To my other GT6 pages

January 16, 2022

Wiper Wheel Boxes

The windscreen wipers on the GT6, as on many other British cars of the period, operate with a reciprocating cable driven by a wiper motor

in the engine compartment. The cable is wound with a wire so that

it is in effect a long flexible toothed rack. The rack cable is

guided to wheel boxes that contain pinion gears on the spindles that the

wiper arms attach to. It's an ingenuous system that works well

when in good condition.

The wheel boxes are not sealed, but have back pieces that clamp the guide tubes in alignment with the pinion gears.

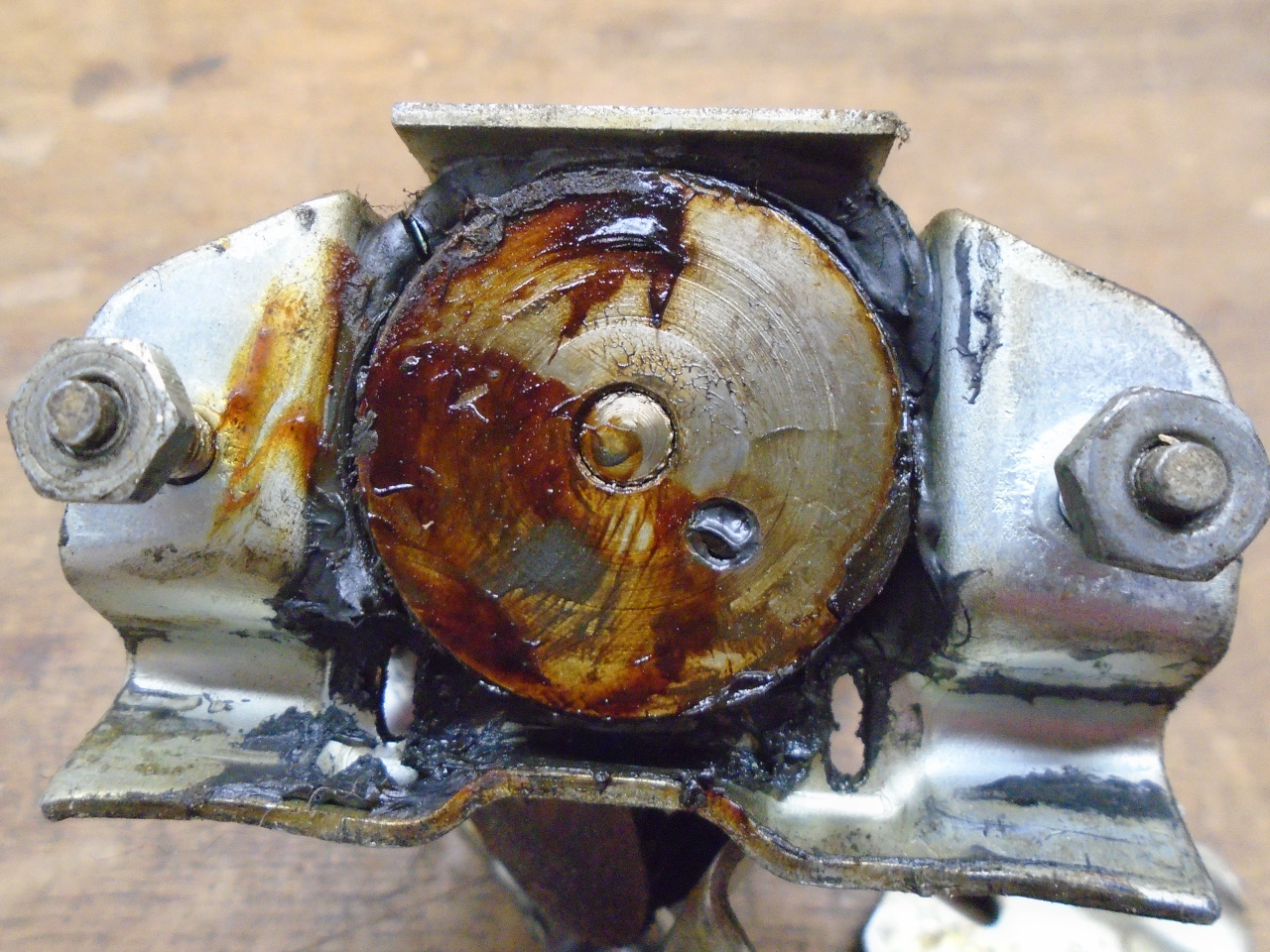

There was plenty of grease in my wheel boxes, but most of it was pretty dried up.

On inspection, most everything looked OK, except the nose threads on one

of the boxes. I remember having trouble with the octagonal finish

nuts on these when I was disassembling the wiper gear. The nut

was seized, and by forcing it, I succeeded in stripping the aluminum

threads. On the other box, I pre-emptively cut off the nut. I

think this is a pretty common malady.

Now, I know new wheel boxes can be bought, but it seemed like a fairly

simple repair, and a nice little shop job for a snowy afternoon. First

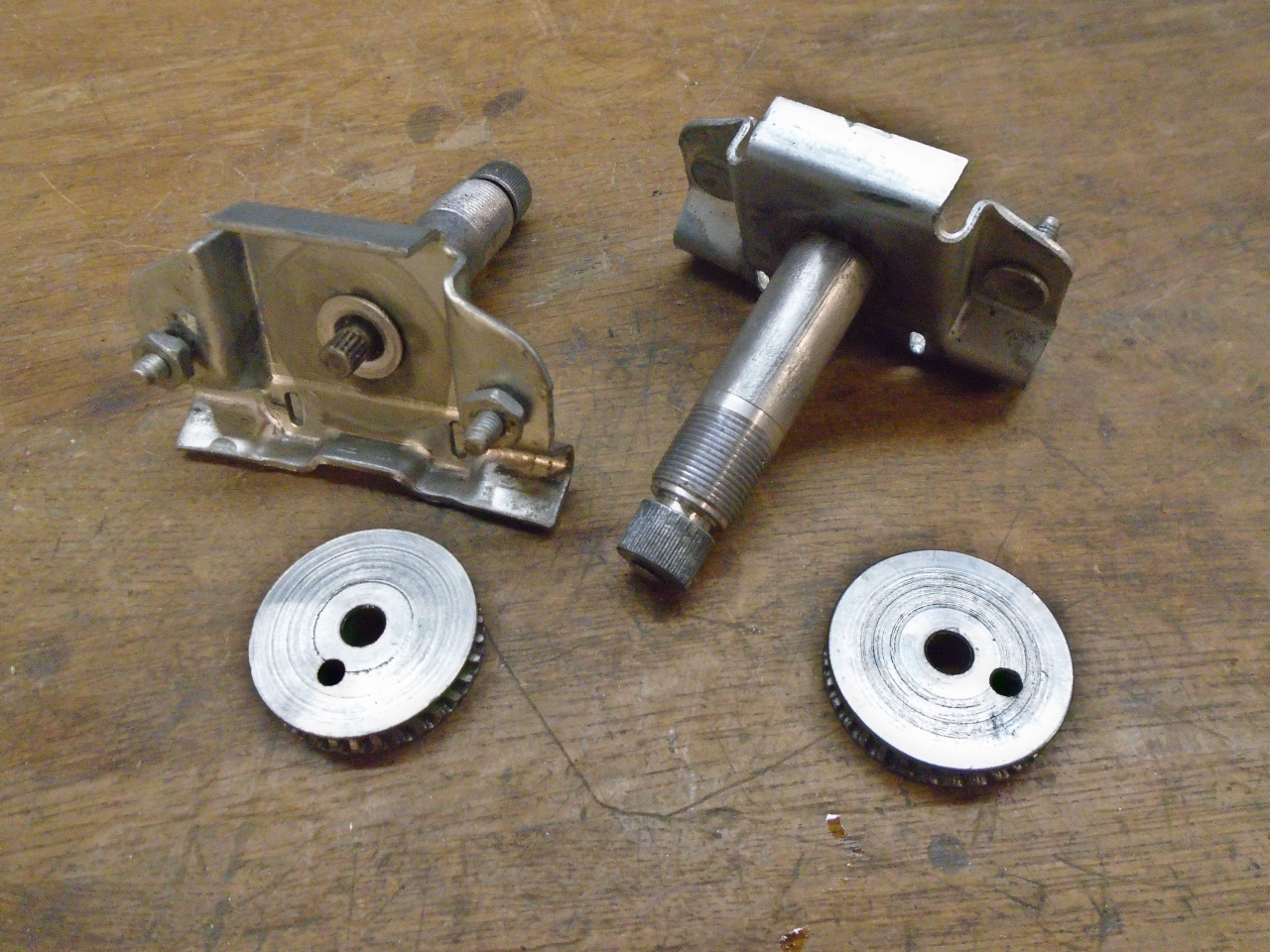

thing to do was get rid of the damaged area...

...then press fit an aluminum barrel with some red Locktite...

...then turn it down and thread it to 5/8-24, to match the other one.

I should say something about those spindles. I had to remove the

spindle to do the thread repair, and it was not exactly easy, since the

splines that mate with the pinion gear are larger that the bore in the

housing. My theory is that the spindle splines were formed by

pressing the hardened gears on to the unsplined spindles after they were

in the bores. So, removing the spindle did score the bore a

bit. This concerned me, but when I put the unit back together, the

fit actually seemed a little better than before. It's not

uncommon to "knurl" bores to improve a loose fit, so I'm just going to

call this a knurled bore. In fact, the knurling may serve as a

reservoir for lubricant. Maybe this is just rationalization, but

it satisfied me enough that I removed the other spindle so I could

properly clean out all of the ancient grease.

The spindles went back home with a coating of moly loaded grease thinned

with some light machine oil. They both turned very smoothly.

Then pressed the gears back on.

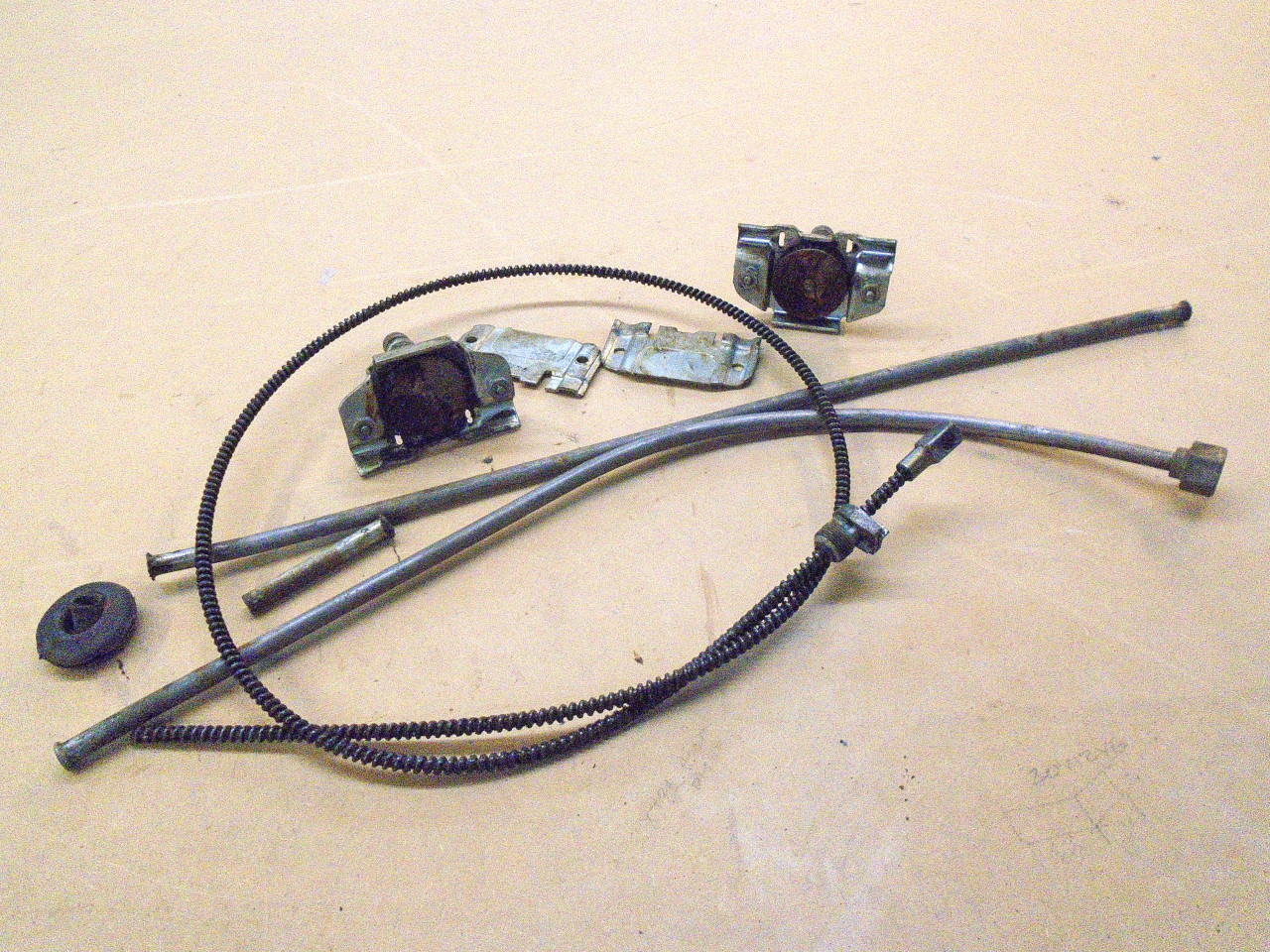

Some of he ancillary mounting parts. Note the broken nut.

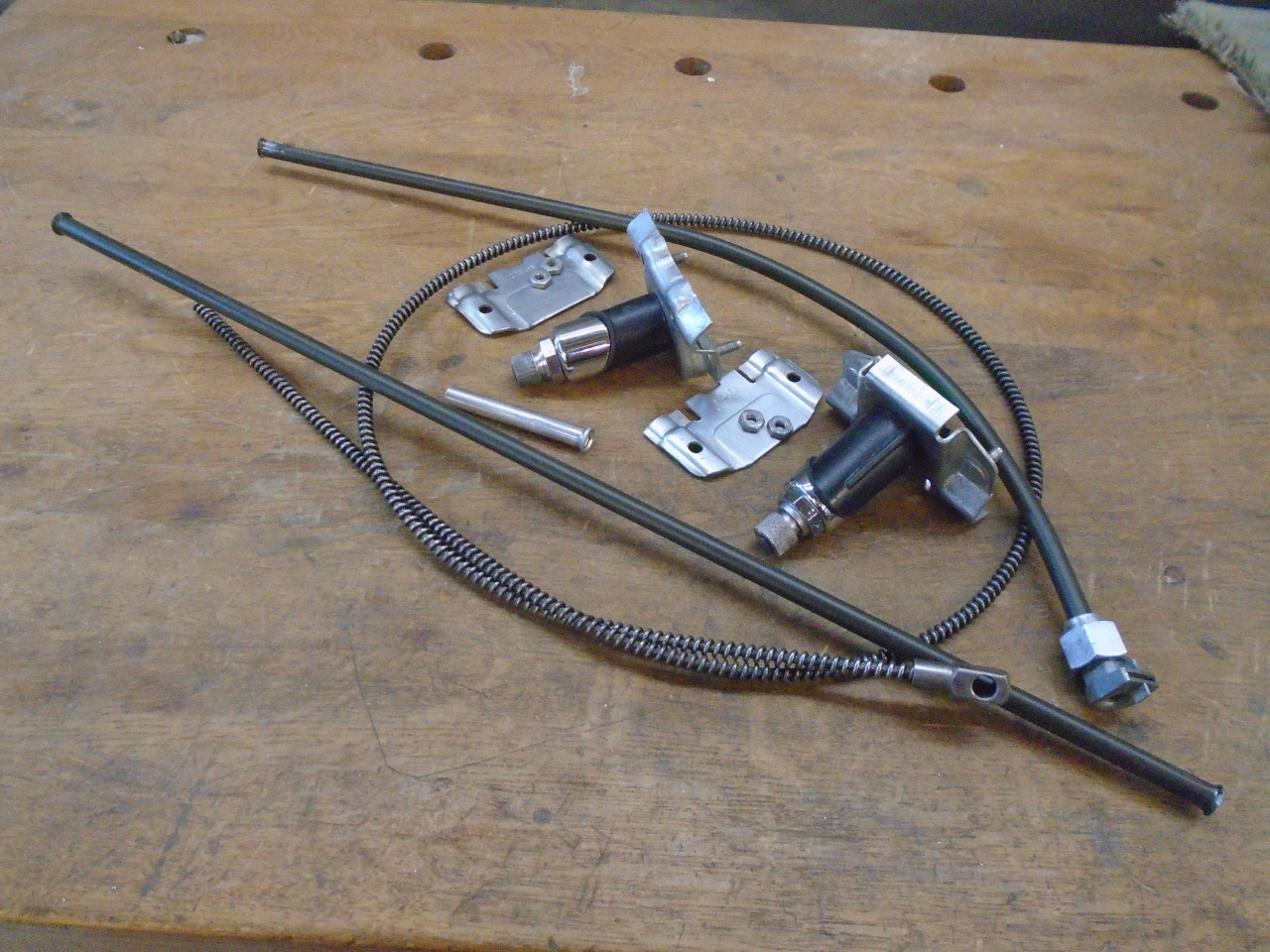

When I went to order the new octagon nuts, I splurged and bought the

fitting kits that included the chrome bezel, the chrome nut, and the

oval gasket.

I also made new cable guide tubes. They are just 5/16" OD steel

brake line tube, cut to length, and flared. The curved one will

likely have to be tweaked at install.

This was a fun little project. Cost was around $15 for the fitting kits.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages