To my other GT6 Pages

November 26, 2019

Alternator

I

believe all GT6 cars had alternators installed to maintain battery

charge. Mine had a Lucas 15ACR unit, rated at something around 28

amps. It was pretty crusty, but I believe it was working fine

when the car was put away over 30 years ago.

According

to this tag on the alternator, it was a rebuilt unit. I'm

assuming the number on the left is a date code--probably week 21 of

1973.

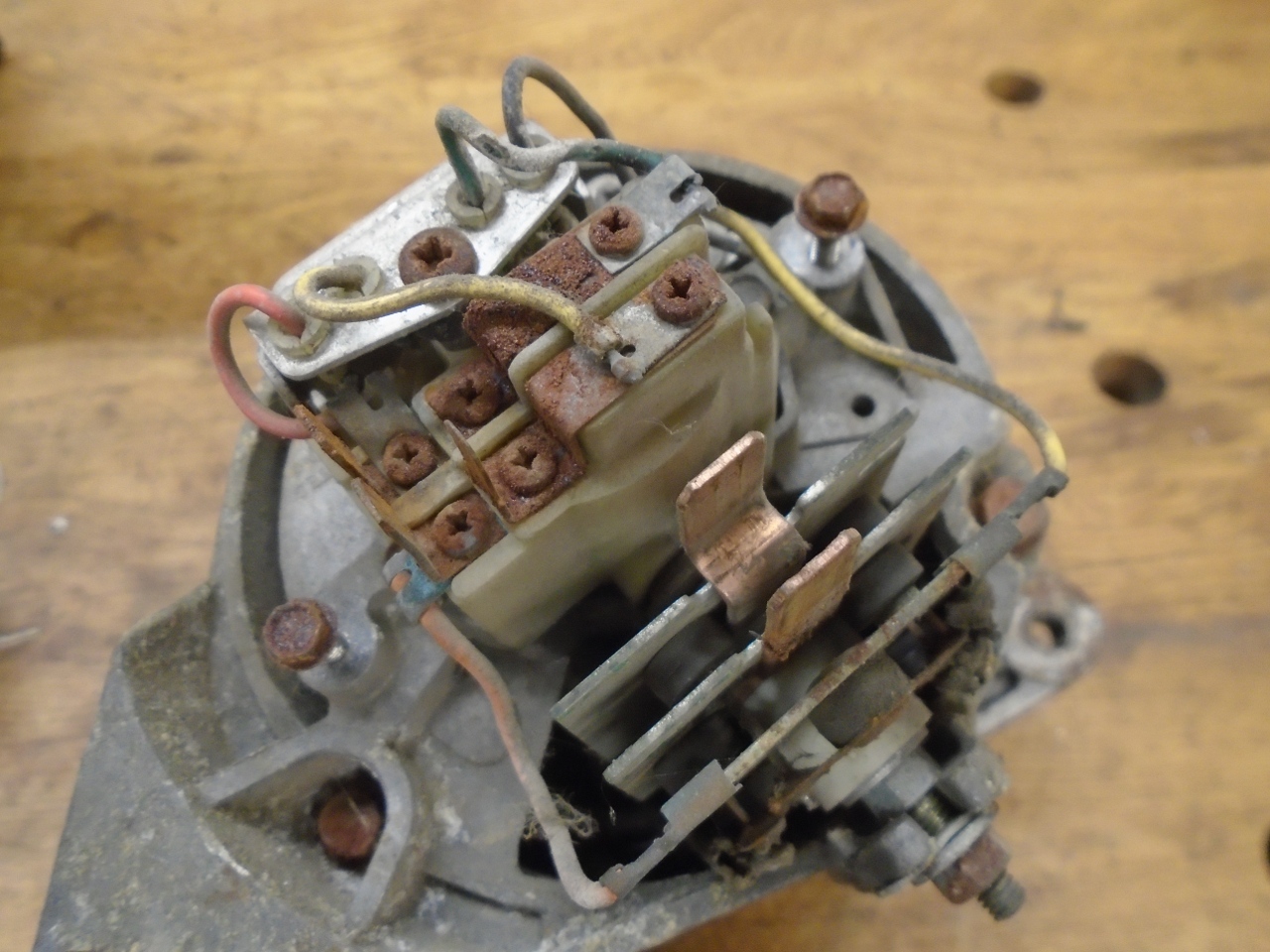

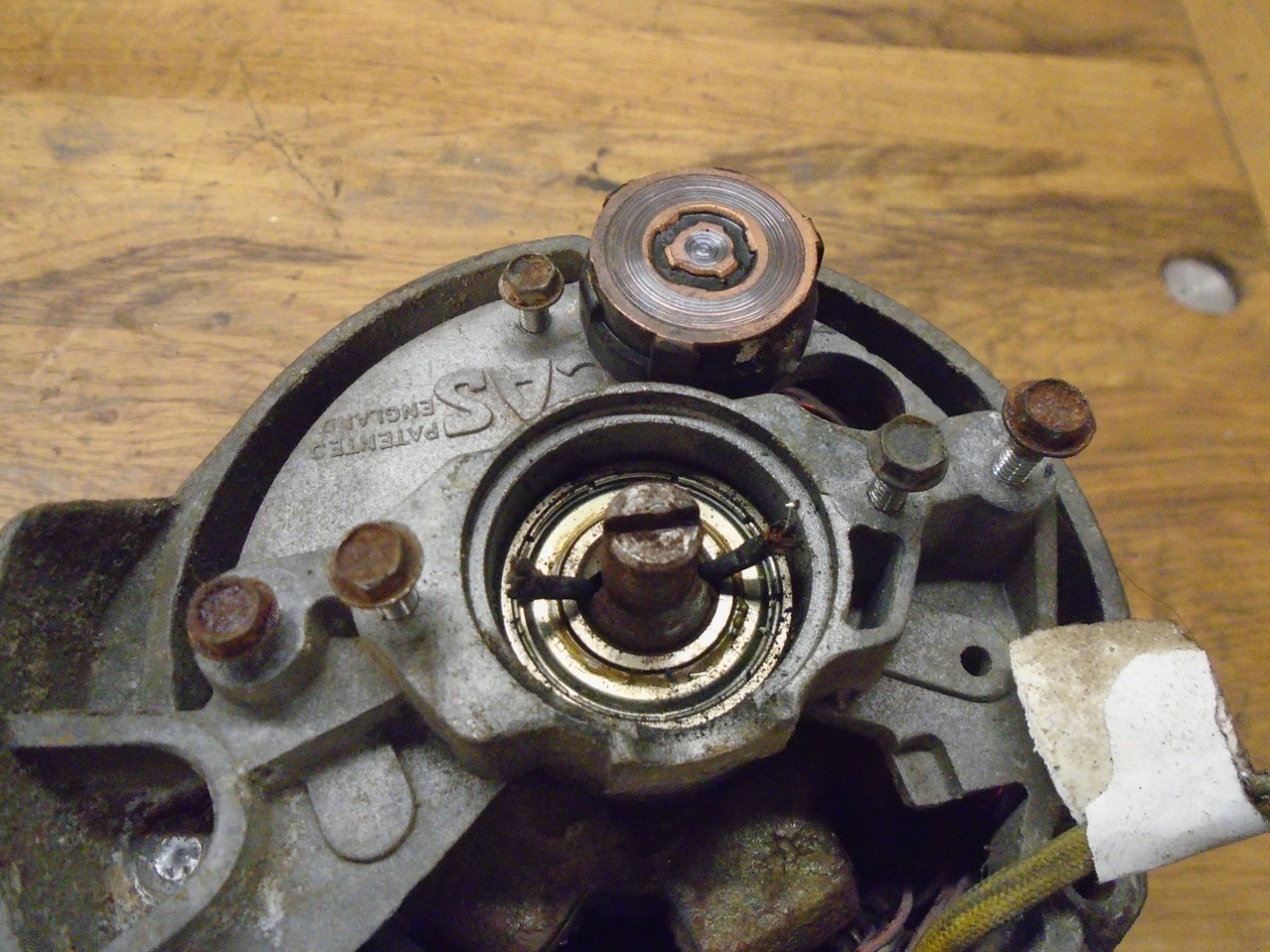

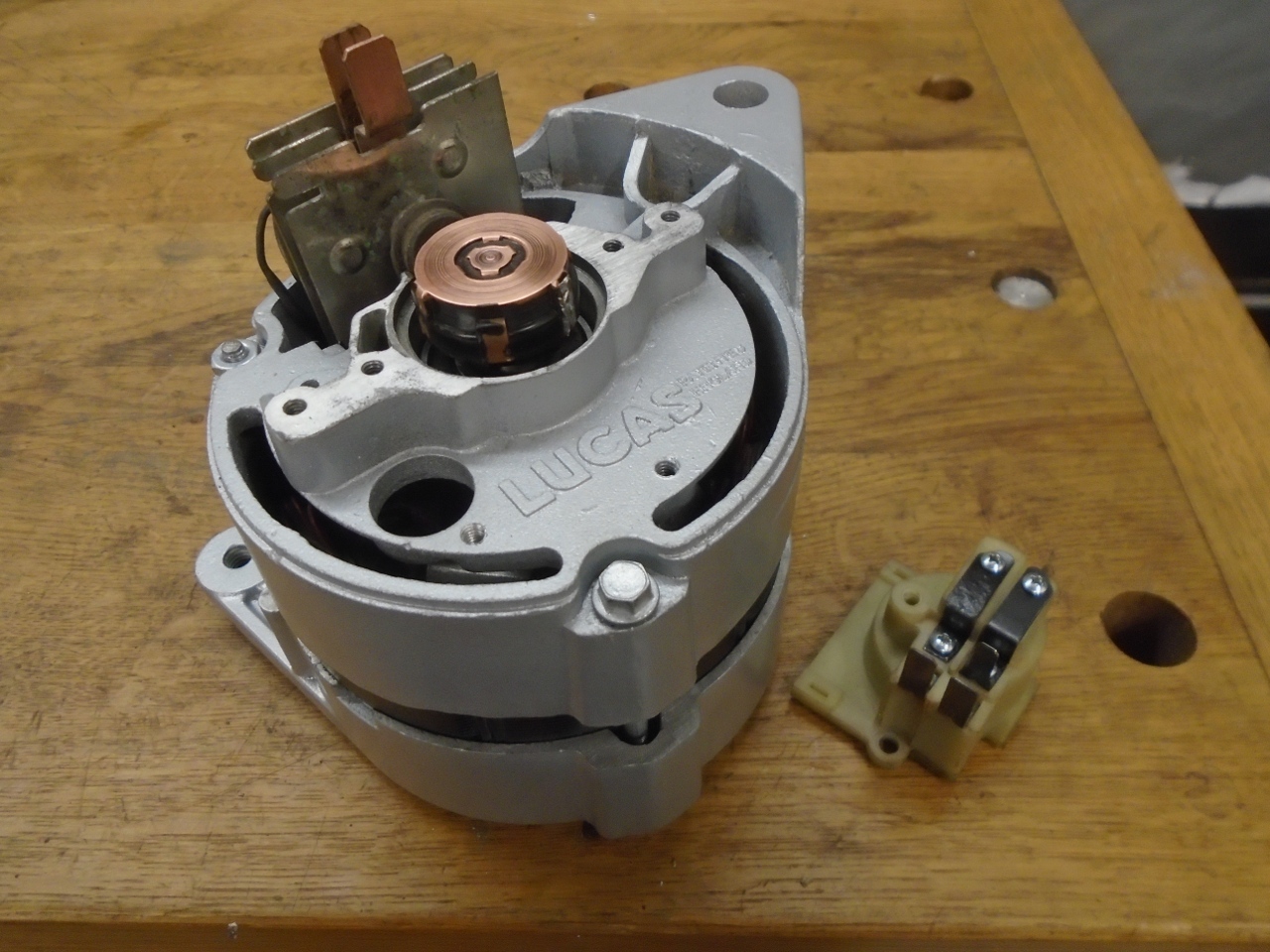

In

a cursory inspection, there was a lot of corrosion under the rear

cover, and the bearings felt a little rough. I decided there

wasn't much to lose by taking it apart, at least to replace the

bearings.

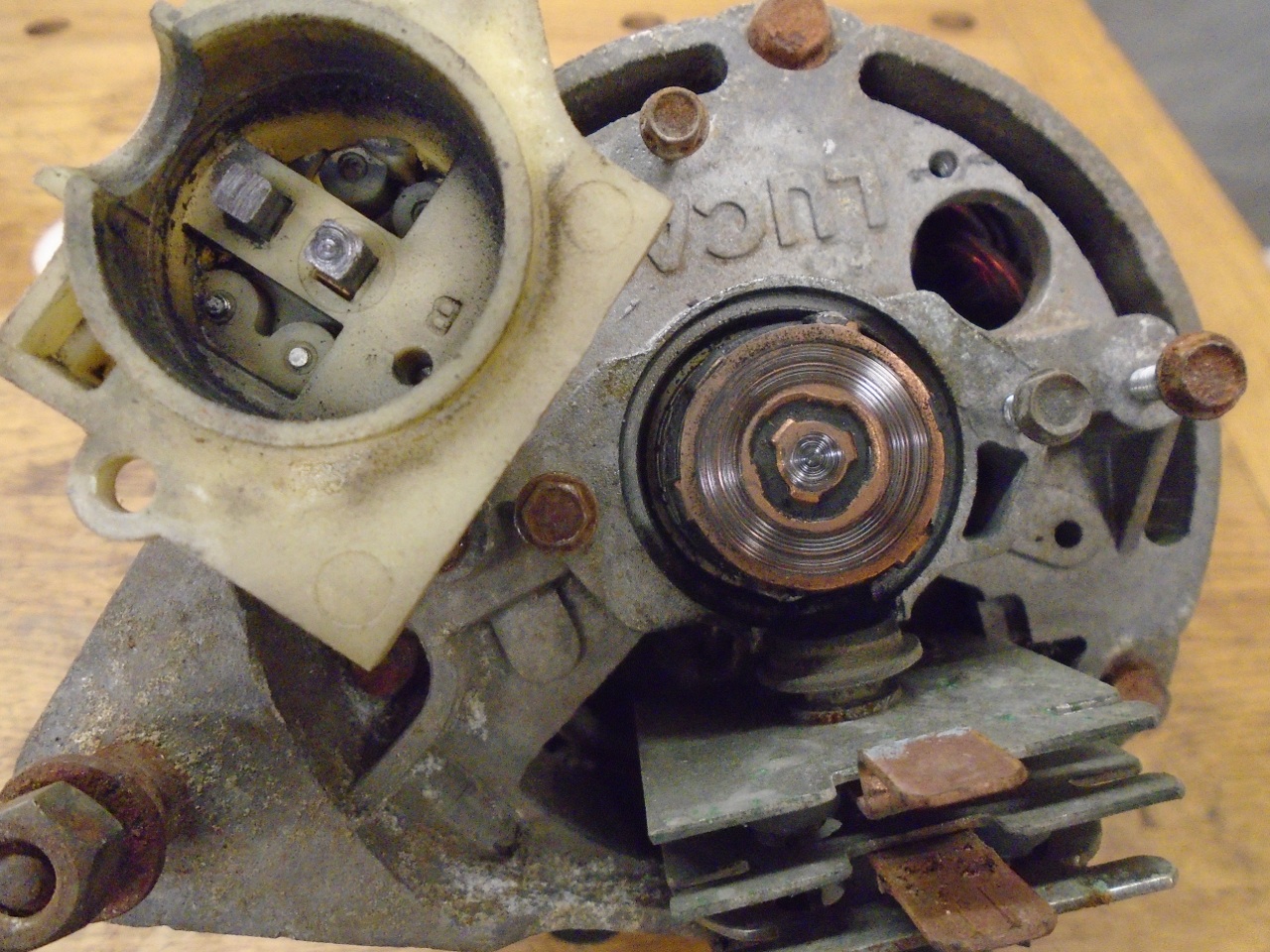

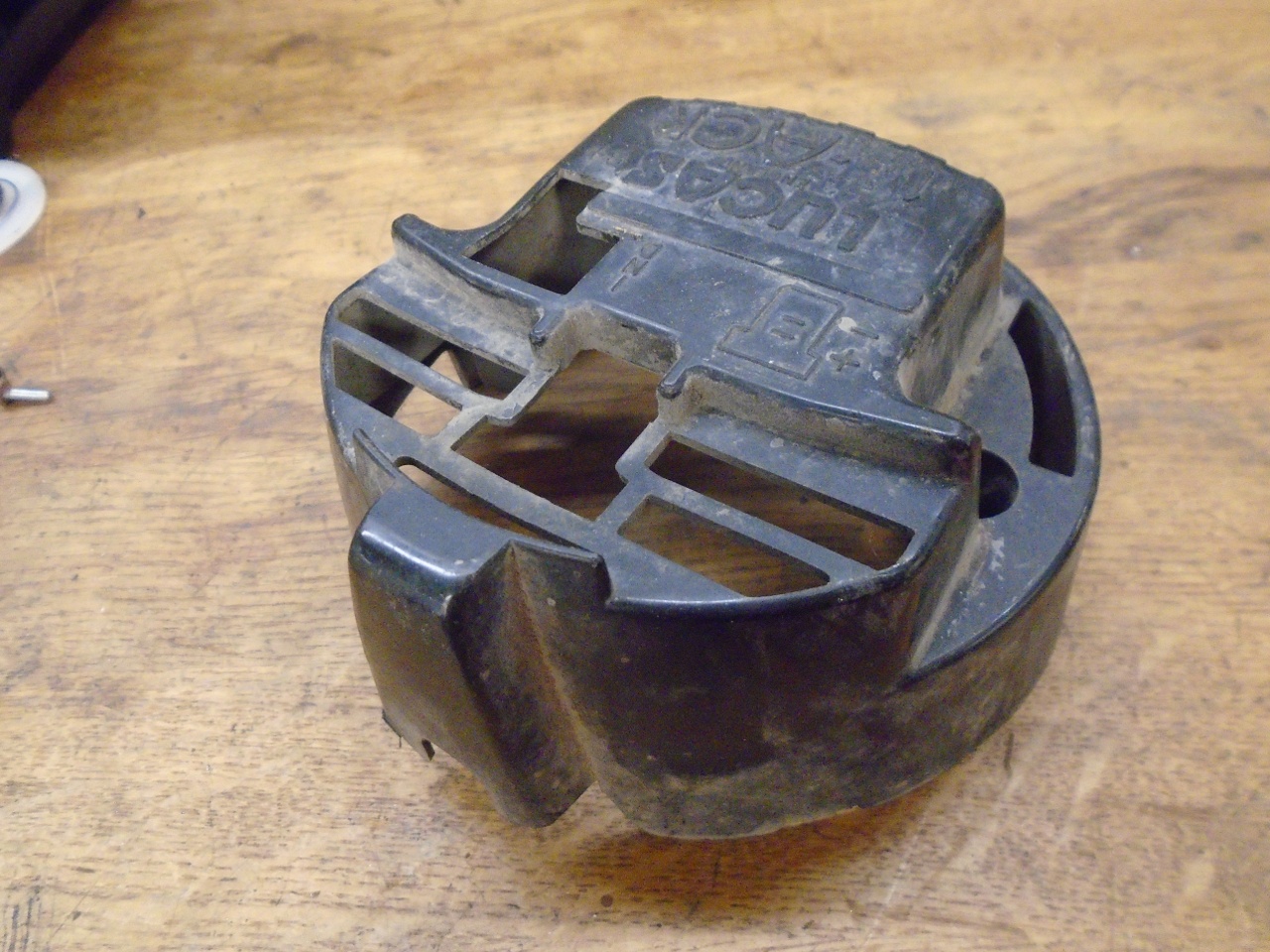

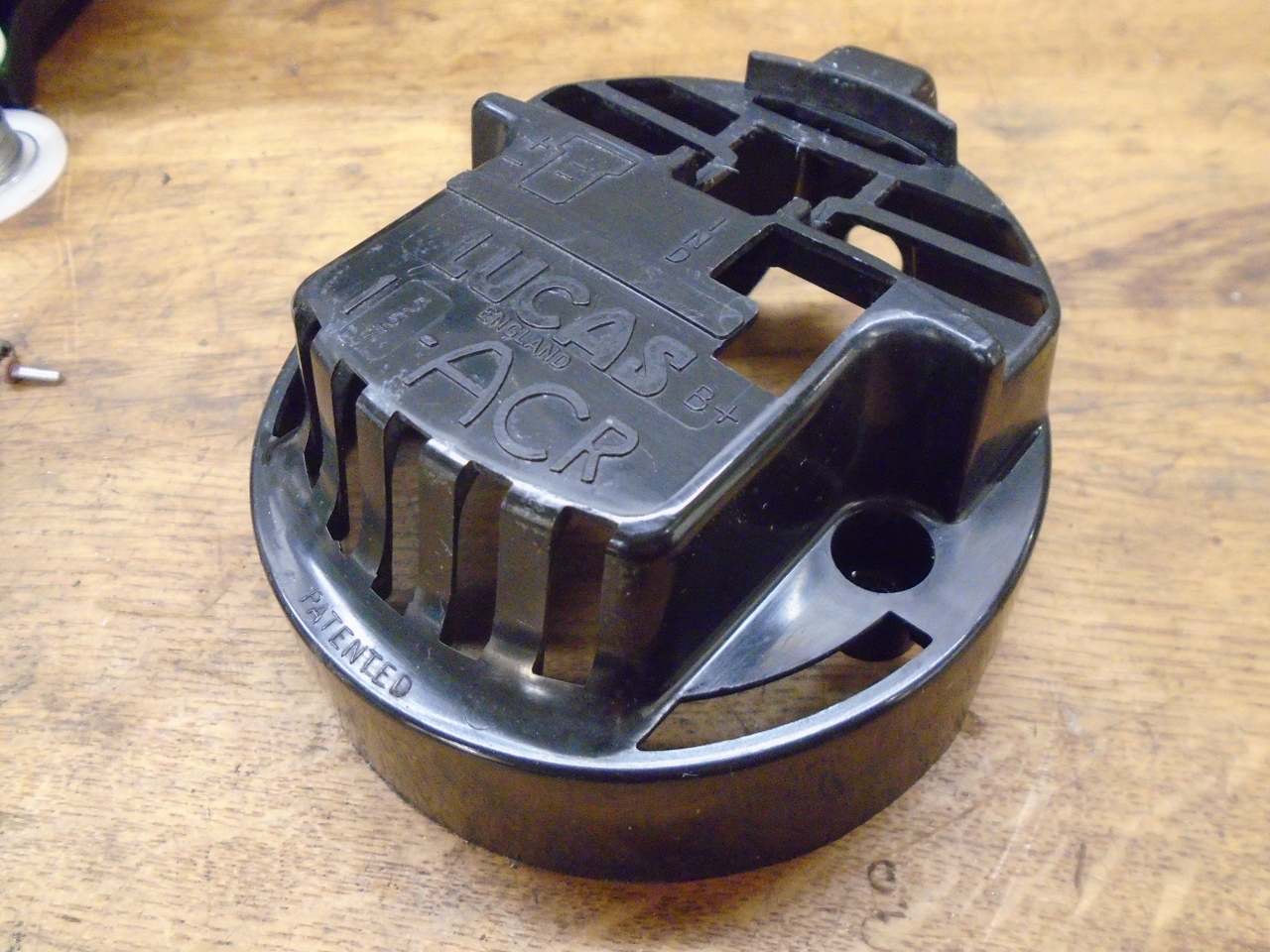

The

plastic brush holder at the back of the unit comes off to reveal the

slip rings. On these kinds of alternators, the field winding

rotates, and is energized by brushes through the slip rings.

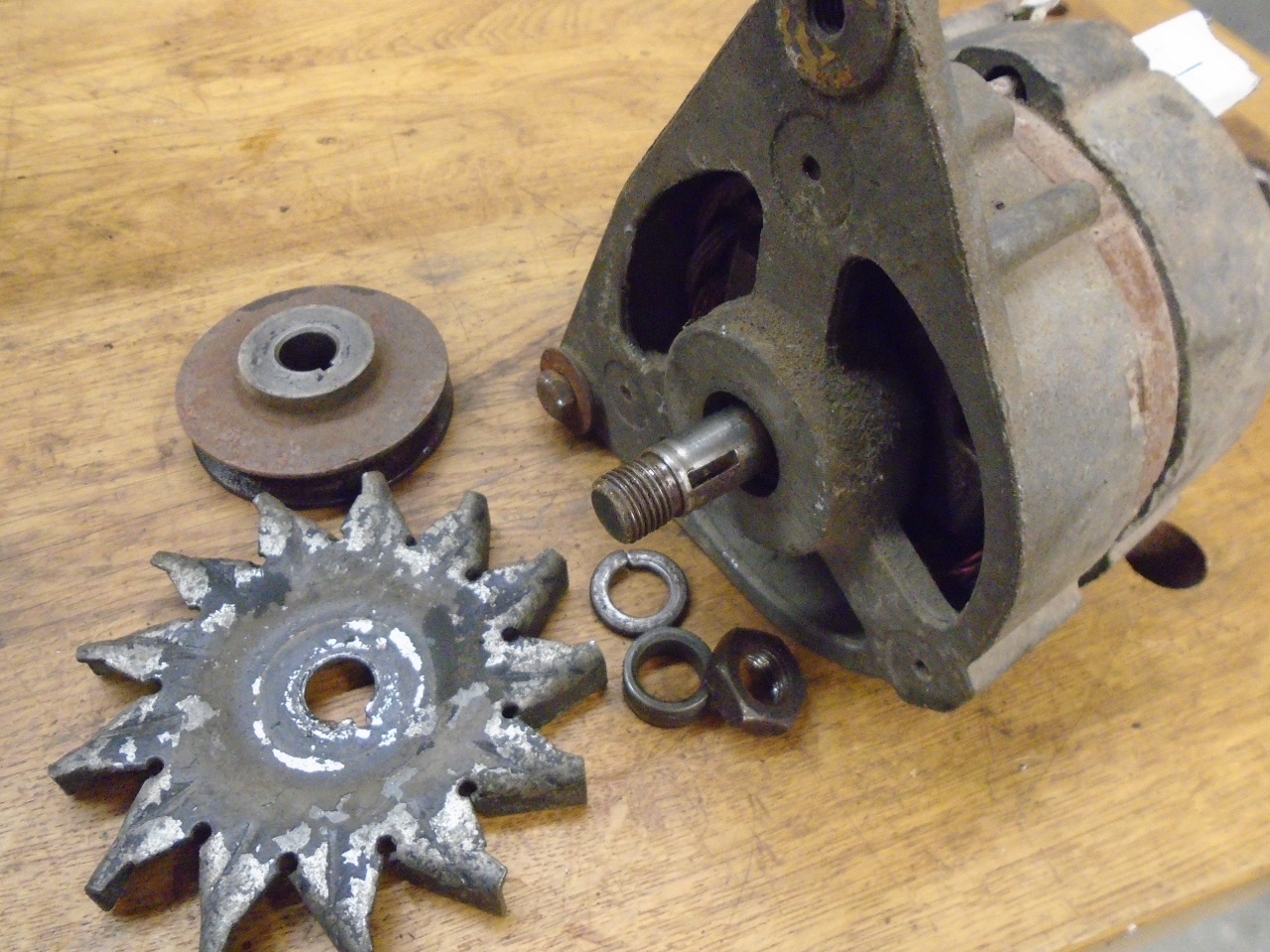

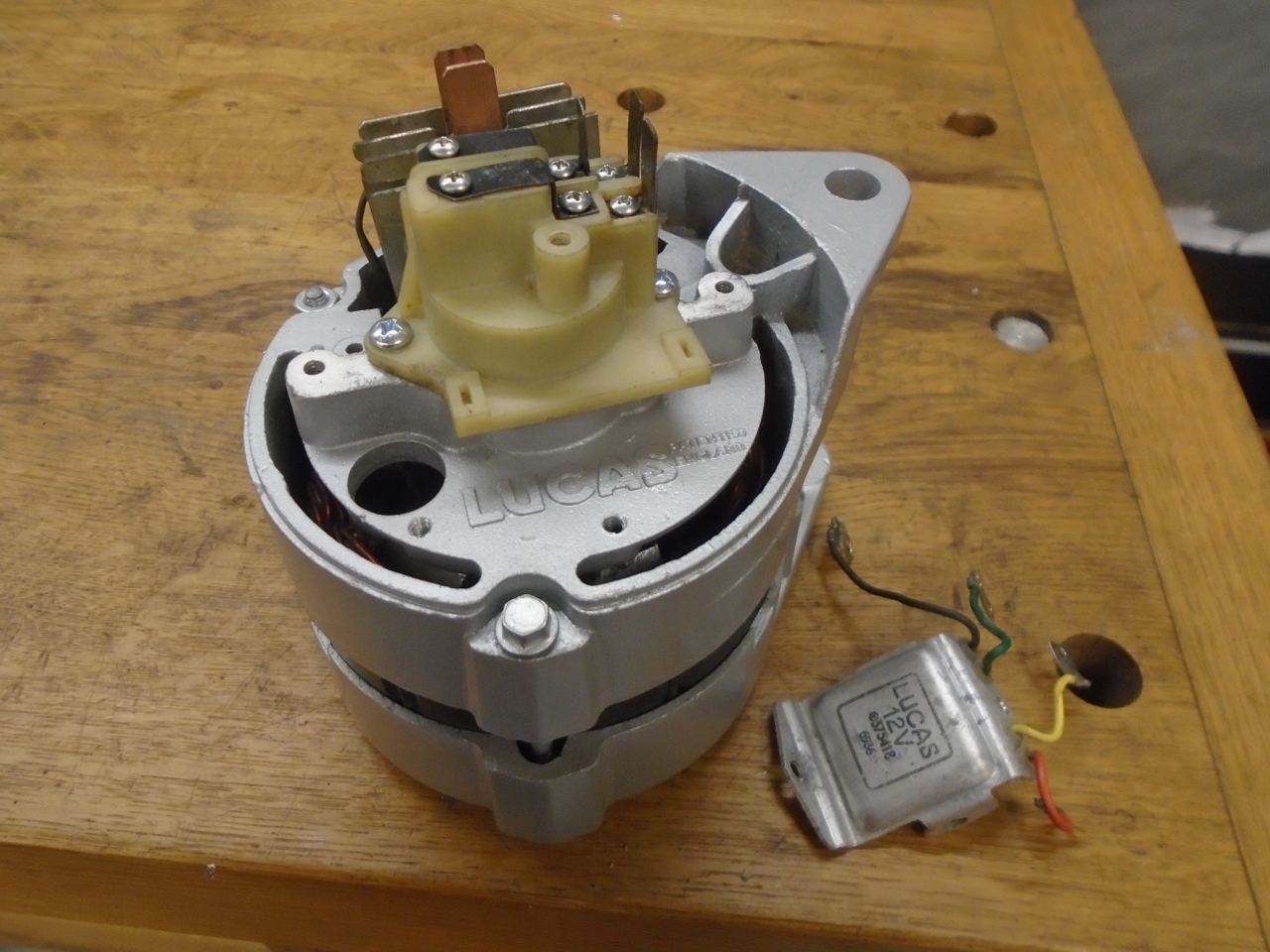

To

get the case apart, rectifier module has to be removed. This

requires unsoldering the three phase connections from the stator

windings. The pulley and fan have to come off the other end.

The slip ring module has to come off the end of the rotor shaft. This also requires some desoldering.

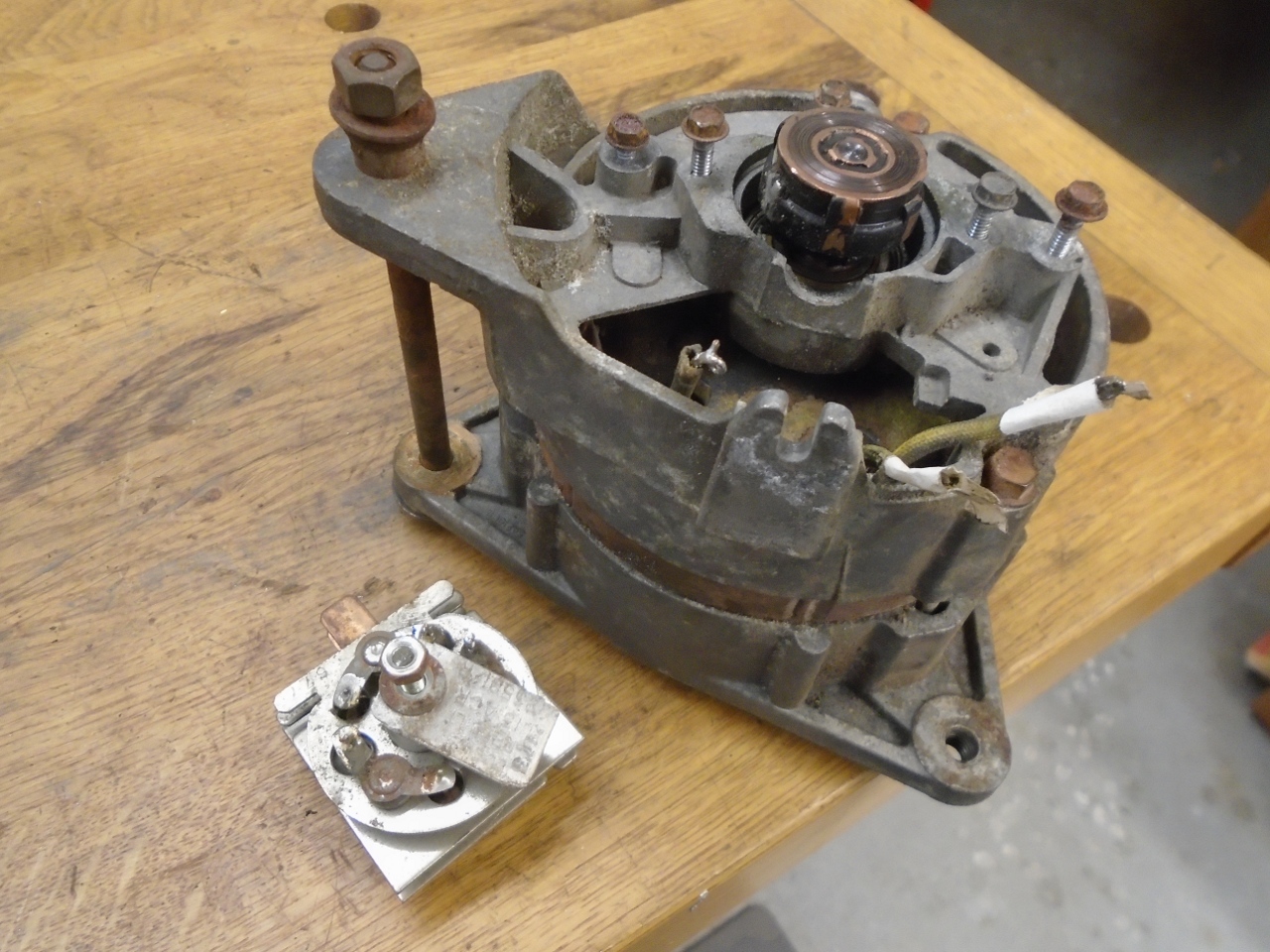

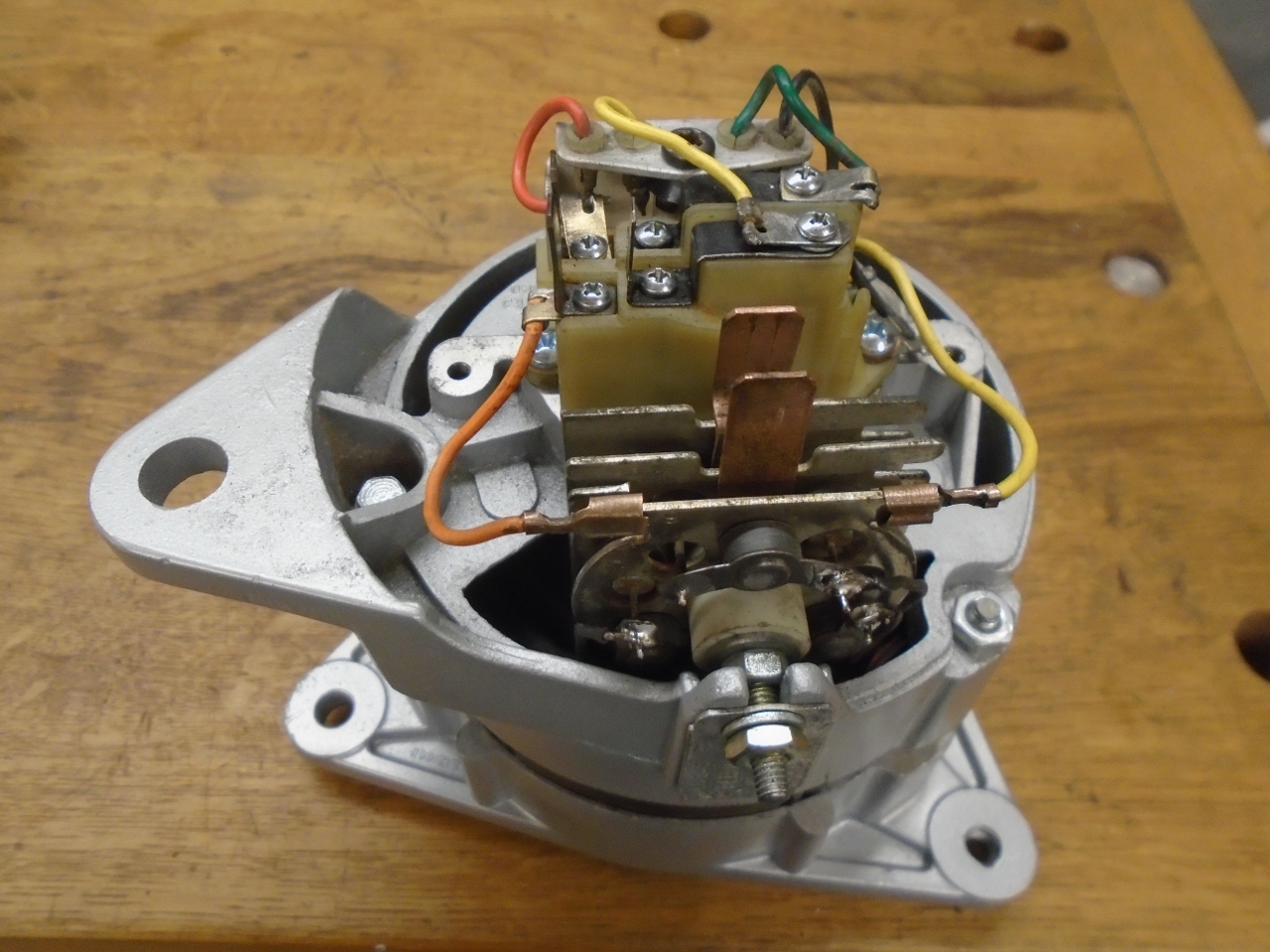

Then

the case can be pulled apart. One of the three long bolts holding

the end pieces together decided to sieze on me, snapping its head off.

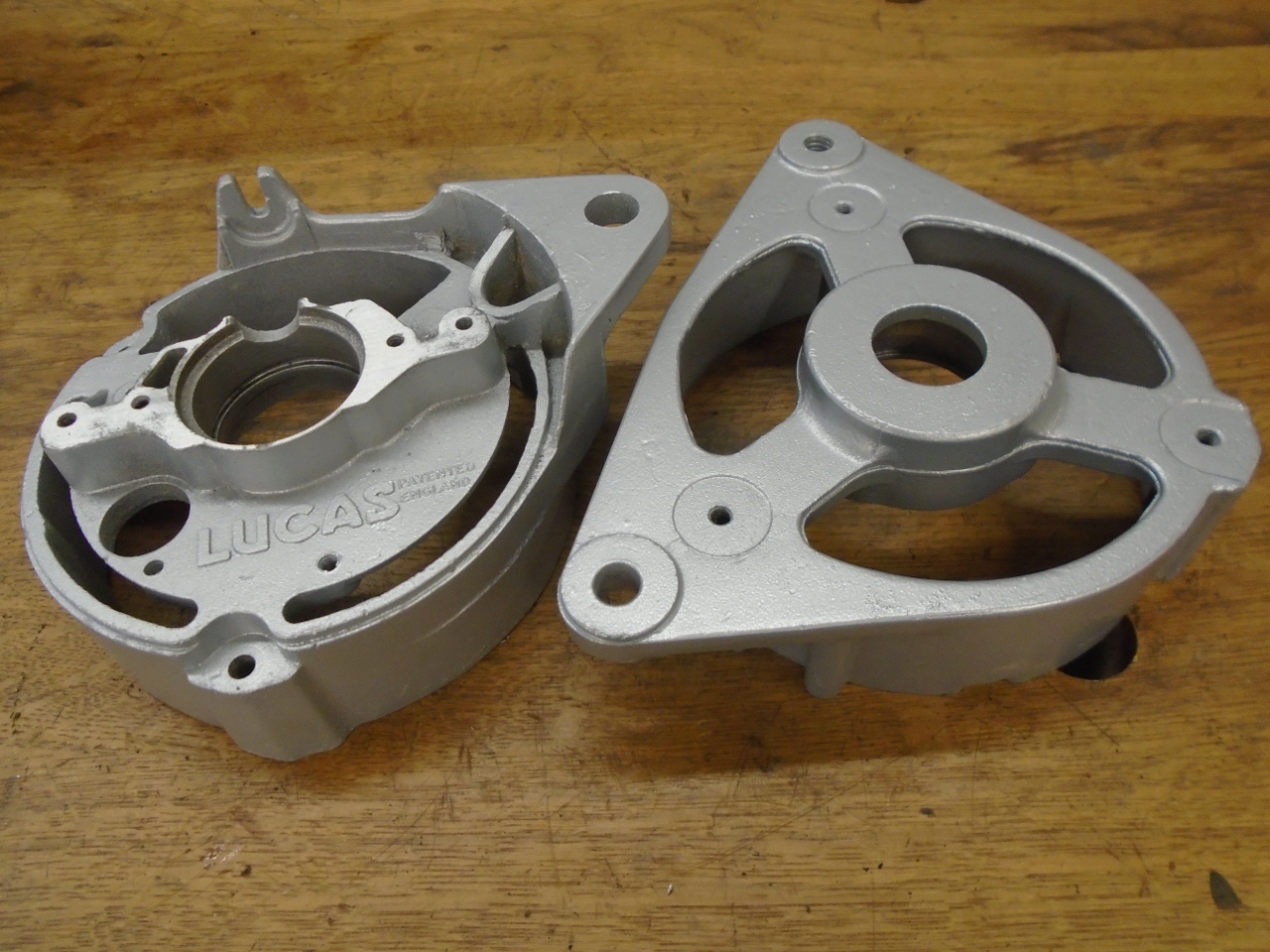

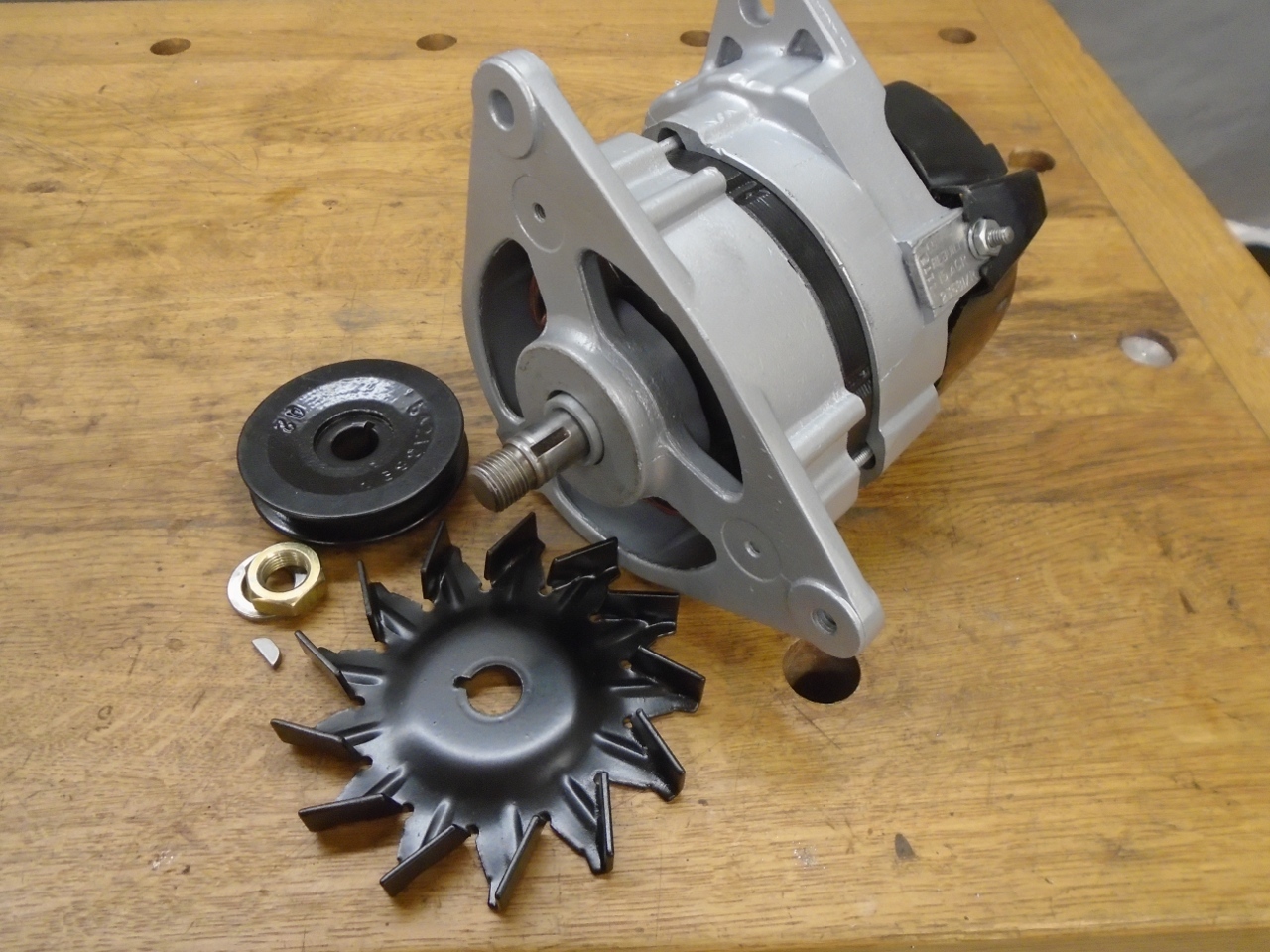

Then the refurb started. A nice powder coat for the aluminum end caps and the pulley and fan.

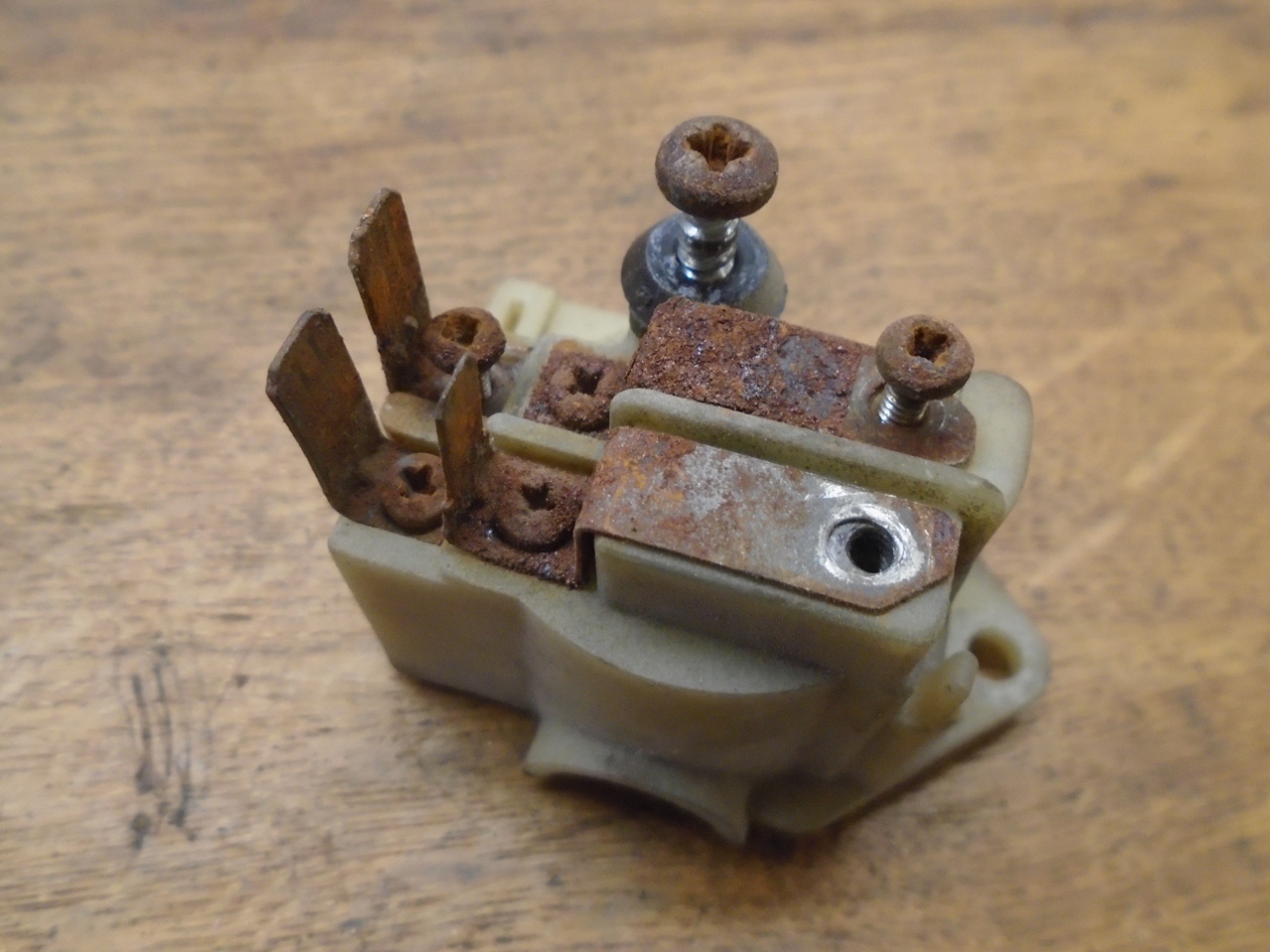

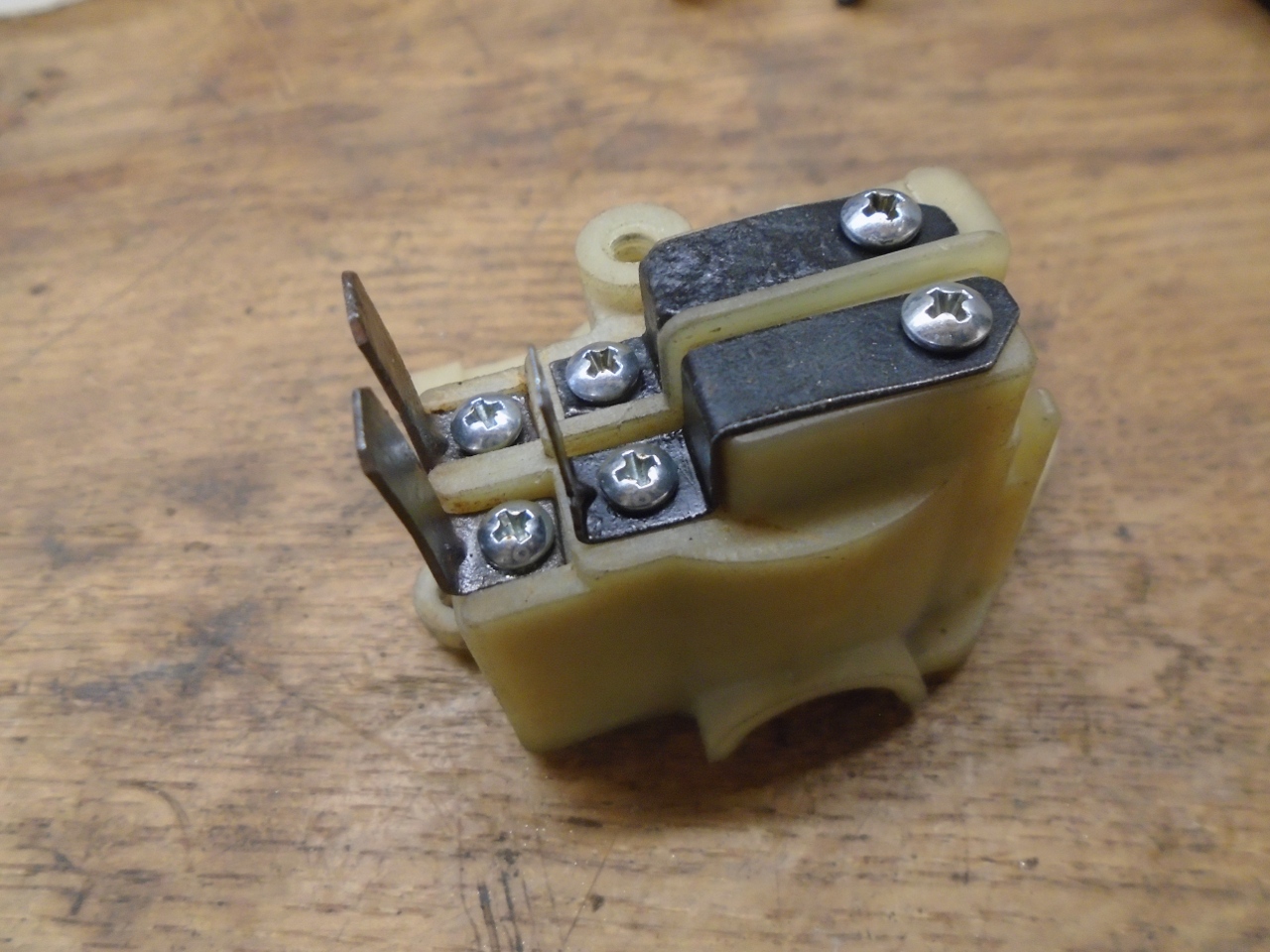

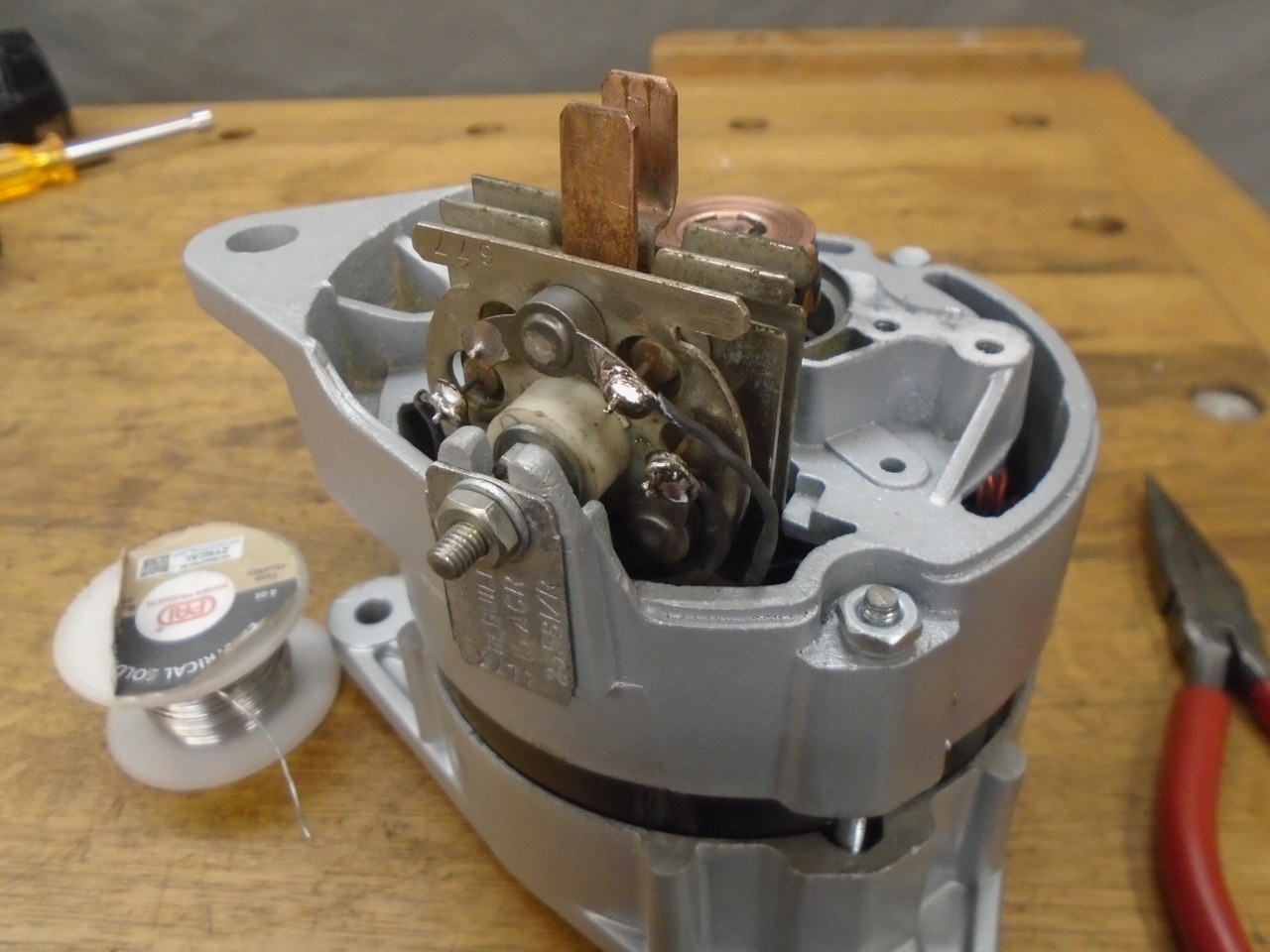

The

brush holder cleaned up OK, but I was disappointed to find that the

metal parts were all steel. You'd expect copper or brass in an

electrical device like this. I'll bet a significant number of bad

ACR alternators failed due to corrosion of the steel conductors and

joints. I briefly considered making new parts from brass, but

attaching the brushes would have been tricky. Though new brushes

and slip rings are available, they were both in decent shape here, so I

just cleaned off all of the rust and painted them.

I

didn't want to subject the stator to powder coating heat, so it

just got cleaned and painted. I replaced the frayed braided

insulation sleeves with something neater.

Even the 46-year old (at least) back cover cleaned up pretty well.

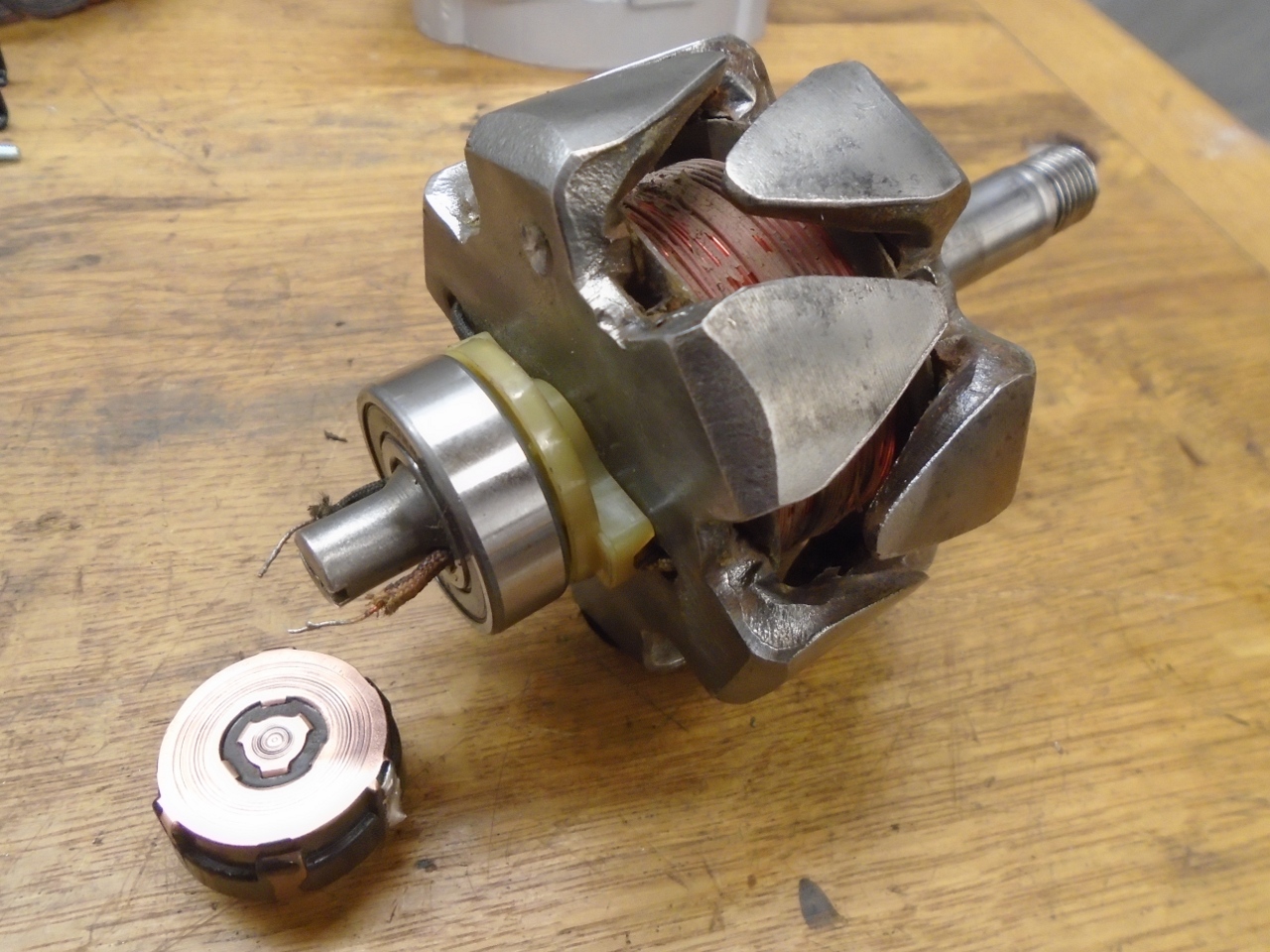

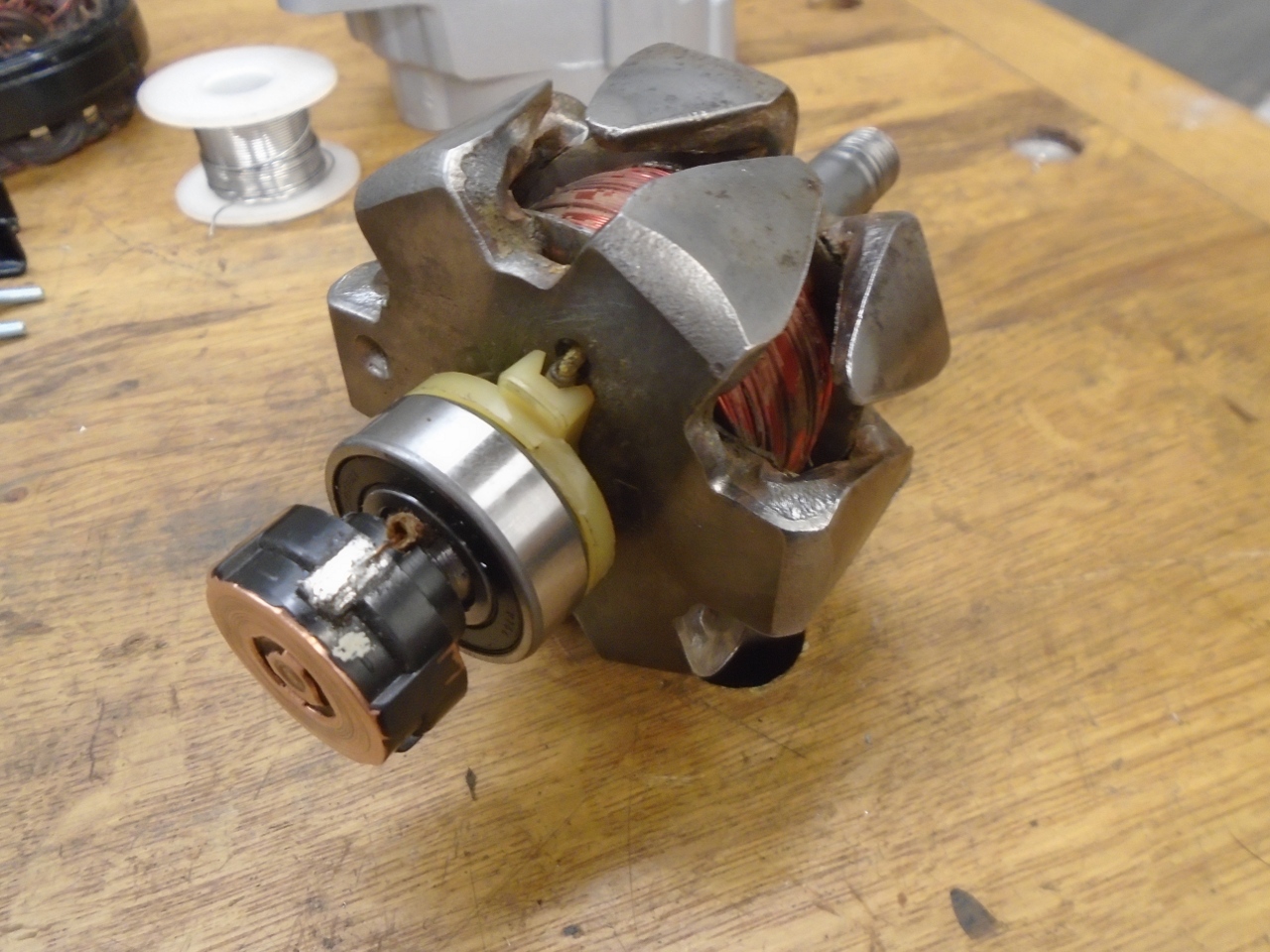

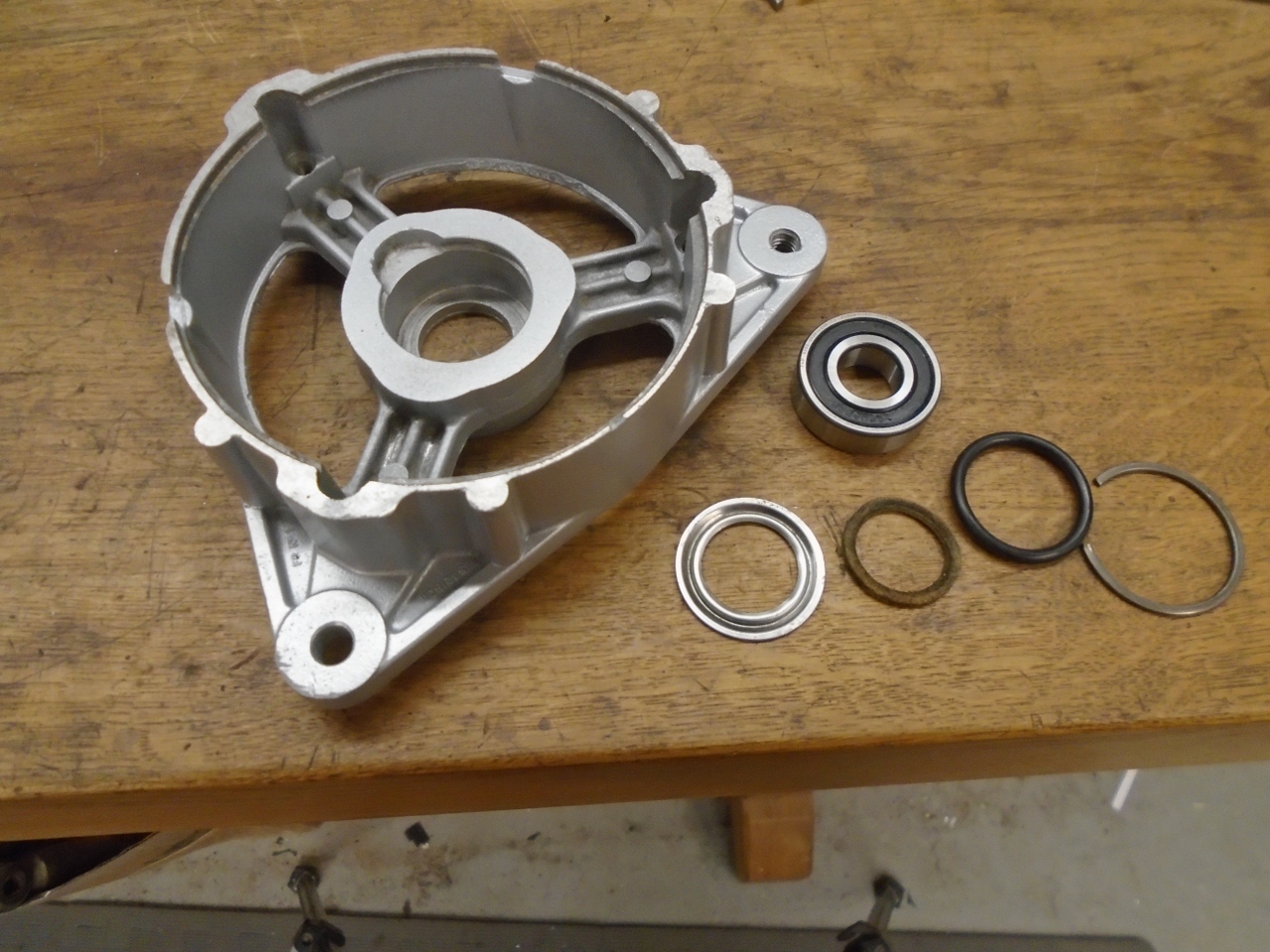

So,

not finding anything unfixable, it was time to put it all back

together. I noted during disassembly that the ball bearings were

shielded units, not sealed. This seems odd to me. This is a

device operating in an engine compartment with a lot of air forced

through it, not all of it clean. The shields probably help, but

it seems like a good application for sealed bearings, so that's what I

put in. The bearings are the ubiquitous 6202 type.

The new bearing and slip ring module go on the rotor shaft, and the winding wires get soldered to the slip rings.

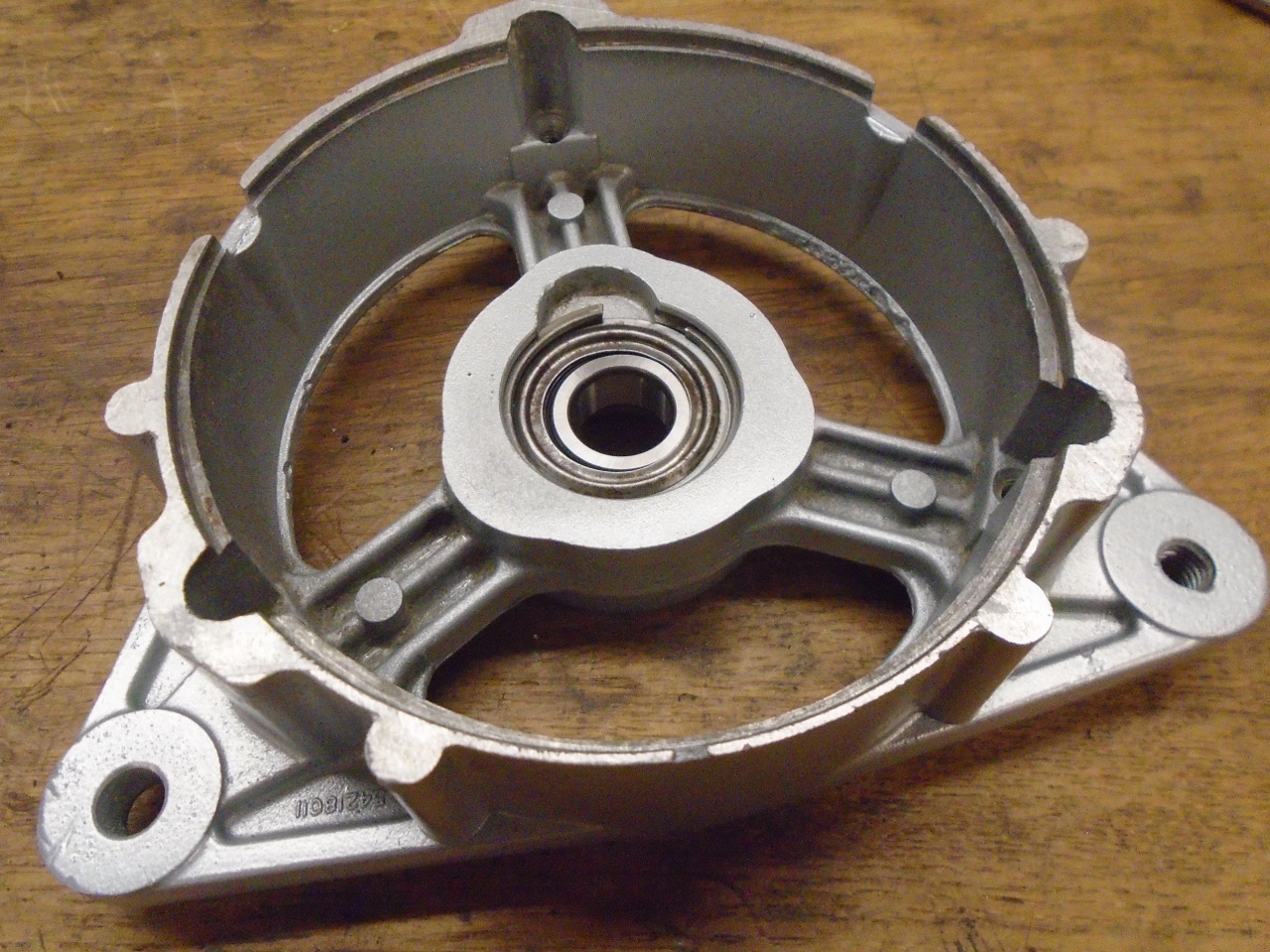

The

other bearing gets installed in the front case. There is an O

ring in there, called a "seal" on some of the parts listings. I'm

not sure what it was sealing, but it probably wasn't necessary with the

sealed bearings. It has to be installed, though, since the

stacked thickness of all the parts is required to make sure the snap

ring holds everything in place.

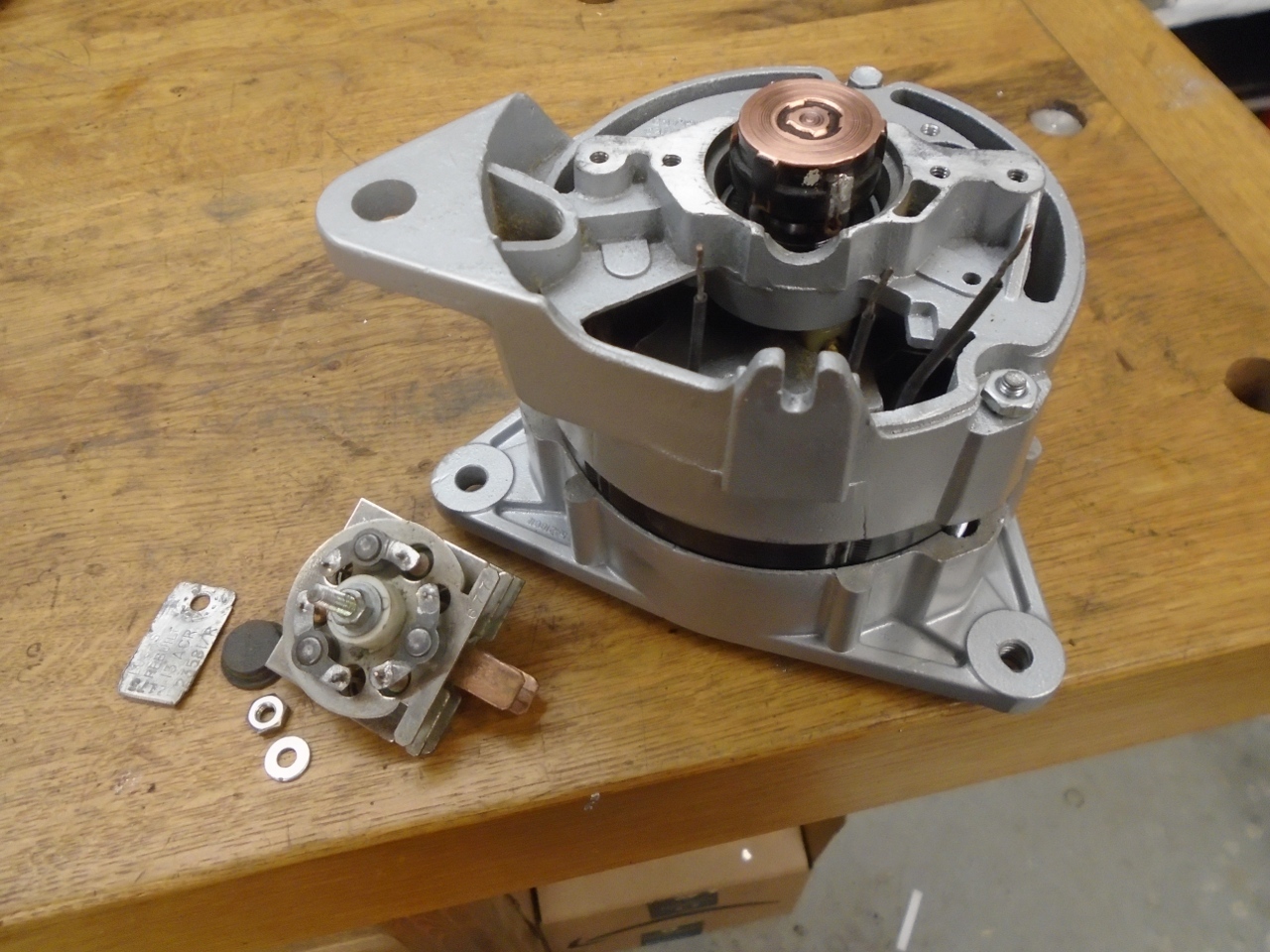

The

two case halves were then assembled with the stator sandwiched between.

The broken bolt was replaced with a length of #10 threaded rod

and a nut. The rectifier pack is standing by for installation.

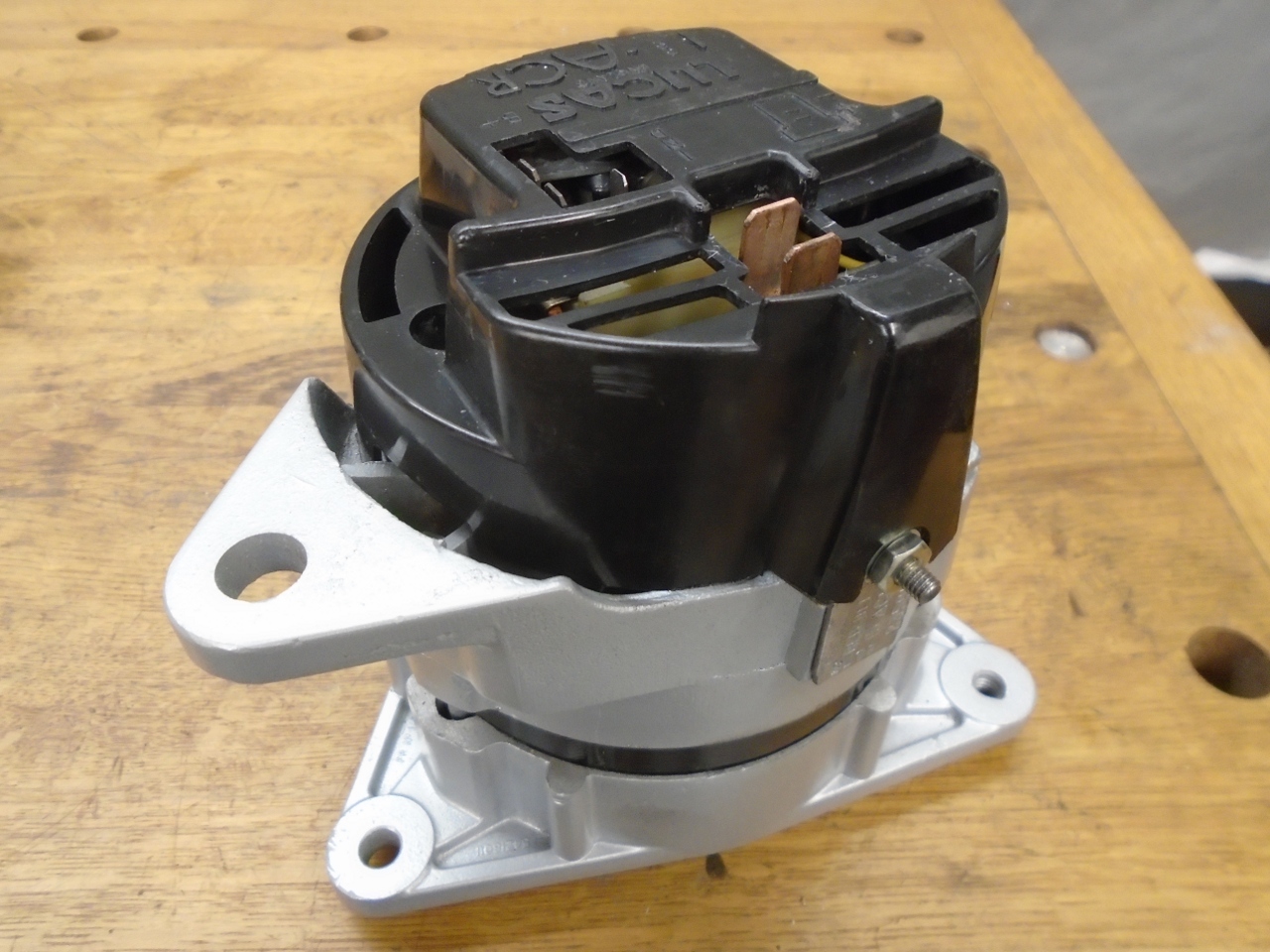

Then the brush holder assembly and the regulator.

Then finished up the wiring...

...and added tthe rear cover and the fan and pulley.

I don't have a good way to test the device, so on the shelf it goes, to wait for installation some day.

This was a fairly quick project, and pretty cheap--less than $20 for trhe bearings and some hardware.

Keeping with the electrical theme, I think the starter motor is next.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 Pages