To my other GT6 pages.

May 12, 2023

Parcel Trays

Most cars in recent memory offered some rendition of a so-called "Glove

Box". Apparently a throwback to a time when Gentlemen always wore

driving gloves when motoring about, it usually consisted of a

compartment in the dash with a (usually) lockable door. Designers

of the GT6 and cousin Spitfires broke from that tradition. It

would be nice to think this was from strict devotion to an aesthetic

design vision, but it's possible that cost was a factor, too. In

lieu of the traditional glove box cubby, they chose a pair of simple

open trays, one on each side of the car under the dashboard.

Styling questions aside, the execution of these trays is seen as a

disappointment to many. They are supported by a pair of padded

struts fixed to the A posts on their outboard ends, and by dash brackets

inboard. These struts look and work fine, and I had renewed them previously.

The trays themselves were box-like constructions made of a cardboard

material that tended to swell with moisture, and fray at the edges and

around the fasteners. Mine were in bad shape when I removed them,

and didn't really improve while stored in the shed for a few years with

stuff piled on top of them.

I decided to attack the passenger side tray first.

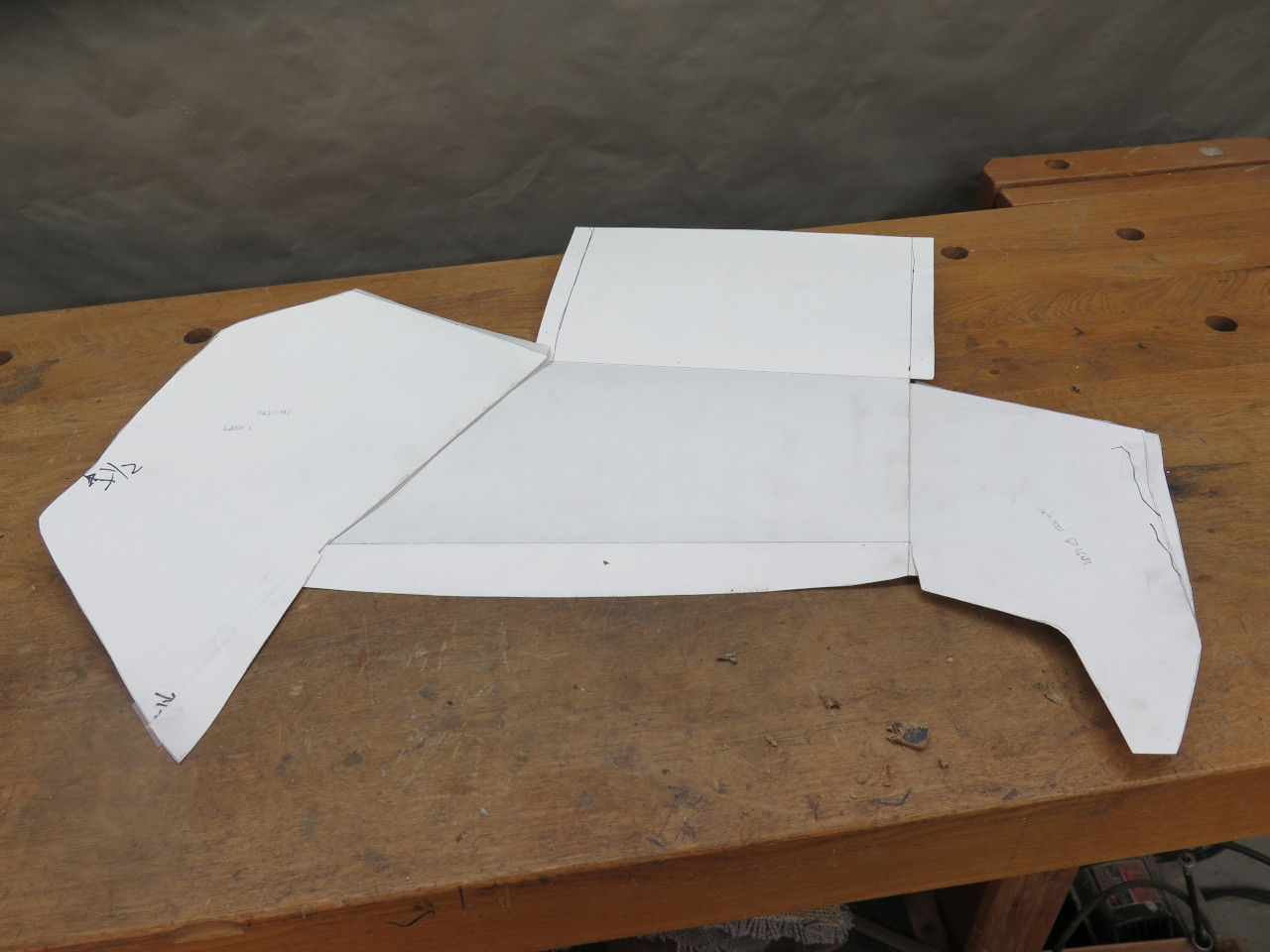

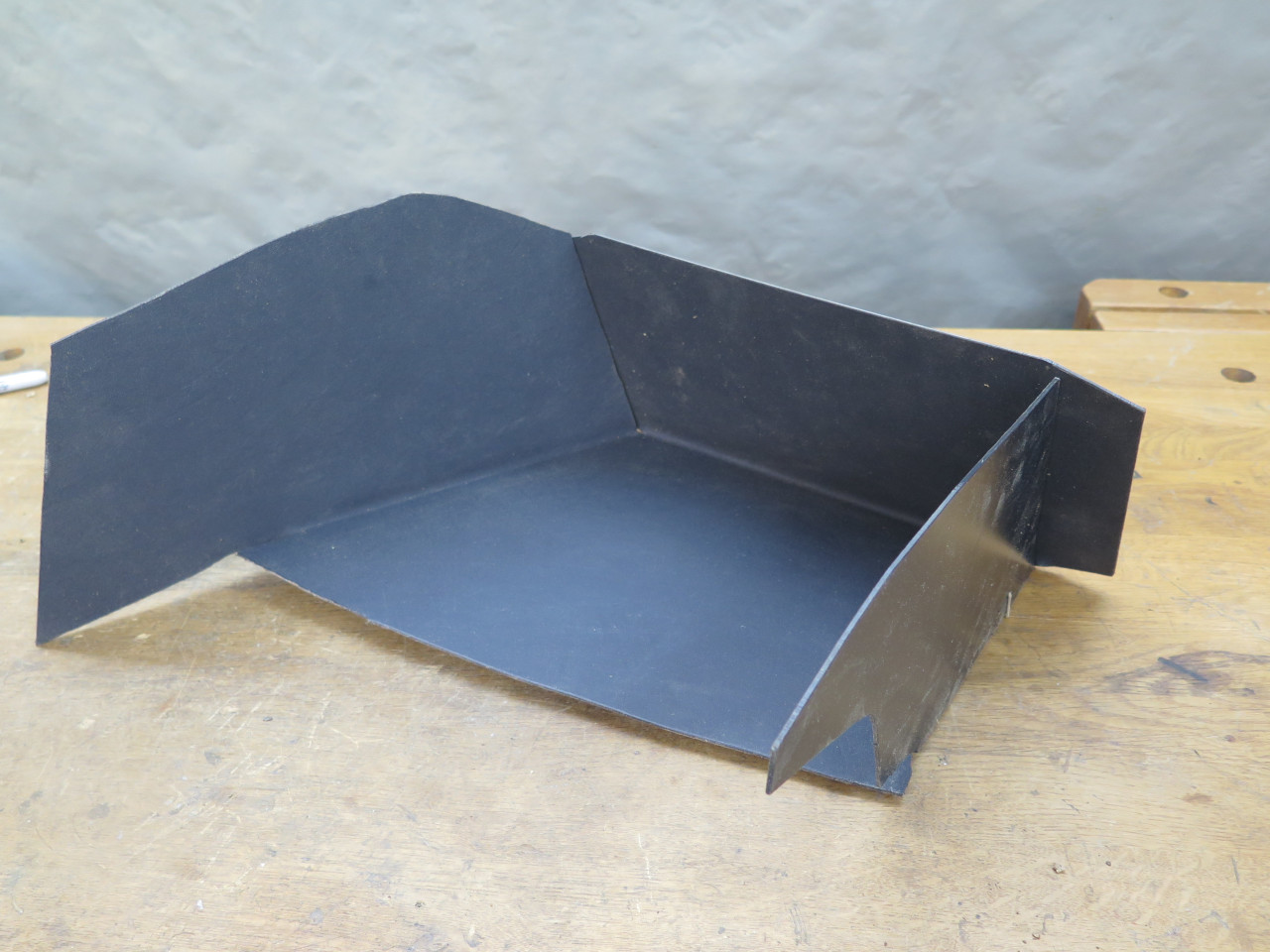

The tray was made from three parts stapled together. I separated the parts to help me see if there might be a better way.

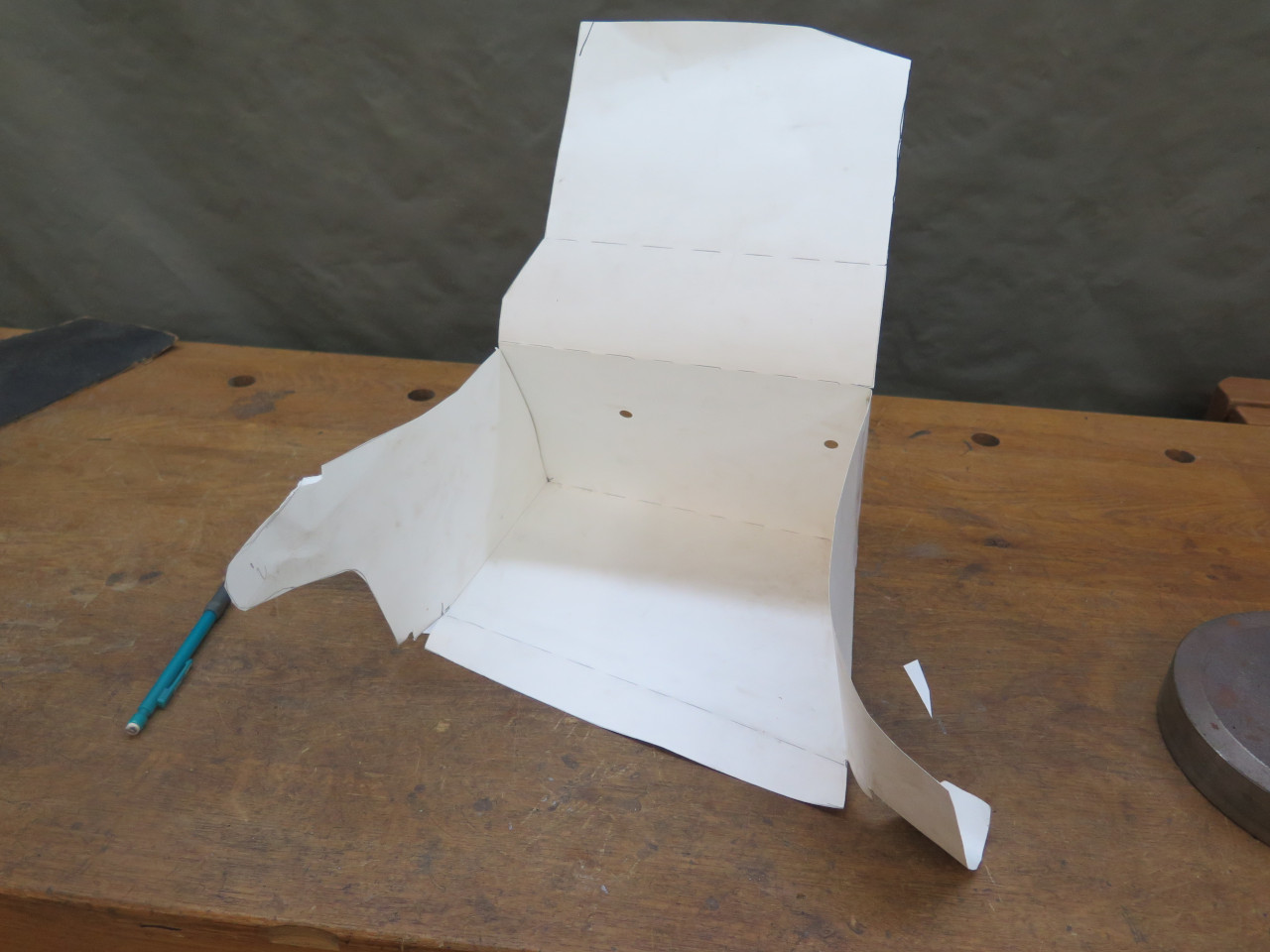

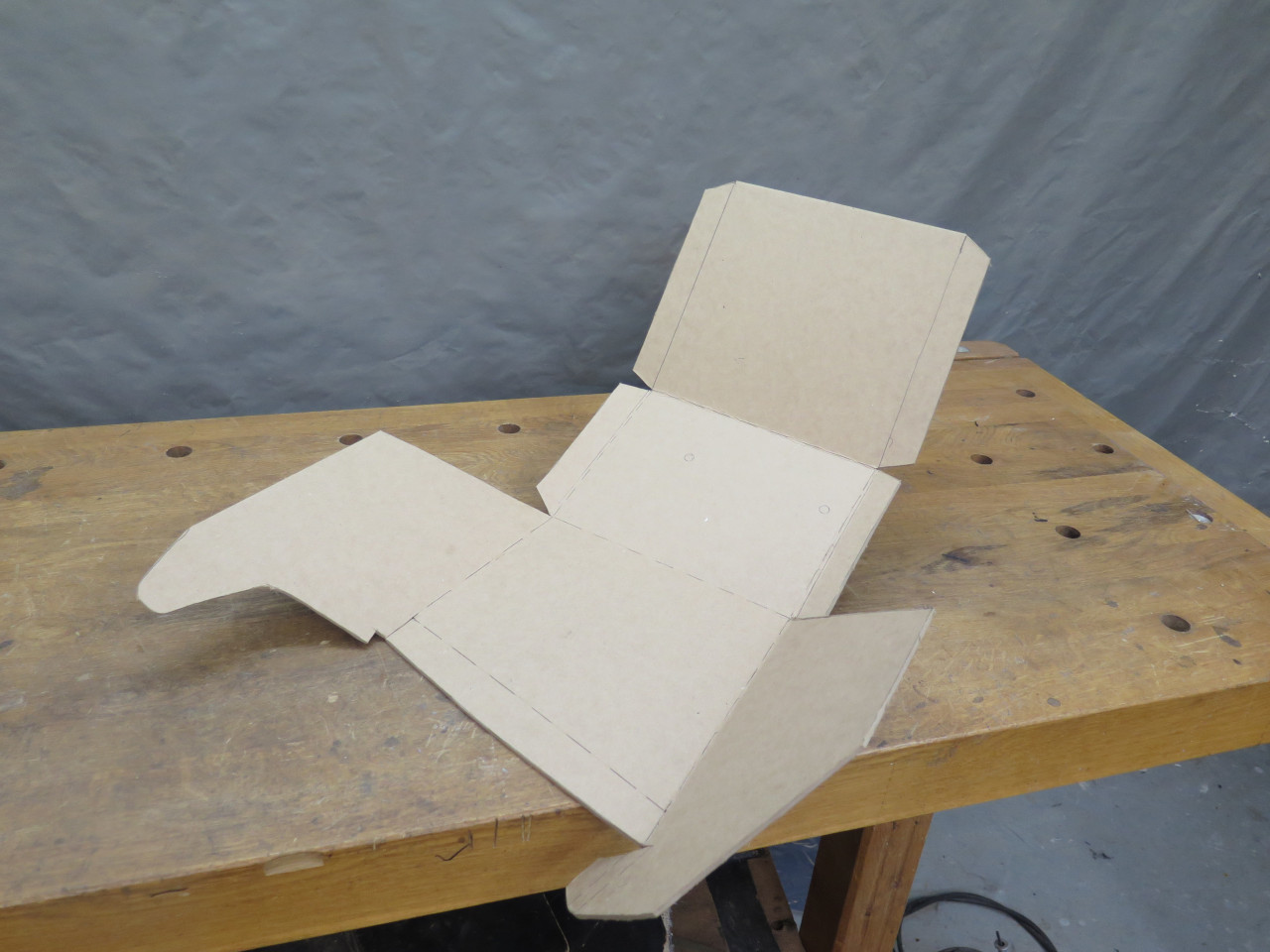

It seemed to me that this box could easily be made from a single folded

sheet. This would eliminate the clumsy stapled overlap

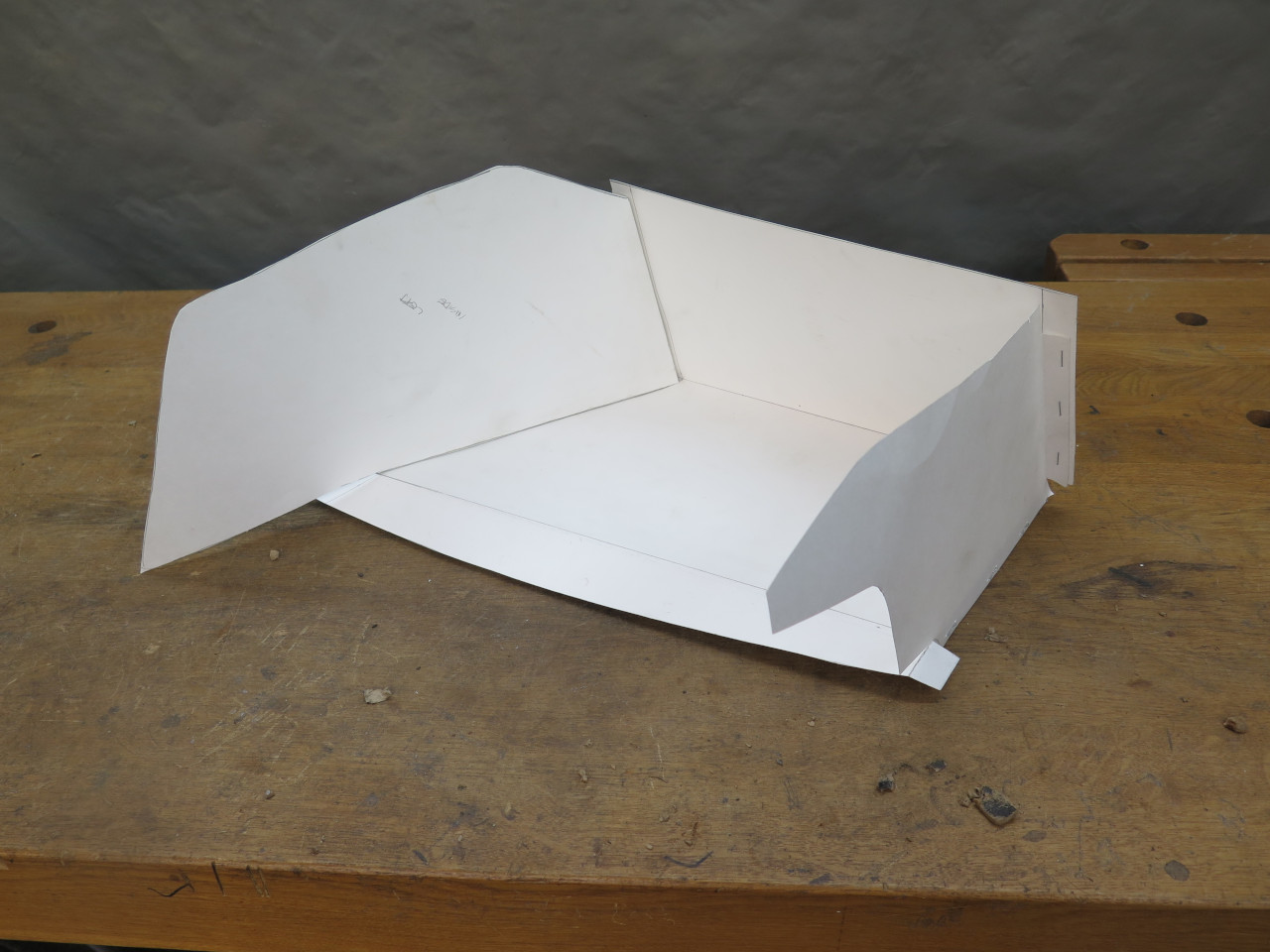

joints. A heavy paper model showed that this approach might

work. I marked a few adjustments on the pattern to improve the

fit.

This was encouraging, but the paper wasn't stiff enough to be

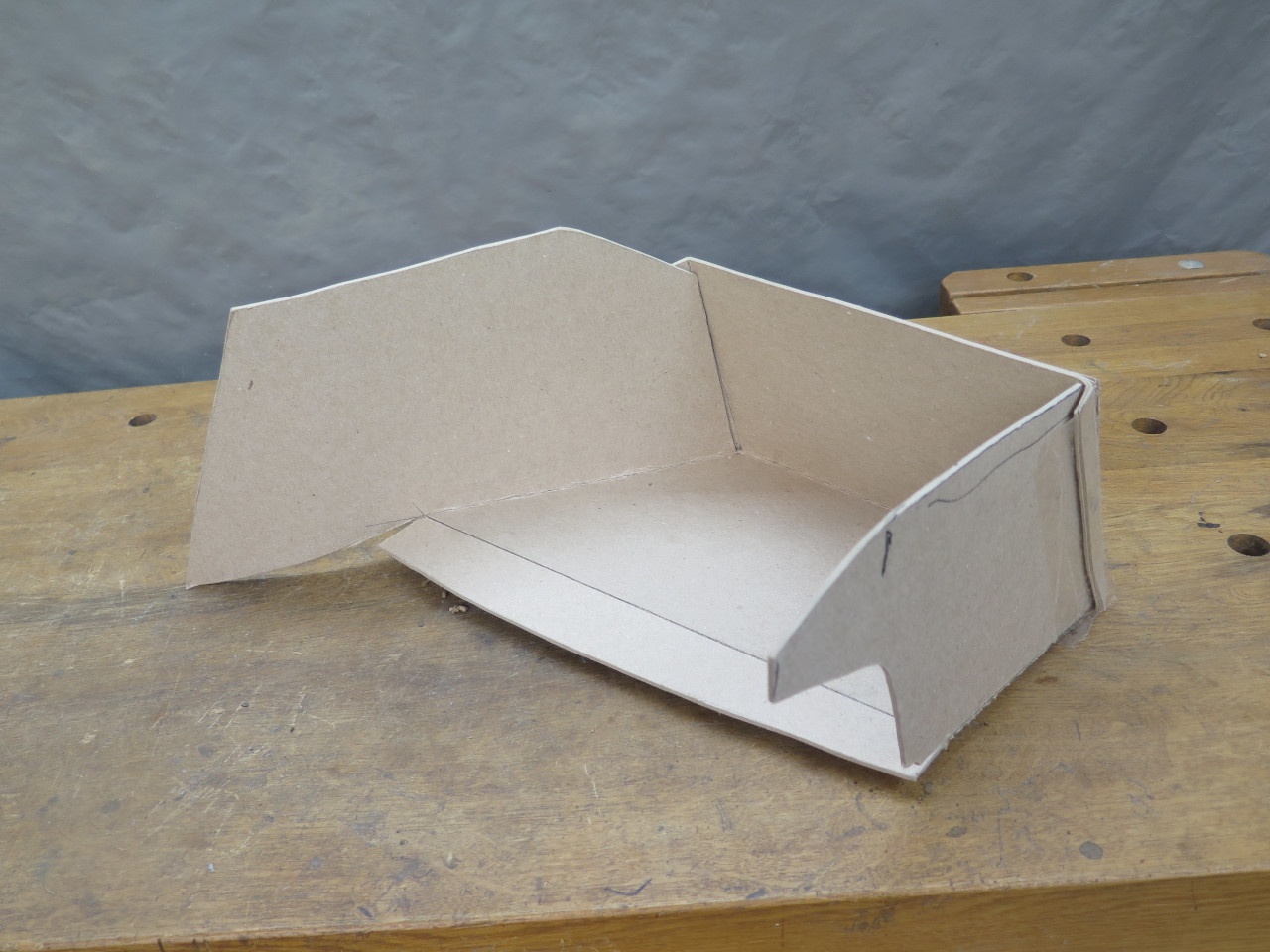

sure. I transferred the pattern with tweaks to some 2 mm chip

board, which isn't too dissimilar to the original material. The

inboard wall of the box has to be curved to meet the support rail.

I decided this would work fine, but really needed to land on the final

material to make the trays from. Just painting the chip board

might give me something close to the factory original, but I thought

there were better choices. I considered aluminum sheet, but

thought it might be vulnerable to denting or scratching. Some sort

of plastic sheet seemed like a good idea. I landed on Kydex--a

PVC/acrylic blend that has some good properties. Originally

developed for fire retardant bulkhead panels for aircraft, it is today

commonly used to make those form-fitted firearm or knife holsters.

Kydex is very tough and stiff, but when heated to around 300º

F, it goes limp so it can be bent and shaped. It cools fairly quickly to hold the new shape.

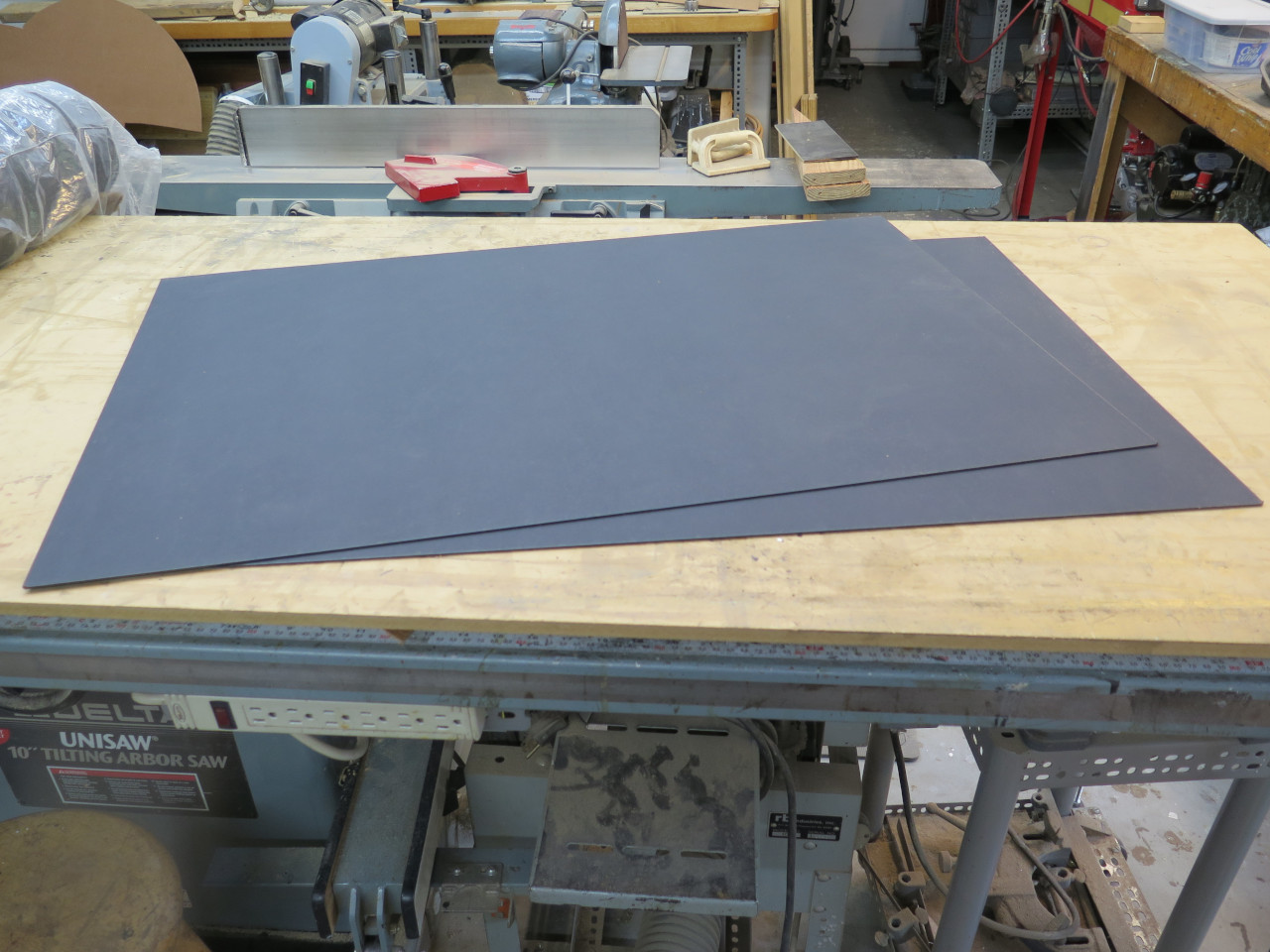

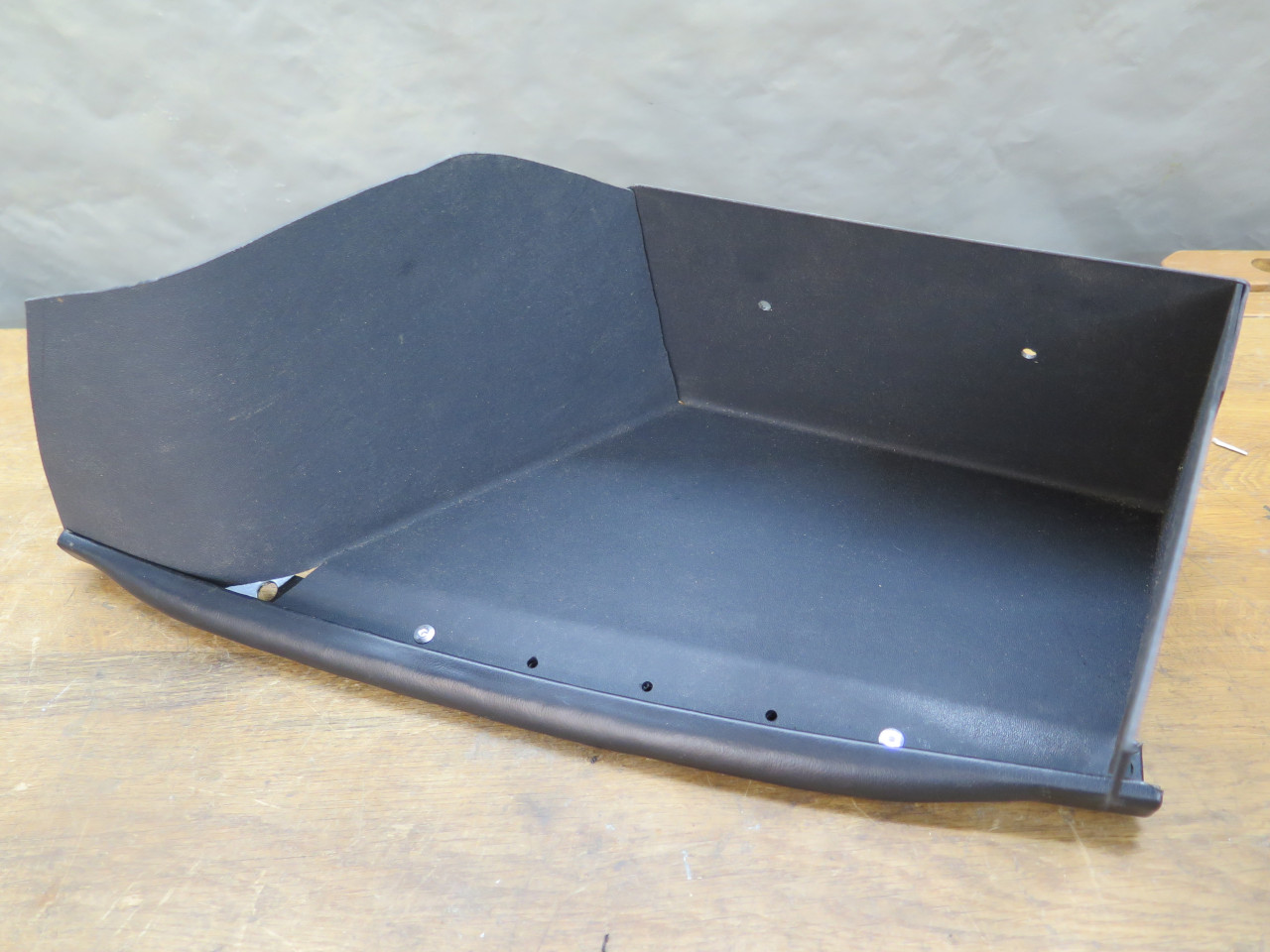

The Kydex I bought is 0.080" (2mm) thick--about a third thicker than the

original cardboard. It has a matte textured surface and a shinier

less textured surface. I'll use the matte side for the interior

of the trays.

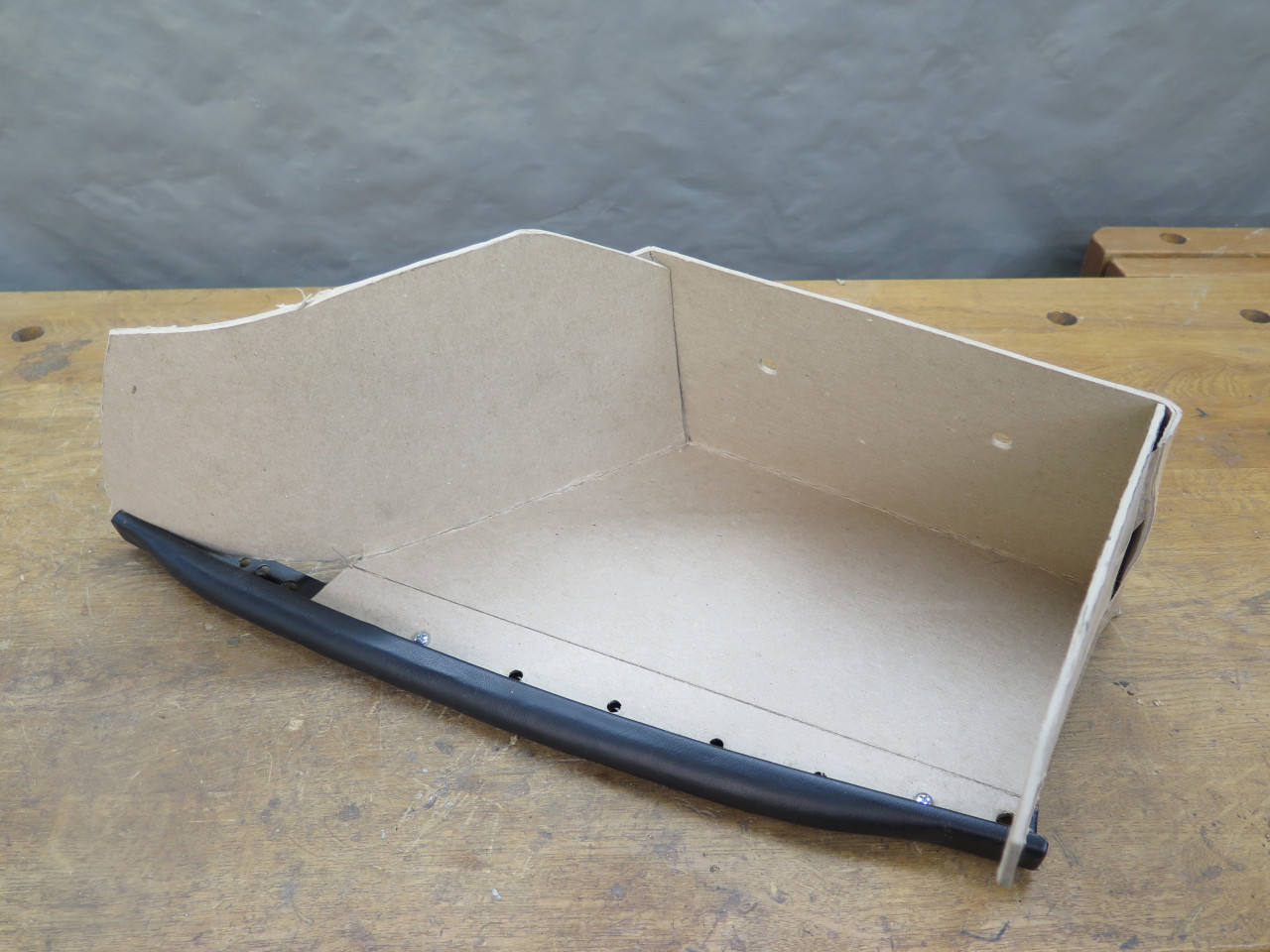

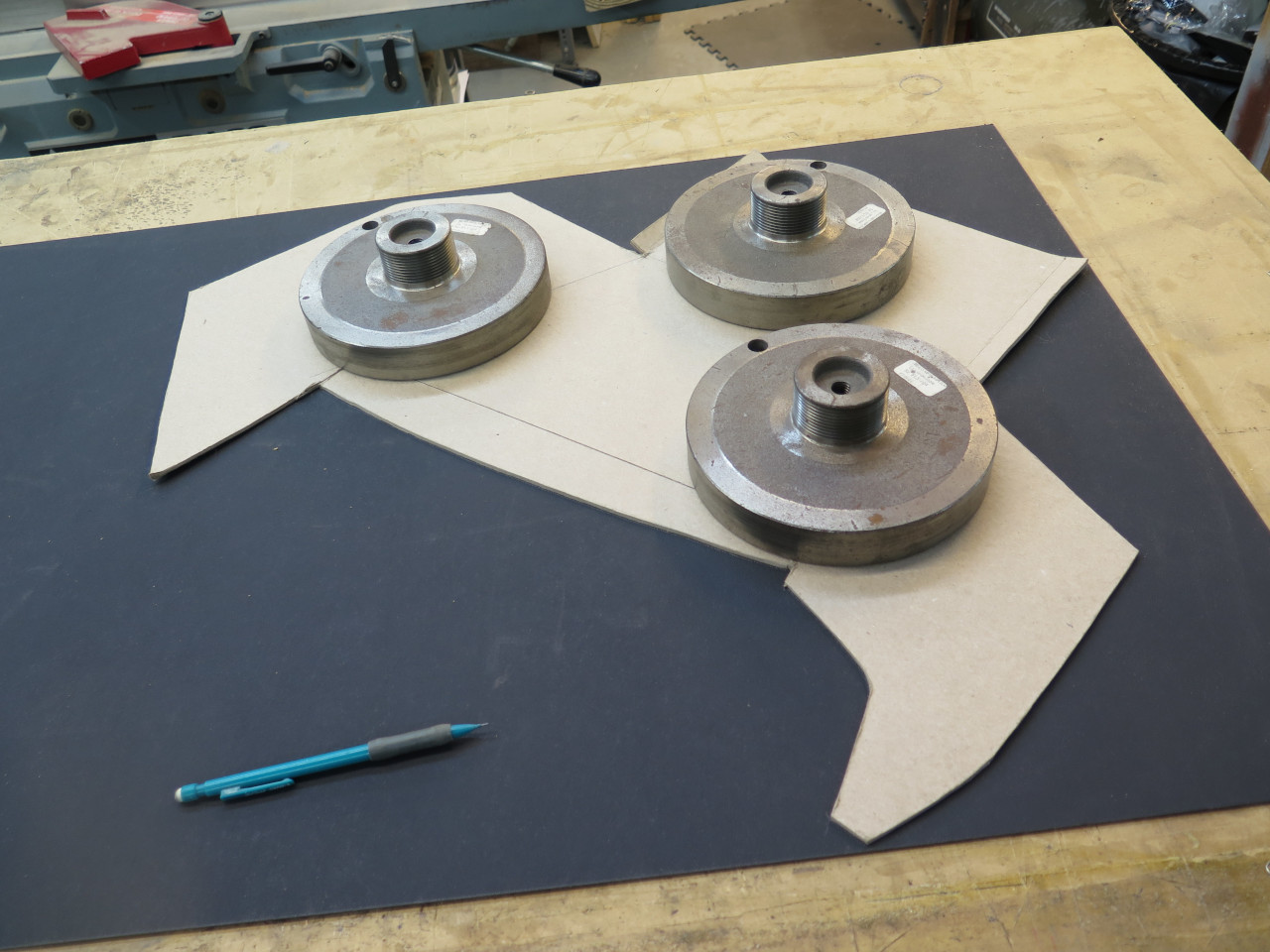

I unfolded the chipboard pattern and transferred the information to the plastic.

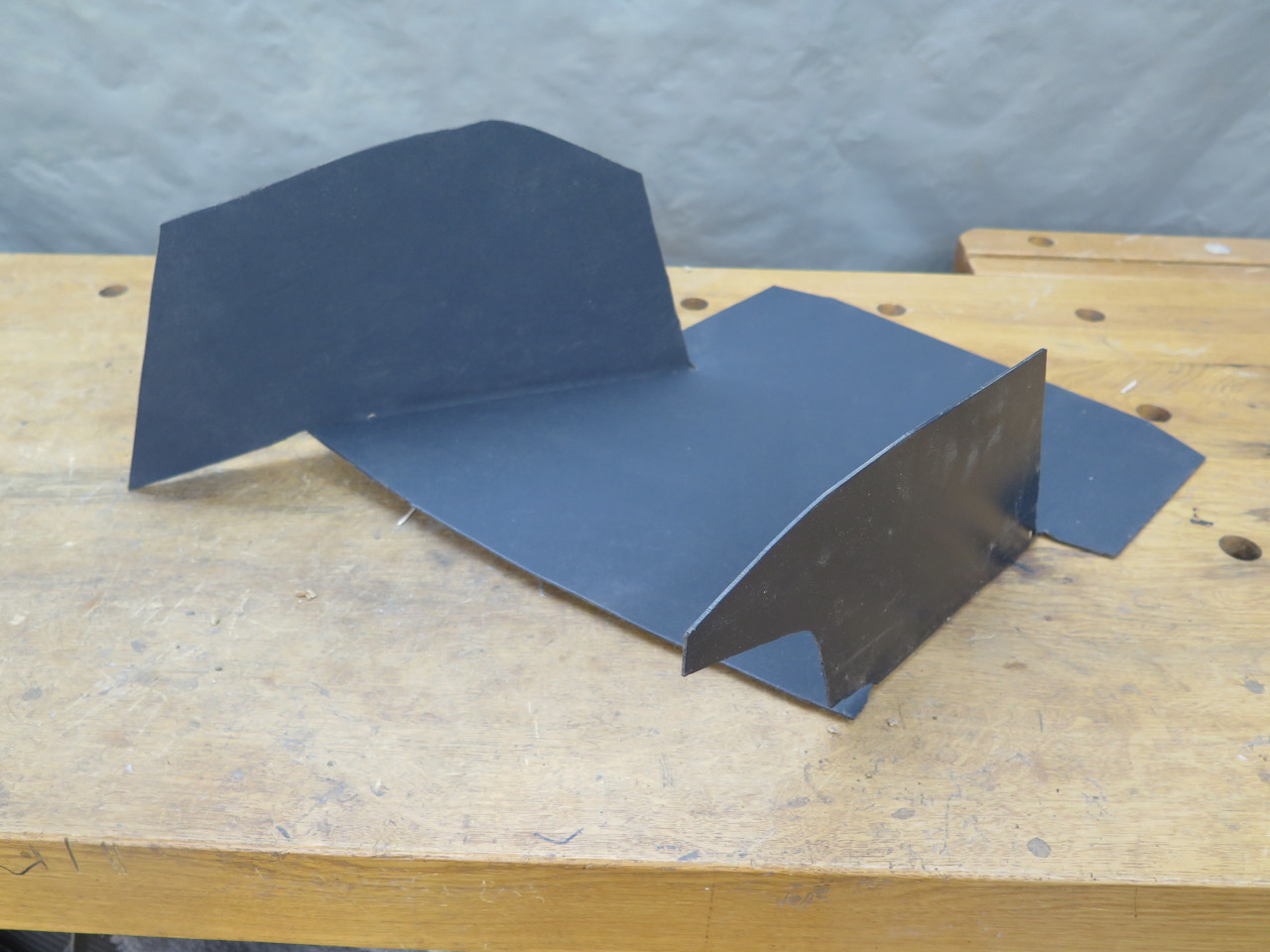

Then, using localized heat and some crude fixturing, made the bends.

Finally, glued the flaps in the back, drilled holes for the support and rear fasteners, and bent the curve on the left side.

After some more slight tweaking, it fit pretty good.

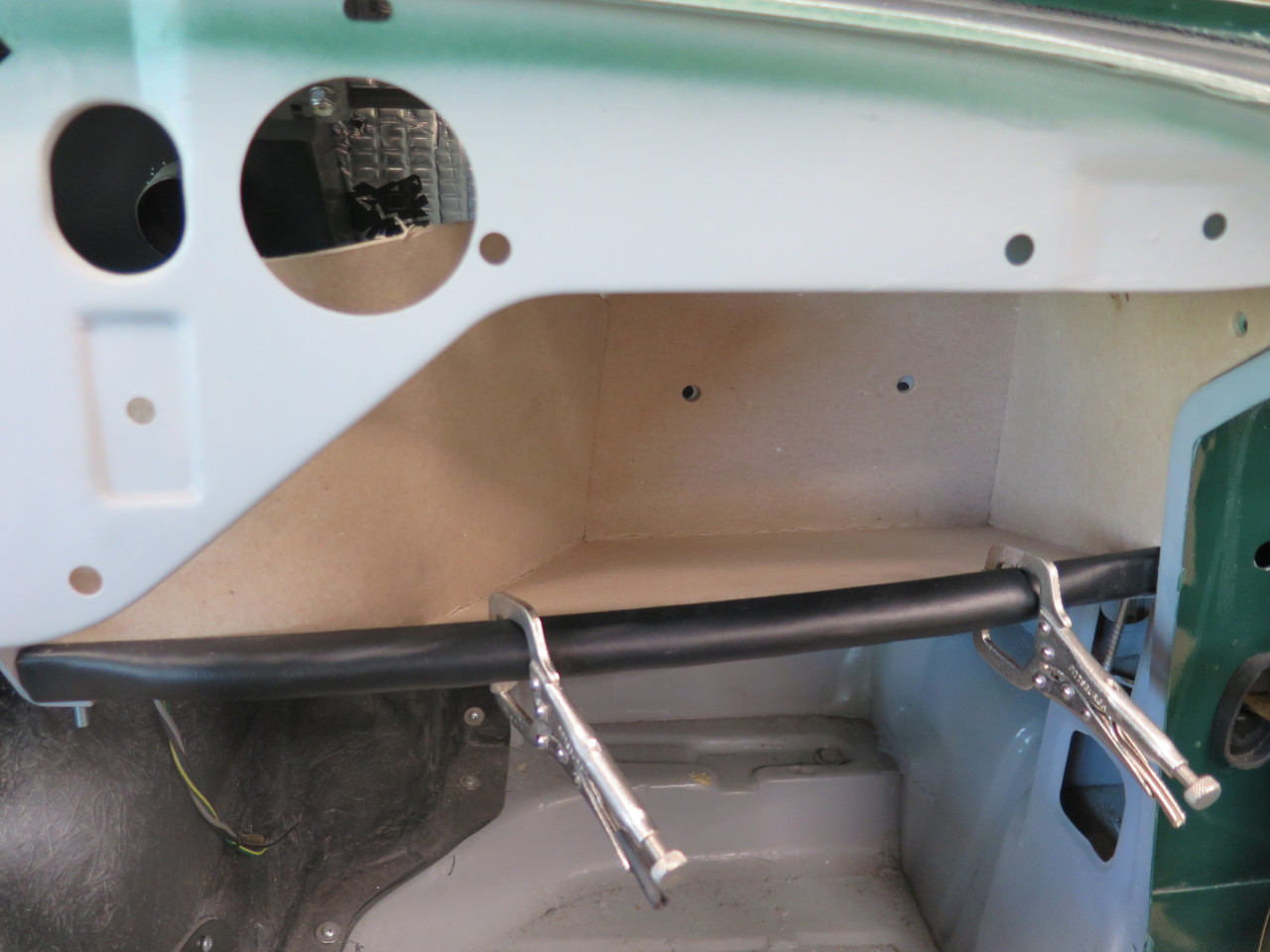

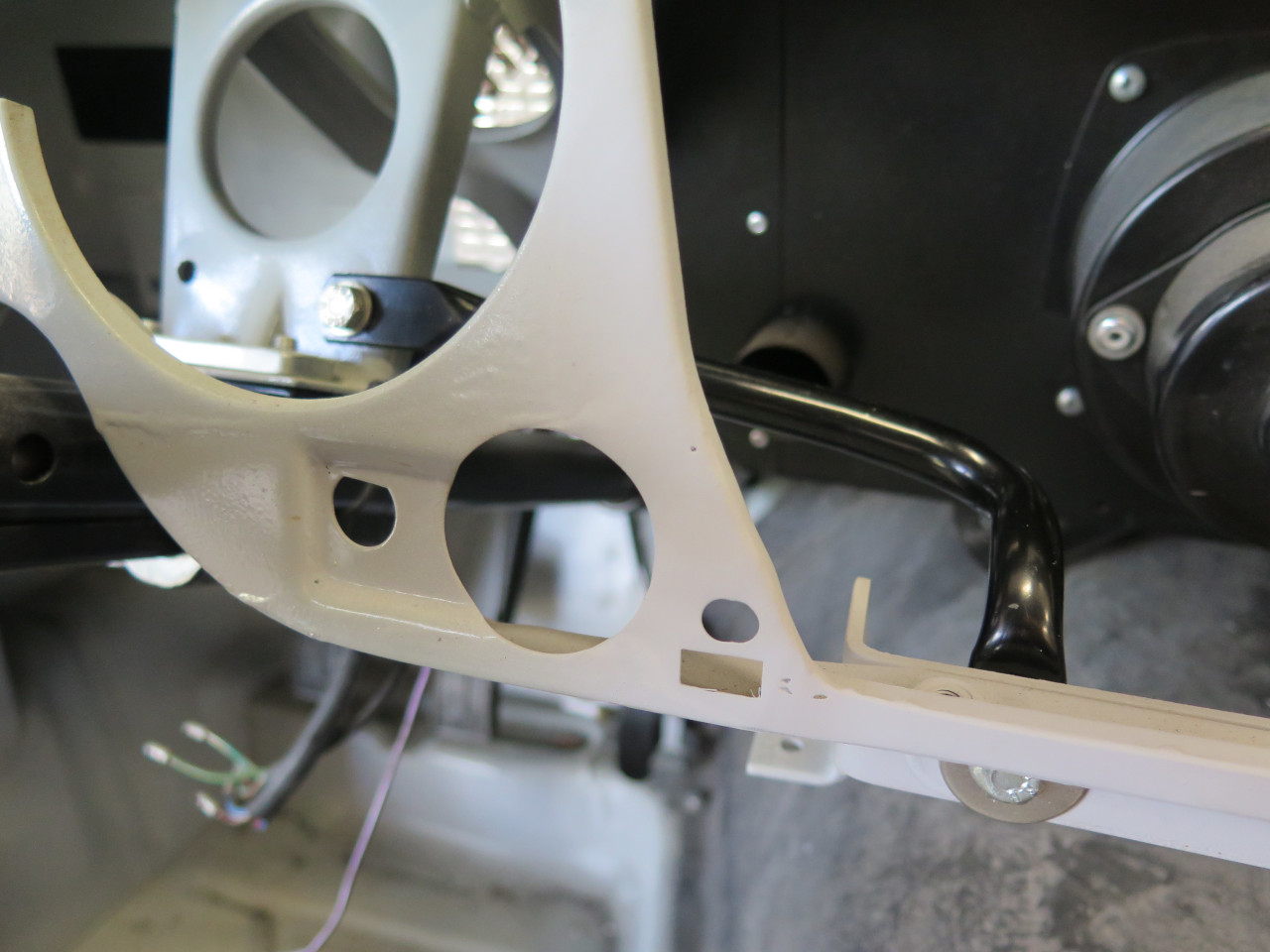

Before test fitting anything to the dash, I fitted this brace. I

was surprised how much if stabilizes and locates the metal dash.

The drivers' side was similar, but differed in a few ways. First,

it is smaller, only extending to the steering column. Second, it

has a top, where the other side was open on the top. Third, there

was a little tail appendage on the inboard side that had me stumped for a

while.

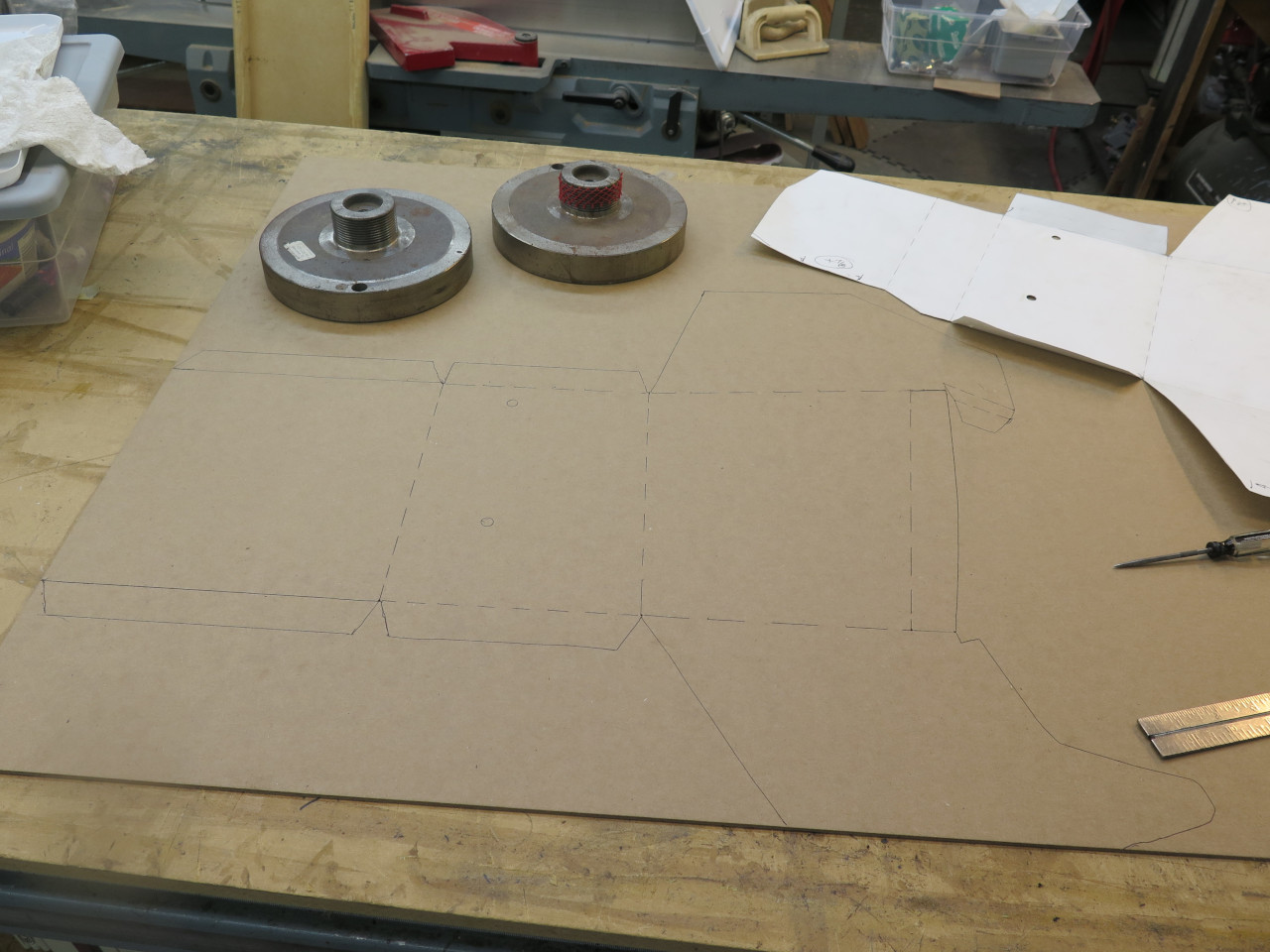

Transferring to paper pattern, overlapping the seams:

Trial of paper pattern:

Chipboard pattern:

Fits OK after some adjustment. The tail on the right side has to

curl around under the steering column ans attach to the support rail.

Then, to plastic:

Probably looks a lot like it did when new.

A little hard to see, but they should look nice with the dash and dash support.

This was a fiddly project, with many fit, mark, remove, tweak, fit

cycles. I'm not sure I saved any money on this job, but I think

these trays are stronger and more durable than the available

replacements. Cost was around $90 for the Kydex and the template

materials.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.