To my other GT6

pages

May 2, 2020

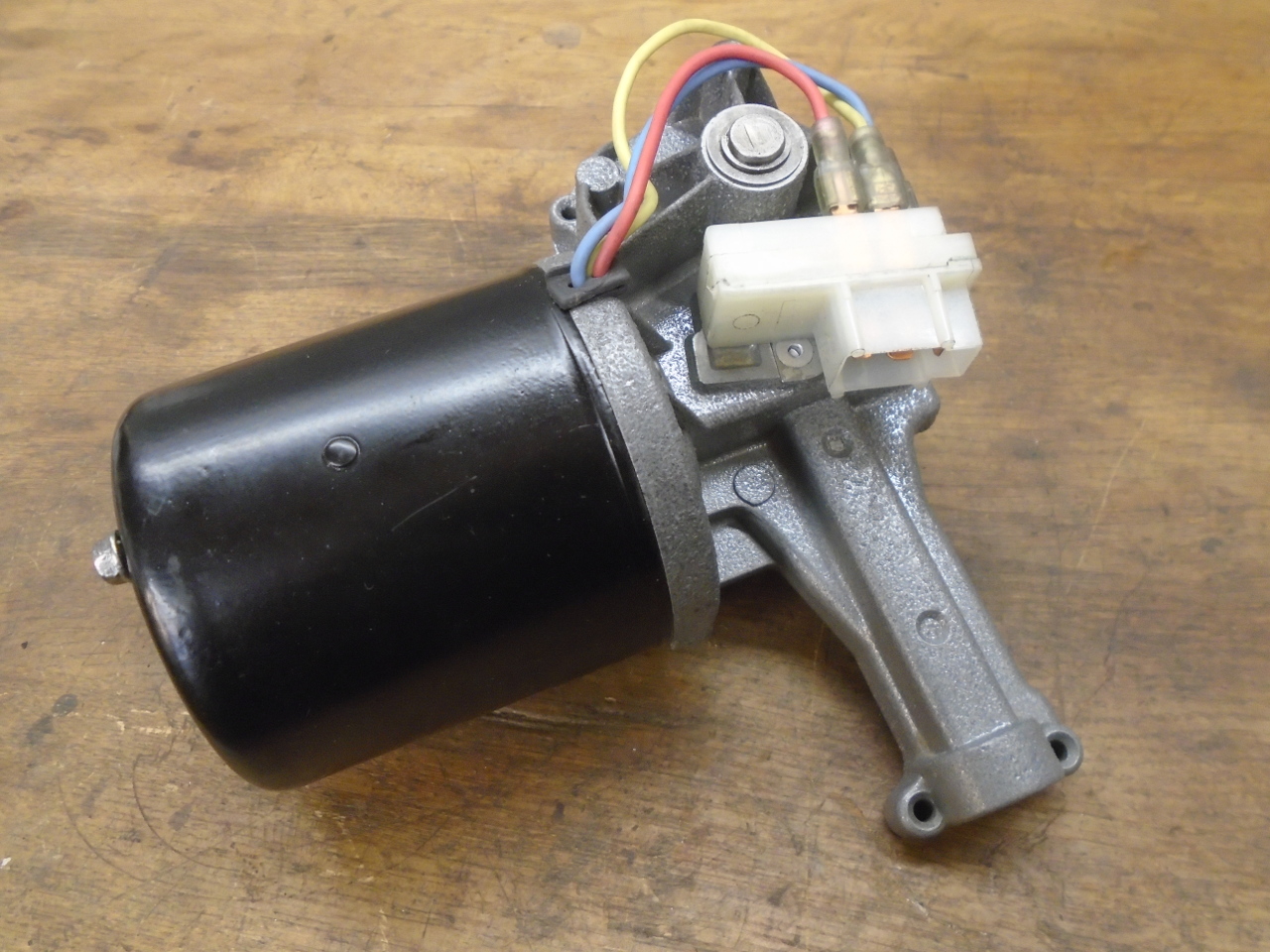

Windshield Wiper Motor

GT6 cars came with screen

wipers powered by an electric motor. The Lucas motor was

pretty ubiquitous at the time, being used in a range of British

and other European cars. Lucas actually provided several

variants of the motor over the years. Mine was a 14W, a

two-speed model with automatic arm parking.

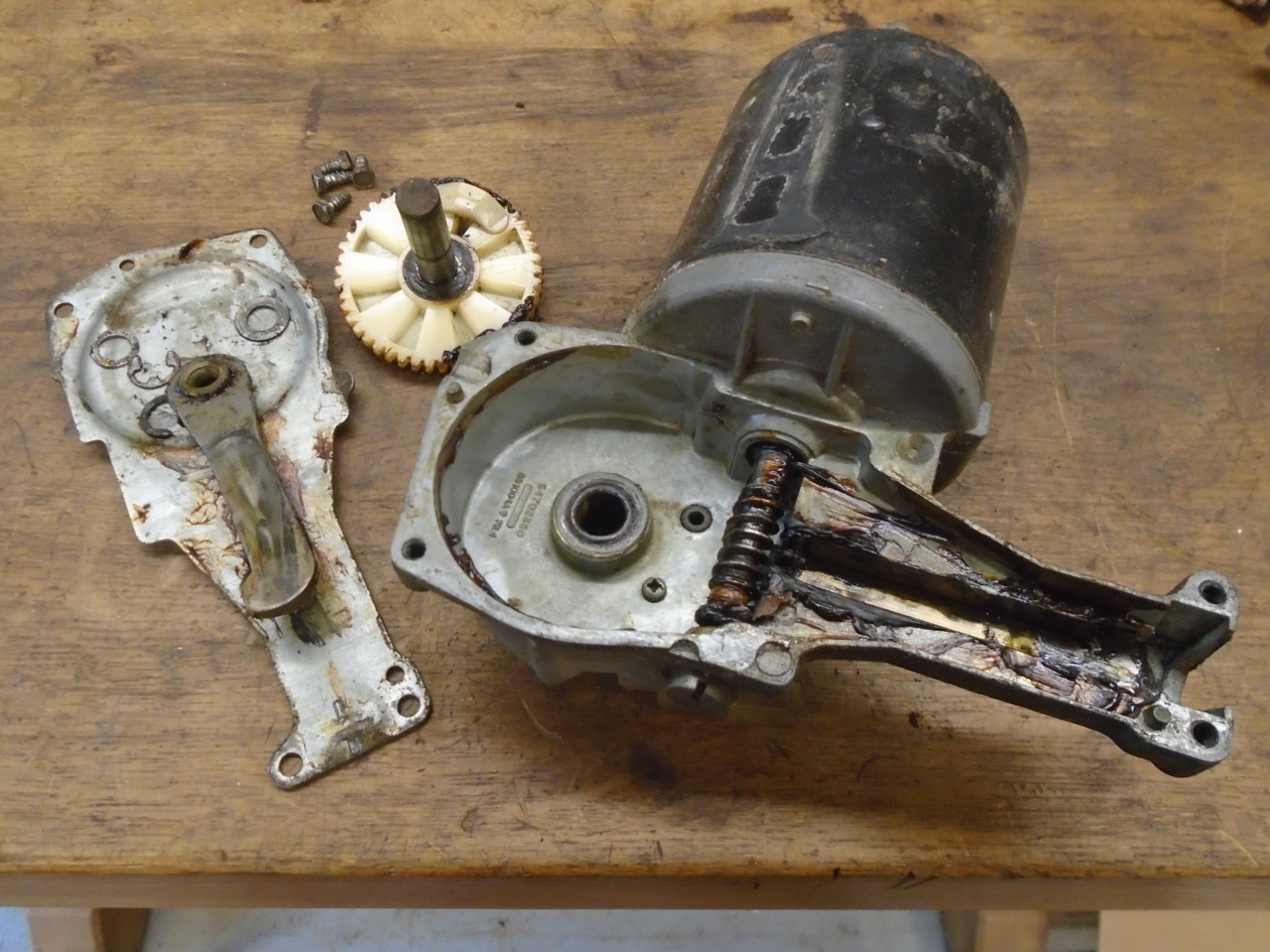

I guess can't blame the 51 year old motor for looking dirty and

tired. Tested from a 12 volt power supply, it didn't run.

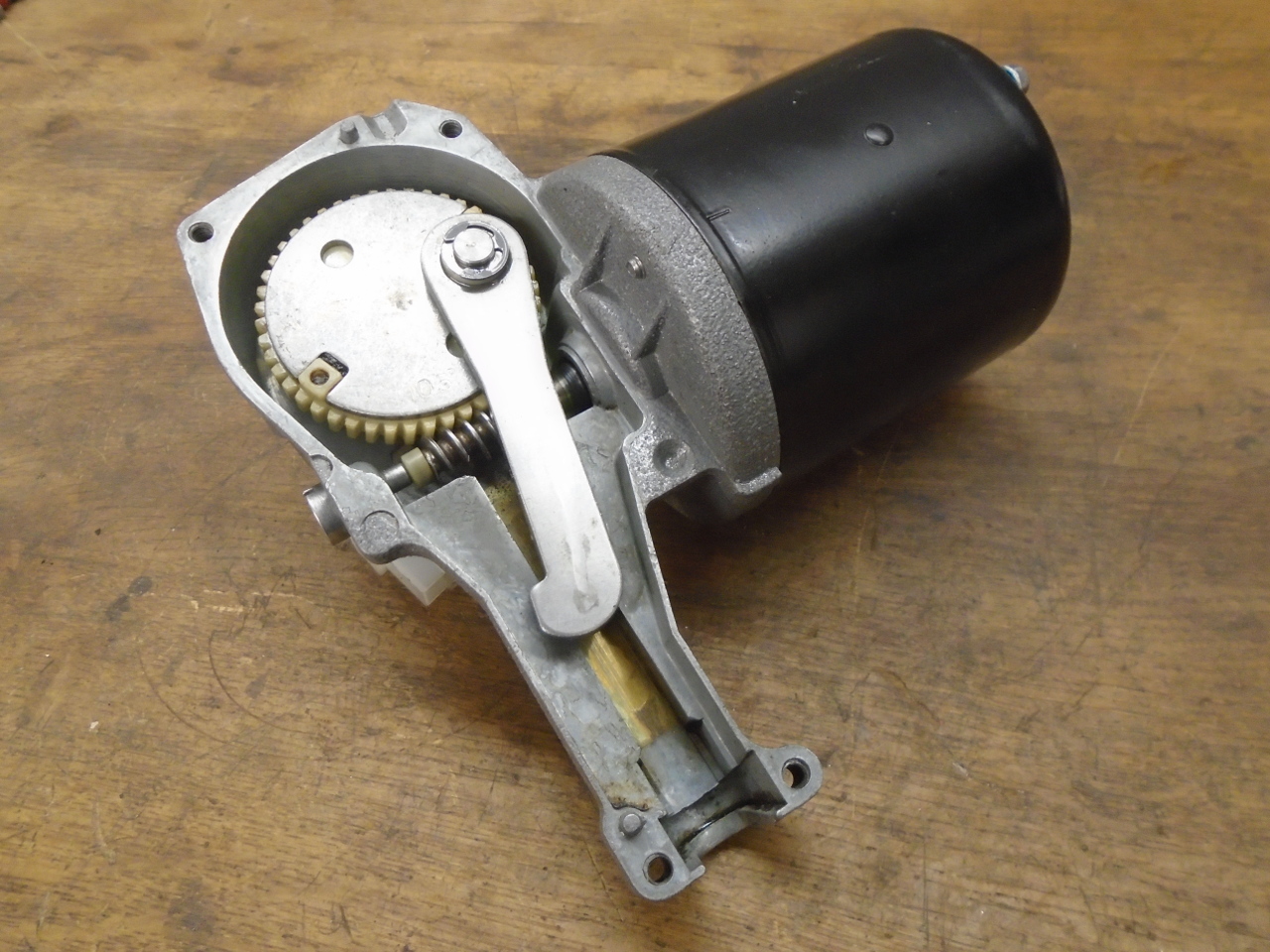

I cleaned the grime from the outside, and opened up the

gearbox. Speed reduction is by means of a worm gear with a

ratio of 46:1 if I counted the teeth correctly.. It was

cleaner inside, but the grease was pretty stiff.

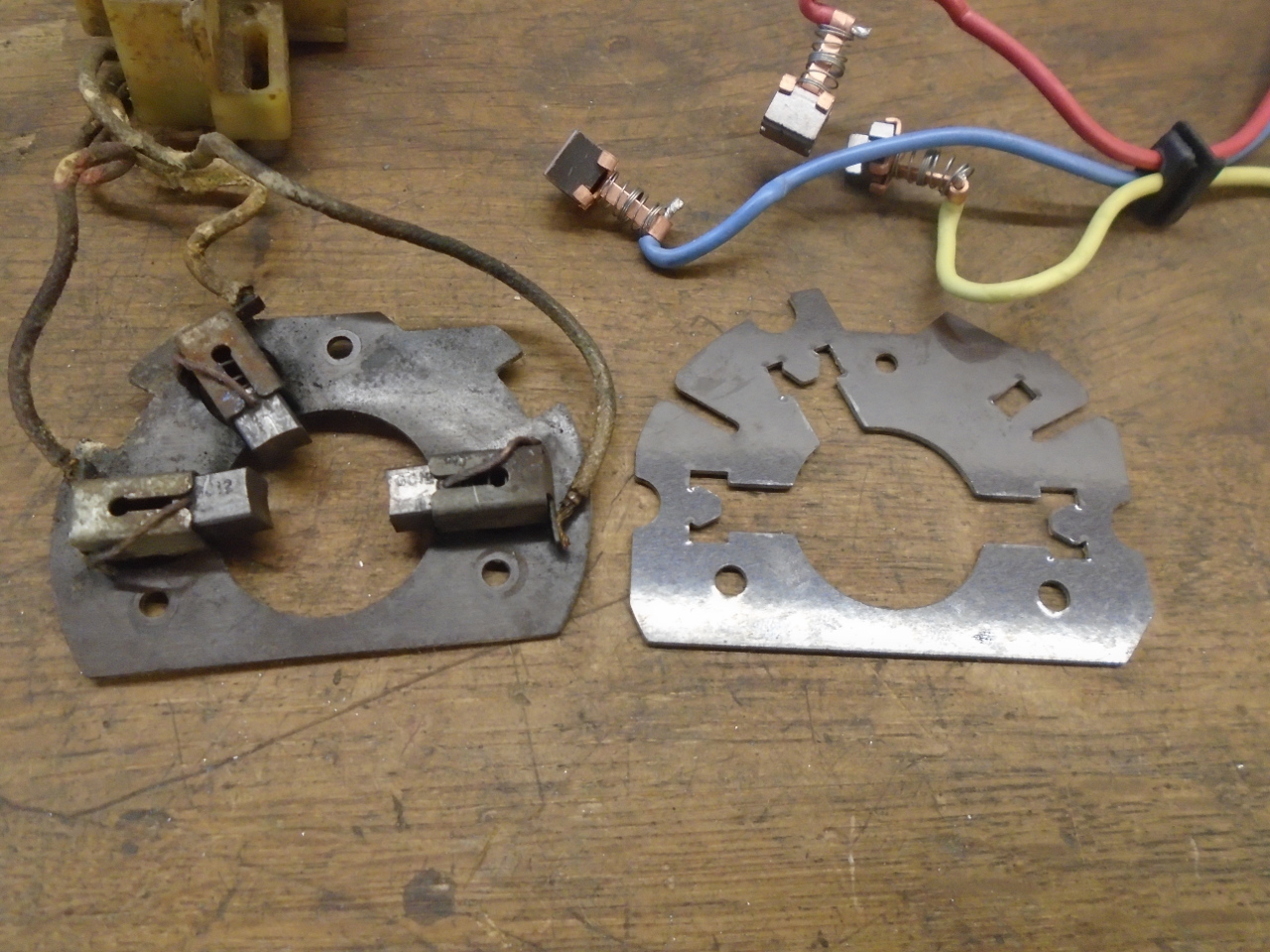

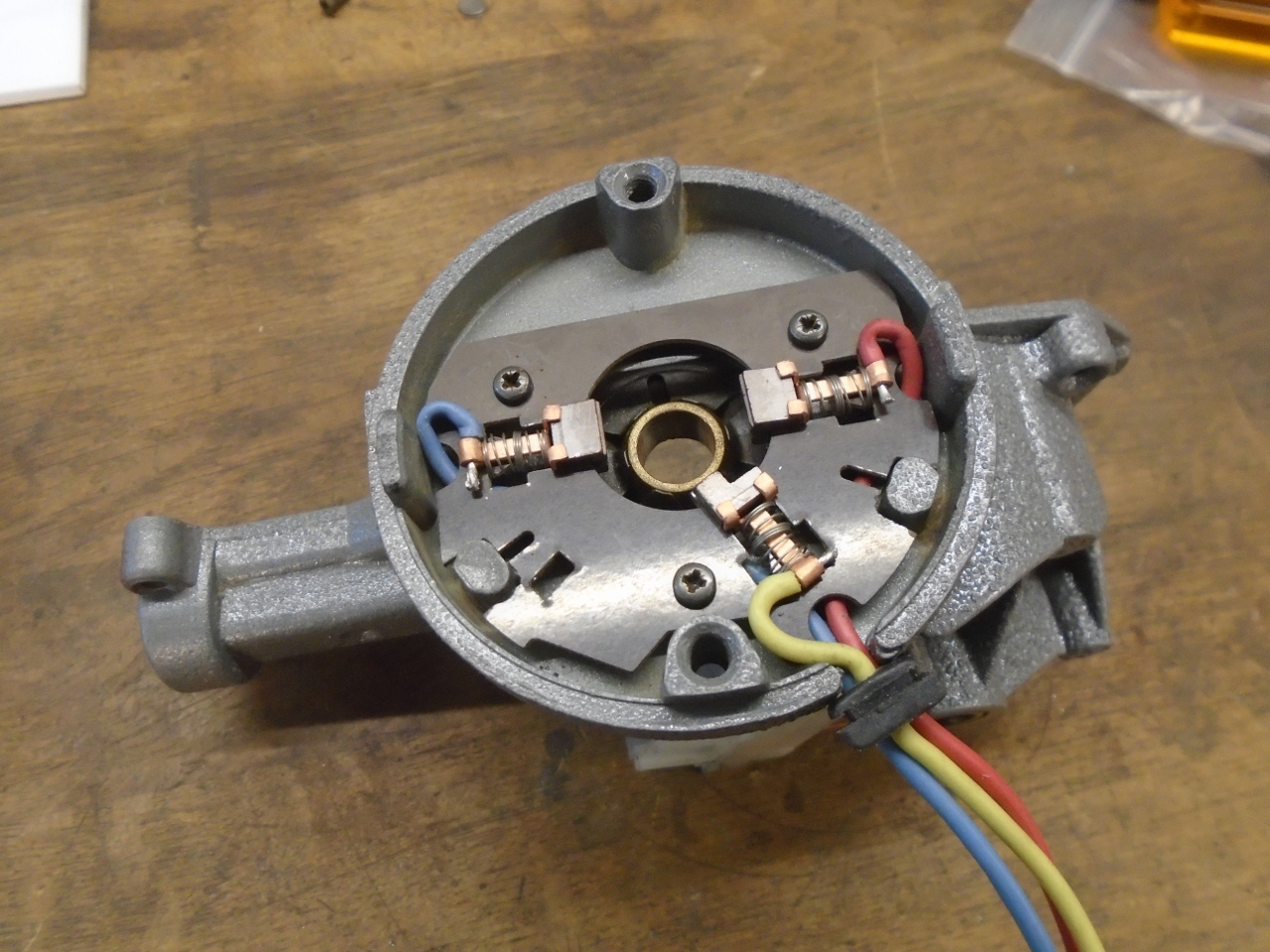

Pulling the motor body off revealed that it was a permanent

magnet motor. The Bakelite brush board was fitted with

three brushes. The extra brush is how the second speed was

accomplished. One of the brushes seemed a little short.

The brushes were hardwired to the park switch, which was mounted

to the back of the gearbox. The innards of the park switch

were mostly missing.

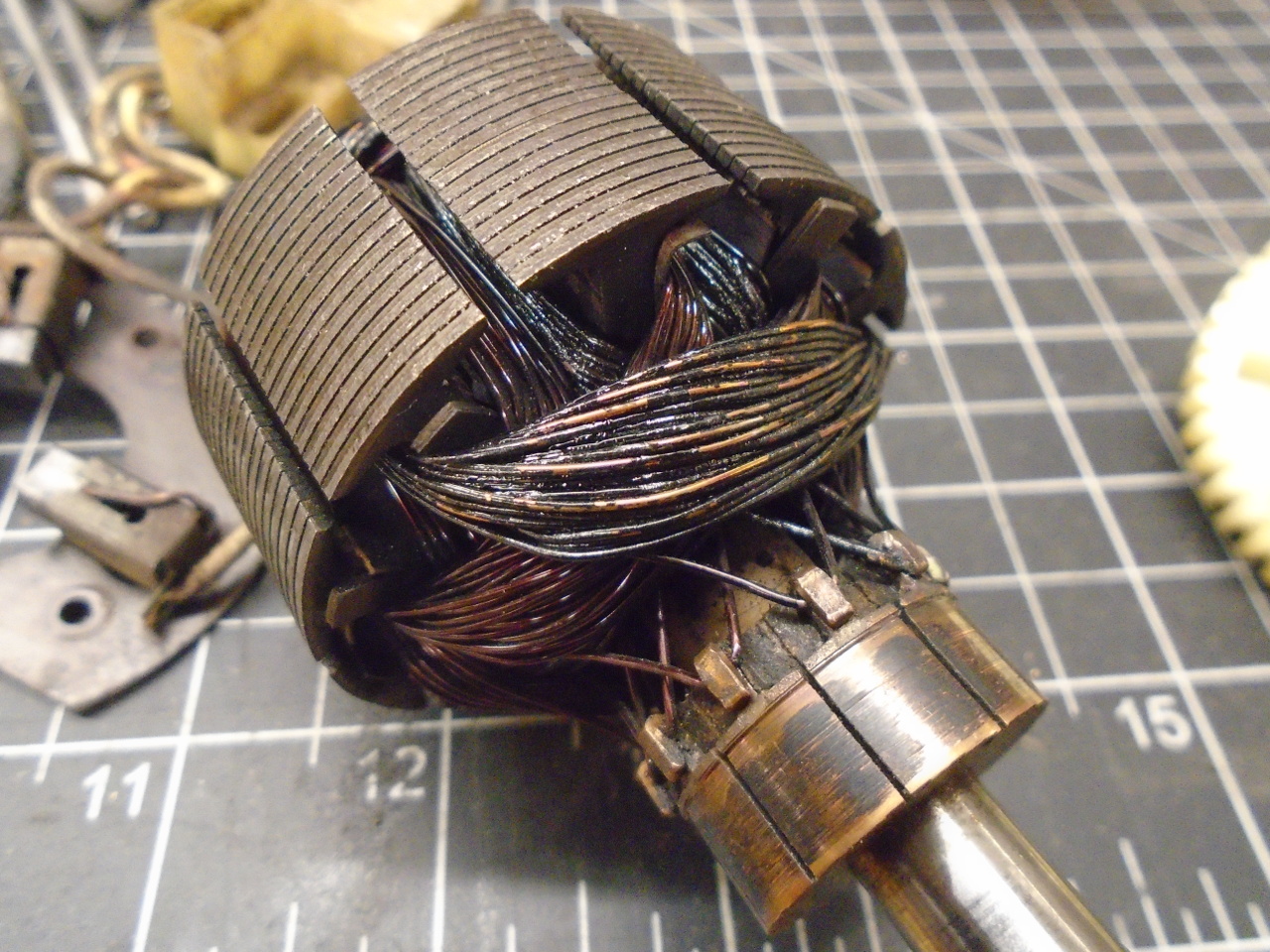

As for the armature itself, it looked pretty bad. Several

of the coils looked burnt.

So, summing up the situation, I had an inoperative wiper motor

with worn brushes, a trashed park switch, and a knackered

armature. A perfect candidate for resurrection! I

was encouraged by the fact that a British company was offering

new armatures for a pretty reasonable price, so I ordered

one. I also ordered a new brush plate and a park switch

from a US supplier. I was ready to order new bronze

bushes, but honestly, the originals were still tight enough that

I didn't bother.

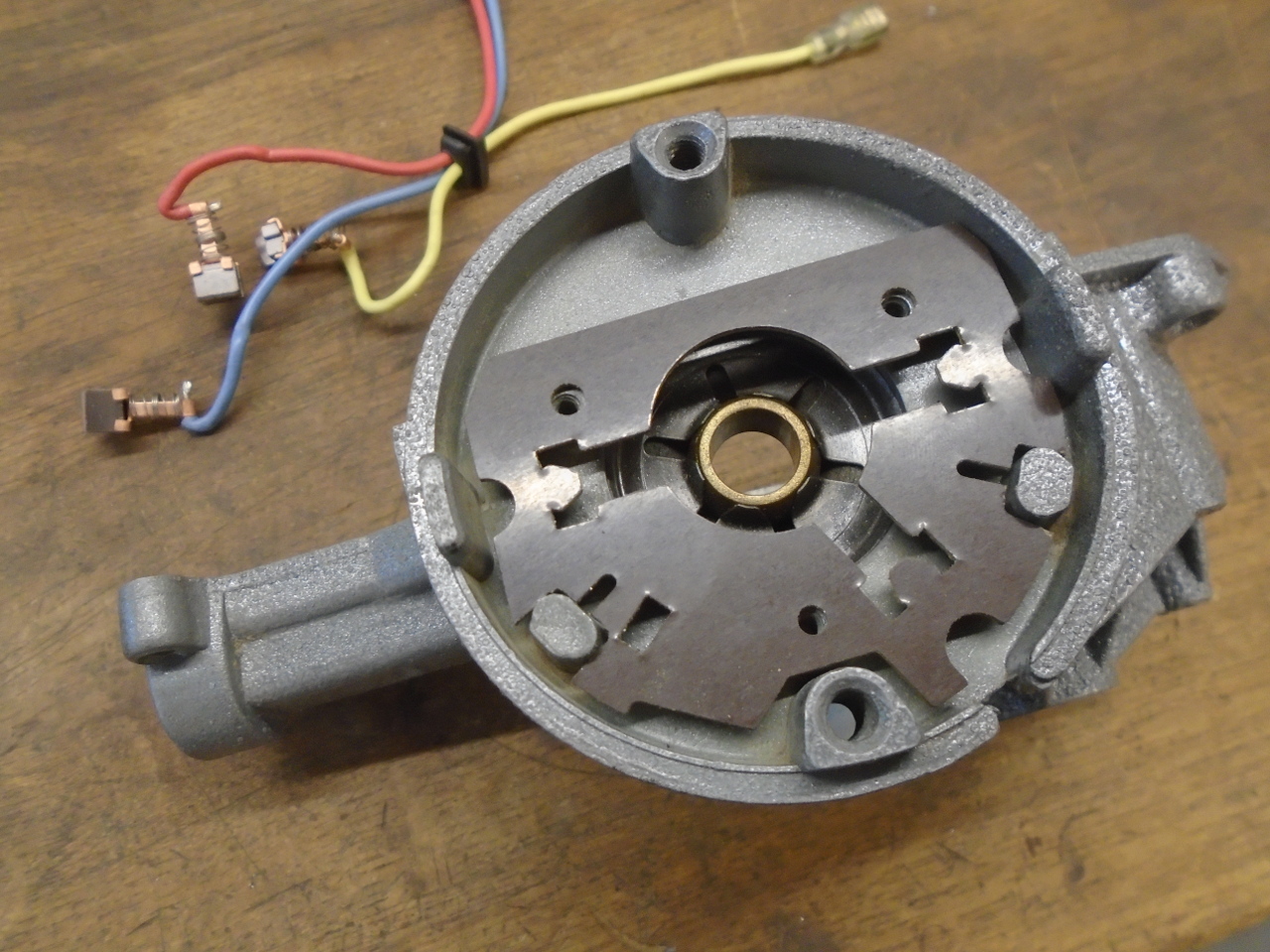

While waiting for the parts, I cleaned up the motor

housing. I wanted to powder coat it, so I pulled out the

magnets so they wouldn't be subjected to the oven heat. I

removed the paint, then the rust, and shot it with powder.

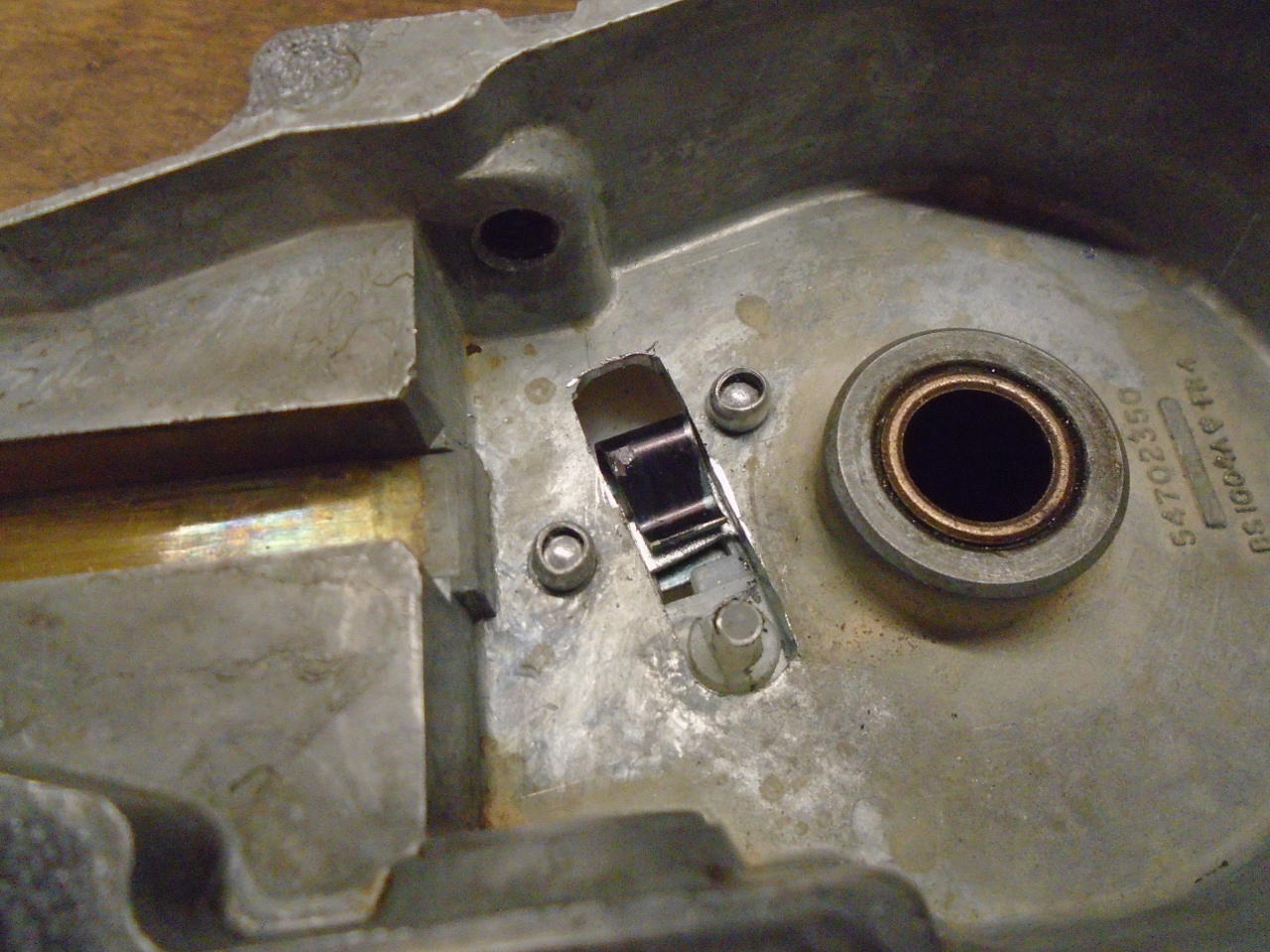

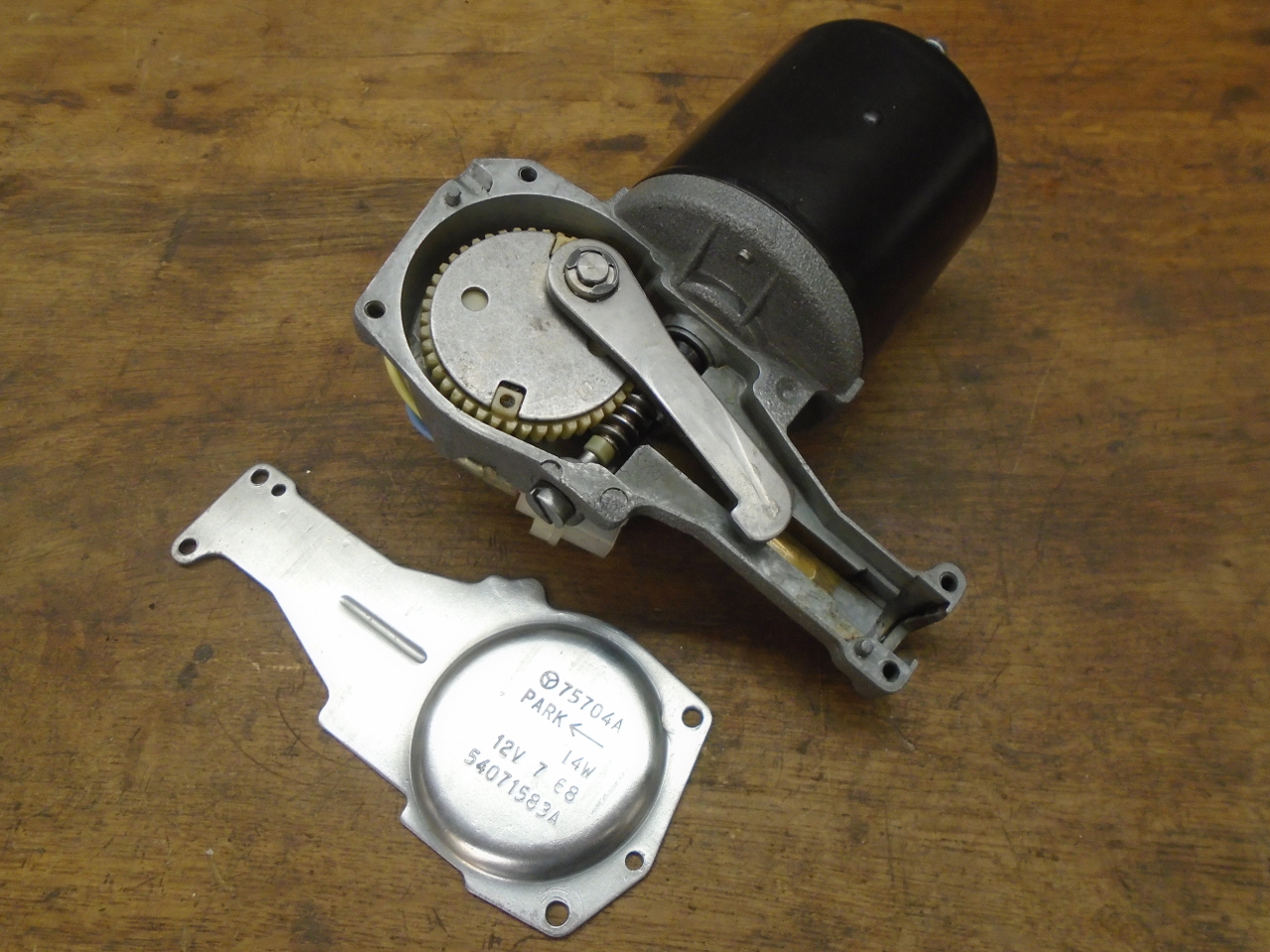

The park switch was the first part to come in. It worried

me a little that it looked quite a bit different from my

original. The original was attached with two screws, while

the new one just had a little metal clip for fastening.

Before calling the vendor, I did some research and found that

what I had was an "old style" wiper motor, as evidenced by the

"A" suffix to the part number stamped on the cover. I also

found that park switch for the old style motors are apparently

no longer available.

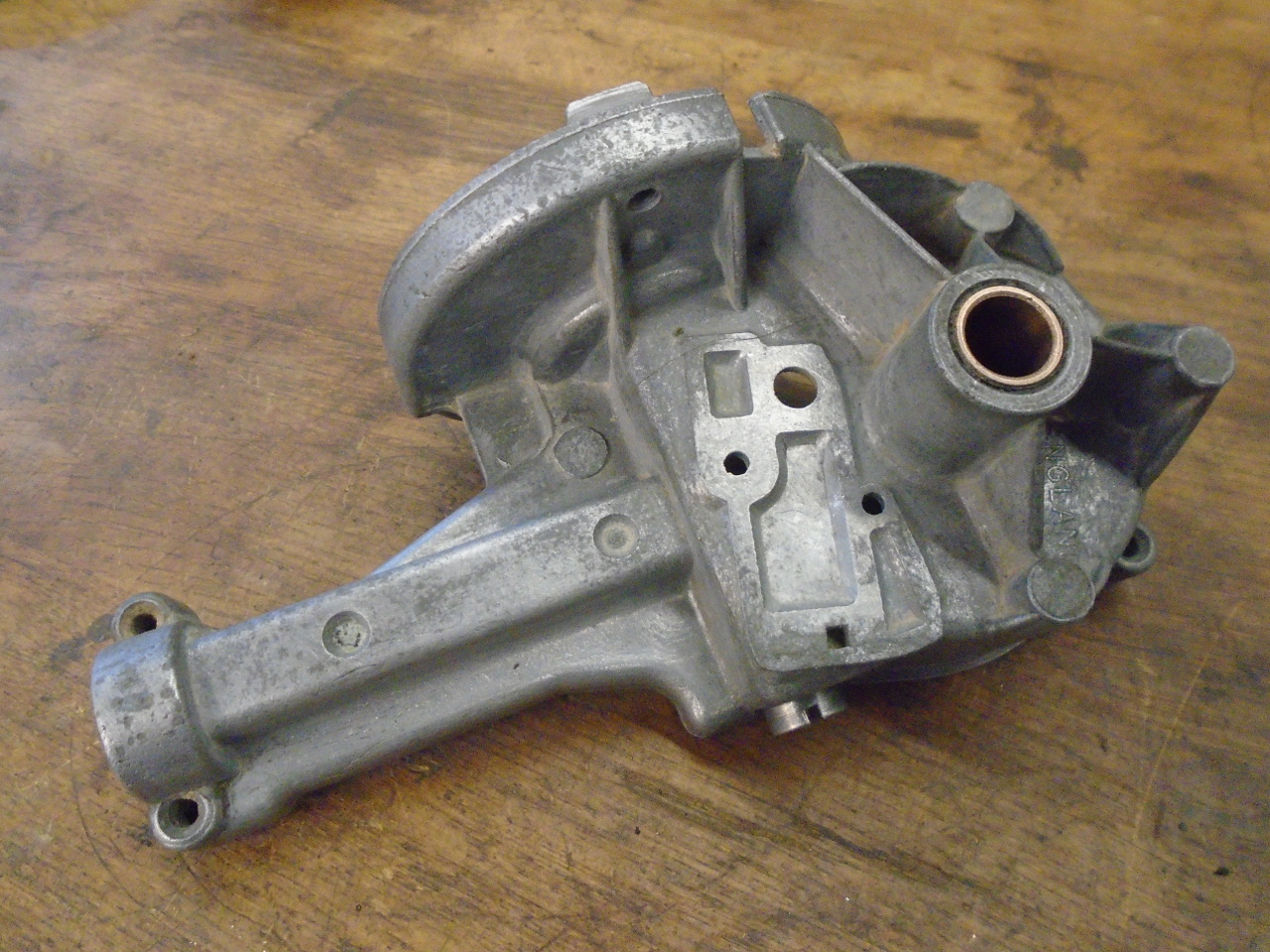

It looked like the mounting was the only difference in the

switches, so I looked at modifying the pot metal gearbox housing

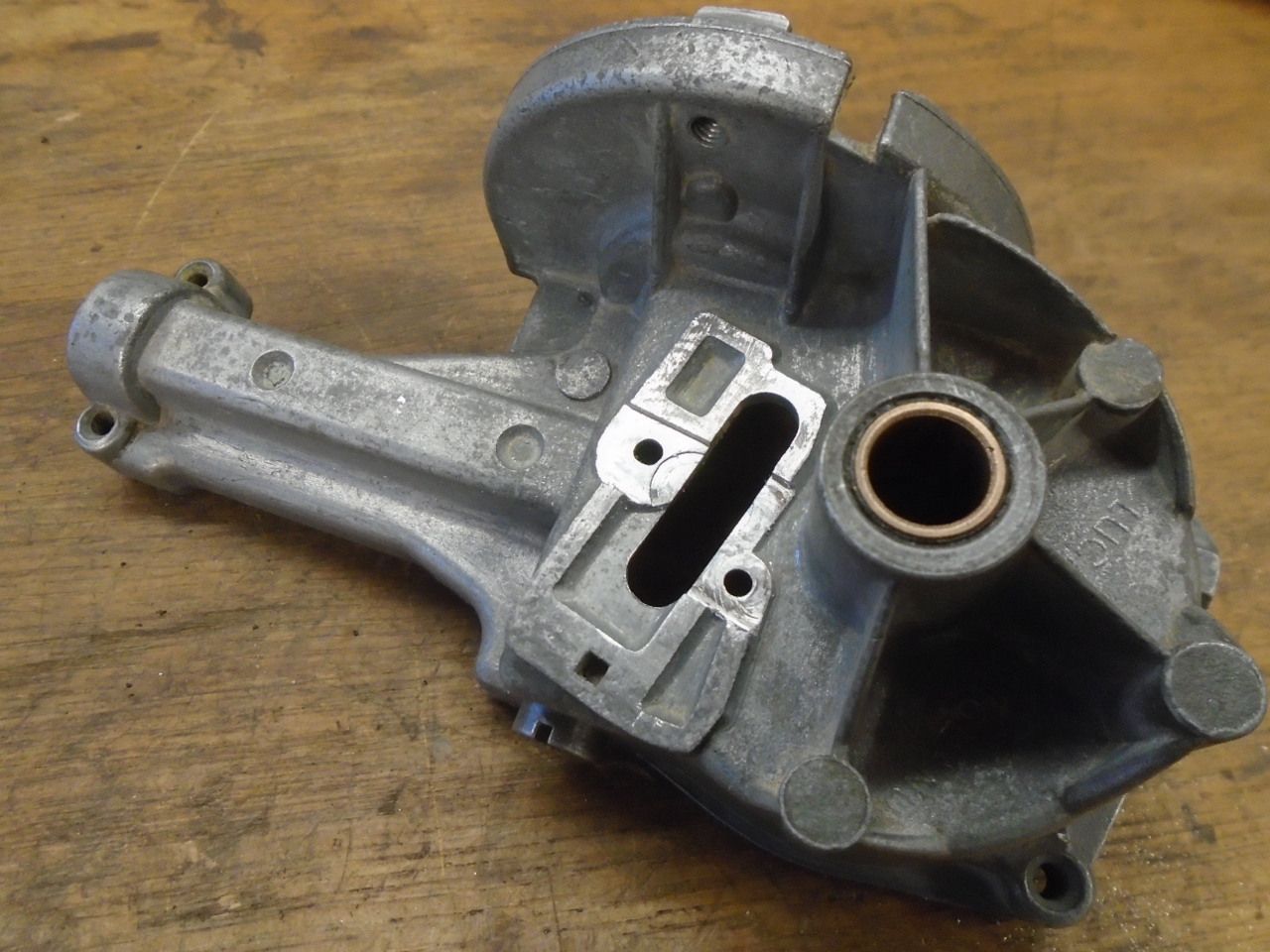

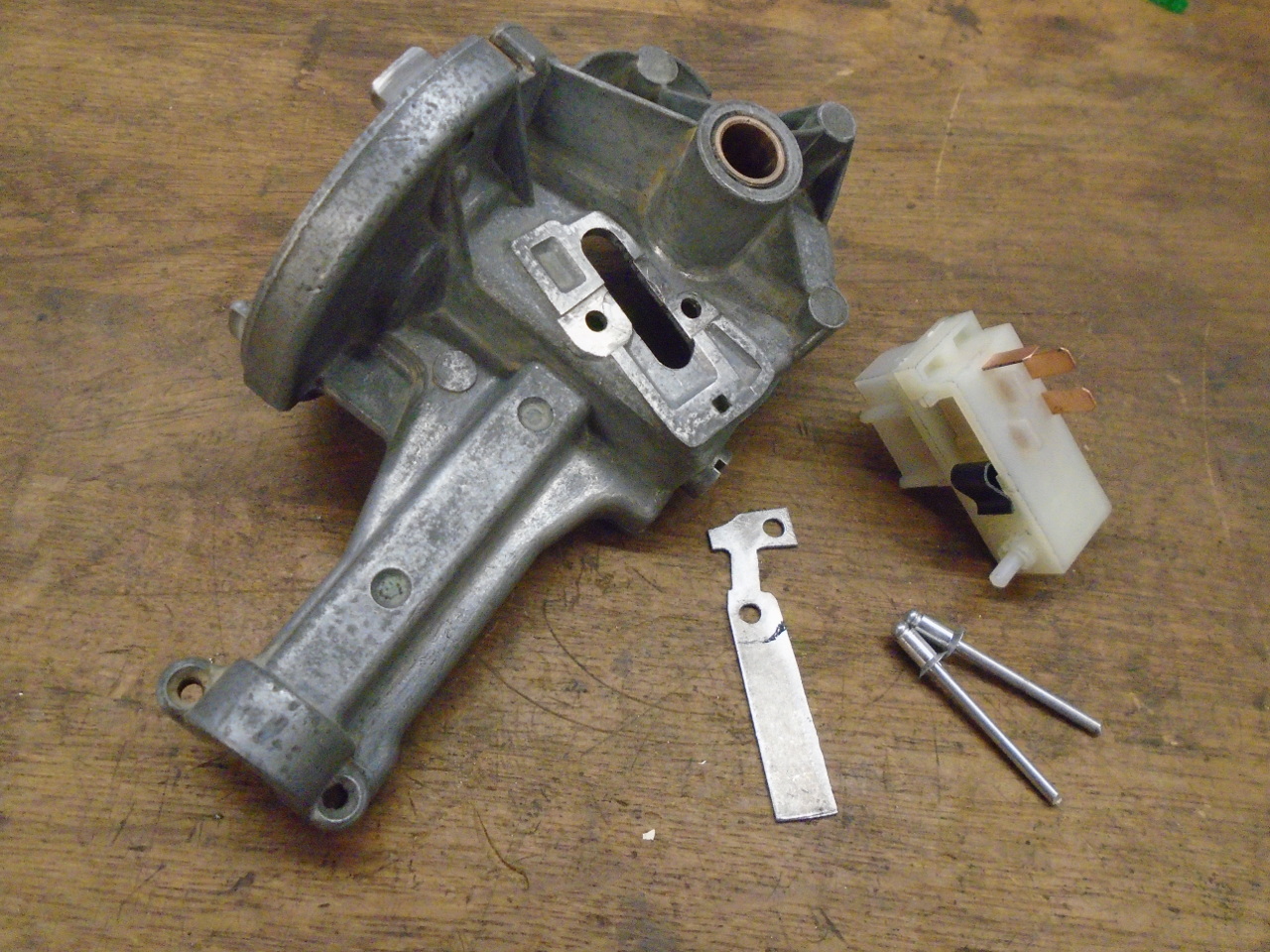

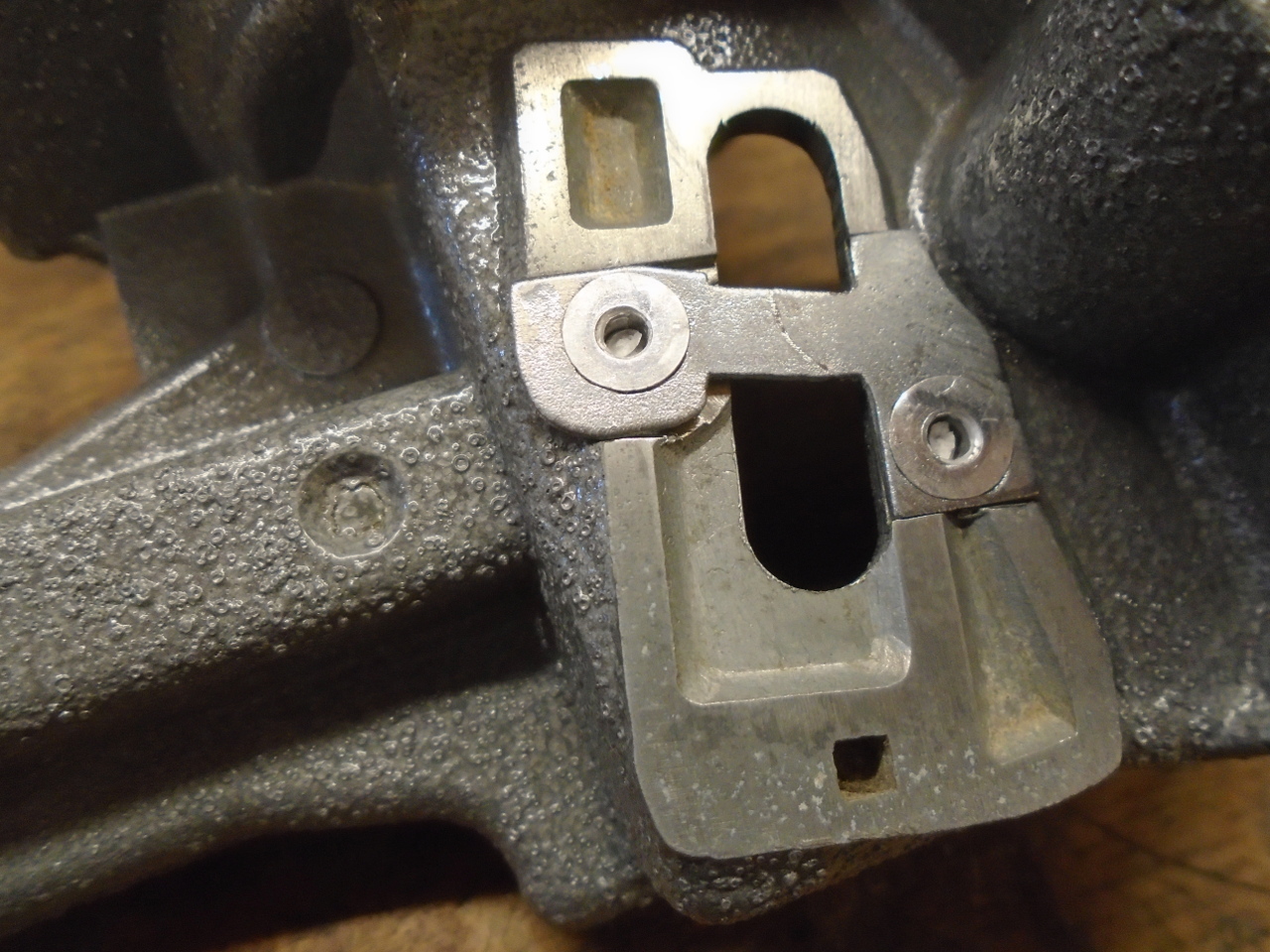

to accept the newer switch. The first pic is the early

housing from the GT6, the other is the later housing from my

TR6. I had to make the GT6 part look like the TR6 one.

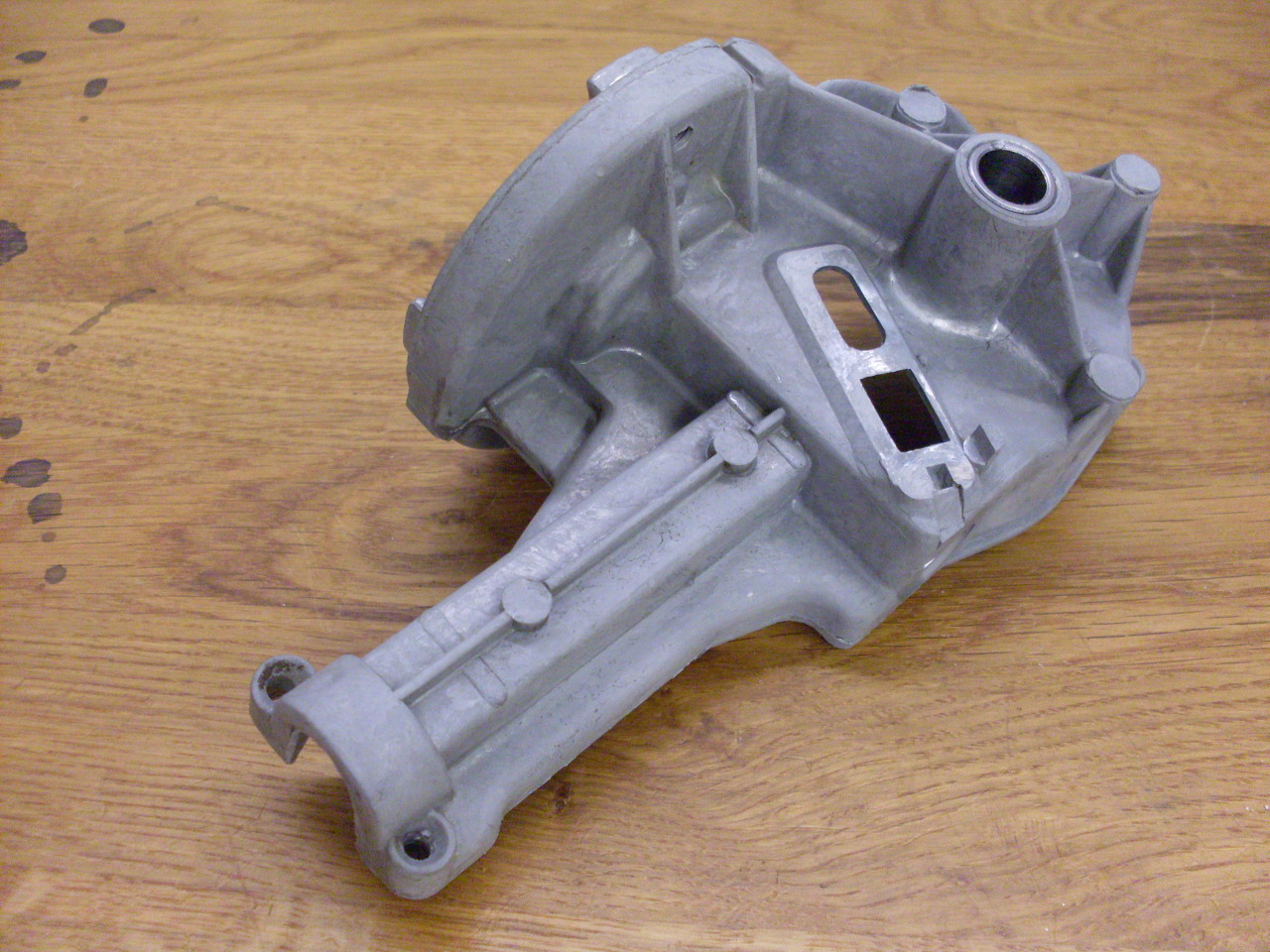

I cut a slot in the housing, and made a little steel bridge for

the switch's clip to grab. The last pic also shows my

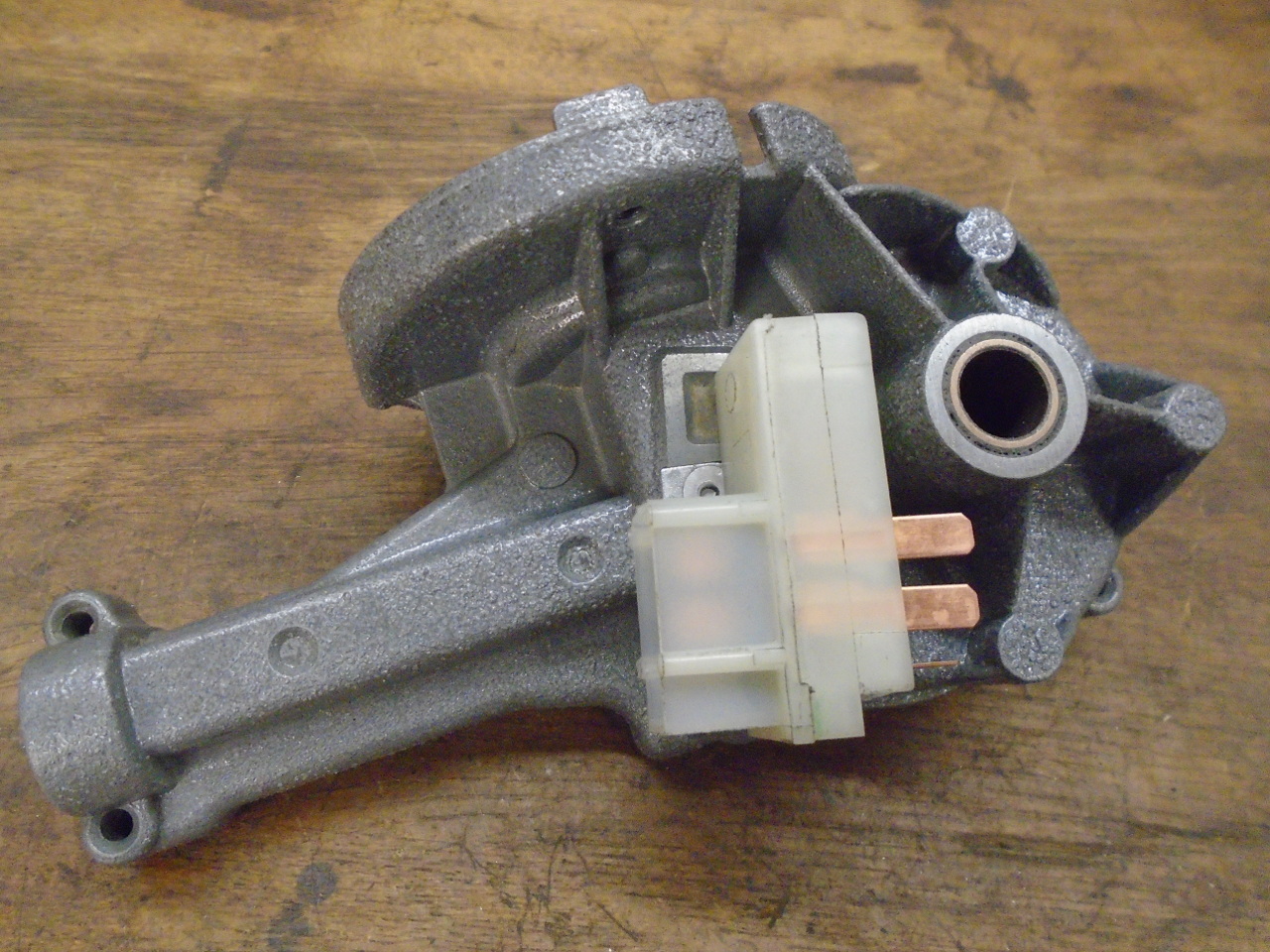

really rough hammertone powdercoat. I'm not sure what

happened there. The bad areas are mostly out of sight, but

if it bothers me enough, I'll strip it and re-coat.

This shows the switch mounted.

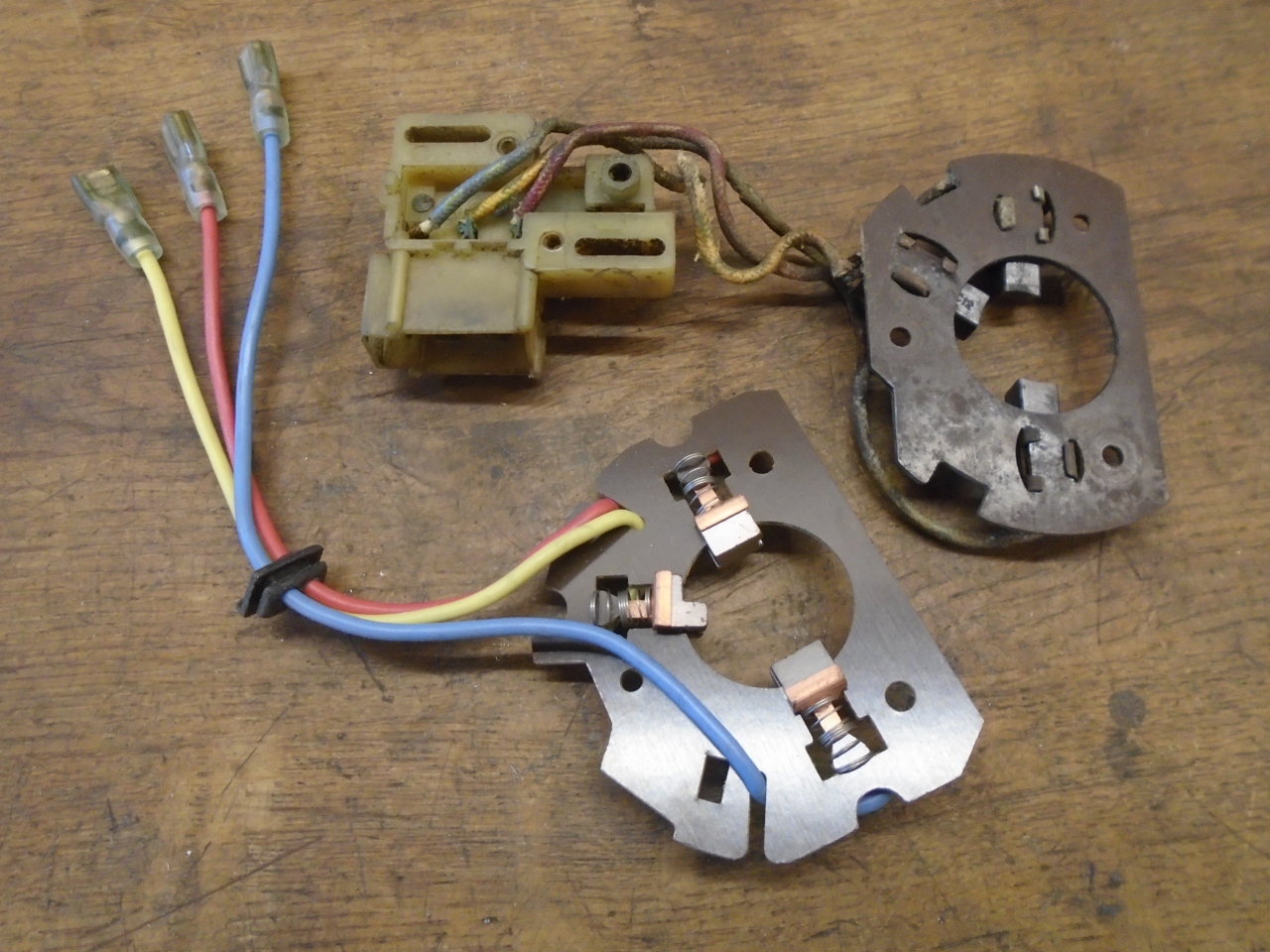

About this time, the brush plate came in. I guess I

shouldn't have been surprised, but it was also different from my

old one.

I had to reshape the Bakelite plate to clear some features of

the housing, and, since the brushes were mounted differently, I

had to space the plate up about an eighth of an inch so it would

be centered on the commutator..

Well, at this point, I had a fair amount of work in this wiper

motor, which made it even more irritating when I got a message

from the British armature supplier saying that they didn't

really have the armatures after all.

There were a couple of options: forfeit all the work to date and

take my chances buying a used or a reproduction assembly, or try

to rebuild the armature.

I had no intention of even considering rewinding the armature at

the beginning of this project, and even though I had zero

experience with the process, I knew it was possible, and the

challenge sort of appealed to me.

With nothing to lose, I started by unwinding the armature,

carefully recording how everything was wound and connected.

Then did some research on armature winding, and while the actual

winding didn't appear too hard, there ware quite a few different

coil arrangements to choose from. Based on my unwinding

records, I chose a technique called "chorded split loop

winding". It is not the simplest way to do it, but it has

the advantage of being symmetrical so it produces an armature

with better mechanical balance than simpler methods. Also,

it was the way it was originally wound.

So, I got some 22 gauge lacquered wire and some "fish paper"

used to insulate the coils.

Ten coils of 35 turns each, and I had a new looking armature.

Popped the motor back together and tried it out. After a

little fiddling, it seemed to run fine.

Hooked up the park switch and installed the worm gear.

And buttoned her up for storage. I'll put off packing the

gearbox with grease until installation time.

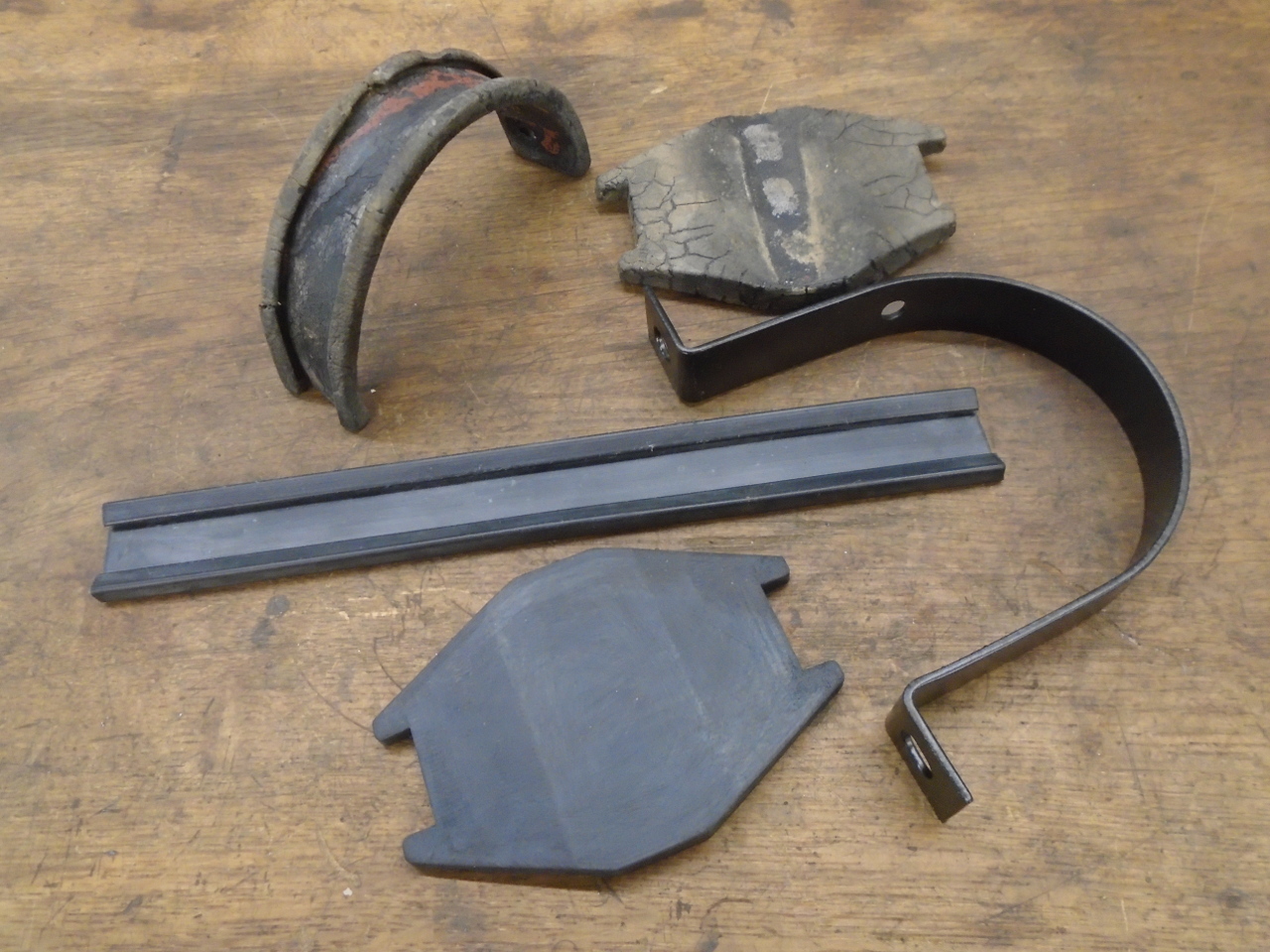

New rubber for mounting.

This project was maybe more trouble than it was worth. On

the up side though, the cost was only around $50, and I acquired

a new skill.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages