To my other GT6 pages

November 28, 2019

Starter

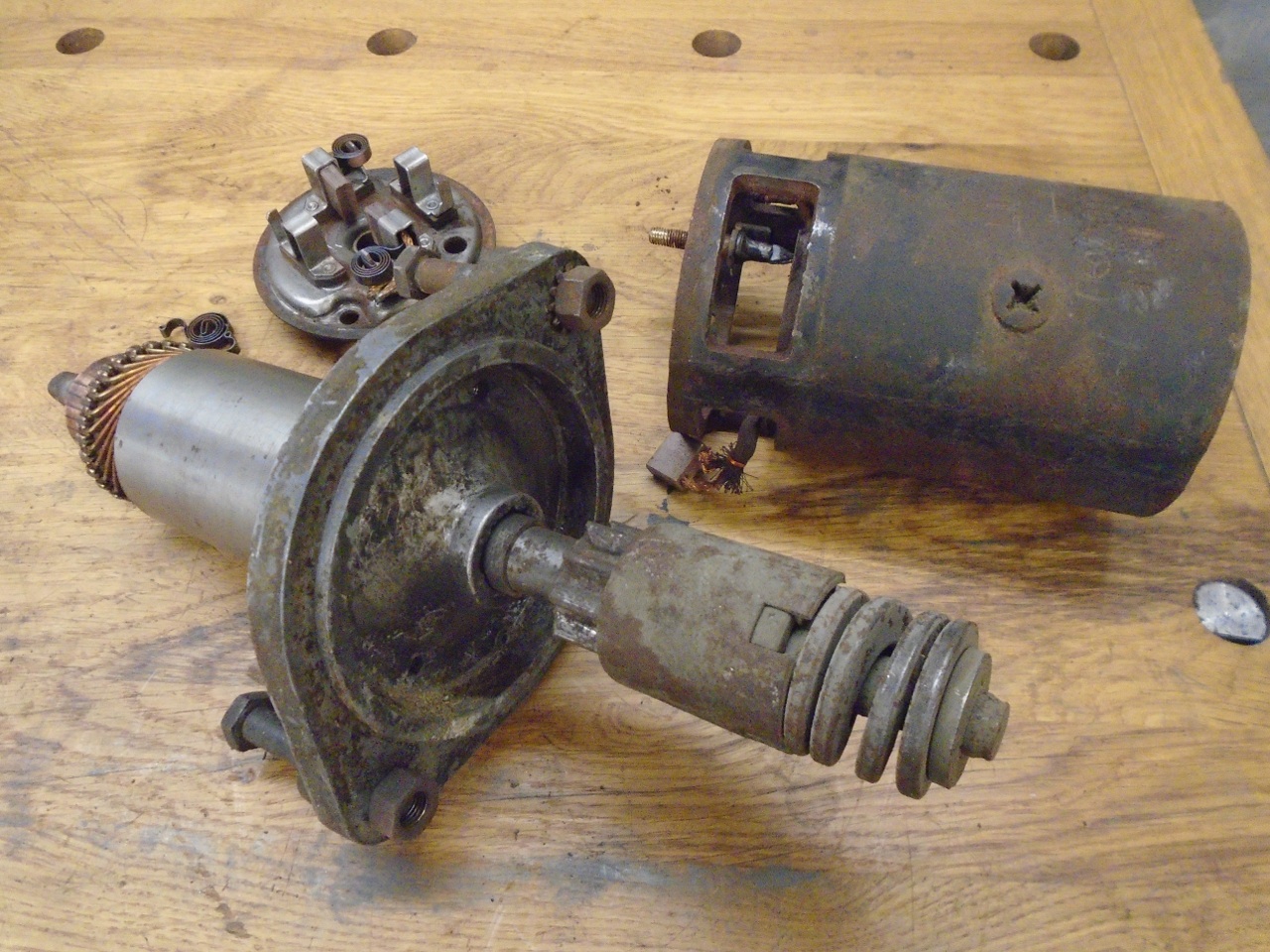

My

GT6 had a Lucas M35G starter motor. This is a ubiquitous motor,

found on a range of British cars dating back at least into the 1950s.

It was fitted with an inertial "Bendix" drive mechanism for

engaging with the flywheel's ring gear. My starter was pretty

crusty, but as far as I knew, it worked.

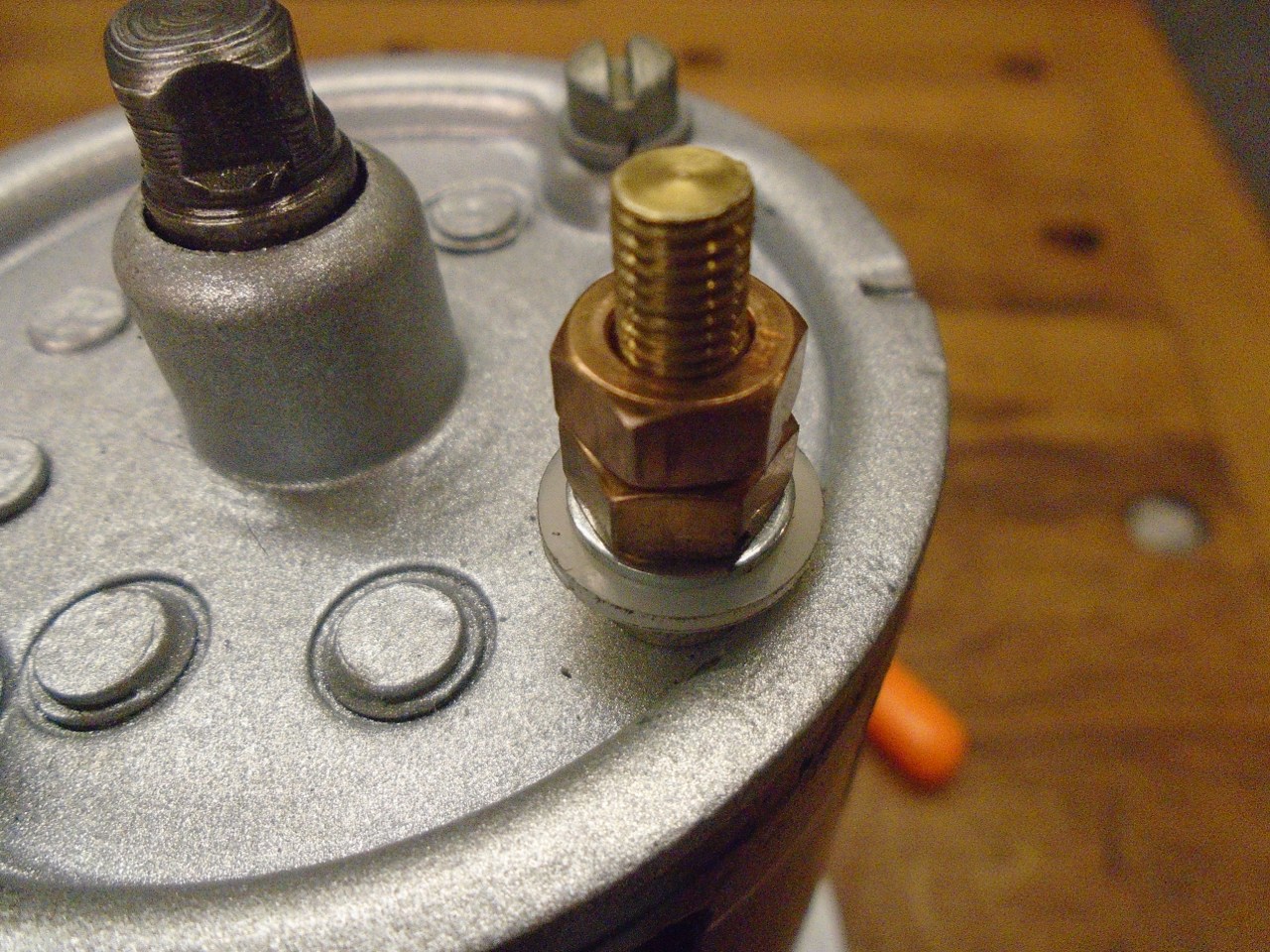

Really,

the only difficulty I had in taking the unit apart was with the

electrical connecting stud. The lower nut on the stud has to be

removed in order to get the end plate off, but it seemed to be seized

on the stud. The stud was turning, which didn't seem to be a good

thing. I resorted to cutting the nut off, and when the cap

finally was removed, I saw the result of the spinning stud. That

flat on the stud is supposed to keep it from turning, but it didn't.

So I could then pull the armature from the main body.

To

get the other end cap off, the Bendix parts have to be removed.

This little section of pipe with an arc cut out allows access on

the press to remove the little snap ring.

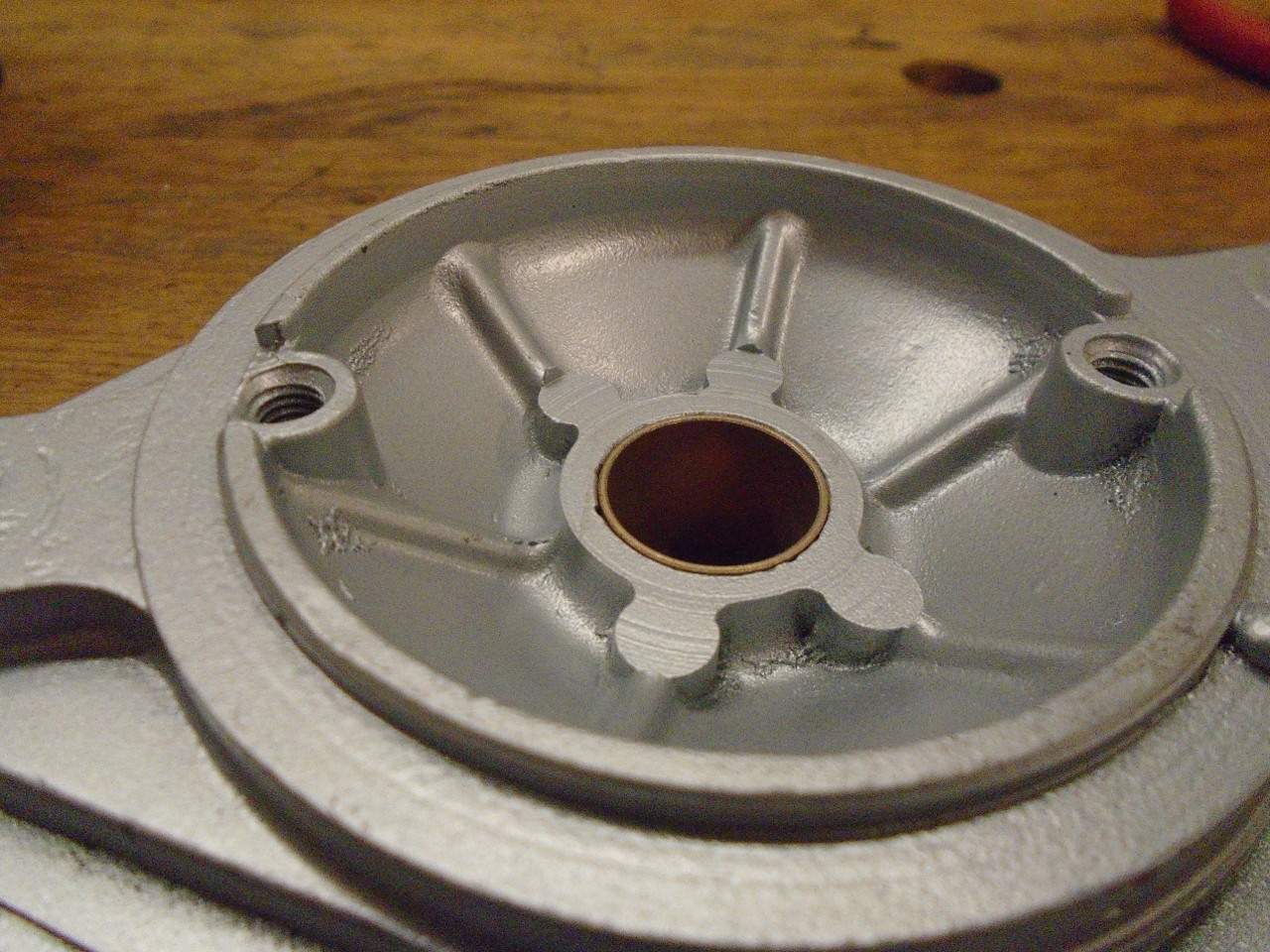

Each of the end caps has an sintered, oil impregnated bushing.

Now,

back to that troublesome electrical stud. The threads on it were

pretty beat up. In fact, they were so bad that when I measured

them so I could chase them with a die, I thought they were M6-1.

Well, they weren't, they were 1/4-28, and the M6-1 die just made

it worse. Finally, I just unsoldered the stud from the flat field

conductors.

"Why

stop there?" I asked as I proceeded to remove the field windings.

The windings are held in place by iron pole pieces, which are in

turn attached to the body by big oval head screws.

Taking

out the field windings made cleanup much easier, and also allowed me to

powder coat the main barrel. I'm not sure the field winding

insulation could have taken the heat. I noticed that the starter

had a date code of 9 64, implying that it was probably a rebuilt

replacement.

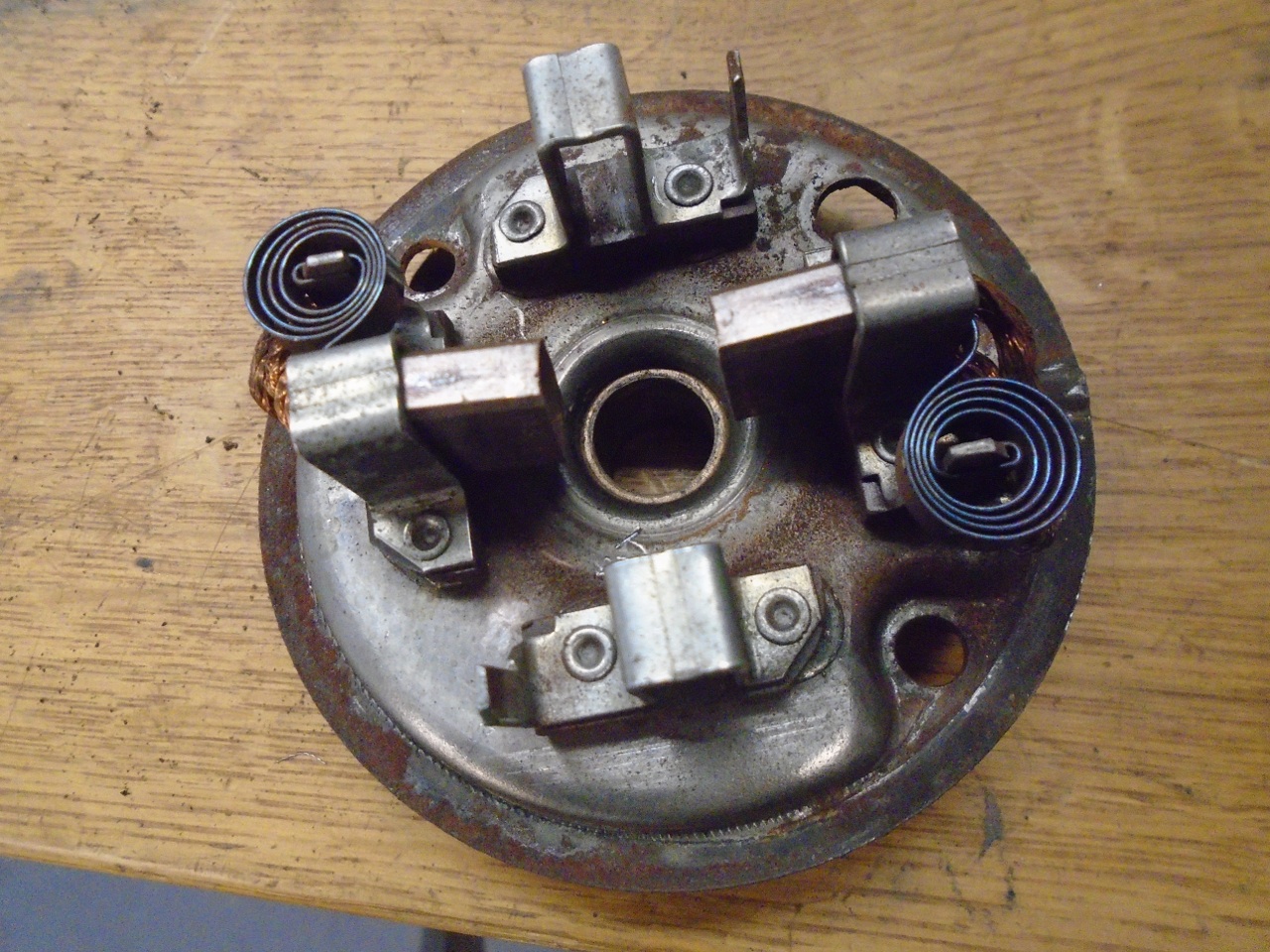

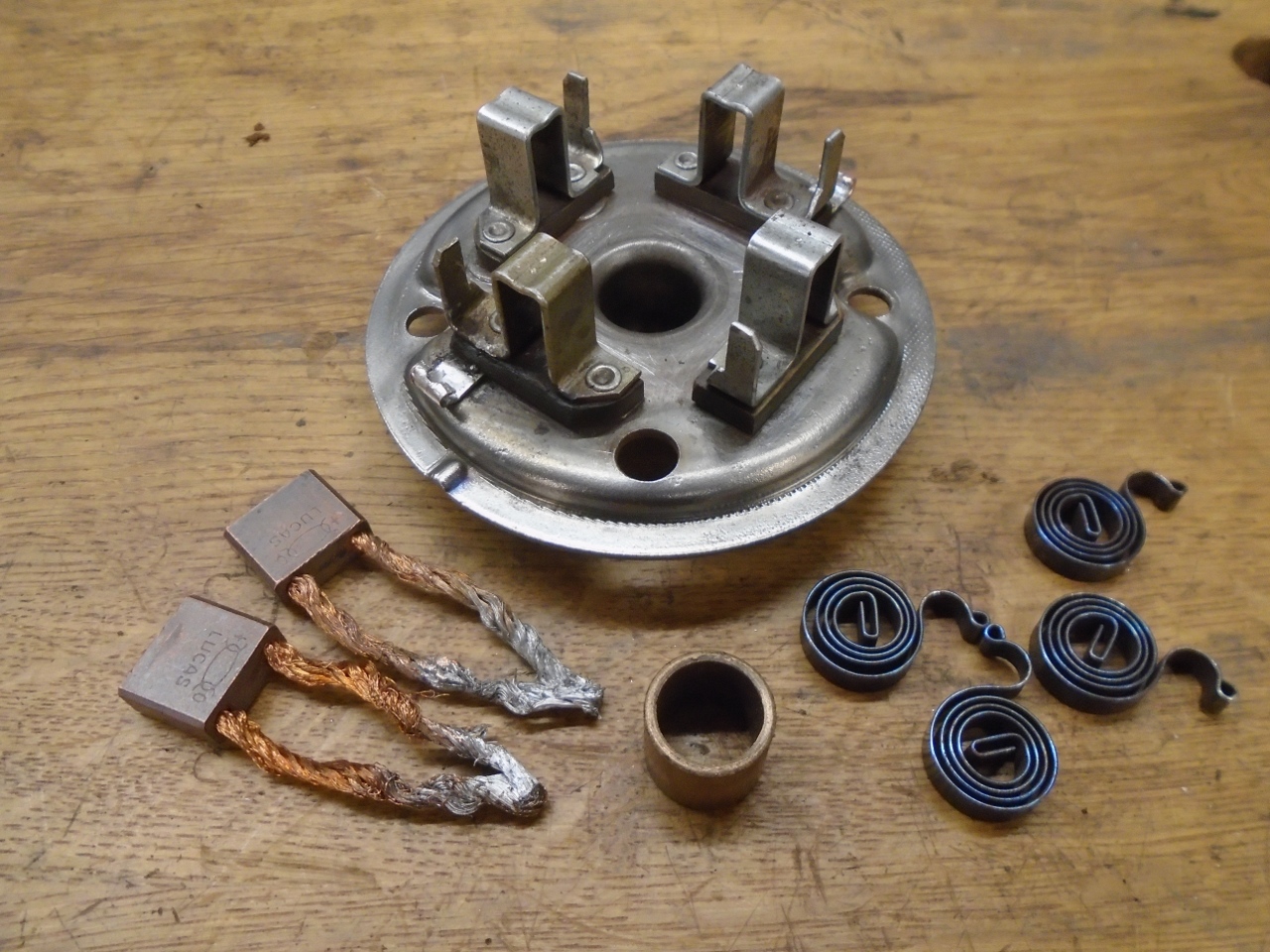

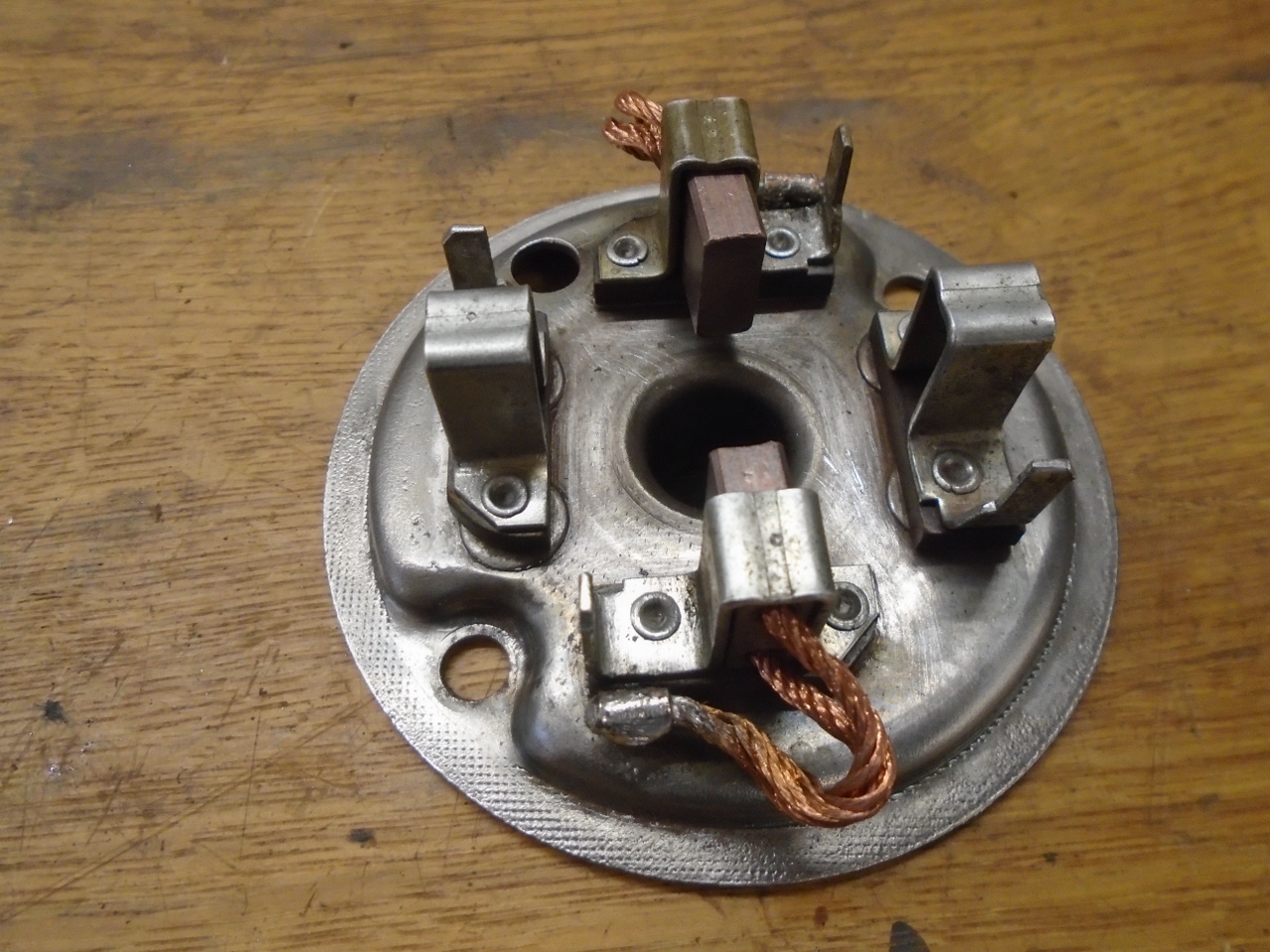

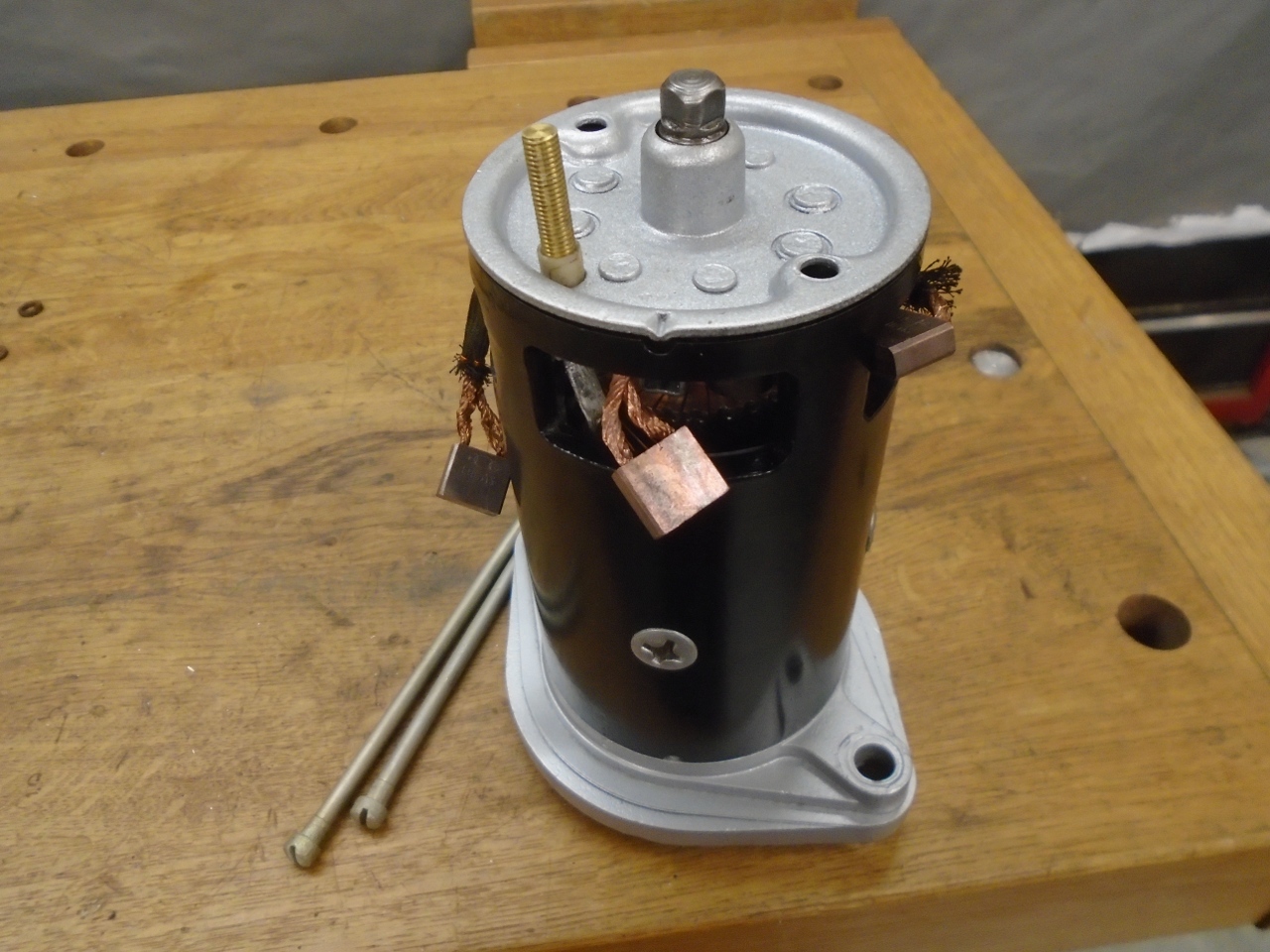

The

brushes all appeared to be OK for length, but the wire leads on the

ground bushes in the end cap were very stiff with solder. This

can happen when replacing them if the heat is left on too long, and

solder wicks it the braided lead. I removed the ground brushes

and replaced them, but left the other two brushes as they were.

It takes quite a bit of heat to solder on a part with this much

metal. The biggest soldering gun I have is 300 watts, but I have

two of them, and it took them both.

Back to the stud once more. I didn't see a good way to salvage it, so I made a new one.

Then

strapped the field coils together around a dummy core to attach the new

stud. I had a hell of a time getting the solder to flow well. I

struggled with it for a time until It dawned on me that the field

windings, which I had assumed were tinned copper, were actually

aluminum! In hindsight, I the light weight of the coils should

have been a clue, but I missed it. I ordered some special solder

that will bond aluminum and brass, and that worked fine.

So

then the main body was ready to go back together. Originally,

there was a paper insulator that went around the inside of the

barrel near where some of the bare connections are.

It seemed a little frail, so I replaced it with a like-sized

piece of sheet nylon.

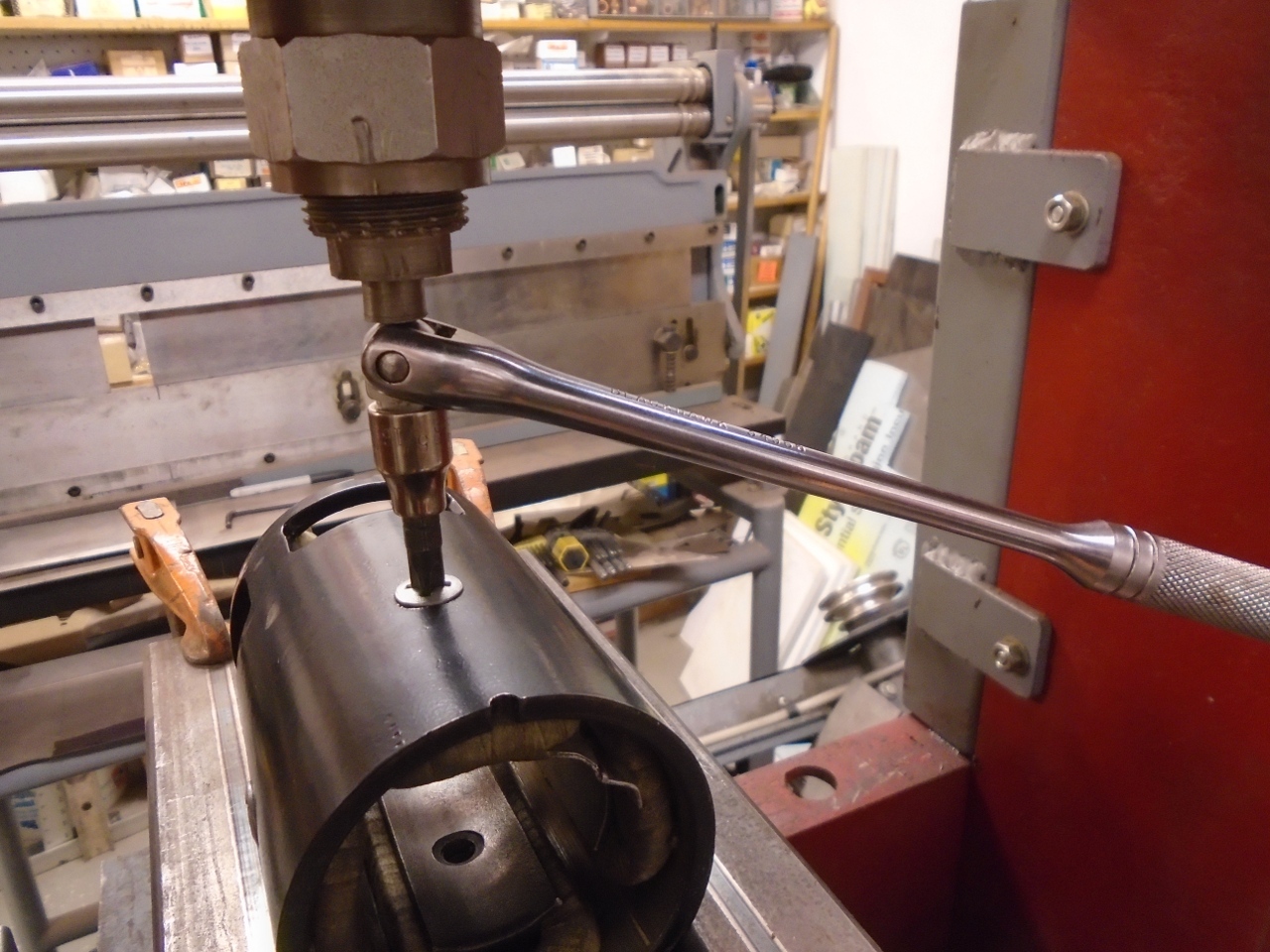

To

tighten the screws holding the pole pieces, shops have a special tool

that presses a large phillips bit down while it is turned. My

makeshift version worked well for both disassembly and assembly.

New Oilite bushes in the end caps. One side note here. On

the driving end cap, some powder coat got into the threads for the long

screws. "No problem", I said, reaching for the 1/4-28 tap to

clean them out. The tap didn't seem to want to start.

Before I forced anything, on a hunch, I grabbed one of the long

screws that hold the caps to the body, and checked the thread pitch.

Sure enough, it was a rather unusual 1/4-26, known to the Brits

as BSC threads Those Brits sure do like theuir odd ball threads.

In a stroke of luck, I actually had a 1/4-26 tap that I bought

when working on my British motoryucle.

To get the electrical end cap on, the field leads had to be spread a little to lower the stud.

The

electrical stud of course has to be carefully insulated from the body

of the starter. There is a plastic sleeve that comes up through

the end cap (seen above), then a metal sleeve goes over that to take

the thrust force of the nut, then an insulating washer (the original

fiber one and my nylon one shown below), then a steel washer , then the

stud retaining nut, then the cable retaining nut.

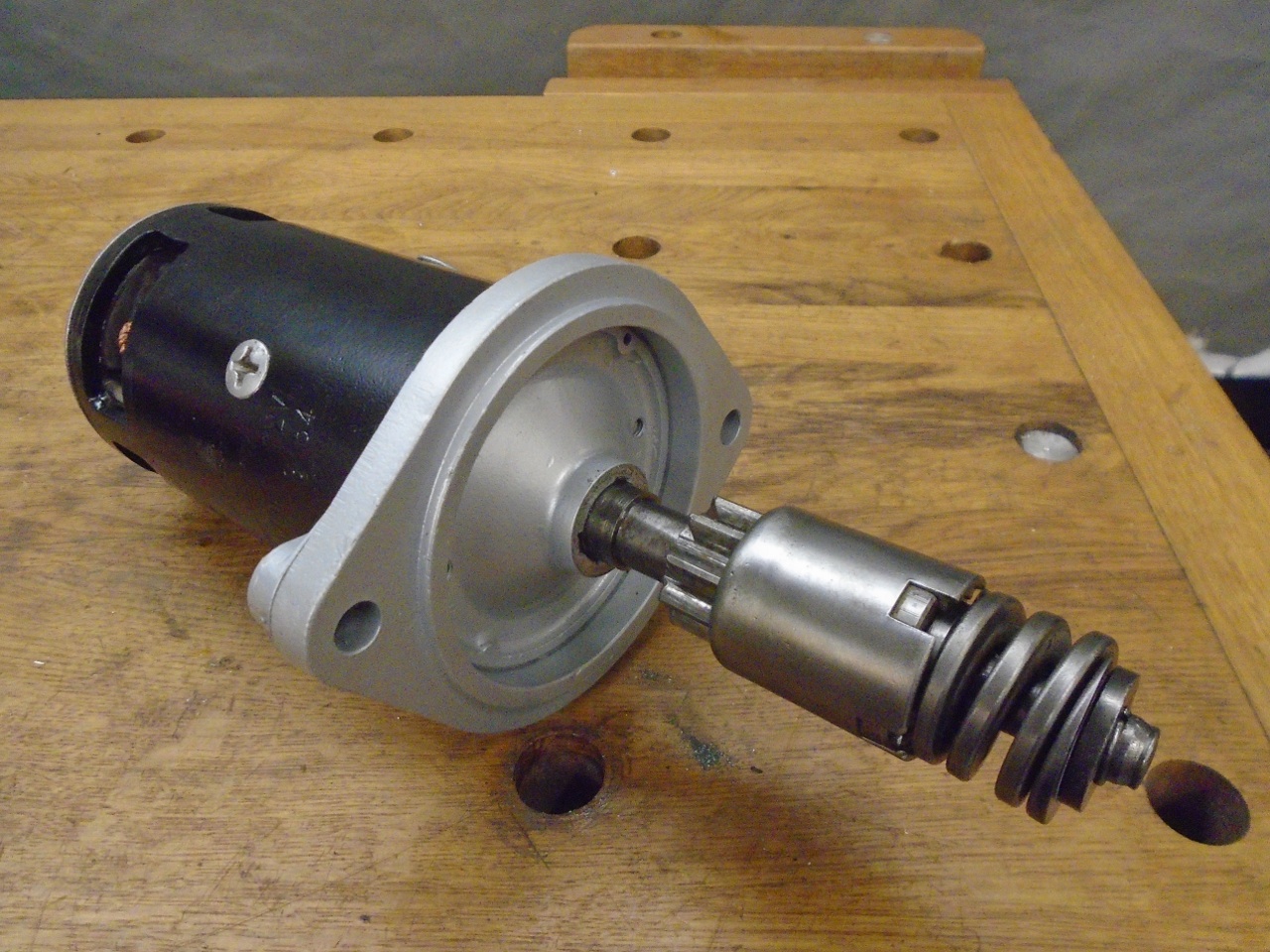

Then

replaced the cleaned up Bendix parts. Putting grease in it didn't

seem right, so I just sprinkled some graphite powder on the parts

before assembly.

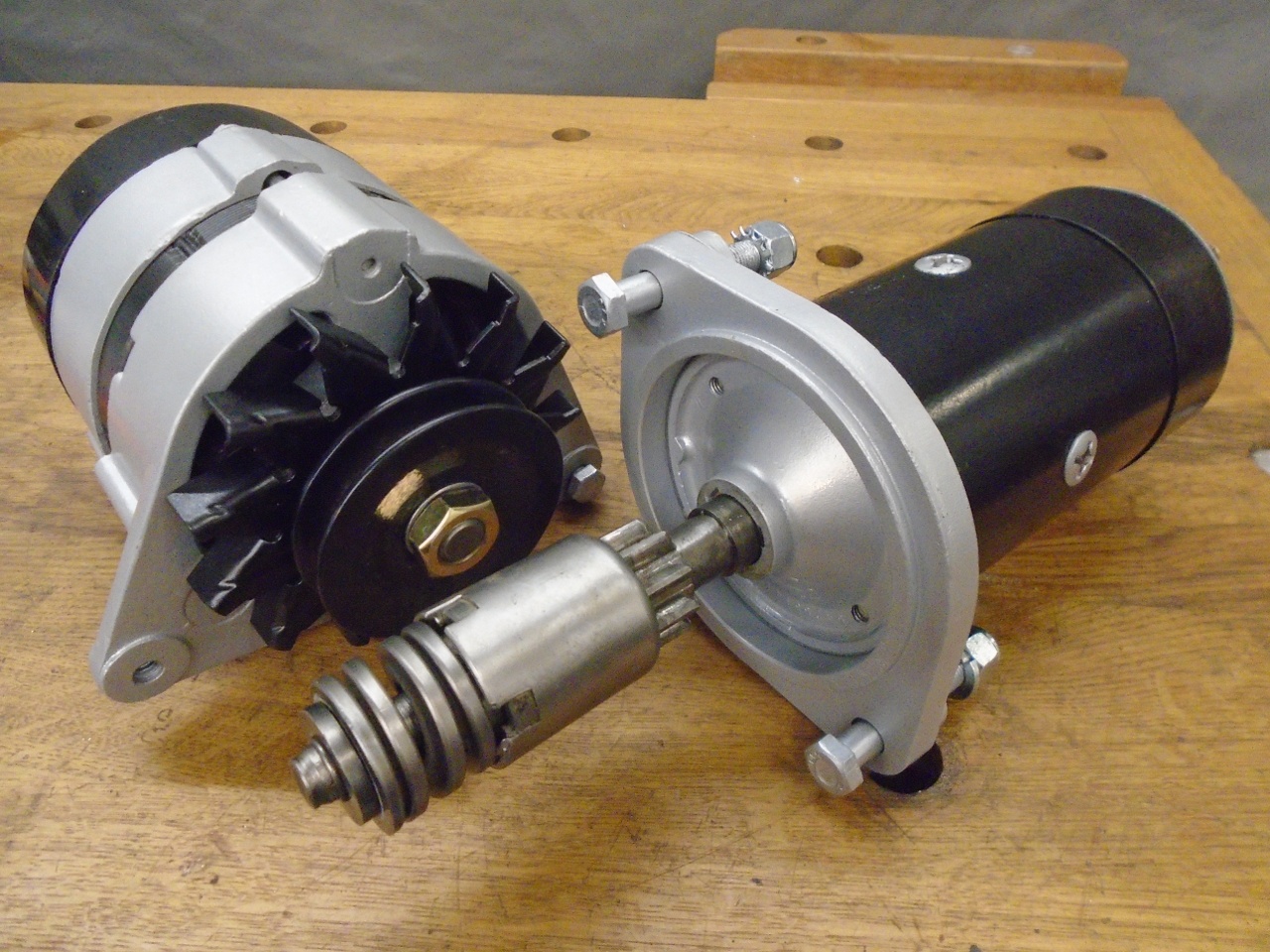

So here is the recently done alternator

and the starter ("The Twins"). They sort of do opposite things.

They go on the shelf, waiting for install one bright day.

This

was an enjoyable project, with some things I hadn't done before.

Cost was small--less than $25 for bushes, brushes, some hardware,

and a hunk of brass.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages