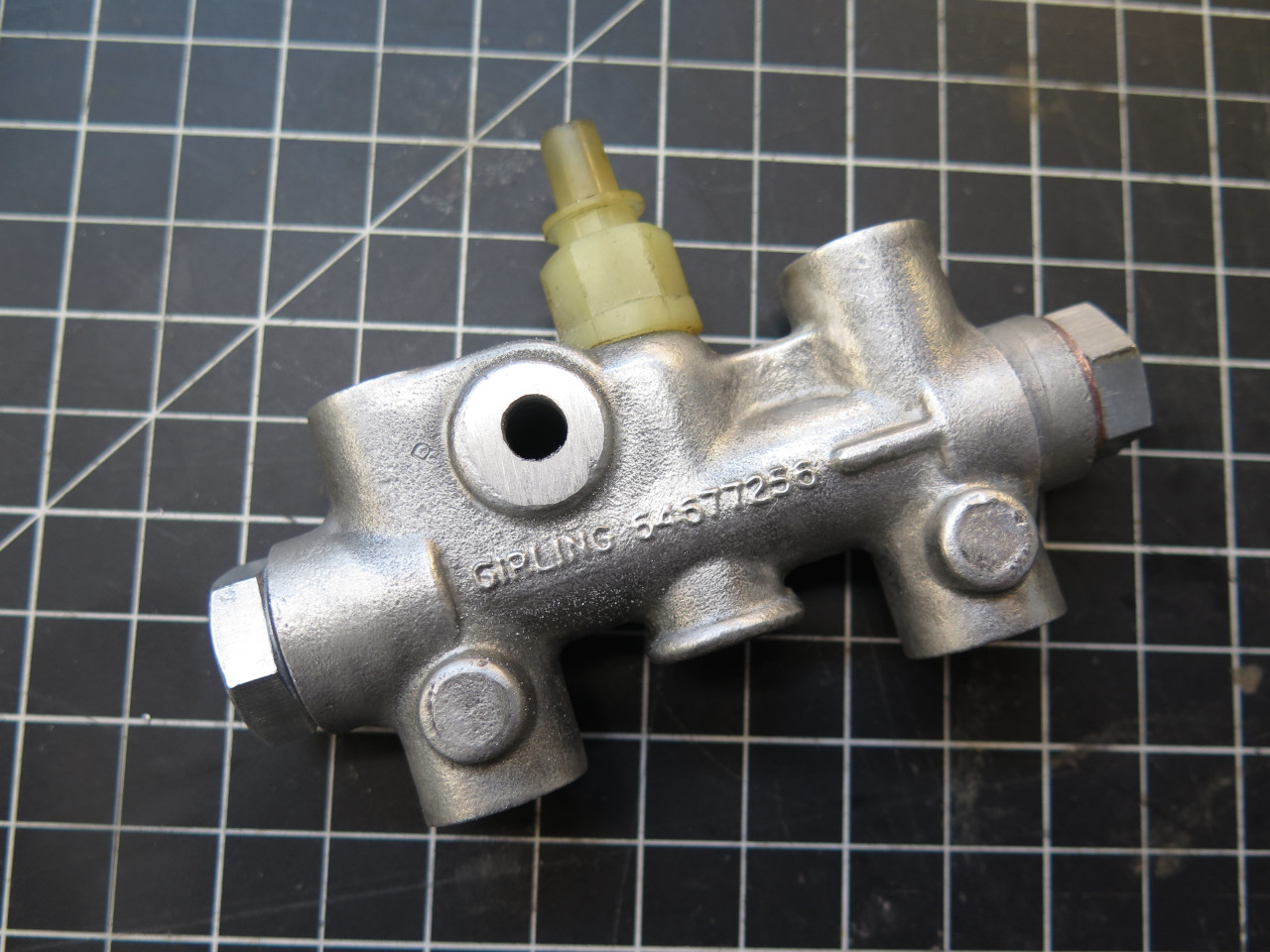

Everything else is cleaned up. I typically re-use copper sealing

washers, but I flatten them and anneal them first. The end plugs

were pretty rusty, so they got derusted and zinc plated. The

switch didn't work at first, but some exercise and some contact cleaner

brought it back to life. The little ball bearing is what rides in

the groove in the middle of the two part shuttle. When the

shuttle shifts, it is forced up into a hole in the body and pushes the

snout of the switch.

One part of the shuttle is inserted into each end of the body. The

shuttle is in two parts so that neither of the seals have to be pushed

across the switch opening in the bore, which could damage the

seal. Looking down the switch hole, it is obvious when the shuttle

groove is centered. The ball bearing is dropped in, then the

switch installed.

Both the brake master cylinder and the PDWA have two different threads

on their hydraulic ports: 3/8-24 for the rear circuit, and 7/16-20

for the front. This makes it harder for the system to be plumbed

incorrectly. I was able so save most of the fittings from the

original system by stripping and re-plating them. The slightly

shinier fittings are new, the rest are just re-furbed.

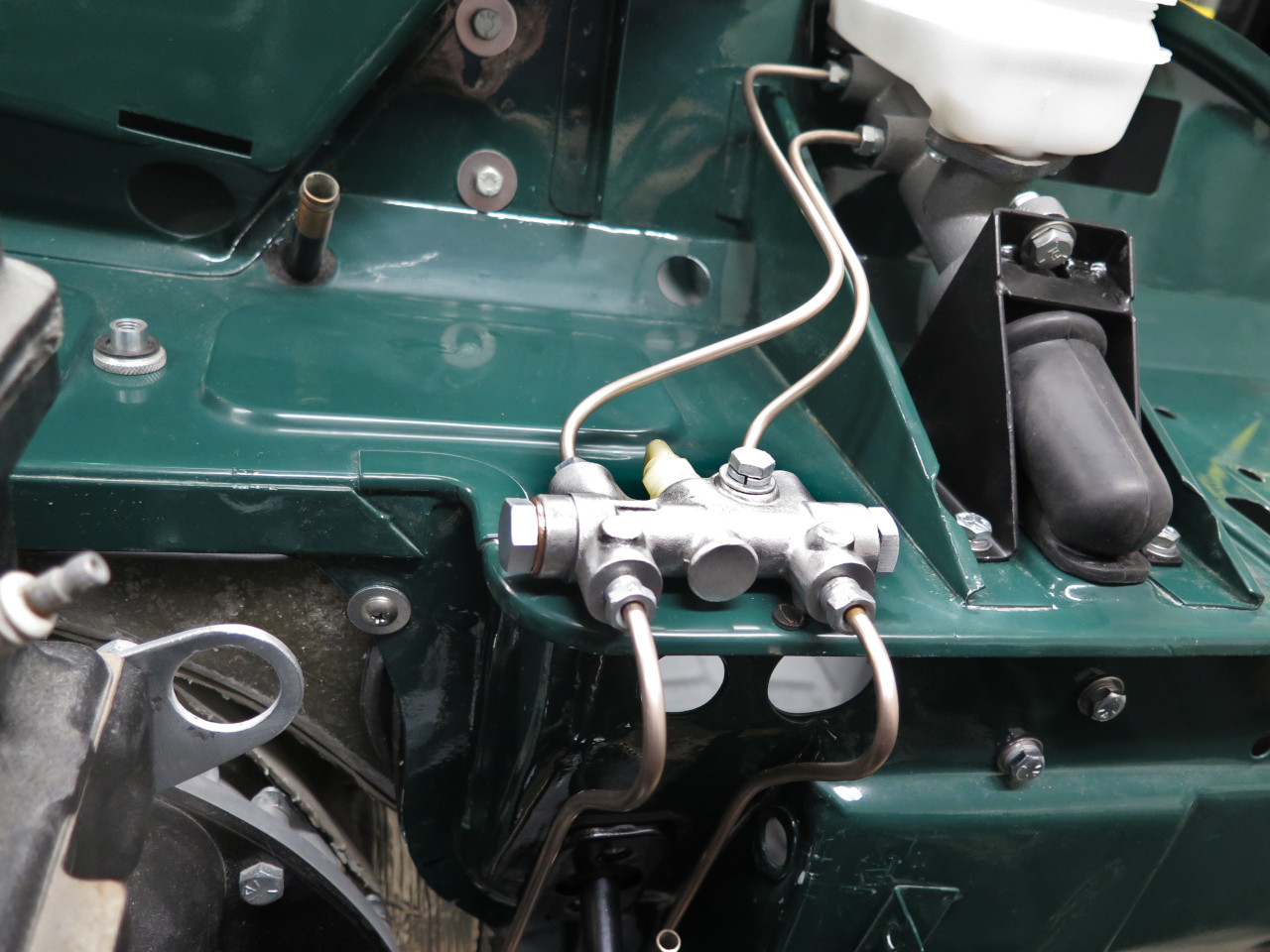

I made new lines to connect the PDWA to the front and rear

circuits. The old lines were a pretty good guide for shape.

To finally button up the braking system, I drug out the master cylinder, along with its assorted bracketry...

...and got 'er installed with her eight bolts.

The last two hydraulic lines. These are the originals, which made decent patterns.

The new replacements. I use a copper-nickel-iron brake line. It doesn't corrode, and is pretty easy to form by hand.

This finishes off the brake system, and it feels good to put a big fat

check mark in that box. Cost for this part was maybe $10 worth of

tubing and a few bucks for the seals and new fittings.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 Pages