To my other GT6 pages

January 18, 2022

Behind the Dash

With a temporary reprieve in the cold weather here on the prairie, I got

a chance to play in the garage for a time. I used the opportunity

to install a couple of the things that have been on the shelf.

When installing things on the interior of the car, it makes sense to

start behind the dash. It is one of the hardest places to access,

and the more items we add, the worse it gets.

Before I did anything under there, I wanted to apply some sound damping

material. Much of the unwelcome noise in a car is generated by the

car's panels themselves. Driven by normal engine, road, and wind

vibrations, some panels can resonate and create sounds of their

own. The larger and flatter a panel is, the louder, lower, and

more sustained the resonance can be. Smaller panels with a lot of

shape aren't usually a problem. I use the "thump test" to

determine whether it is worth trying to damp a panel's vibrations.

I give the center of the panel a good thump with a knuckle. If

the sound is a dead thud, damping won't change anything. If it

sounds like a gong, damping will help. Between these two extremes,

it's a judgement call.

The vertical firewall panel isn't all that large, but it's relatively

flat, and the thump test suggested that some damping would be a good

thing. I use CLD (Constrained Layer Damping) mats, which, when

applied to a steel panel, makes a sandwich of two metal layers with a

gooey substance in between. The mat increases the mass of the

panel, which lowers the resonant frequency. Vibrations stress the metal

layers, and the goo absorbs the energy.

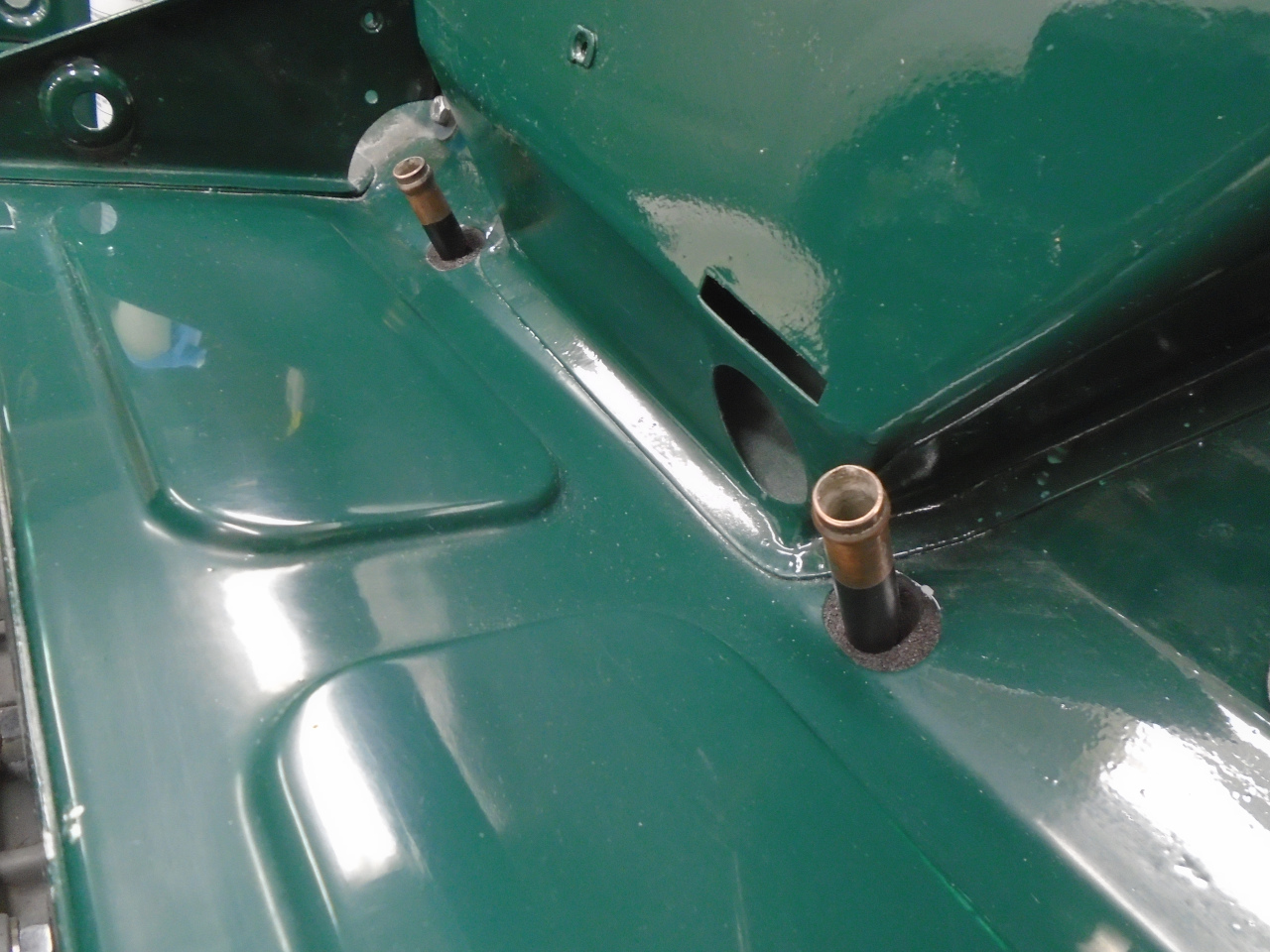

This is the firewall. The big hole is the heater air intake.

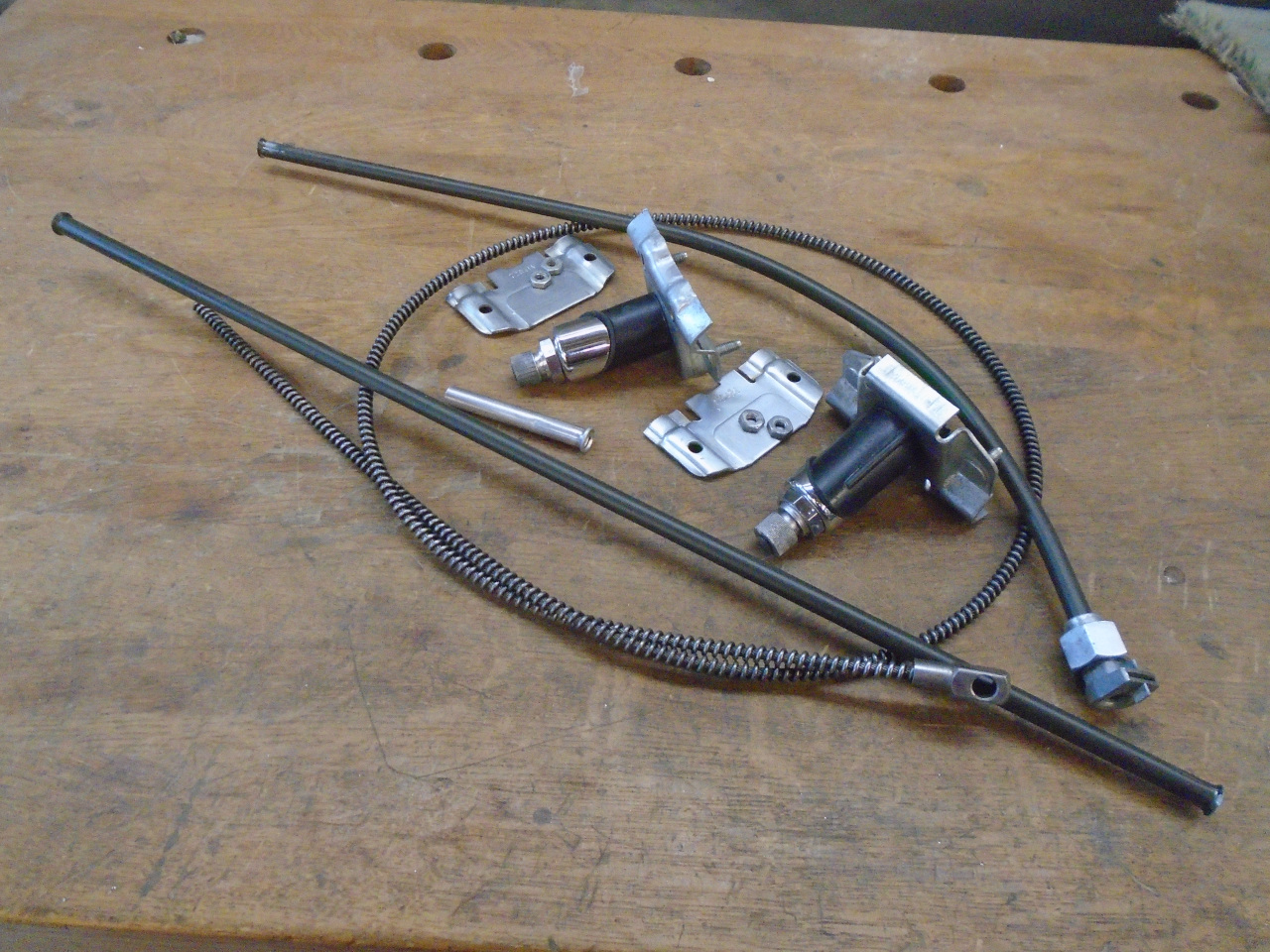

That being done, the first-up install was the recently finished windscreen wiper wheel boxes, and associated parts.

I put the wheel boxes in first, then connected them with the new guide tubes for the drive cable.

I lubed the boxes, cable and tubes pretty well, and, shoving the cable

in, everything appeared to operate smoothly. The factory manual

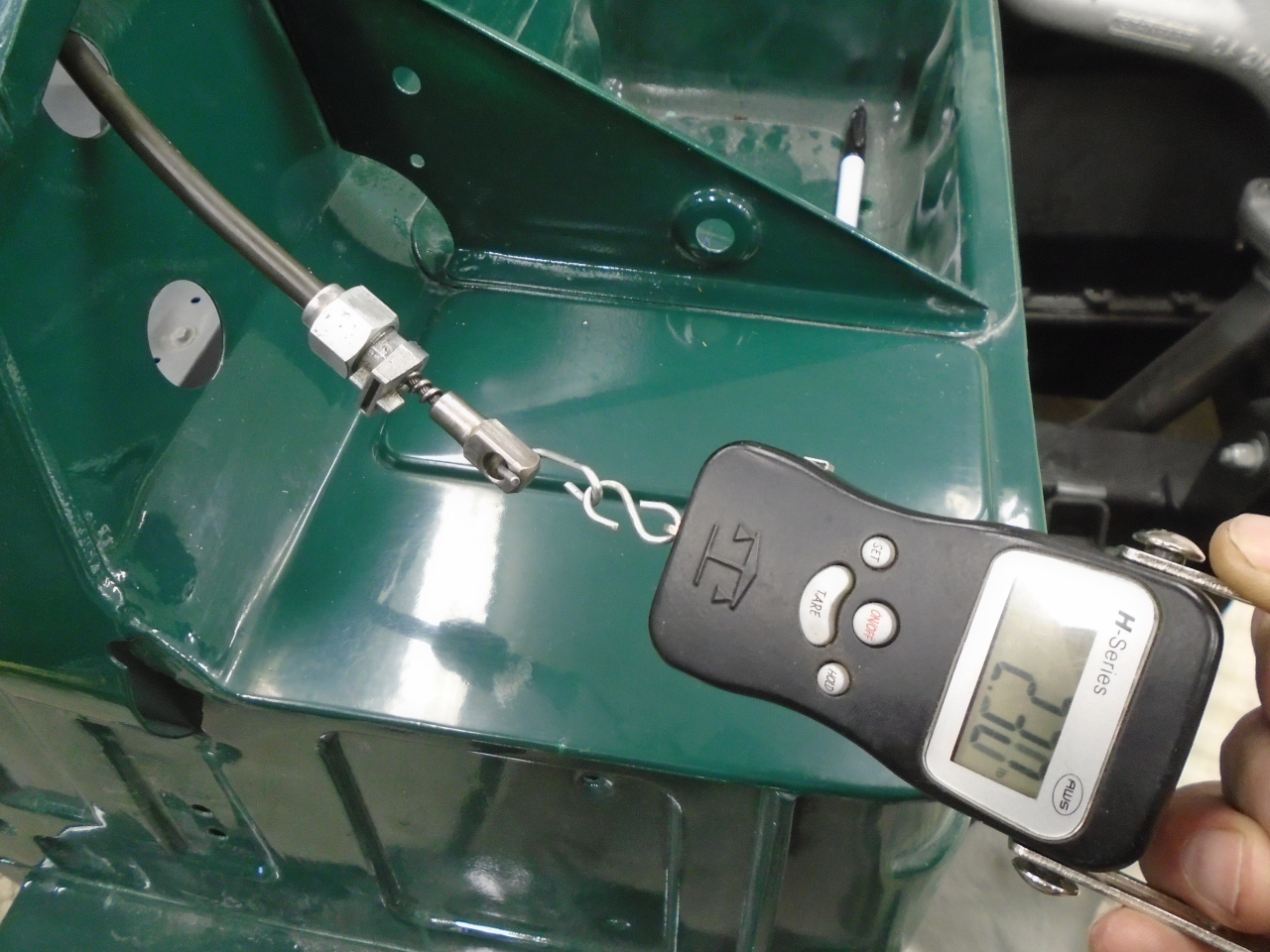

advises that the maximum permissible force needed to move the cable

without wiper arms is six pounds. I was really happy to see that

only a little over two pounds would move my cable through its whole

stroke.

I made sure to add a little anti seize to those weird octagonal nuts on

the wheel box noses. Those are notorious for seizing.

One small step...

Related to the wiper gear, I turned to the washer jets. I couldn't

find my originals, so I ordered replacements. Literally minutes

after pressing the "Place Order" button, I remembered where the

originals were. They were dirty, but still clear.

I neglected to change the order, so when the new ones showed up, I had a

chance to compare them. The new ones looked fine, but there were

some differences. The hose barbs on the new ones were

significantly smaller than the originals. I don't know if that

would be a problem. Also, rather than the 1/4-28 threads of the

originals, the replacements were 5 mm metric. It's a little

irritating when a replacement isn't really a replacement.

In the end, I decided to use my originals. They are in good shape

except for the fiber washer that goes under the hex to protect the

paint. I've got some on order.

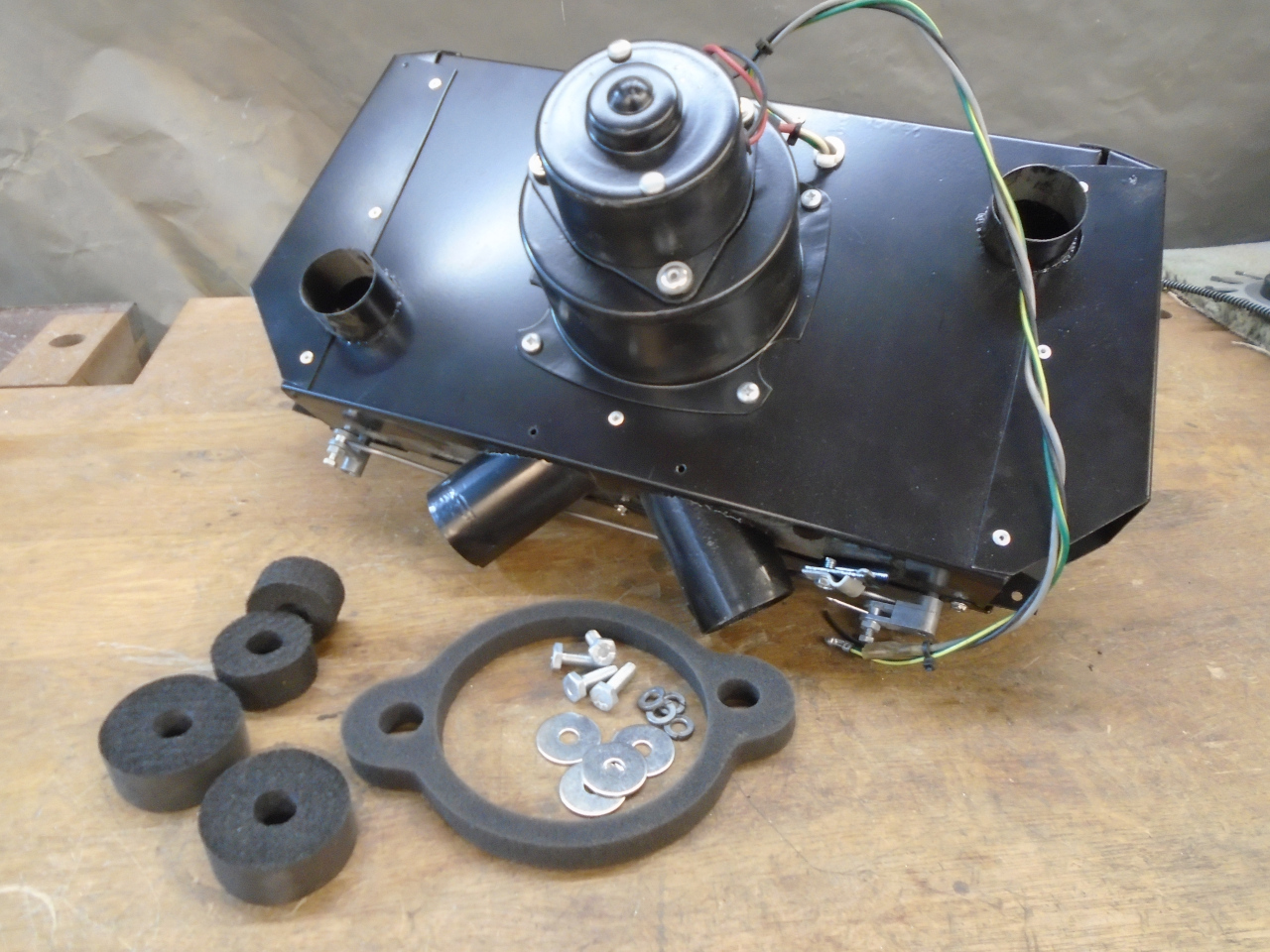

Next up was the rebuilt heater, which had been on the shelf for almost two years.

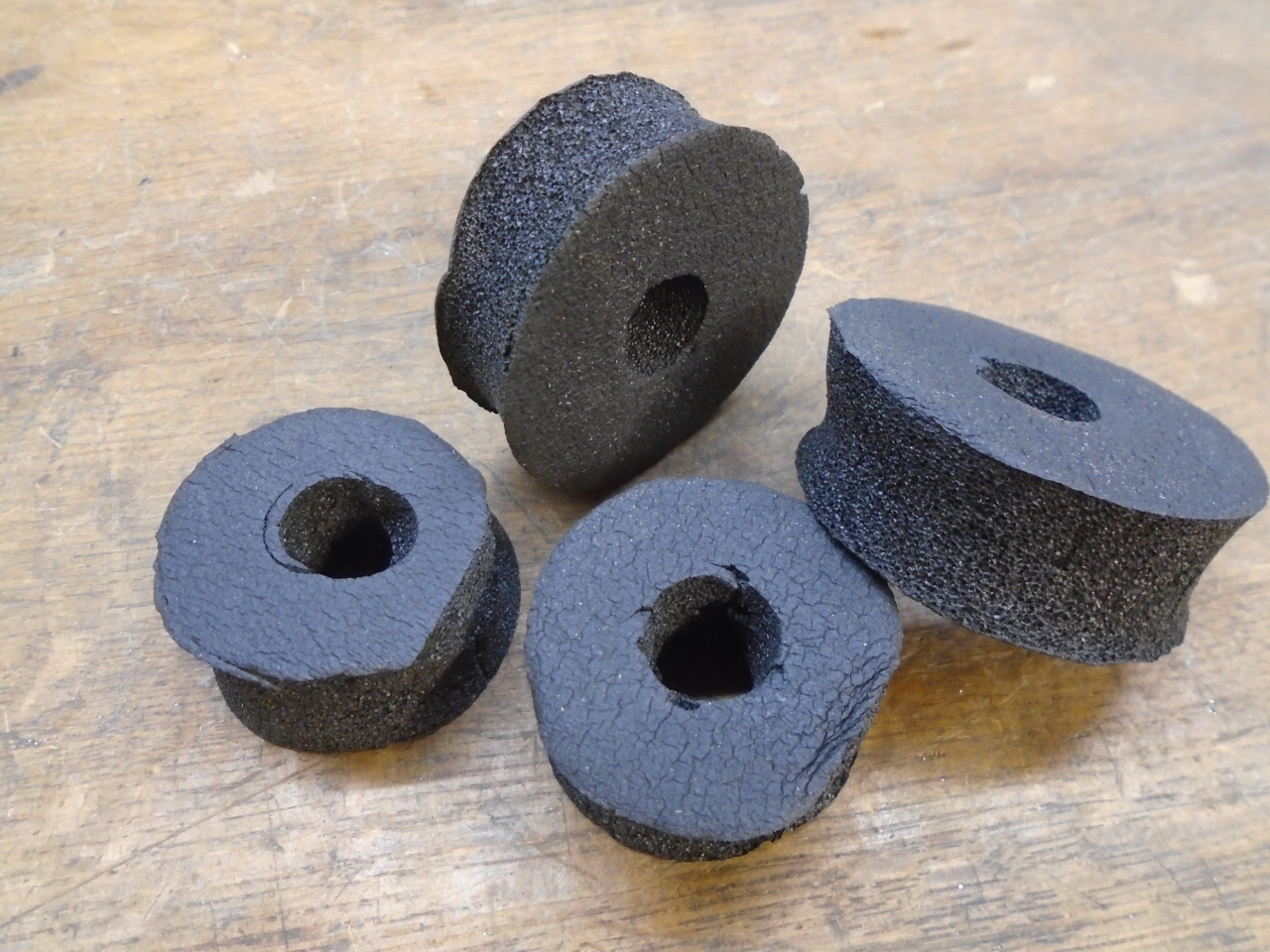

There was a small disappointment attached to the heater install.

There are some foam rubber gaskets or seals that close off the largish

holes in the firewall where the coolant tubes pass through. This

is what I paid good money for from one of our vendors.

Now, it's true, they didn't cost a lot of money, and, once installed,

they will probably do the job, and no one will ever see them again, but I

still had some expectations that weren't met here. I couldn't in

good conscience use these.

Here are some seals I made by slicing off short pieces of some pipe insulation. The material looks and feels identical

There was also a gasket for the air intake. Nothing at all wrong

with this part. (Other than I don't see the purpose of the two

ears. This is probably a part borrowed from some other

application.)

Gathered all the parts, replated the original mounting bolts, and hauled it all to the garage.

It actually would have been a little easier to install the heater before the wheel boxes, but it finally went home fine.

The funnest part of this project is bolting stuff onto the car, but it

probably won't be until Spring that I can do much more of that.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages