To my other GT6 pages

January 21, 2024

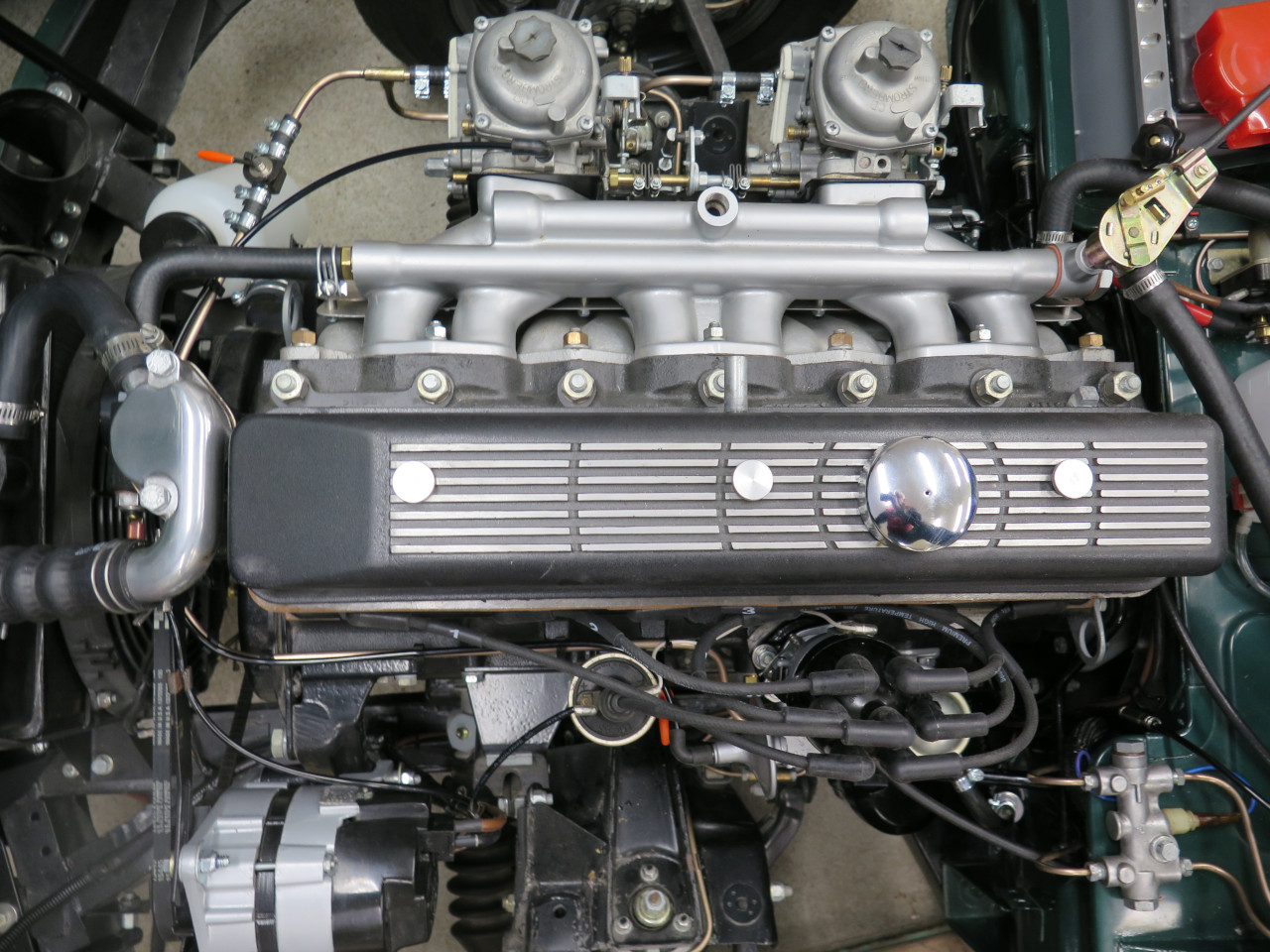

Ignition System

The GT6 and it's kin all used the ubiquitous Kettering ignition system

from the factory. The heart of the system is the distributor,

which in conjunction with the coil, produces a series of high voltage

spikes that are timed and routed to the proper cylinders to initiate

combustion.

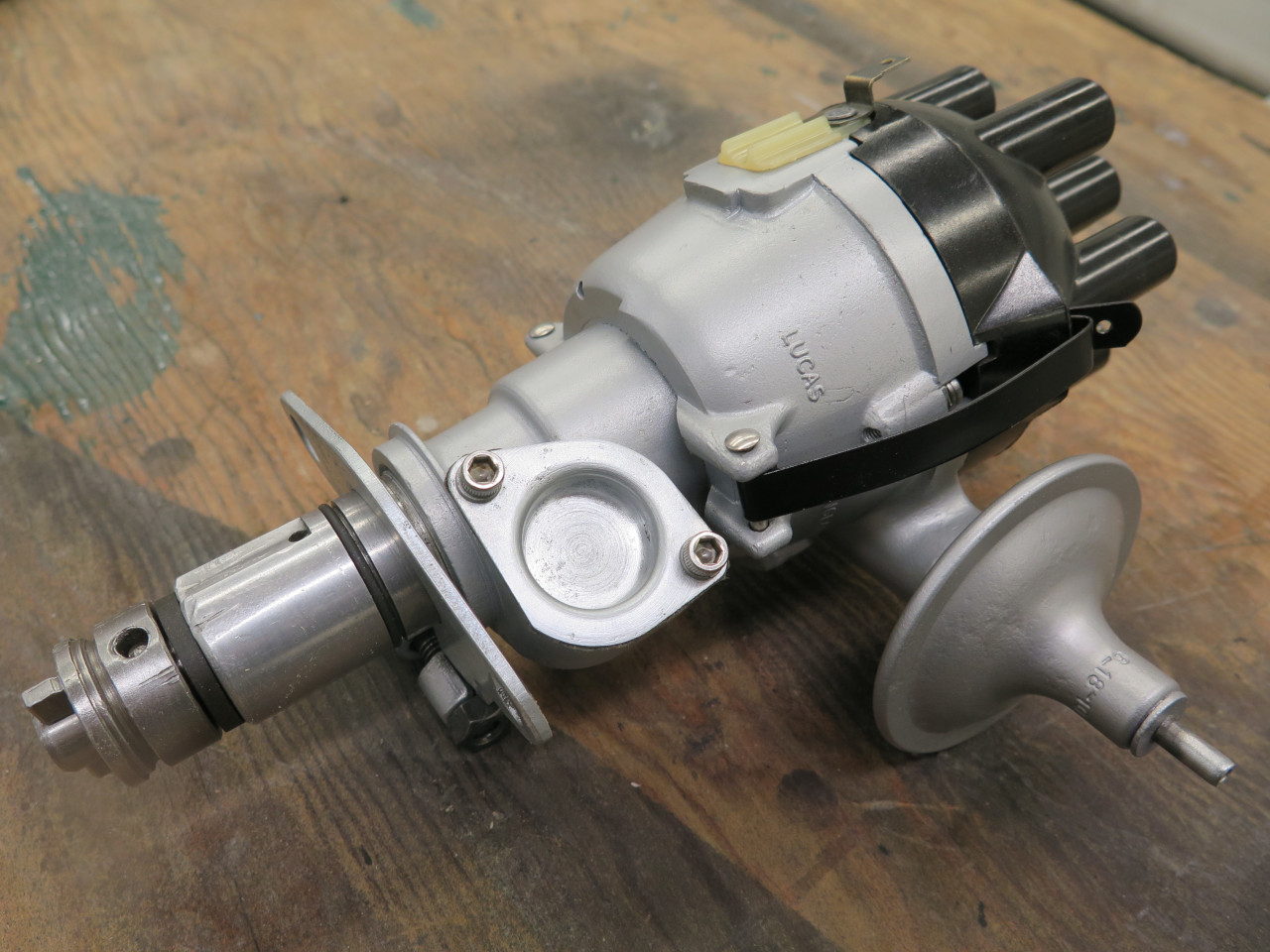

I dug out my refurbed distributor.

There were a few chores to do before dropping that bad boy in place

though. First task was to prime the oil pump. This isn't

strictly necessary, since a crank over with the starter motor will do

this, but I think there is an advantage to having all of the oil

galleries already full on the first crank.

Dumped in oil until I got a good reading on the dipstick. Filled the oil filter too.

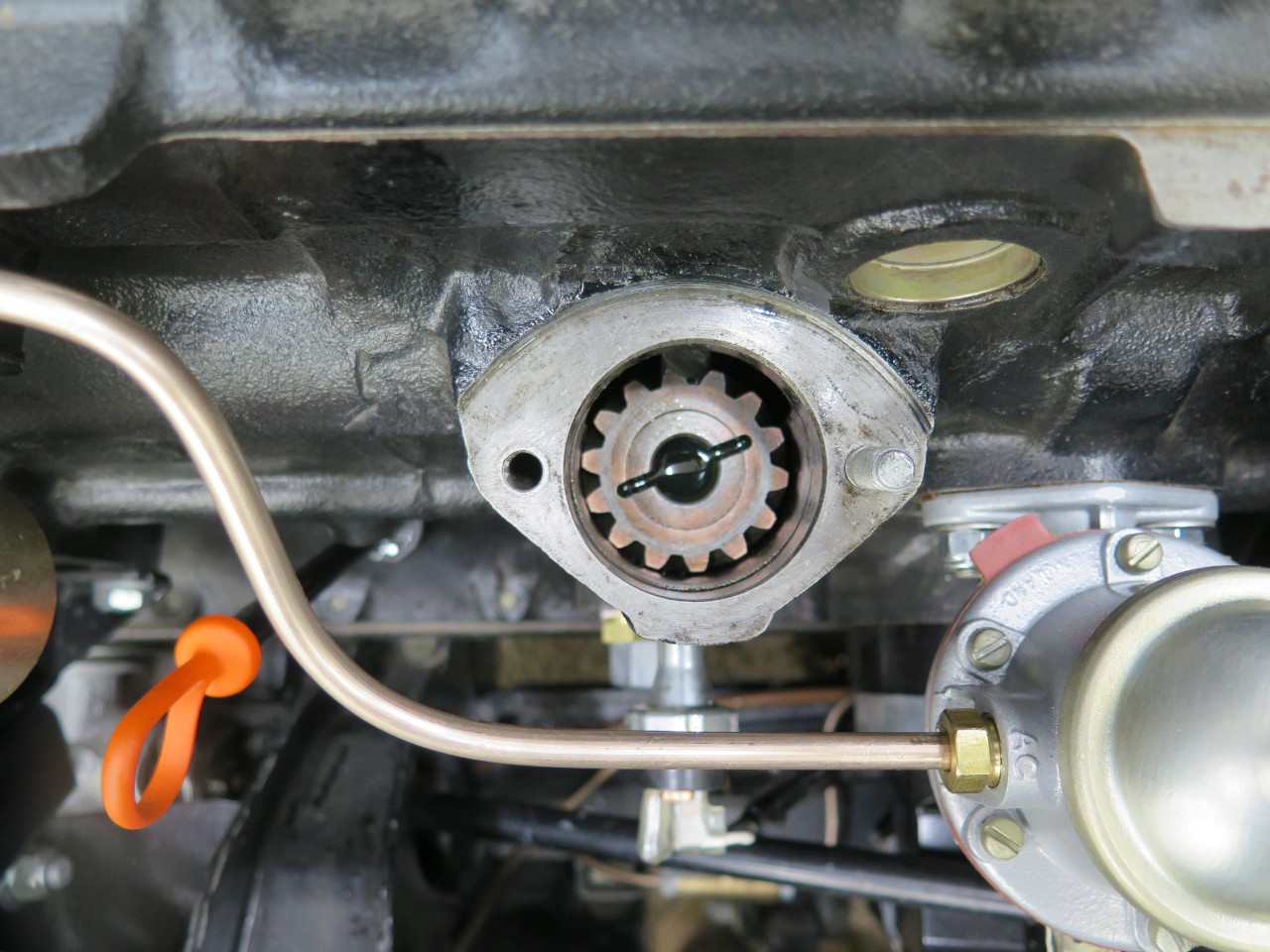

The oil pump is driven from a gear that also drives the

distributor. That gear is driven by the camshaft. The little

fork on the bottom of the drive gear shaft mates with a tongue on the

oil pump shaft. To drive the oil pump directly, it just takes a

shaft with a duplicate of that fork. Spinning the pump with a

drill motor pulls oil out of the sump. It's obvious when the pump

sees oil--the load on the drill increases, and oil will start to well up

in the cavity. I

had one leak at the oil gauge line coupling that made a bit of a mess,

but it was just that the tubing wasn't seated properly.

The next job was to set the drive gear float clearance. The gear

itself runs between the top flange of the oil pump shaft bush below and

the distributor pedestal above, and needs a little room to make sure it

isn't bound up.

Setting this clearance is a little tricky, and the factory suggests sort

of a round about way to do it. They say to put a temporary spacer

of known thickness under the drive gear, and place the pedestal in

place on top of that. The pedestal now won't seat, and the gap

between the pedestal seating surface and the block is measured. A

little arithmetic then determines how much the pedestal has to be

shimmed up to give the drive gear between 0.003 and 0.007 inches of

clearance. The actual shims provided look like paper gaskets, but

they are very thin, and several of them are included in gasket sets.

I used that method, but found it just about as easy to use bent feeler gauges to set (or check) the clearance.

The gear then comes out so the temporary spacer can be retrieved, and

the gear re-installed. The position of the gear is important since

it sets the timing for the distributor. The pedestal and shims

can then go on.

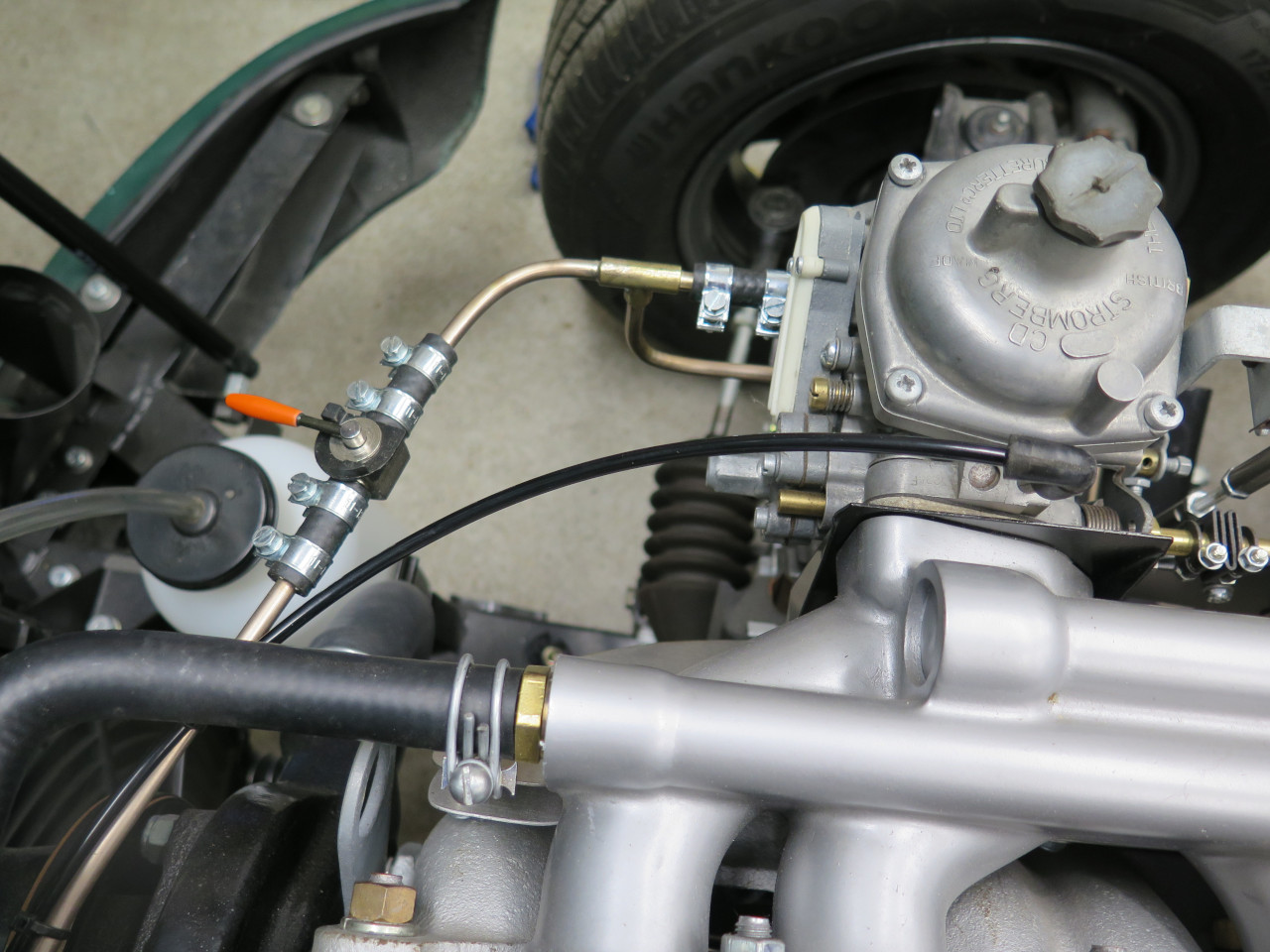

With the distributor in place, the spark plug wires could then be

installed. In the past, I've just bought plug wire sets specified

for the car. I was always a little disappointed though, since it

looked like the sets were made up of a selection of wires of standard

lengths, so most of them were longer than they needed to be. I

temporarily installed the old set of wires just to see how bad it was.

Not really terrible, but I thought there was room for improvement.

I bought some bulk wire, some terminals, and some boots. The

result looks more tidy to me.

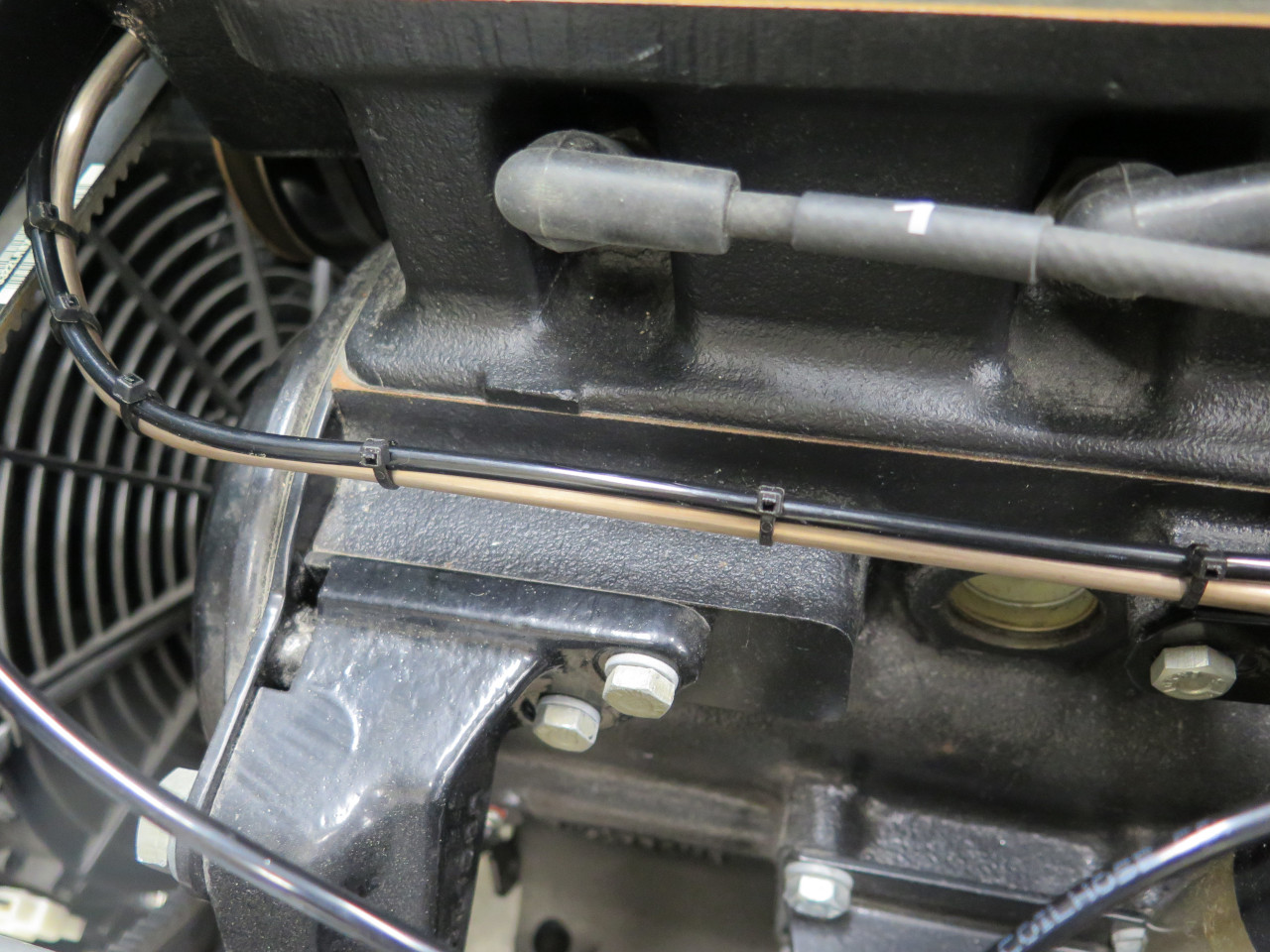

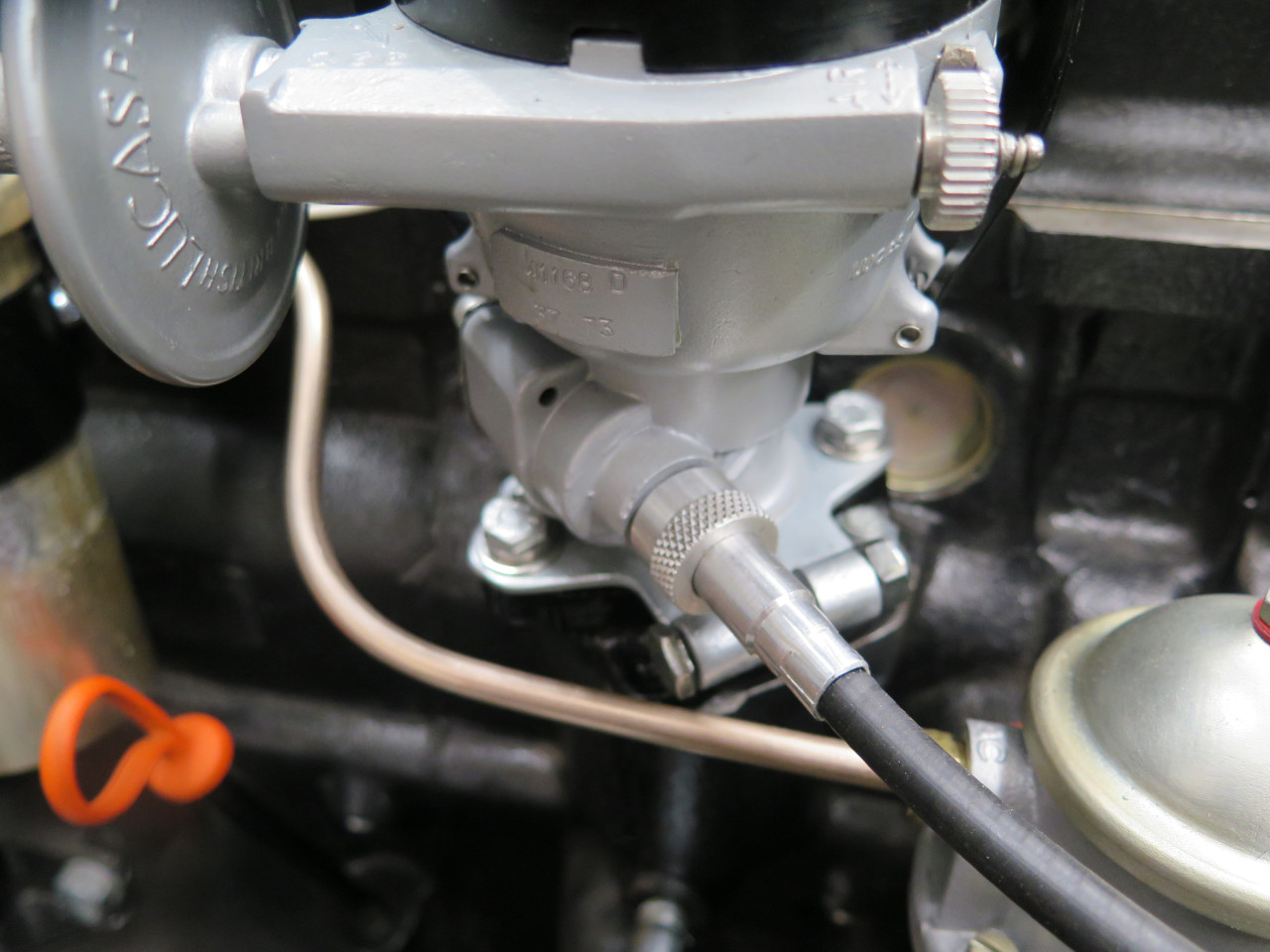

Next up was the line for vacuum advance. The little elbows are aftermarket items, but I got the nylon tubing elsewhere.

I followed the fuel line.

It looked fine, but my mind's eye saw something a little better.

Last up: The tach cable. I'd ordered one almost a year

ago, and finally brought it out to the light of day. The first

thing I noticed when comparing it to the old one was that it was two or

three inches longer.

Well, maybe no big deal. Let's install it. This is when the

heartache started. The inner cable wouldn't go far enough into the

drive spindle for the outer housing to seat properly. The

stickout of the inner cable appeared to be too long.

I cut off the end, and sealed it with a little TIG fusion tack.

But it still would not go into the drive spindle on the

distributor. Is the square section too big? Let's compare to

the original cable. Original first:

The new inner cable is nearly 0.012" (abut 12%) larger than the one that

fits. So is it the wrong cable, or just mis-made? I don't

know, but I had had it so long, I didn't feel I could send it back, even

if I hadn't modified it. I ordered another one from a different

supplier.

This one was two inches shorter, and fits fine.

All's well that ends well, I guess.

These were sort of nit-picky tasks, but not really hard. I had

probably less than $50 in parts and materials, not counting the oil or

the bad cable.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages