To my other GT6 pages

March 24, 2024

Final Exhaust System

It's been two and a half years since I installed the bulk of the exhaust system, and I made some decisions back then that I'm having to follow through with now.

I tucked the silencers (mufflers) up under the boot floor to be more out

of sight, and cut passages through the rear valance for the exhaust

tips. I was unsure back then on exactly what to do to finish the

job, so I just put it off.

Well, it's now time to do something, even if it's wrong.

I determined back then that the original tips wouldn't work as supplied

because they came out at the wrong angle. Even after cutting them

from the silencers, they were still much too long.

So here is the starting point.

I bought some 2-1/2 inch exhaust tubing to experiment with (same size as

the original tips). I like "sausage" cuts on exhaust tips, and

started with a cut angle that sort of followed the contour of the lower

valance.

This looked good to me, but I really wanted them to be polished

stainless and have a little more finished look, so I searched online for

some tips that were close to this. After failing at that, I

started to consider using the original tips after all, just modifying

them to match my design.

The original tips are polished stainless, and a double wall. The 1-3/4"

inner tube is the actual exhaust pipe, while the outer 2-1/2" polished

pipe is more cosmetic. The stainless was tough to cut. I

used a composition blade on a chop saw.

I had to expand the silencer's stub pipe a little to get the tip to slide in.

Trial fit. I think this will work.

Welded the tips to the silencers with stainless MIG.

Well, no mod like this ever goes without a fly or two in the

ointment. In this case, the fly was the fuel tank outlet. It

was just above the left front corner of the left silencer, and it

didn't appear that there was enough room for the fuel pipe to come out

and make a graceful turn.

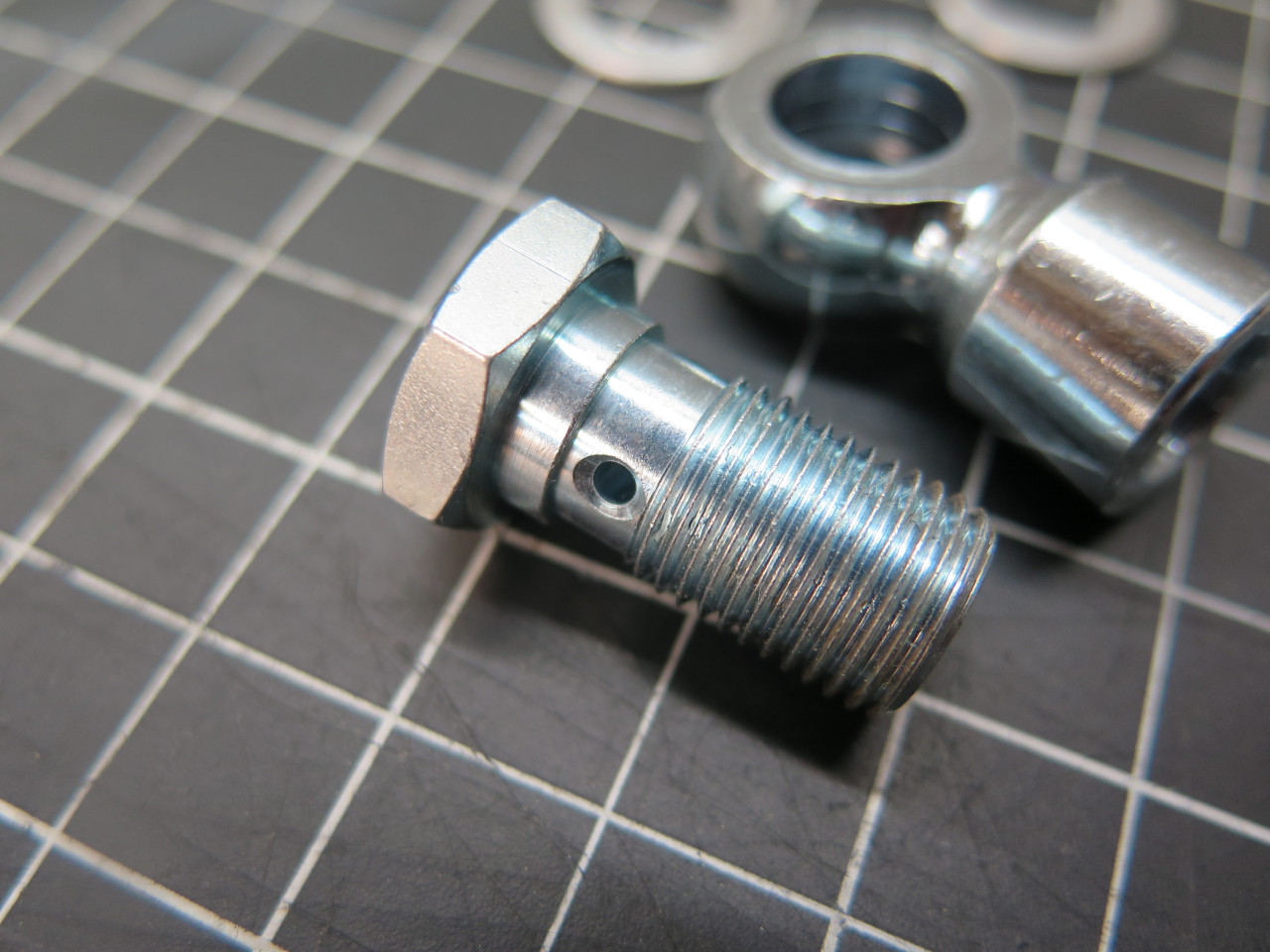

I needed a way to make a more compact right angle fitting. After

mulling a few complex and wonderful solutions to this, I finally decided

to look at using a standard banjo fitting. The female thread for

the original compression fitting is 1/2-20. This is not a common

thread for banjo bolts, but I did manage to find one.

I believe the normal use for this banjo fitting may be in brake systems,

which is a high pressure, low volume application. Thus the pretty

small passages.

I thought they were too small for a fuel system, so I drilled them out to a more respectable size.

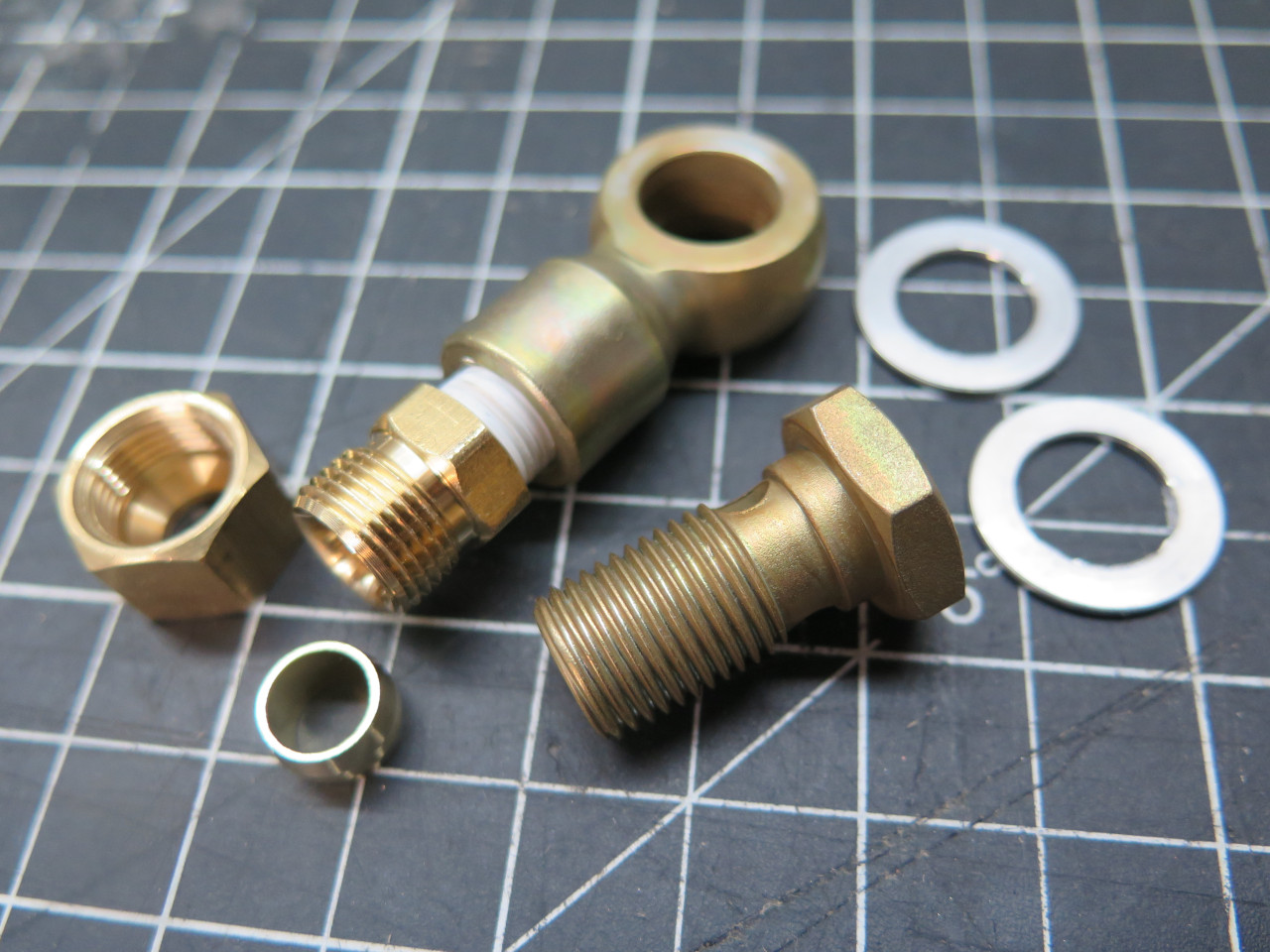

Also, considering the exposed place where these parts will live, I

fretted about the zinc plating they came with. I know from

personal testing that the zinc on typical hardware items is pretty much

just cosmetic, and doesn't last long in the wild. So they got

stripped of their token zinc, and replated, followed by a nice chromate

passivation to protect the zinc. The banjo had a 1/8" NPT outlet,

so a 5/16" compression adapter was screwed in to accept the fuel line.

I bent up a piece of welding wire to the shape of the fuel pipe that has

to route to meet the pipe that comes from the front of the car.

They meet on the outside of the left frame rail just in front of the

rear suspension. Then bent some copper nickel tubing to match.

The other issue with this new fuel pipe arrangement is that the lower

rim of the compression fitting on the tank was not designed to be a

sealing surface. I did my best with a small sanding block to make

sure that there was a flat area on the rim to mate well with the banjo's

sealing washer. We'll see how that works.

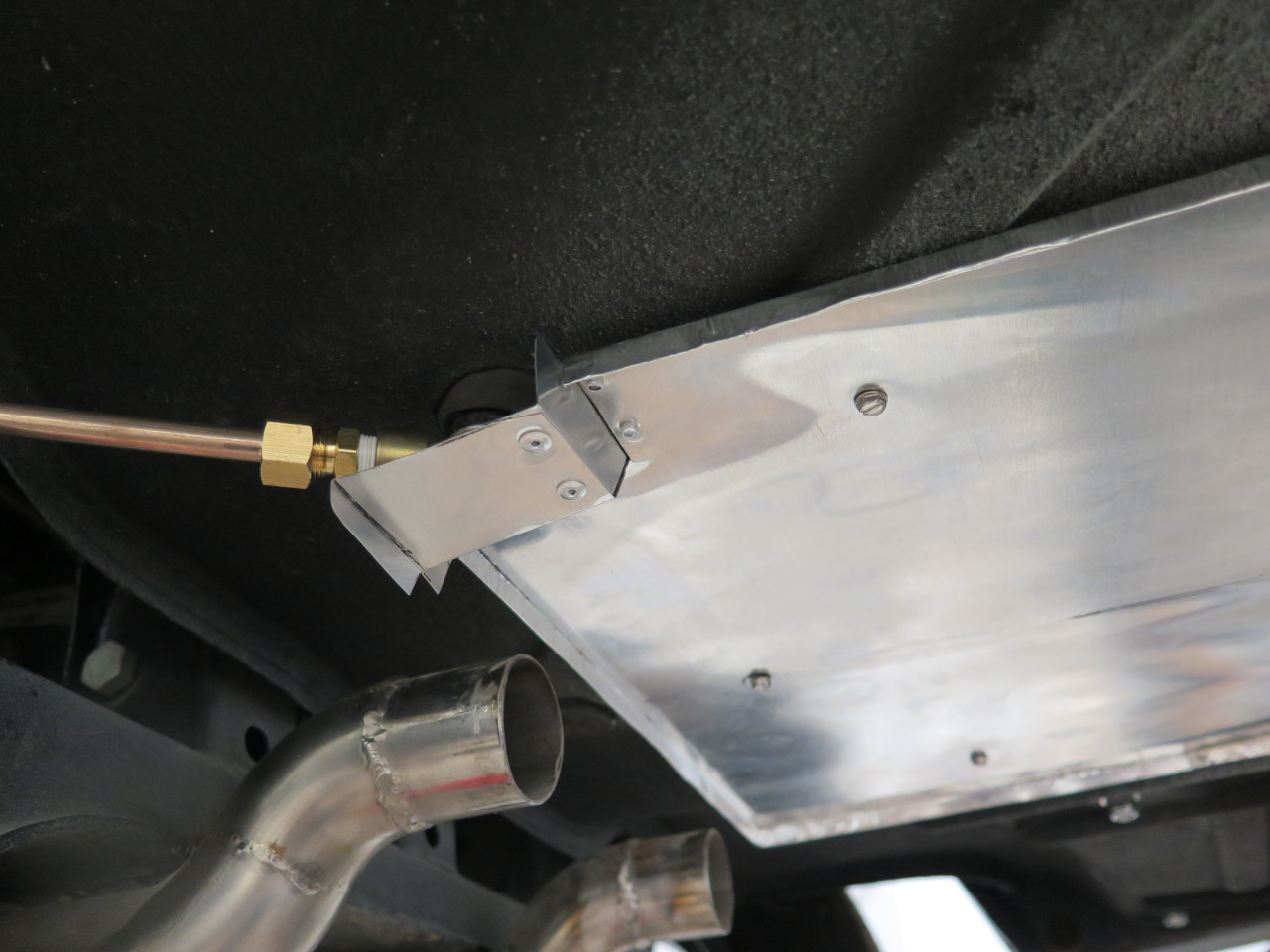

One last thing. The silencers are fairly close to the underside of

the boot floor, spaced maybe 3/4" away. The undercoating I used

has a service temperature only around 200º F, and I thought the

silencers might get the coating hotter than that. The fuel feed

also was fairly close to the left silencer. I thought some sort of

radiant heat shield would be a good idea. This some thin

aluminum, which is a good infrared reflector. The little bump up

on the near corner fits around the fuel fitting. This shield of

course doesn't do much for the hot air coming off the silencers, but

should reduce radiant heat.

OK, time to put her all together. Just to show that I'm serious

about not wanting to see the silencers, I blacked out their rear

surfaces, which actually showed a little through the tunnels, with some

high temp wrinkle paint.

Looks good to me.

The re-designing of the rear of the exhaust system was quite a lot of

work spread over a couple of years. Other than the purchase of the

exhaust system, the cost was next to nothing, since I was able to just

rearrange things. I'll have to wait to see of the changes make any

difference in the sound.

Comments to ed at elhollin1@yahoo.com

To my other GT6 pages