To my other GT6

pages

January 31, 2020

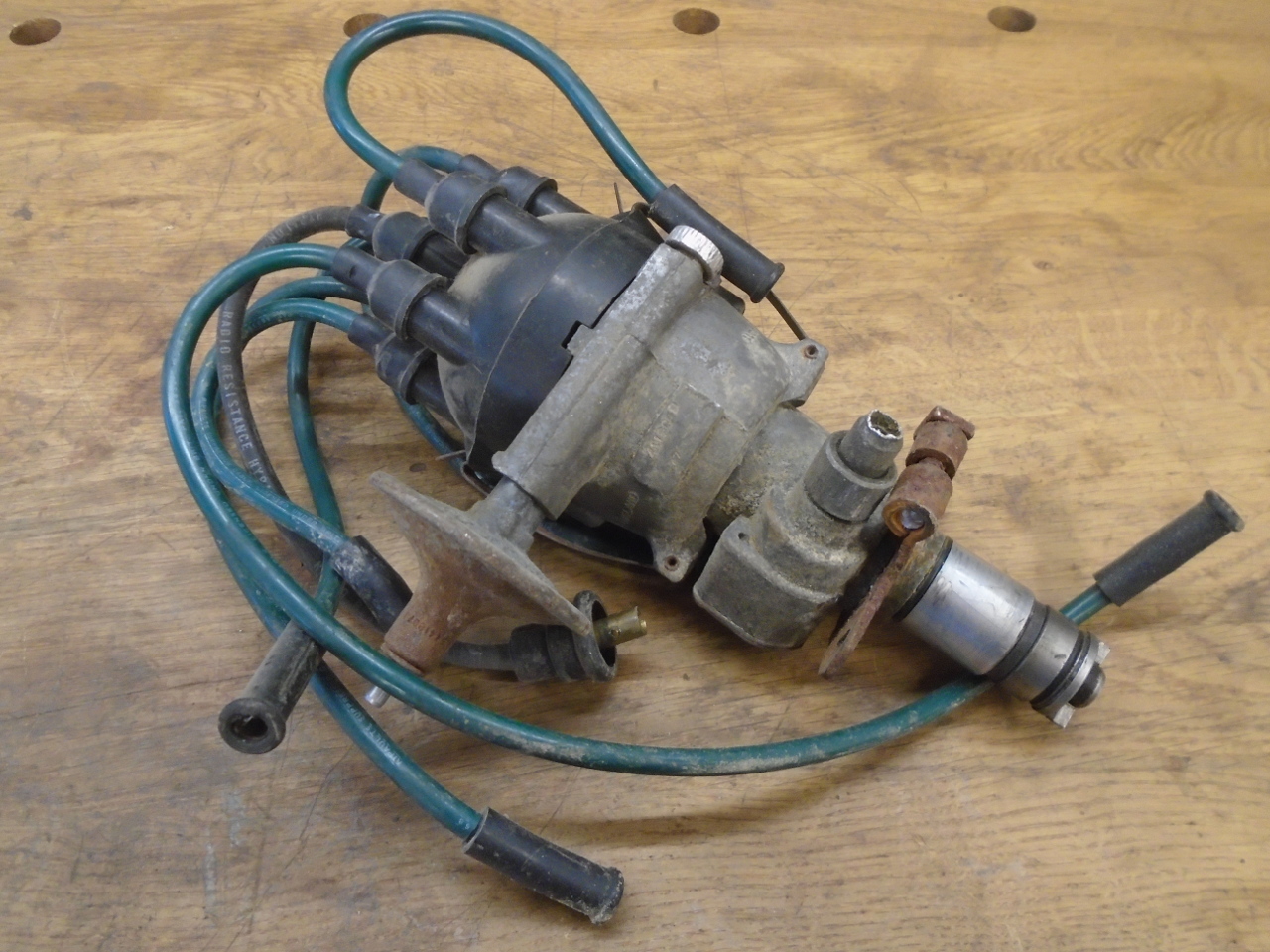

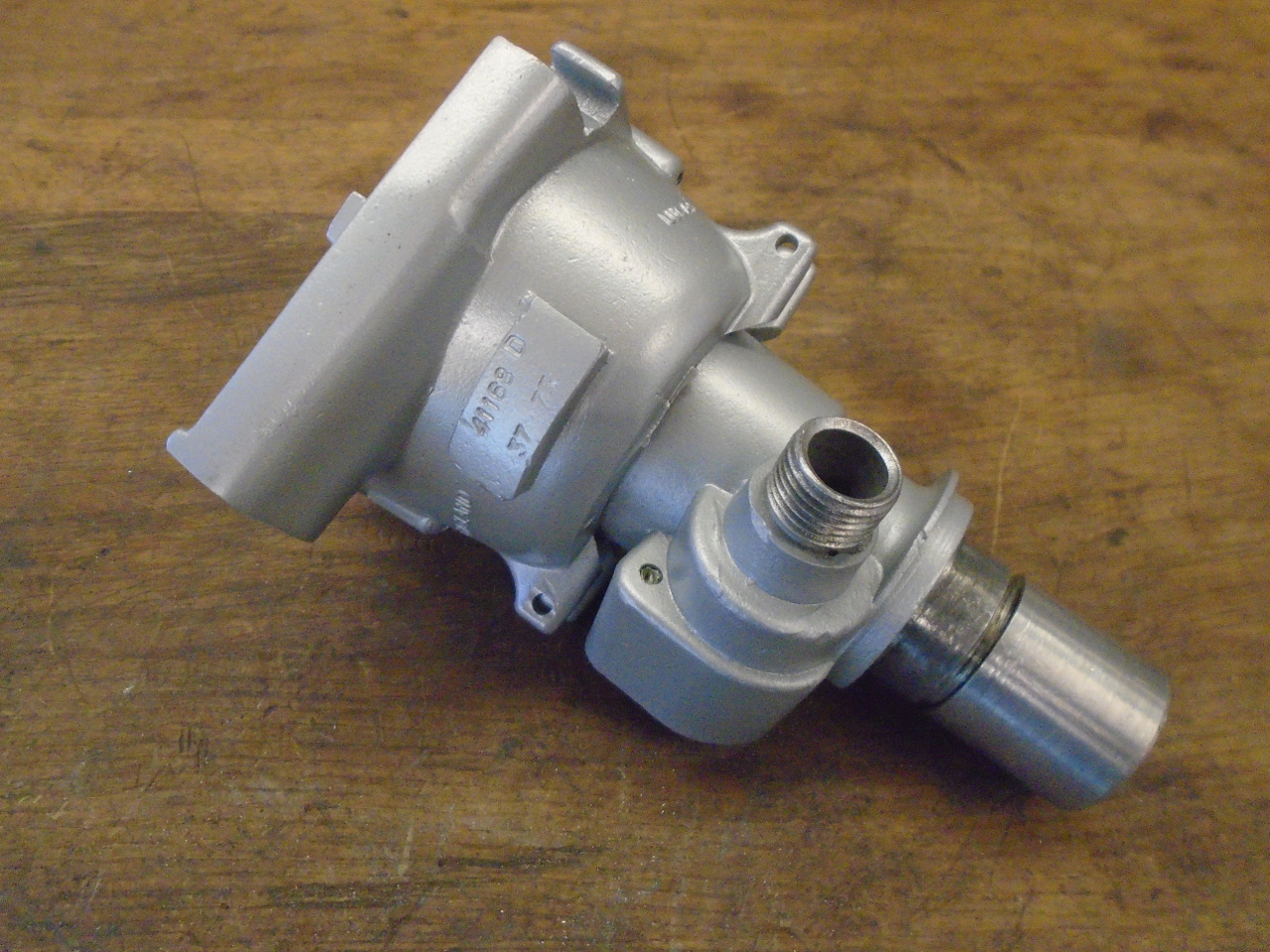

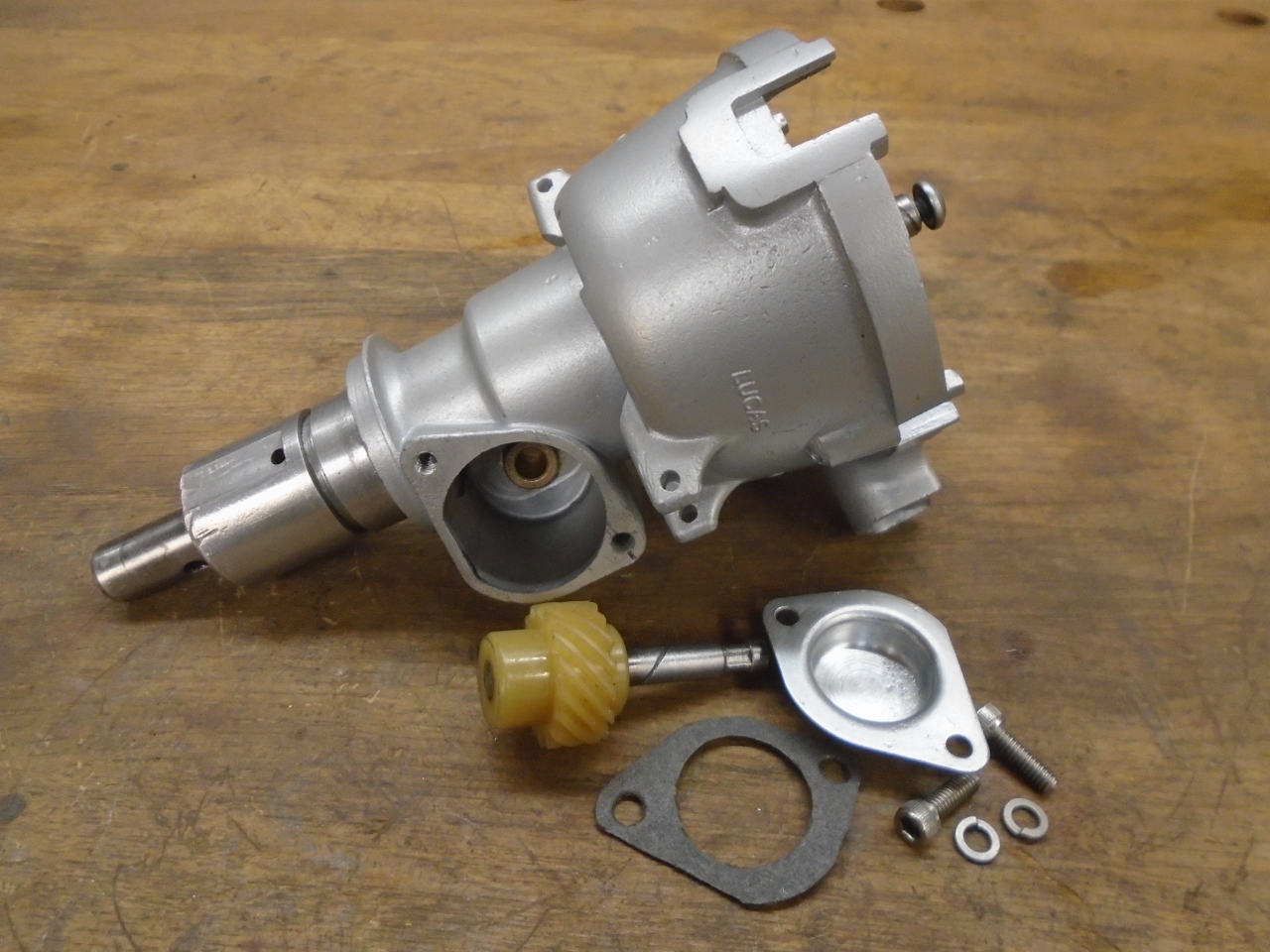

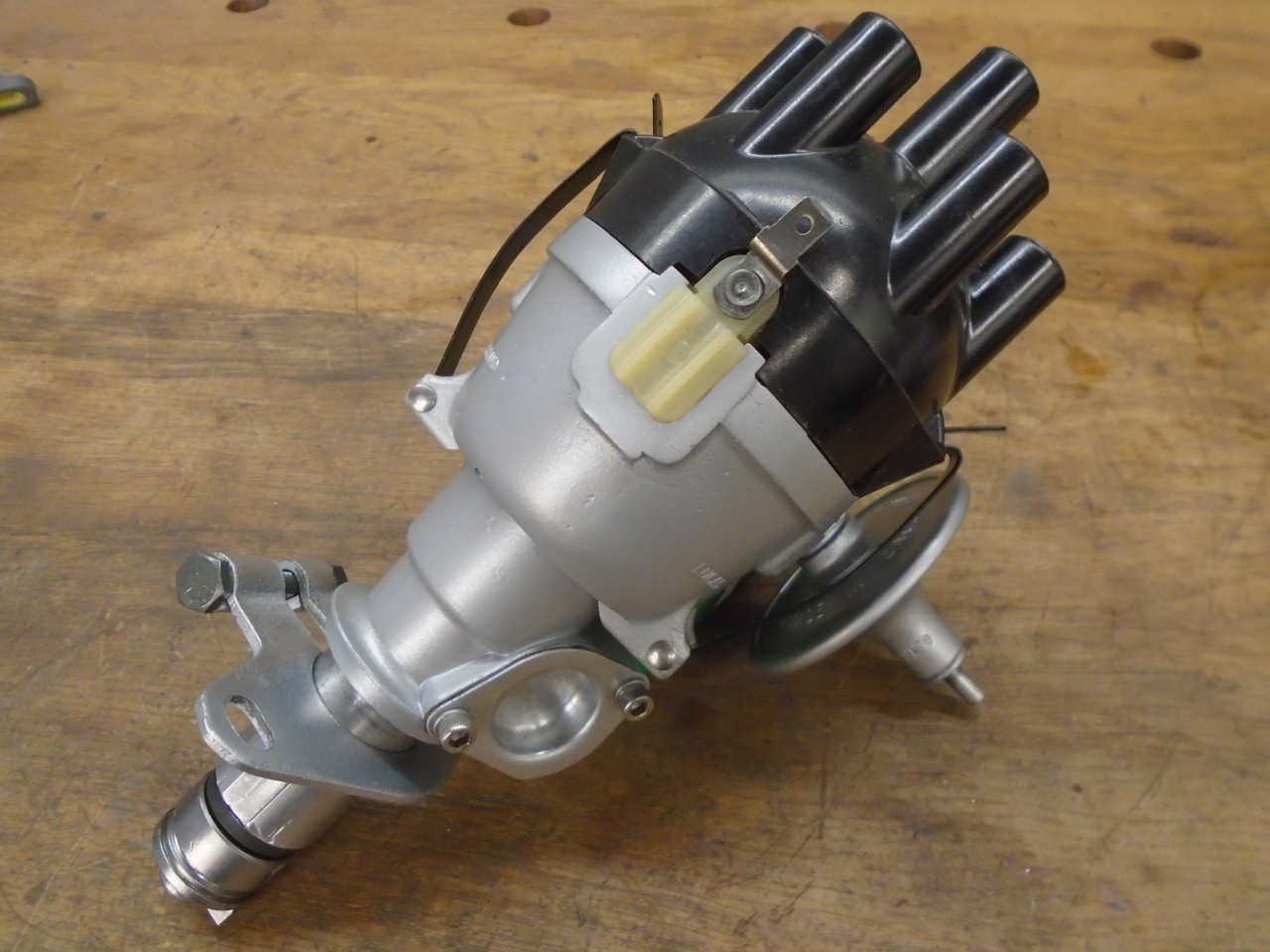

Distributor

Lucas made distributors that were used in a wide

range of cars, trucks, and other equipment of the era. My

GT6 had the ubiquitous 22D distributor. This is a pretty

ordinary distributor, which includes provisions for both

centrifugal and vacuum advance, and also provides a take-off for

a mechanical tachometer. With a date code of 37th week of

'73, it wasn't original, but an early replacement. It was

corroded and dirty, and had some visible broken bits. I

hoped the insides were in better shape.

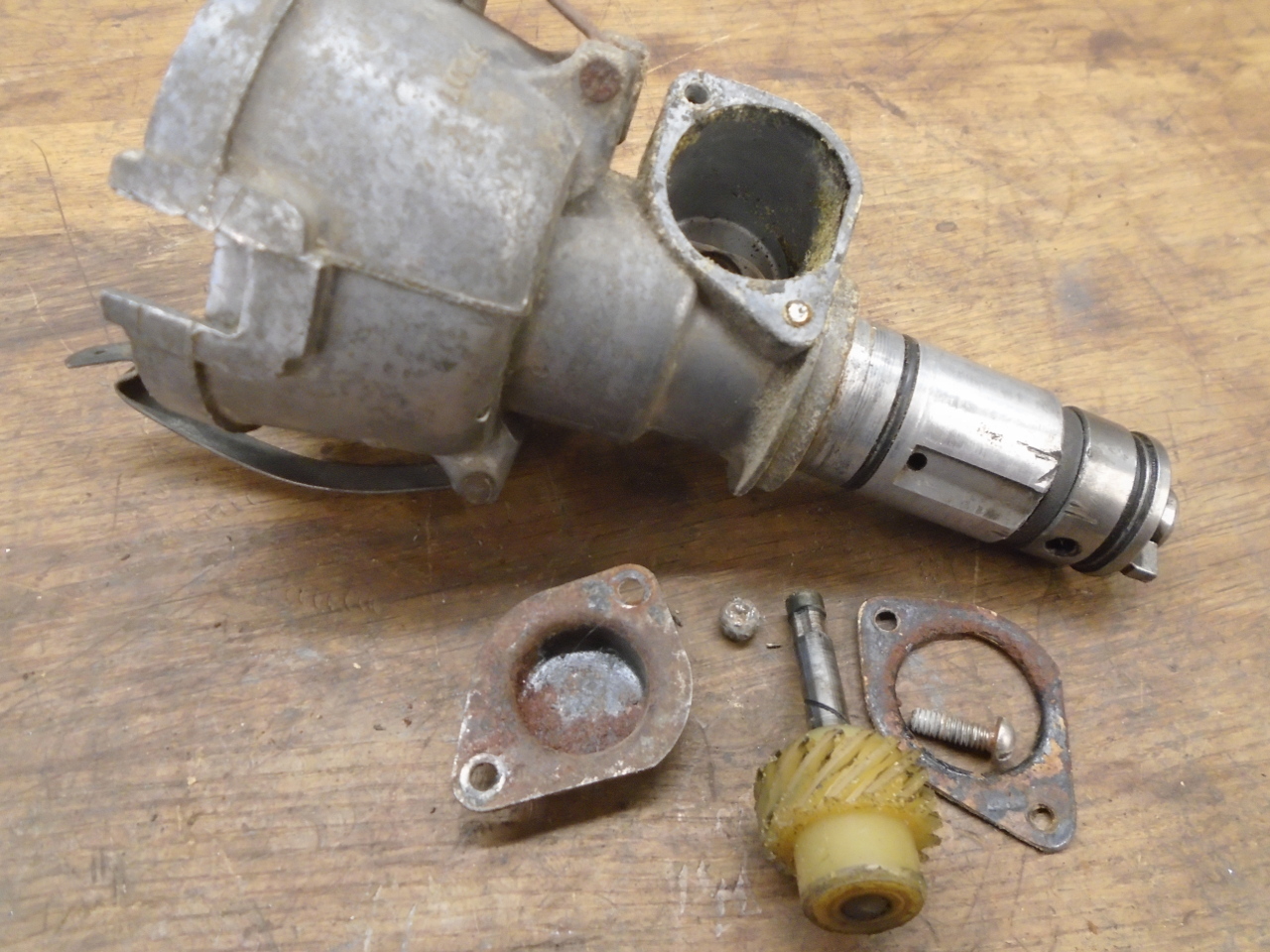

Disassembly went OK until I got to the cover for the tachometer

drive gear. Oddly, the two screws were different

sizes. The bigger one came out alright, but the smaller

one came to a tragic end, its head twisted off its body.

The reason for the mismatched screws came back to me

slowly. I had this distributor apart once before--a minor

refresh back in the 80s. One of the screws broke back

then, and I had to re-tap the hole for a larger 8-32

screw. It was time for the encore.

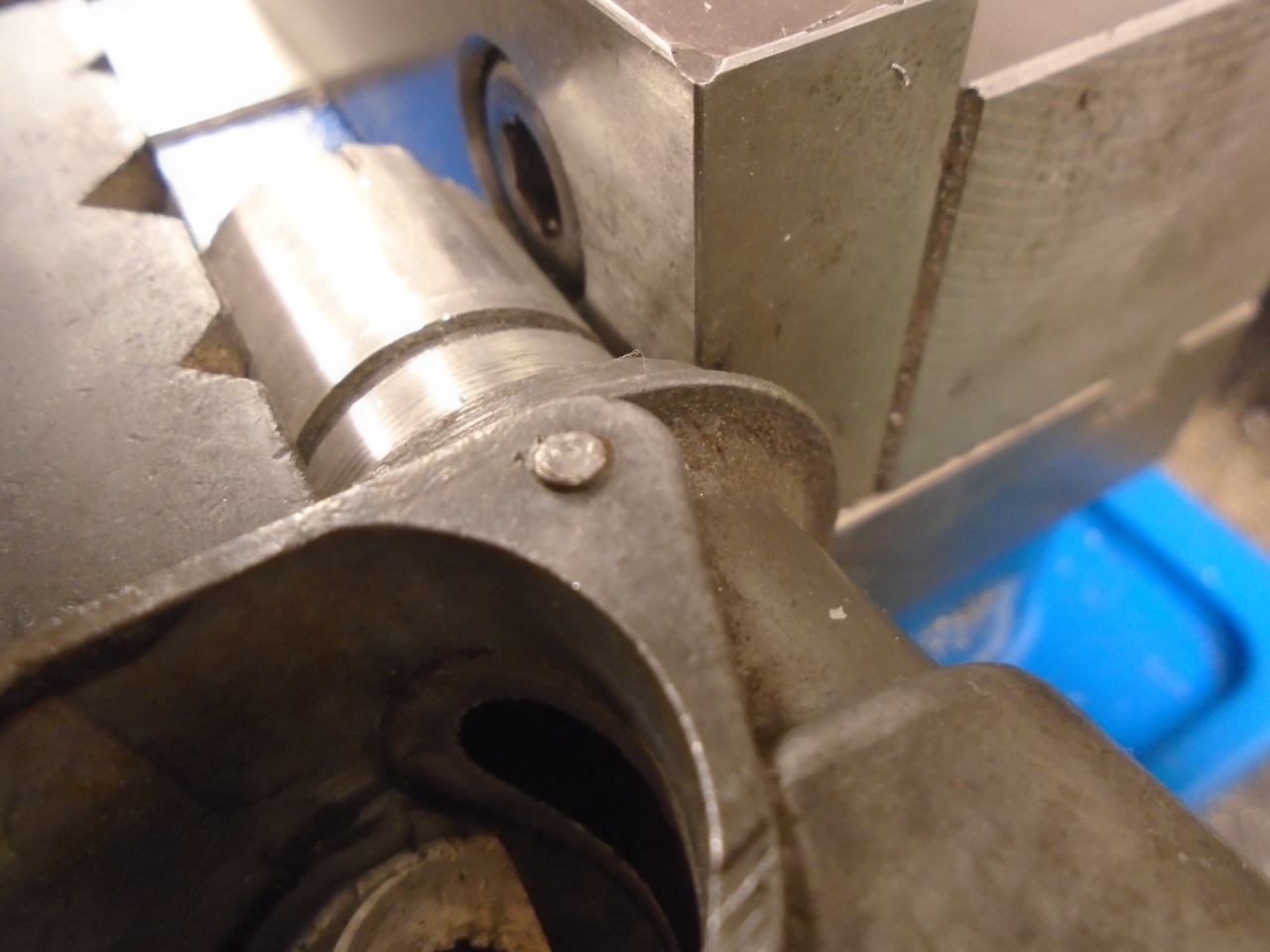

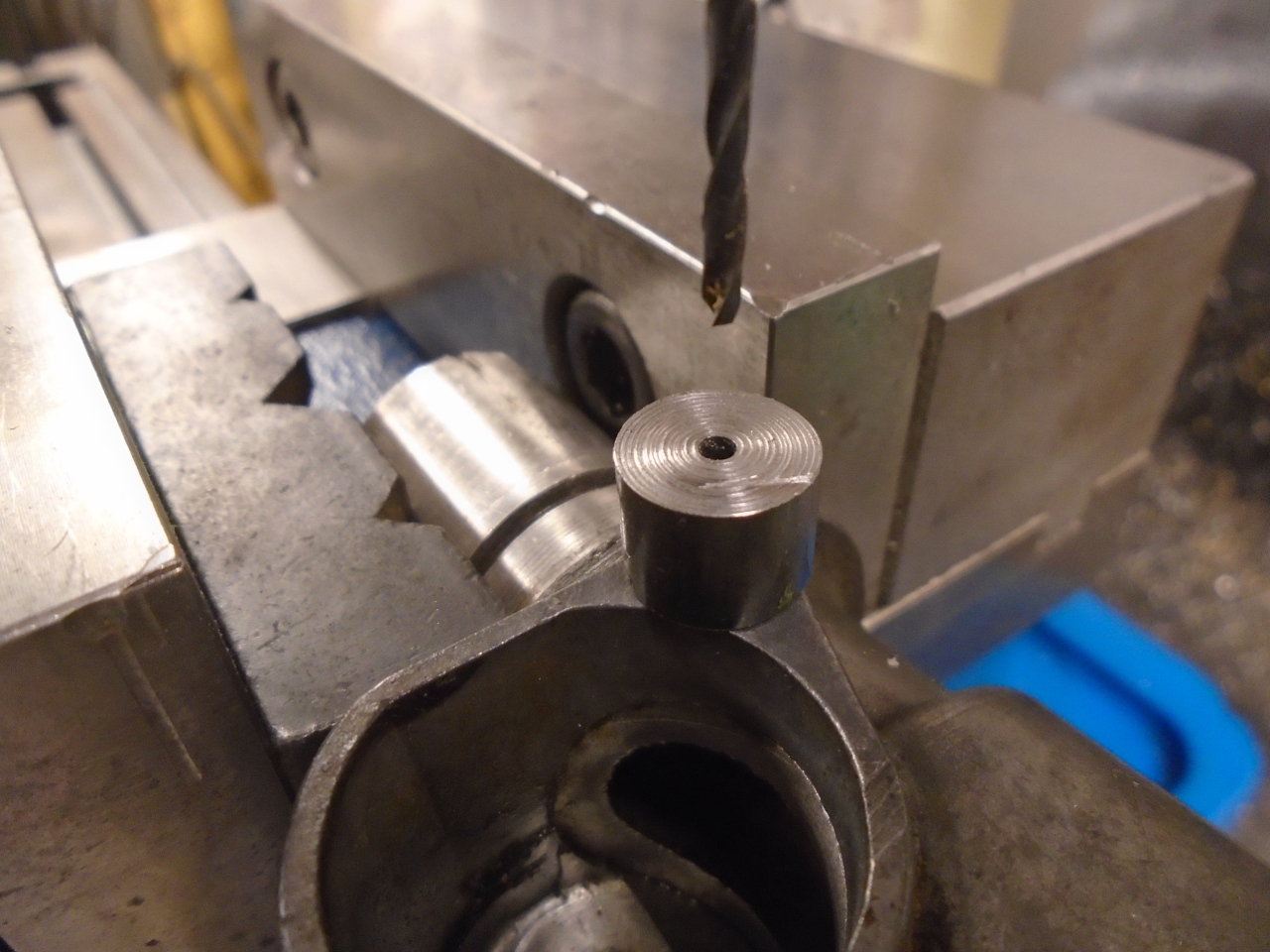

I wanted to make sure I could fix the broken screw before I

spent any more time on this distributor. I decided to try

drilling the remains out. The main challenge in drilling

out a small screw like this is getting the drill bit centered on

the screw. If the bit wanders off the steel screw and into

the softer body metal, it will just shift the hole position at

best, and could make things worse by leaving a broken drill bit

lodged in the body.

The screw was broken off just a little proud of the body

surface. I made a little drill guide with a recess on the

bottom side that would just fit the screw stub. This

centered a small pilot hole that would guide a larger bit to

remove the screw and size the hole for an 8-32 tap. So,

after 30-some years, the holes match again.

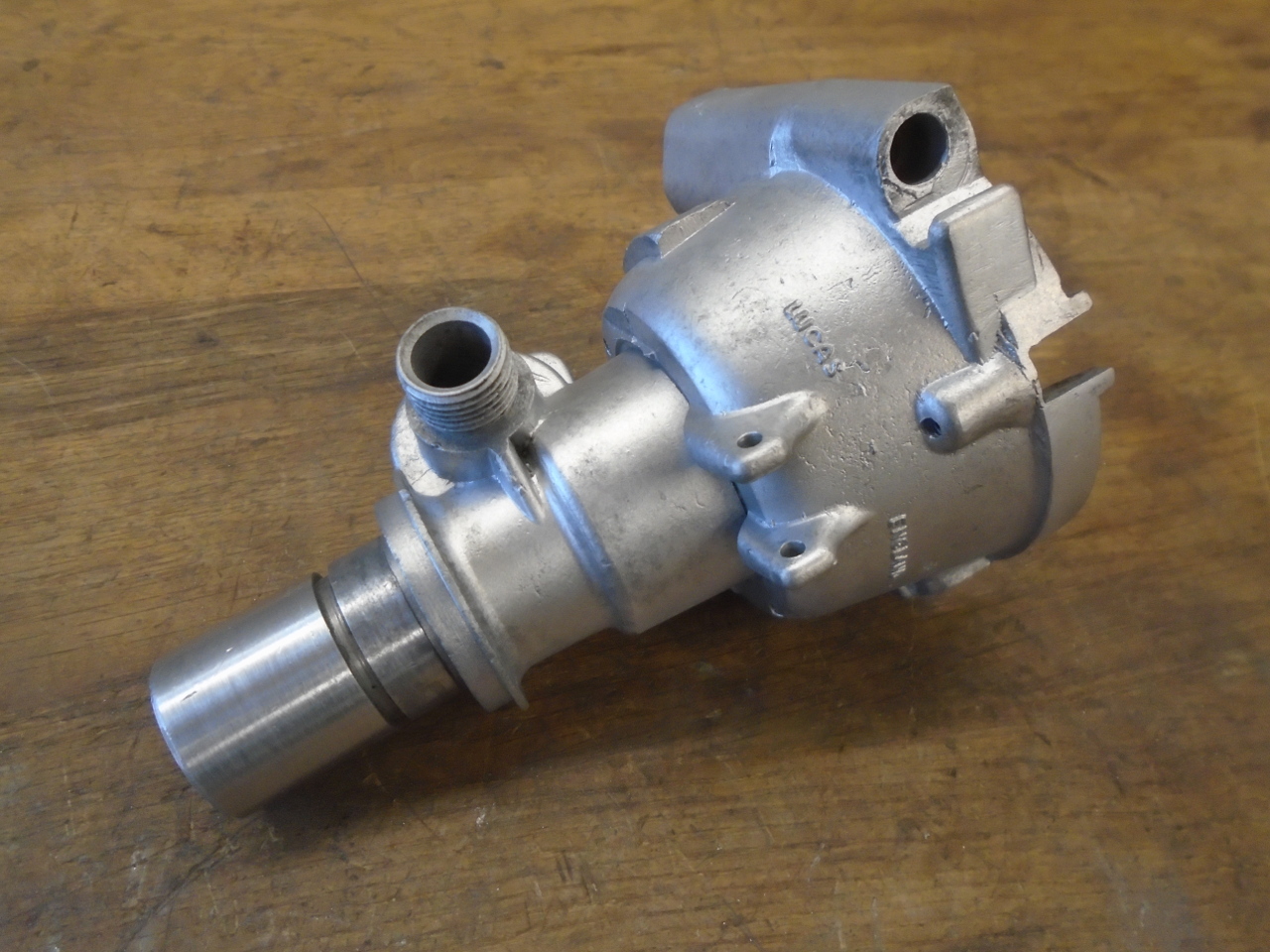

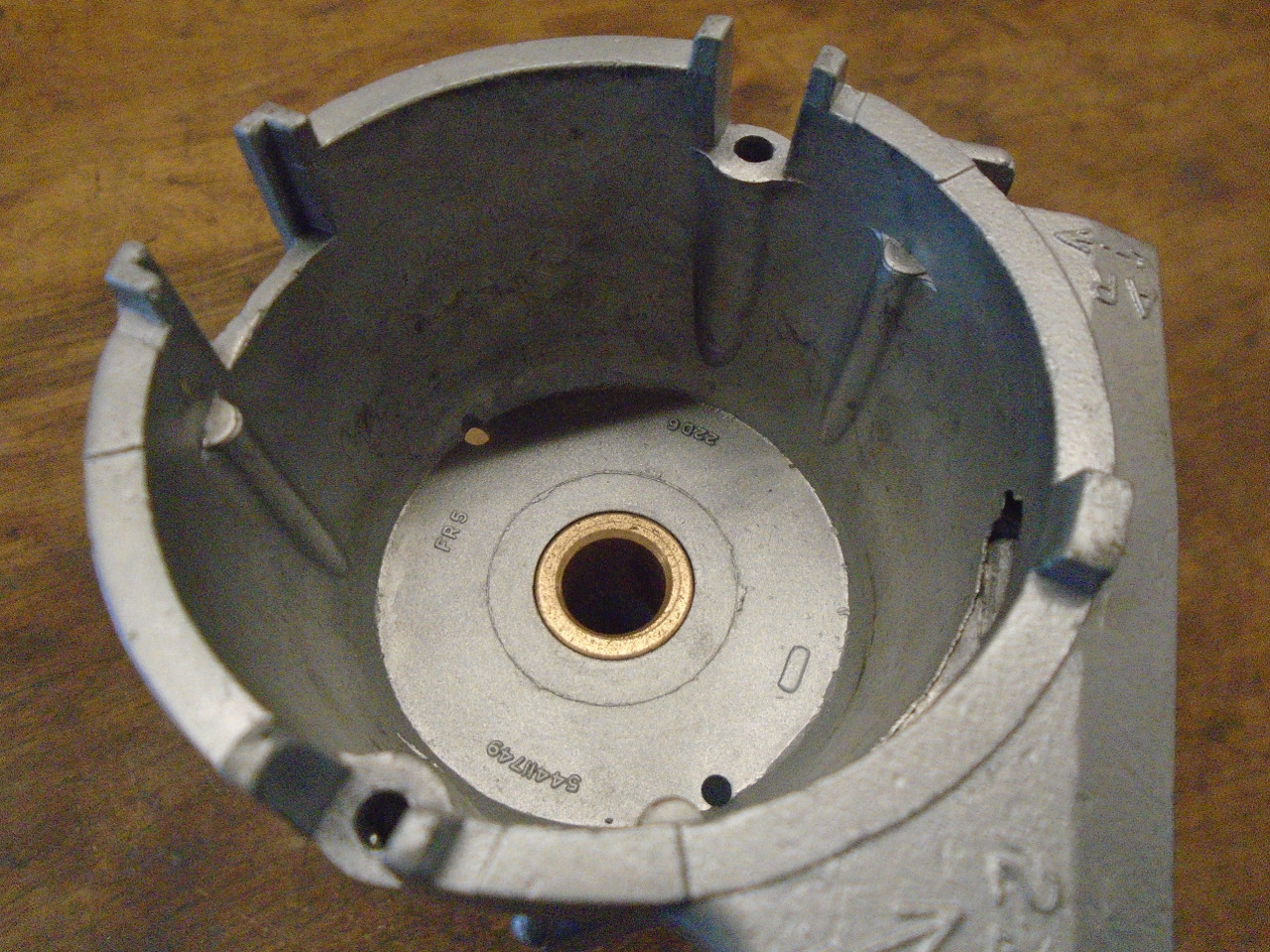

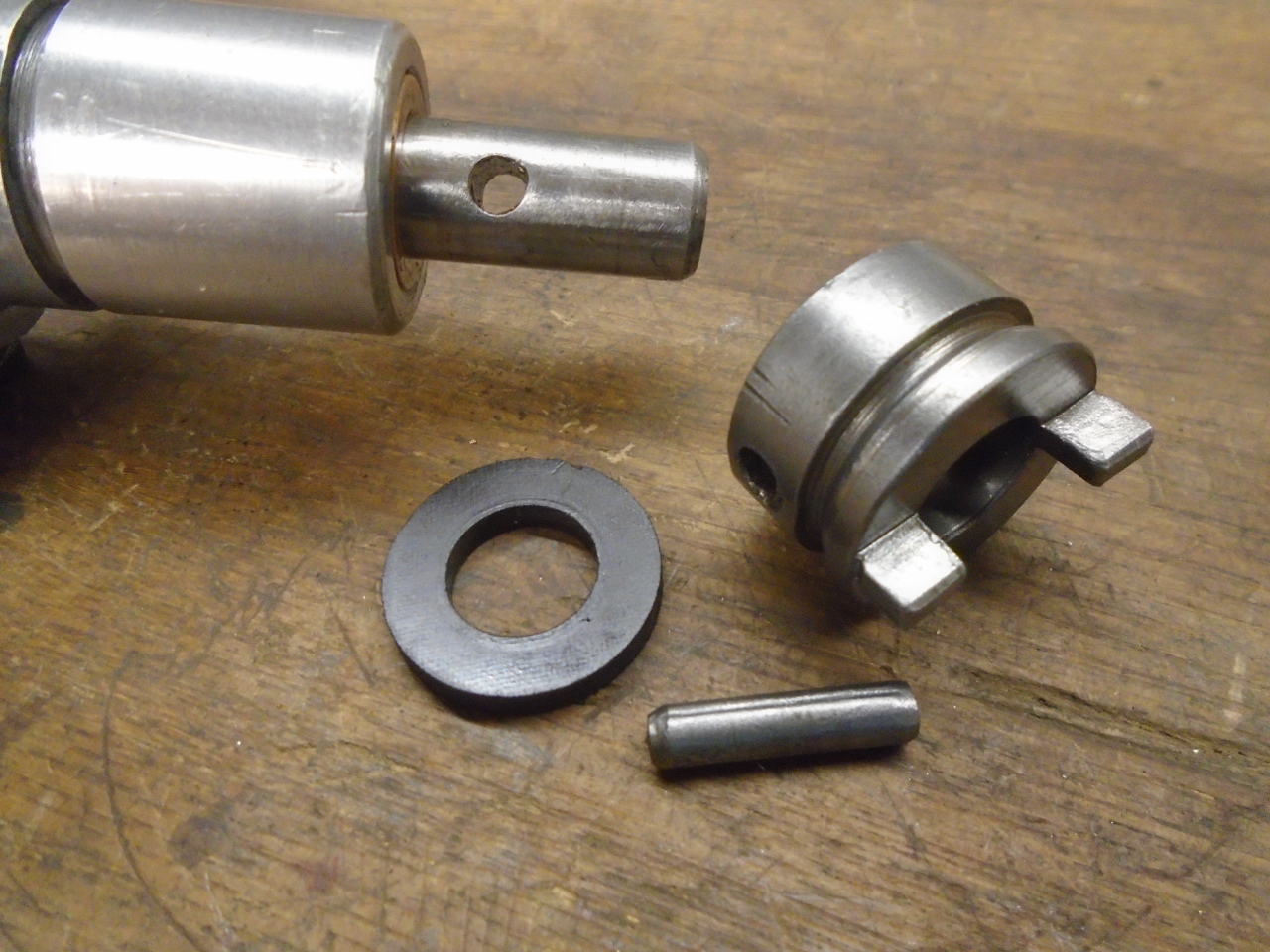

So. with that tragedy averted, I proceeded to clean up the

body. During disassembly I tried to evaluate the condition

of the spindle bushings. I concluded that they weren't

terrible, but I was aiming for something a notch or two above

"not terrible". So, out came the spindle bushes. And

the tach drive bush, just because.

The bare body got a light blast, which made it look a lot

better.

This pot metal won't keep that finish, though, and it will

gradually morph to the faded, mottled finish we are used to

seeing on these kinds of parts. For that reason, I've

lately taken to powder coating many pot metal and aluminum

parts.

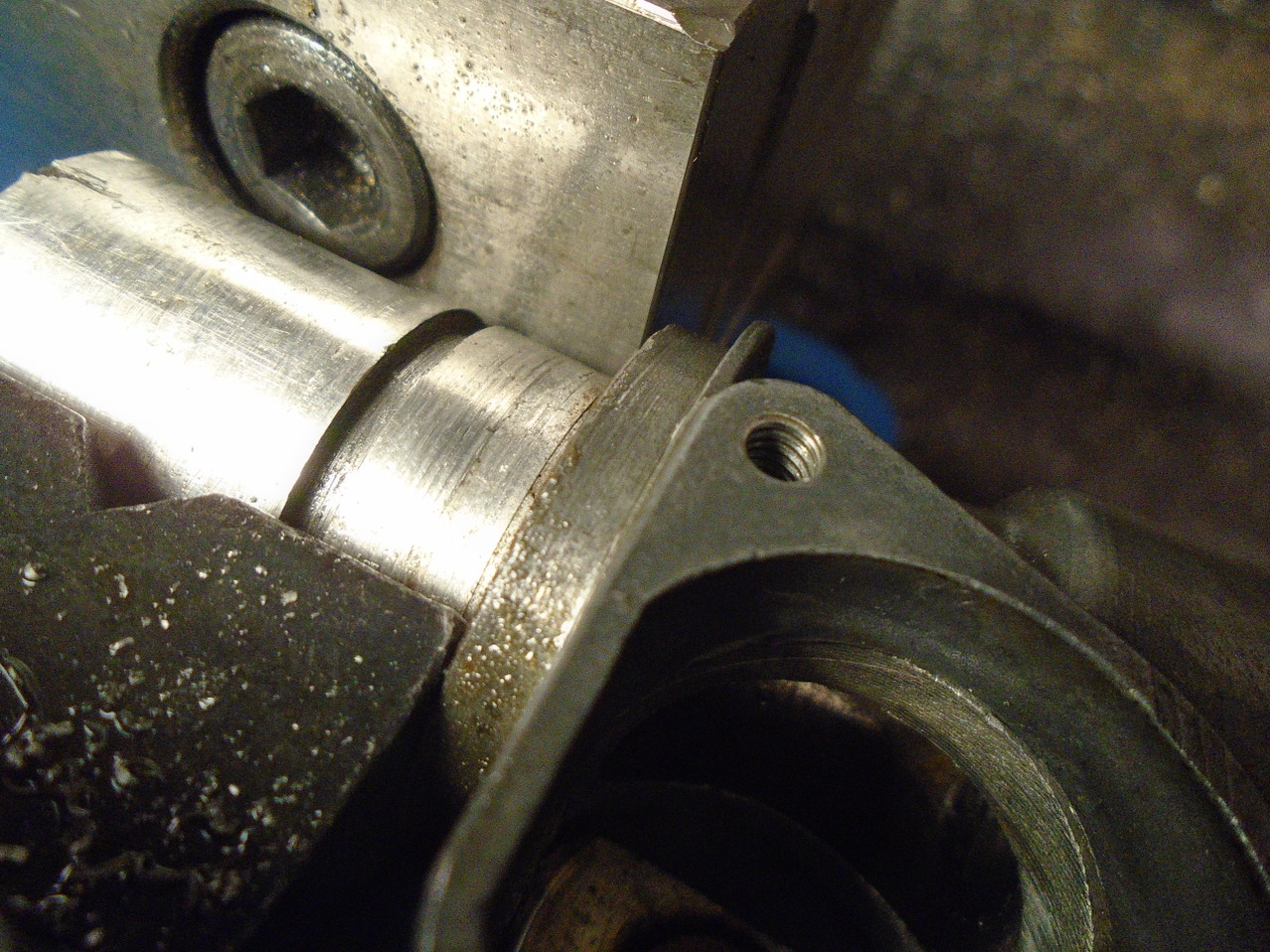

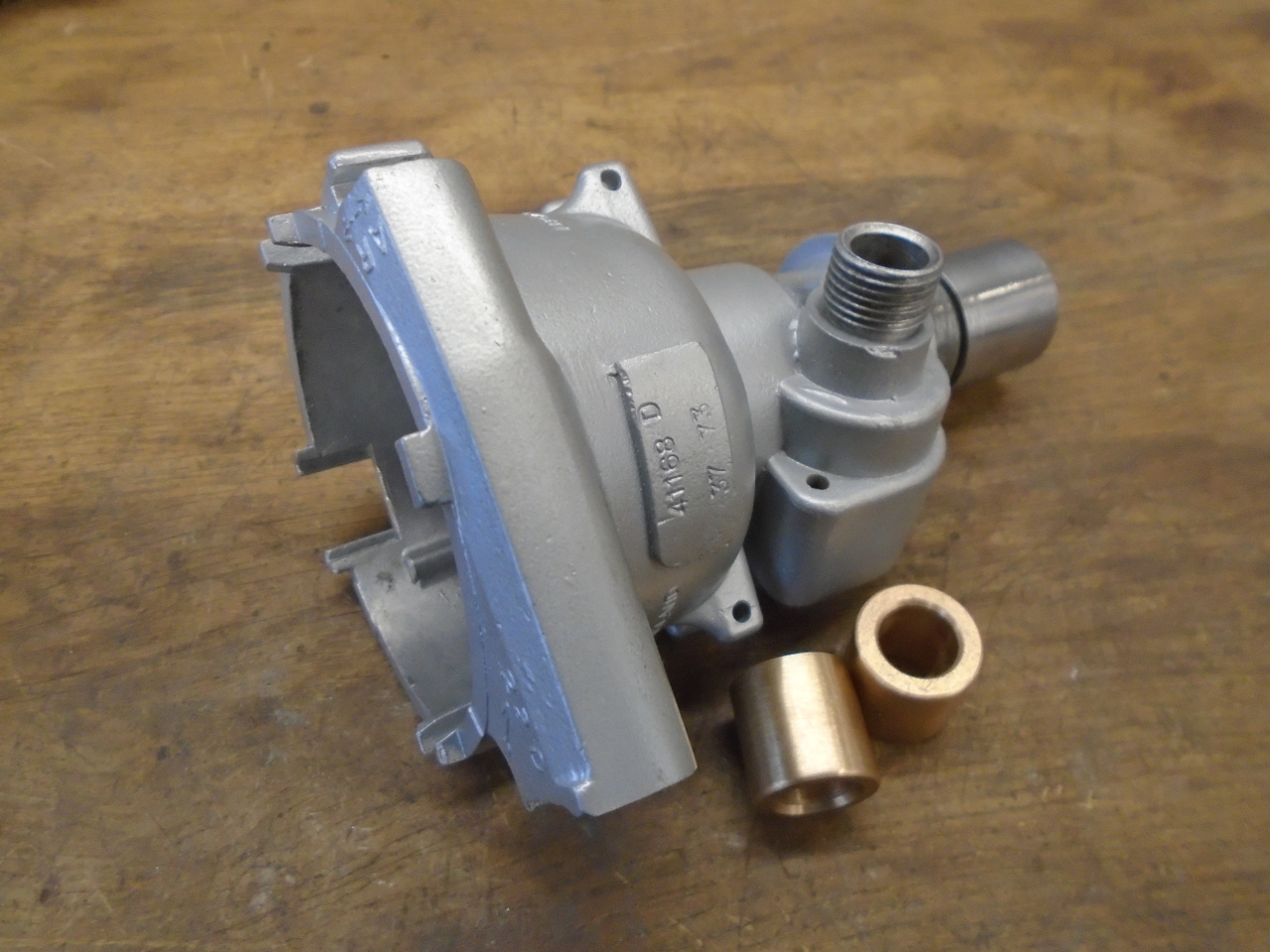

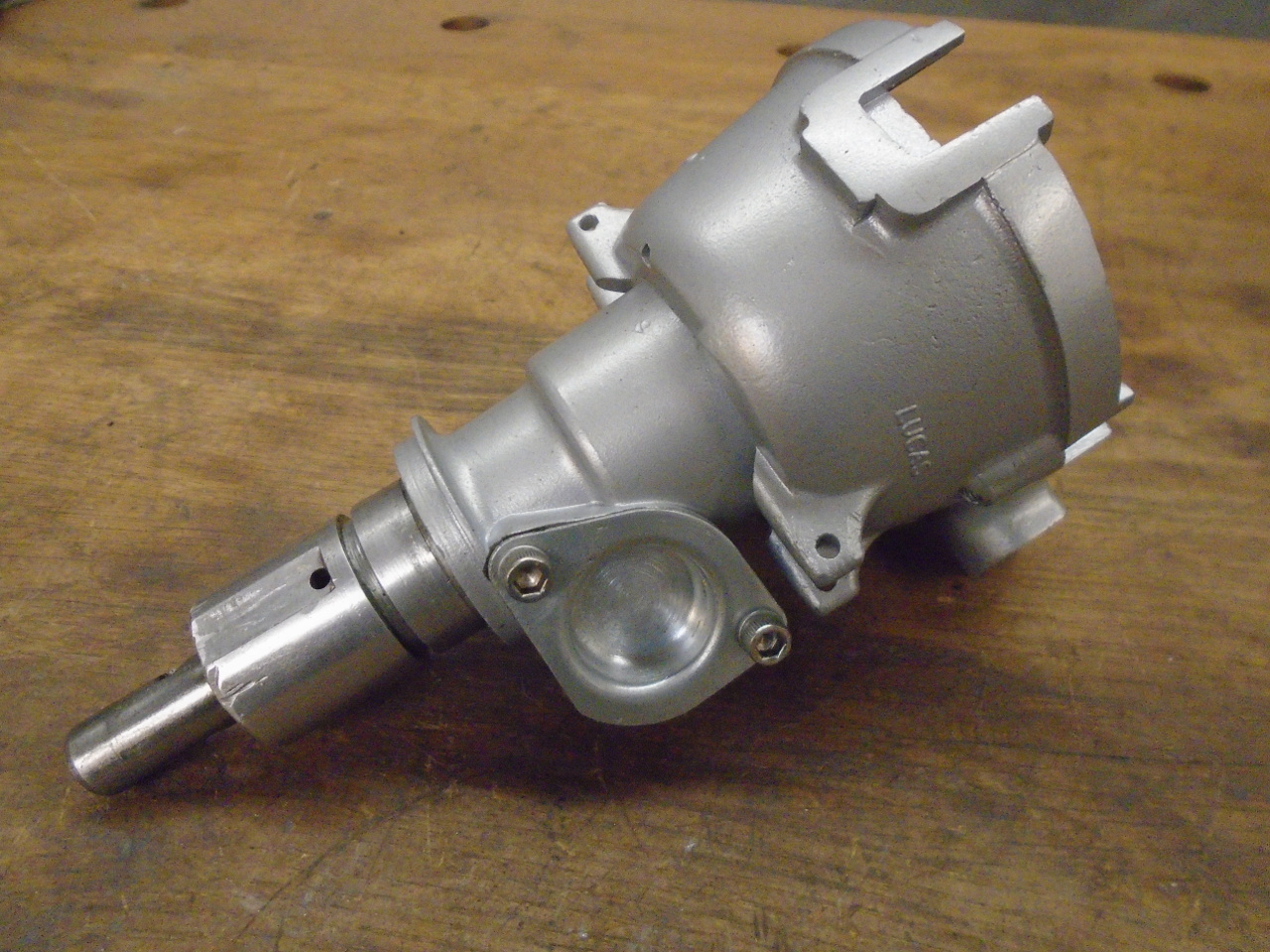

So then we come to the bushings. I discovered when I did

my TR6 distributor--also a 22D unit--that Lucas opted to use a

non-standard size for the spindle bushings. The OD, which

looks like 3/4", is slightly less--about 0.745. The ID,

which looks like 1/2", is also less--about 0.490". I

suppose this was intended to keep dealers from going out of

network for replacement parts.

In the past, I bought these bushes from a popular distributor

repair house specializing in British cars. They were a

little reluctant to sell to me though, and the price reflected

that. This time, I just bought some inexpensive standard

3/4" OD x 3/8" ID bushes and resolved to adapt them

myself. Original bushes on the left are sintered

iron. I chose sintered bronze.

After machining the OD to final size and the ID to just under

final size, the bushes were pressed into the body.

There are a couple of reasons for leaving the IDs a little

small. First, Oilite bushes can compress a little when

pressed into place. Second, in a situation like this,

where you want a pair of bushes to have a very nice fit to a

shaft, they really need to be reamed to size. Further,

it's best to "line-ream" them in situ, to ensure that the bores

are coaxial.

Machining these "Oilite" type bushes can be a little

tricky. The sintered material retains oil in pores, and

machining can smear the material, closing up some of the

pores. Very sharp tools minimize this. My spindle

measured 0.489", so I reamed the bushes to 0.491". The

result was a very nice fit, firm but smooth, with no detectable

play.

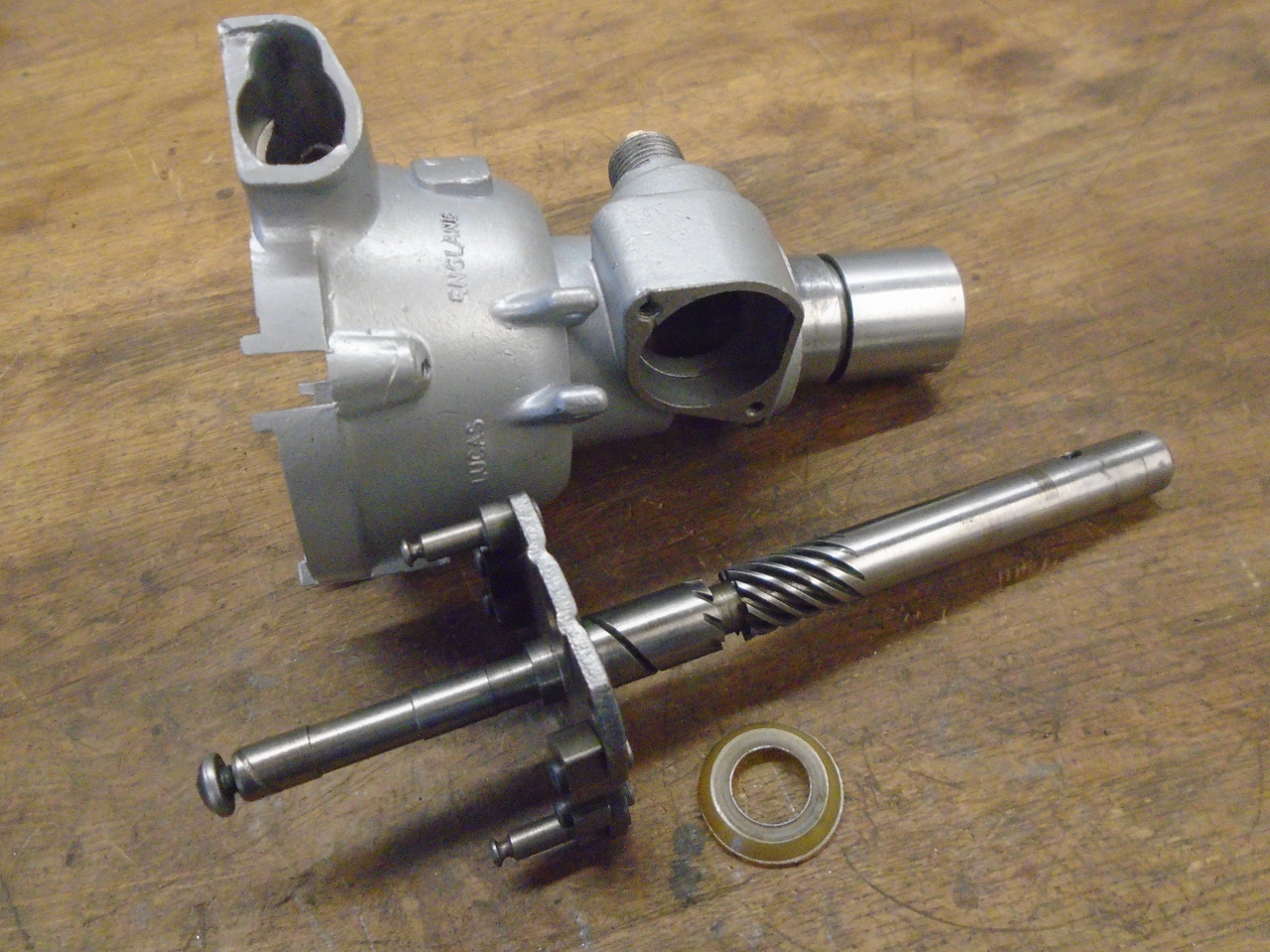

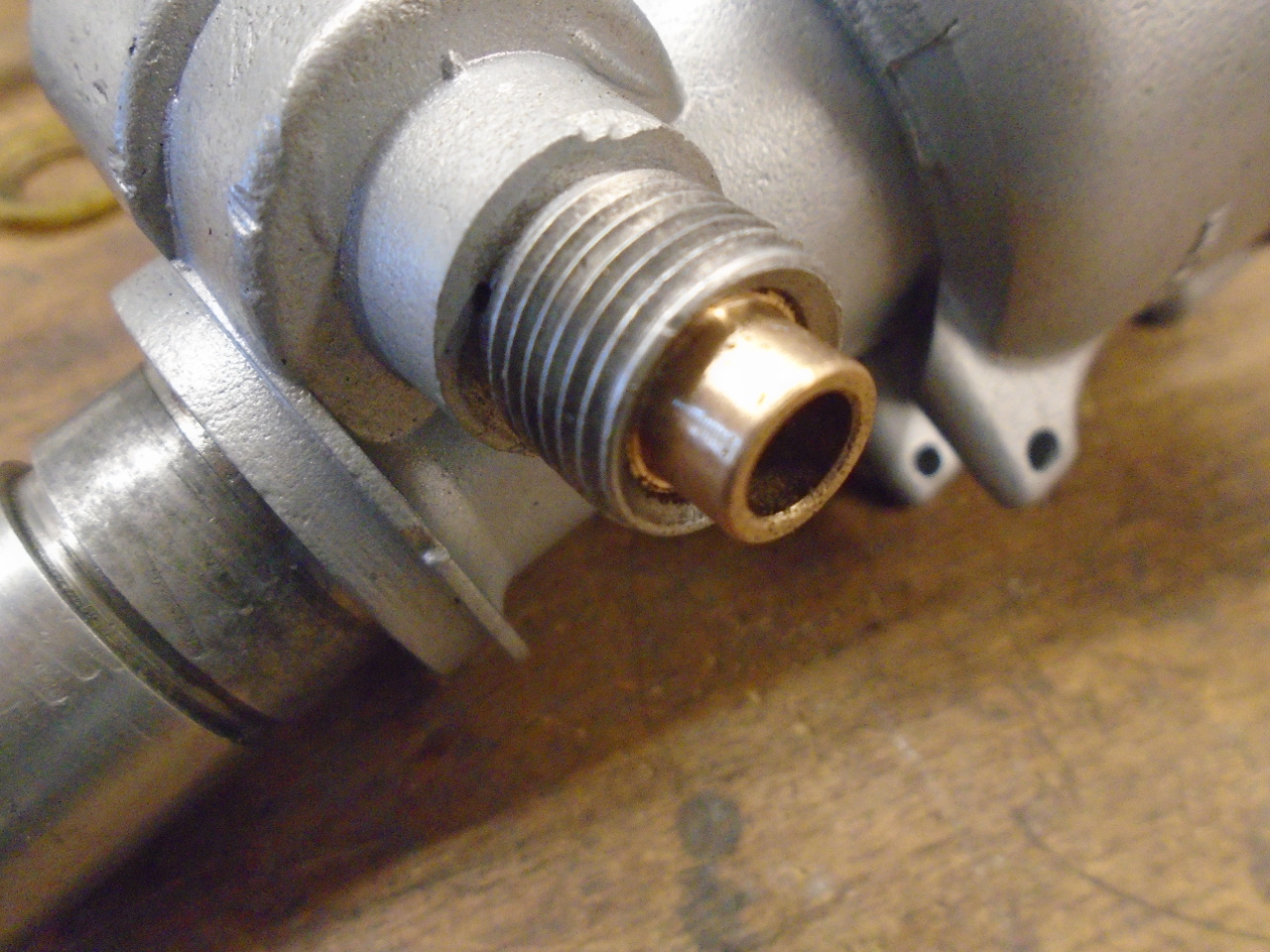

The tach drive bush was simple by comparison. It's a

standard size--7/16" OD x 1/4" ID. I couldn't find the

right length, though, so I went with a pair of shorter

bushes. The step had to be machined.

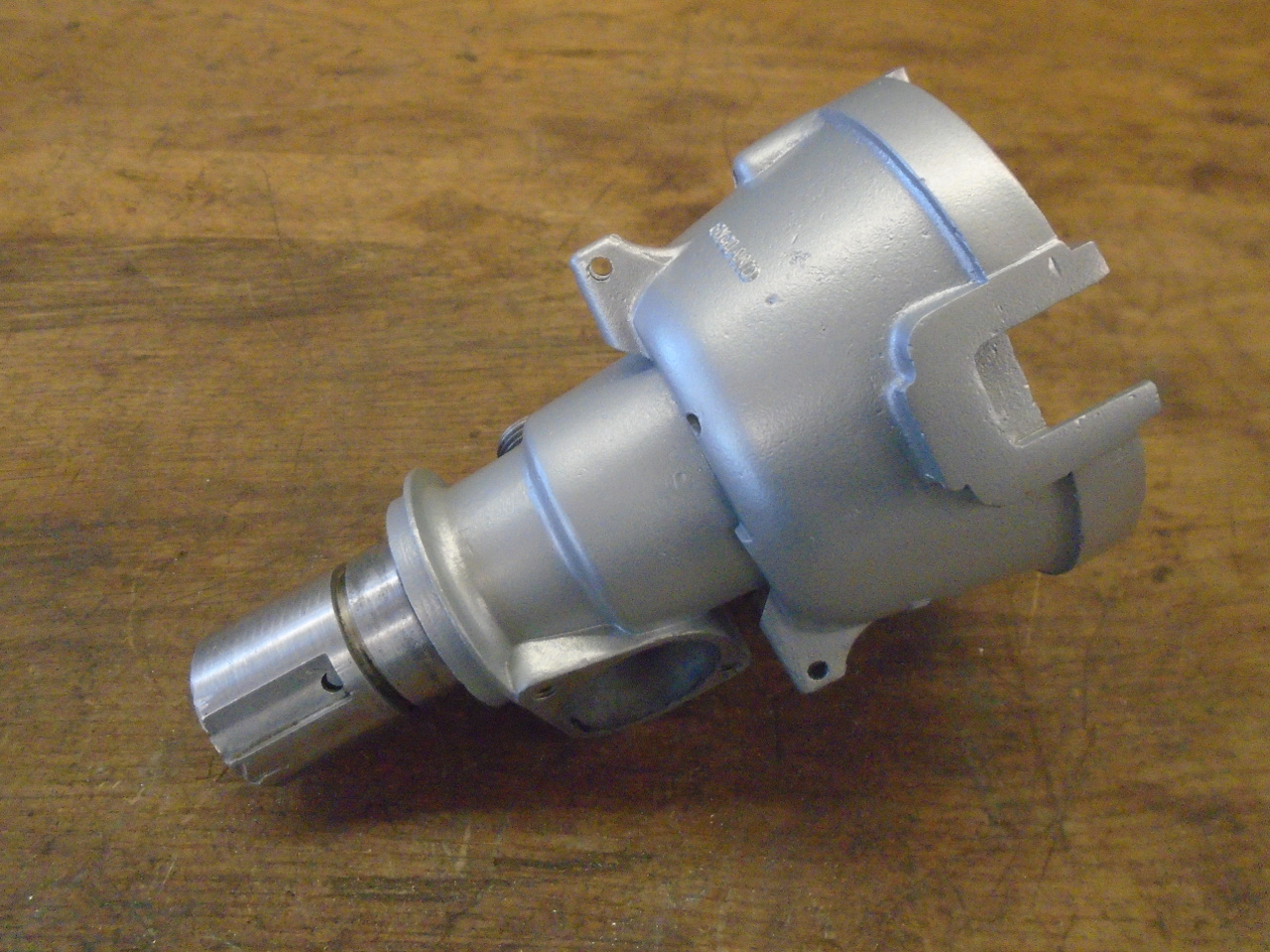

Assembled the tach drive bits, with a re-plated cap and home

made gasket, since I can never remember to order gaskets.

Then the drive dog, and a new O ring. The old ring was

cooked hard. The new one is Viton, which should take the

heat better.

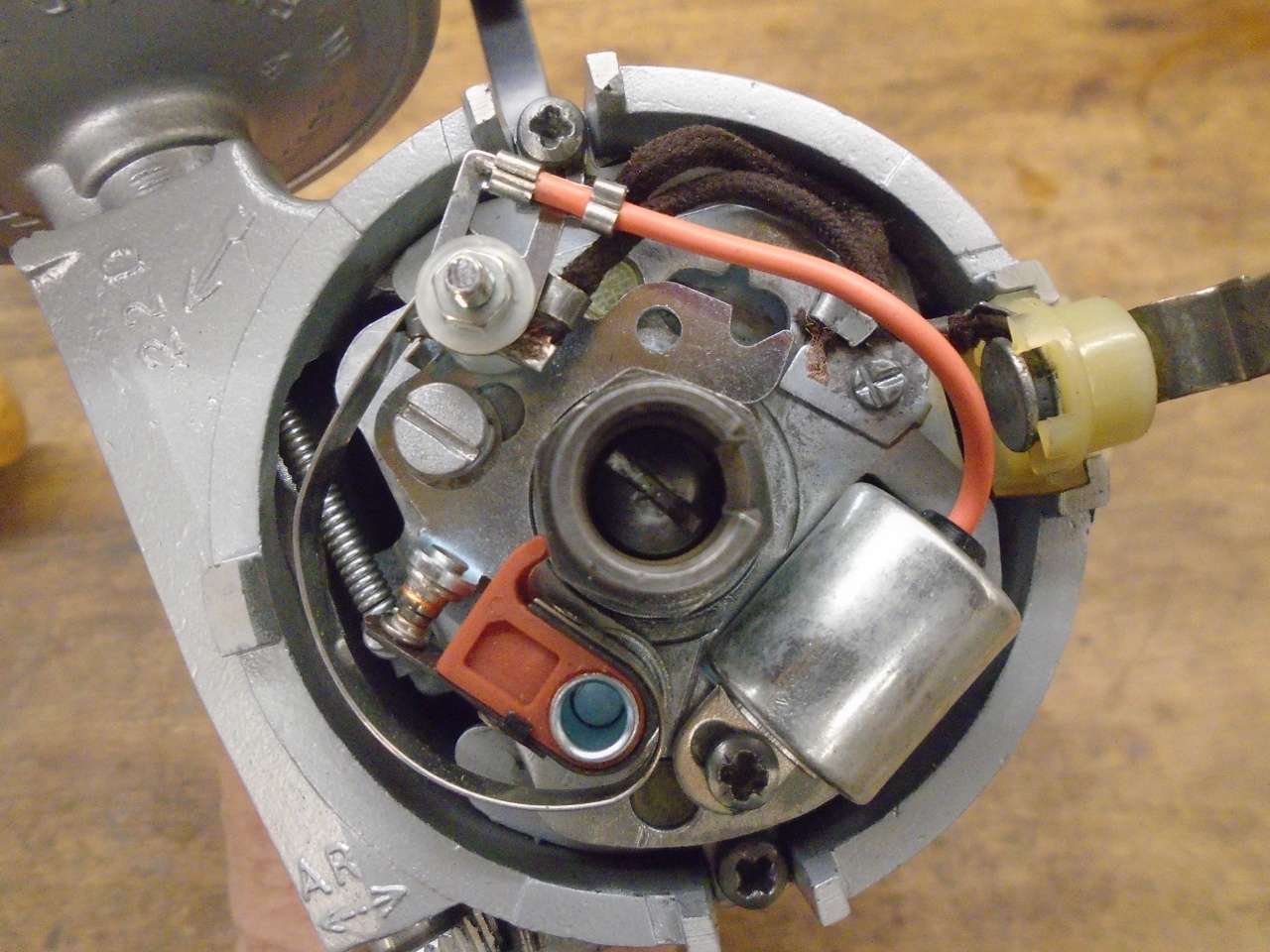

Then it was time to assemble the top end. I'm sure I

replaced the springs during the last refresh, so they are old,

but don't have many miles on them.

The main backing plate looked a little tired, but some new zinc

made it look new. The rotating plate above it was also

tired, but it has a lot of attachments on it, so I didn't want

to acid strip it. I just put a fresh flash coat of zinc on

top. It doesn't come out as shiny that way.

Next was the vacuum advance unit. It was dirty and rusty,

but cleaned up OK. I had no idea if it was still working

after nearly 50 years.

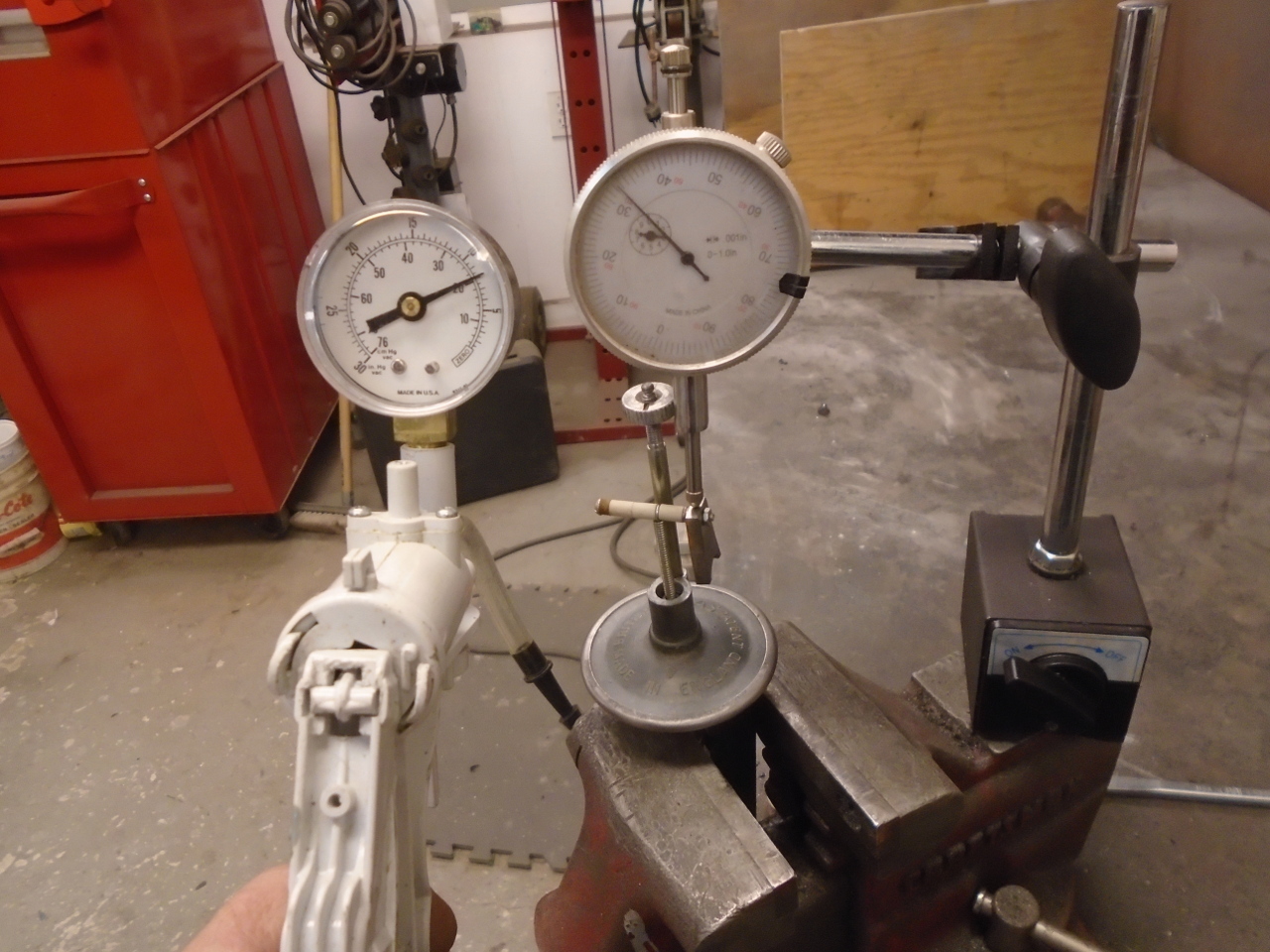

I was curious about that, so before just tossing it, I decided

to test it. I put together a simple test setup with a hand

vacuum pump and a dial indicator to show how much the actuator

moved.

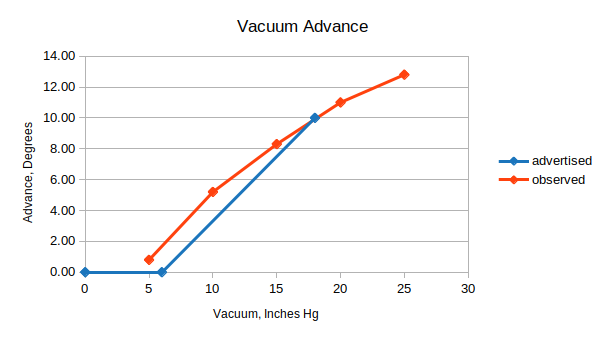

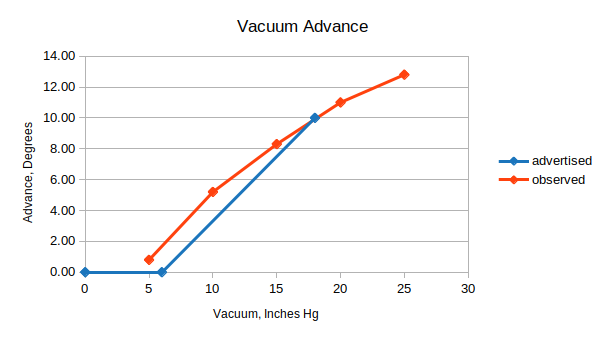

Here is the result. The advance unit is marked

"6-18-10". This means that the actuator starts to move at

6 inches of mercury, and at 18 inches, provides an advance of 10

degrees. The blue line shows the "advertised" advance

curve. The red line shows what I measured. Actually,

I just measured displacement of the actuator of the unit. I had

to calculate what advance would result from the movement.

I think the approximation

is pretty good, actually. No one really believes that the

code marking on these units are dead on accurate. I'm

going to go with this vacuum unit until I have reason to think

it isn't working.

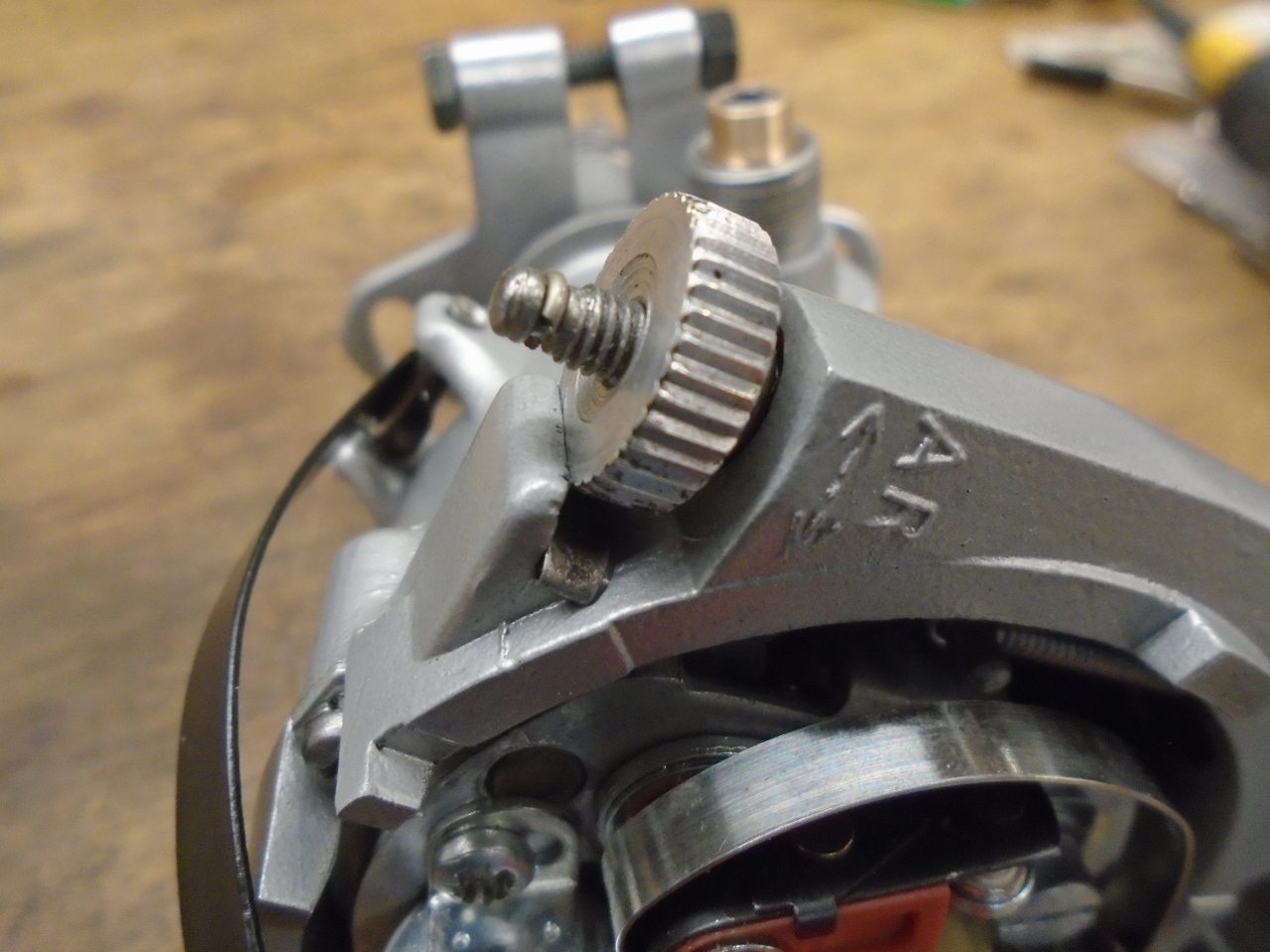

There was one little annoyance with the vacuum unit,

though. The timing micrometer adjuster wheel was really

worn. Its detents were all but gone. I guess you can

buy these, but I really wanted to wrap this project up, so I

devoted a couple of enjoyable hours to making one. It was

complicated by the fact that the thread is not imperial, not

metric, but the odd British 2BA.

The other parts of the micro adjuster. The spring was

missing, as was the little keeper for the end of the threaded

rod. A root through my "box o' springs" turned up a

suitable spring. The keeper was simply a coil snipped from

a smaller spring.

Powder coated the spring retainer arms and put them back in

place.

Installed new points, condenser, rotor, and cap. On the

shelf with this dude.

A few good challenges on this one. That keeps it interesting.

Cost was just for the tune-up kit, what ever that was, plus

something under $10 for the bushes.

Comments to Ed at: mailto:elhollin1@yahoo.com

To my other GT6

pages