To my other TR6 pages

February 4, 2016

Seats

[Click the pics for a larger view]

I've

always liked the stock seats in the TR6. They seem to fit the

spirit of the car--simple and utilitarian, but with a small touch

of padded luxury. I bought the car when it was just a few years

old, and I remember thinking how comfortable the seats were.

While many see fit to swap foreign seats into the TR, I don't see

any reason to, and wouldn't consider it an "upgrade". Buying a

pair of seats from a Miata or some other car certainly would have been

easier and probably cheaper. This was a very involved project and

an expensive one. I have the better part of $1000 in the seat

rebuilds. It is also the first project on this car where I

sometimes felt I was close to being in over my head.

Both

of my seats were beyond tired. They were dirty, misshapen, and

smelled bad. The drivers seat had large open tears in the vinyl.

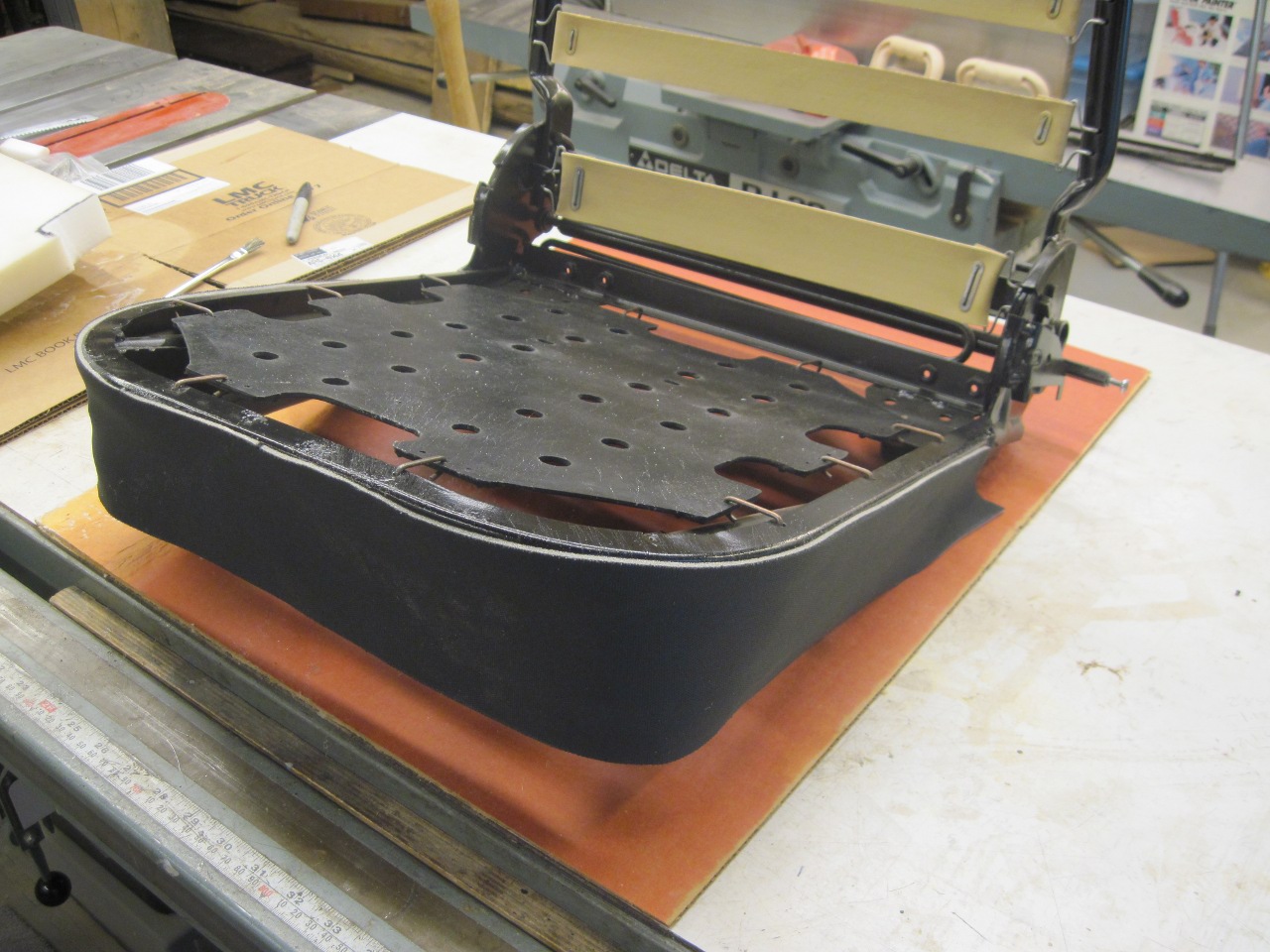

I

carefully removed the vinyl covers and the padding, trying to note how

everything went together. Under the seat bottom cusion, the

rubber diaphragm was amazingly still intact, but was cracked badly.

When

I pulled off the seatback cover, much of the internal foam

literally fell out in a pile on the table. I kept all the

original foam and vinyl in case I had to refer to it.

I stripped all the foam remnants off the frame to get a good look at it.

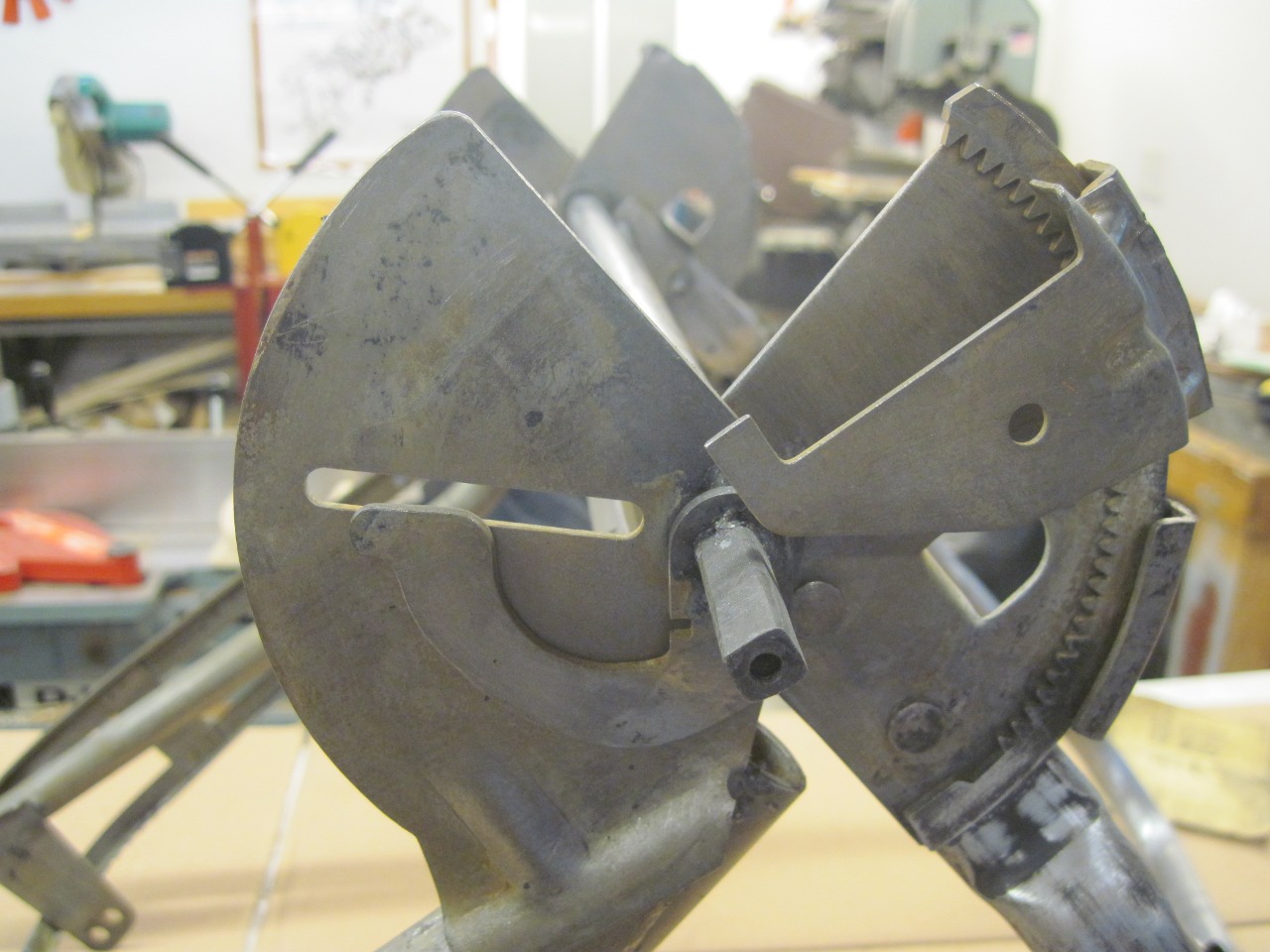

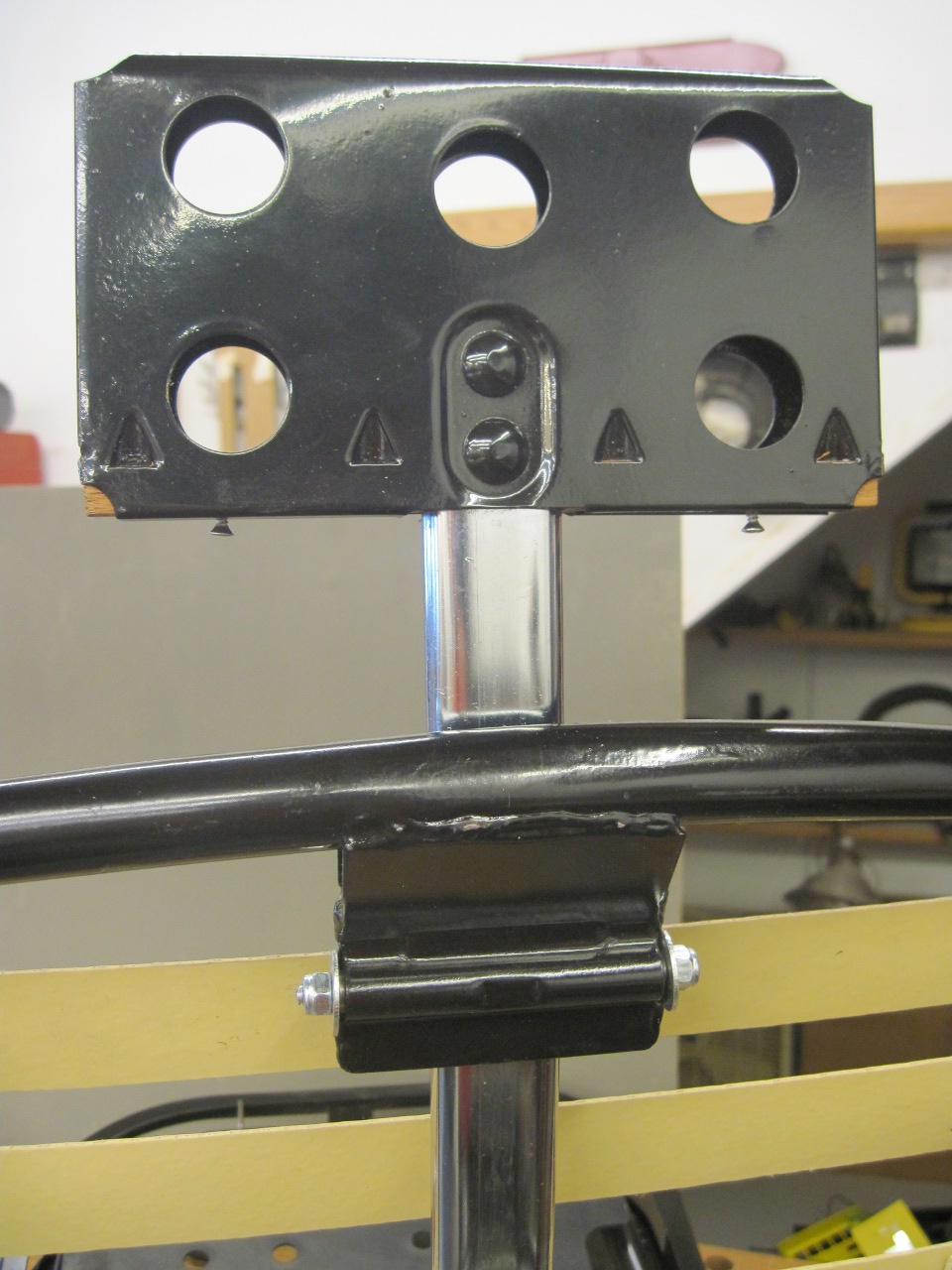

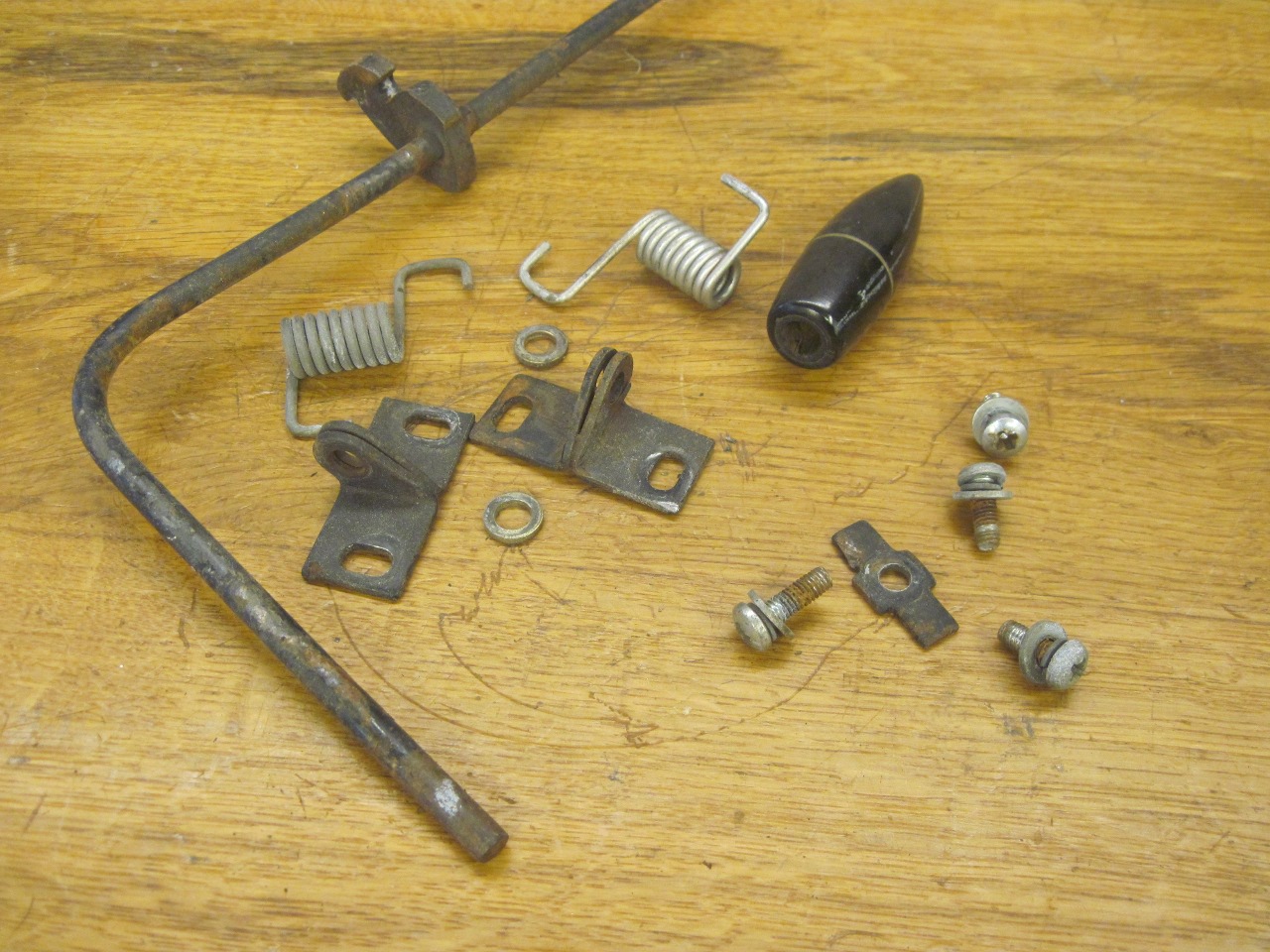

As

far as I could tell, the frame was rrusty in places, but wasn't damaged

in any way. The recline mechanism was very stiff. The seat

recline lever turns a shaft that rotates a cam on each side of the

seat. The cams retract multi-toothed pawls that engage with

fixed teeth on the seatback frame. A folded torsion spring spans

the back of the seat to help bring the seatback to the upright position.

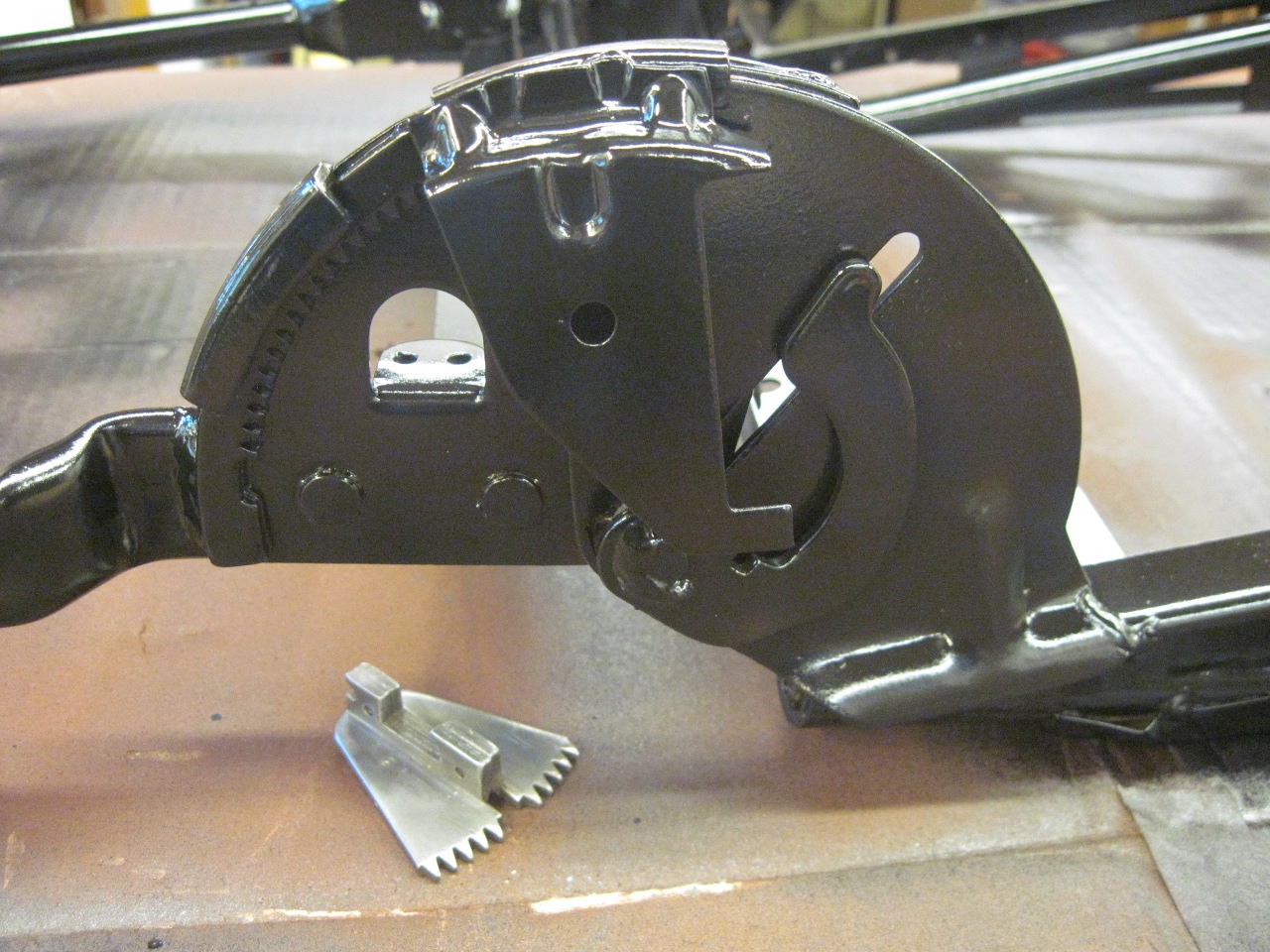

The

first order of business was to derust and strip the paint off the

frame. A nice soak in a phosphoric acid bath took care of that.

The acid leaves a grayish-reddish mottled coating on the steel,

which is only somewhat protective, but is an excellent base for paint.

A prime and a couple of coats of black paint made the frame look a lot more presentable.

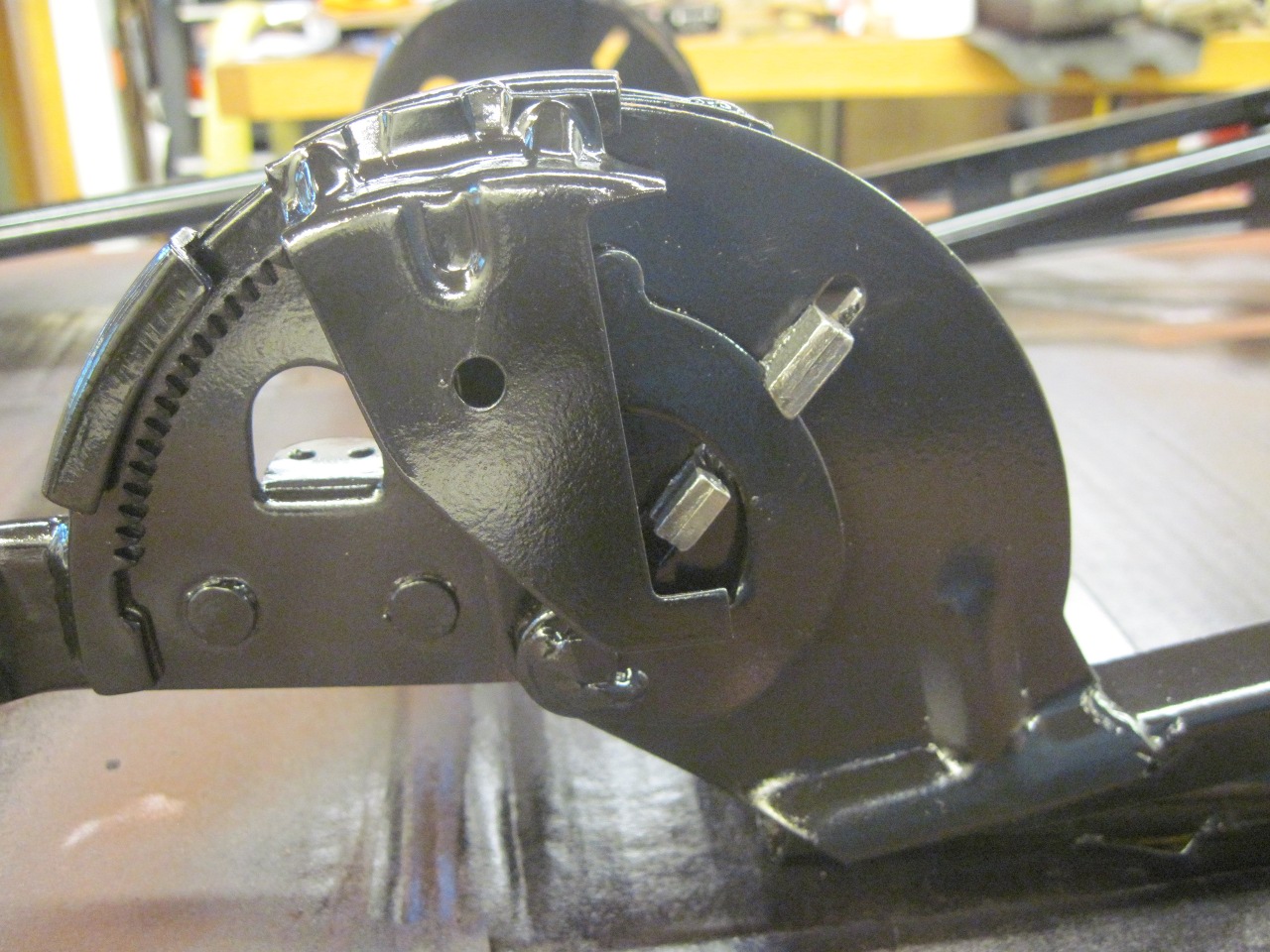

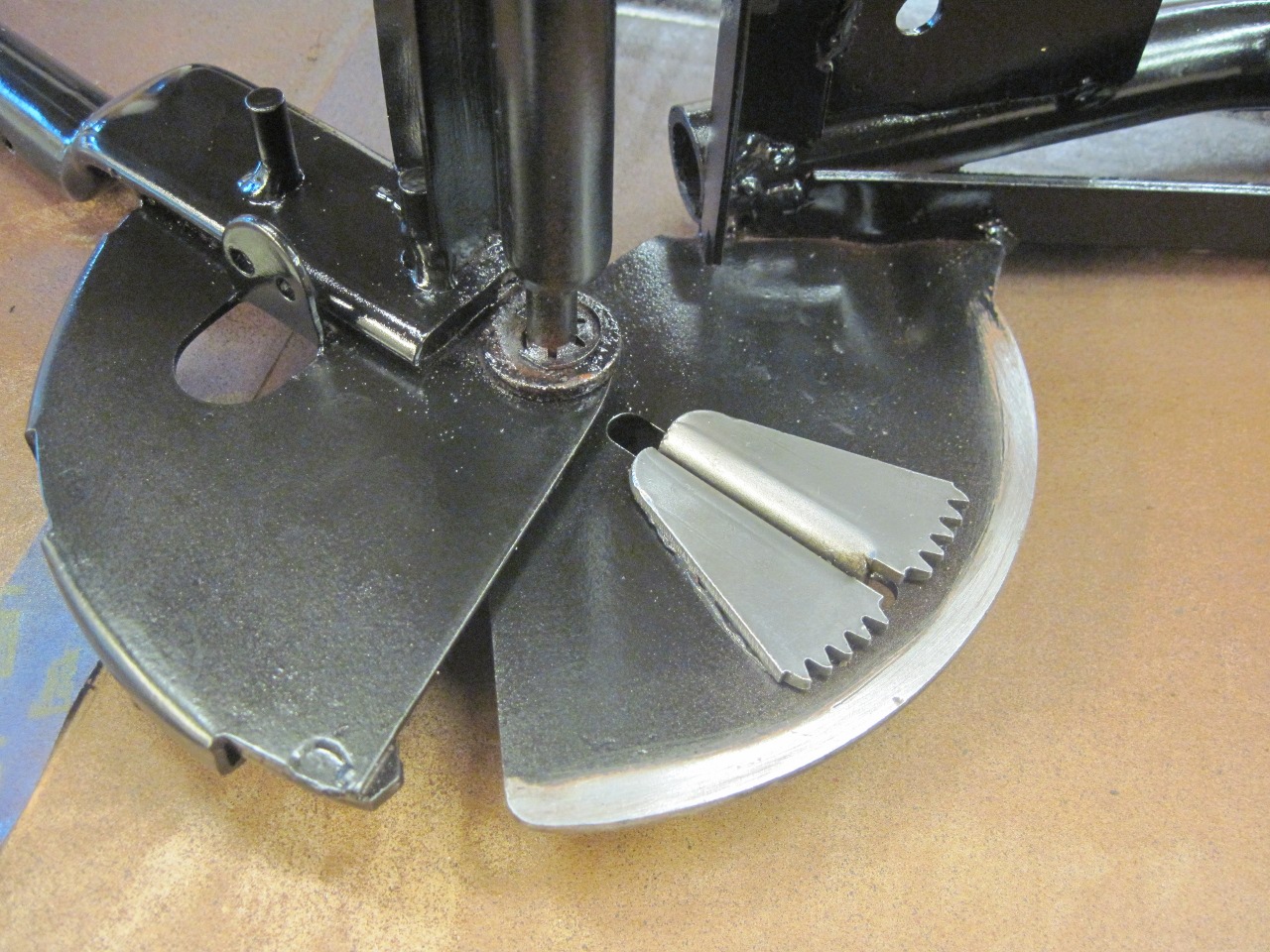

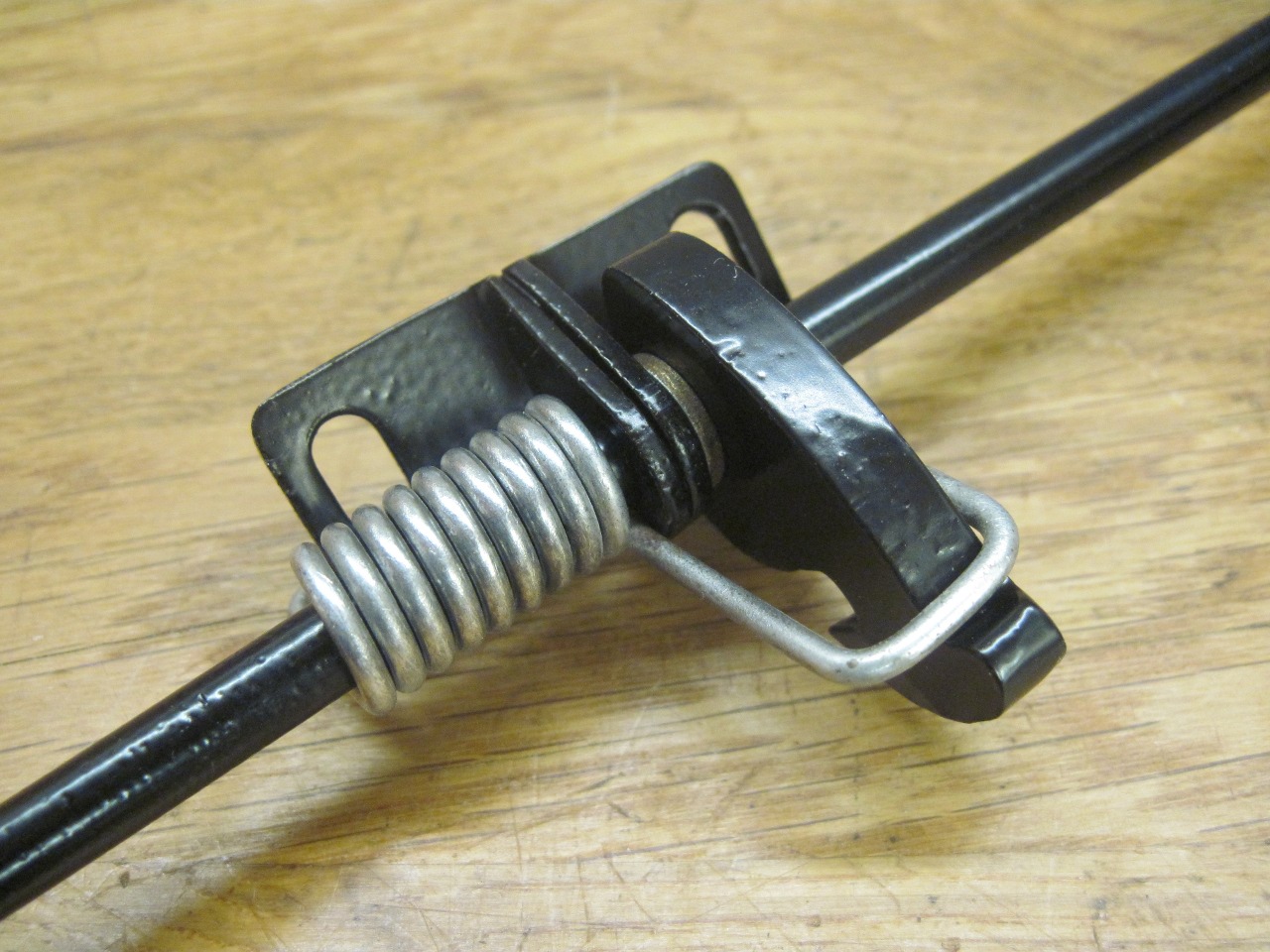

I

had previously removed the pawl to help with the cleaning, so it now

went back into place with fresh lubrication. The last pic shows

one of the springs that keeps the pawl engaged when the lever isn't

pulled.

Torsion spring powder coated and installed.

I did one seat at a time so I could refer to the other one.

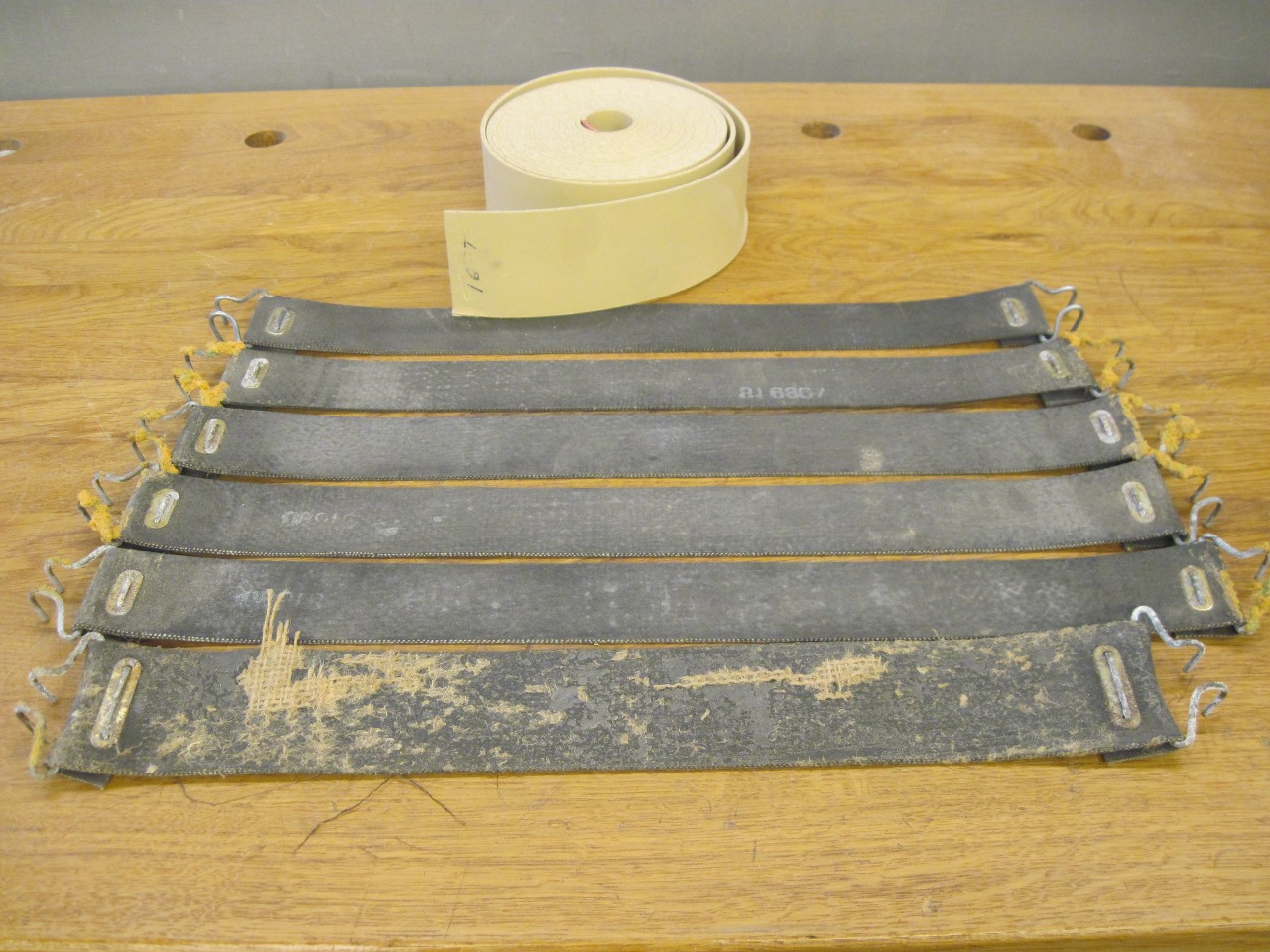

Next,

I restrung the seatback straps to try to determine if they needed to be

replaced. A couple of them seemed pretty loose, so I decided to

replace all of them.

In back of the straps is 16 feet of "Pirelli" strap, used by upholsterers for this kind of thing.

I

was pretty sure I could reuse the end hardware from the original

straps, which consists of a formed wire double hook, a staple, and a

couple of clamp plates.

I

made the new straps about 1/2 inch shorter that the originals,

estimating that this would account for 40 years worth of stretch.

Next, new rubber diaphragm for the seat bottom. It is held to the frame with ten steel hooks.

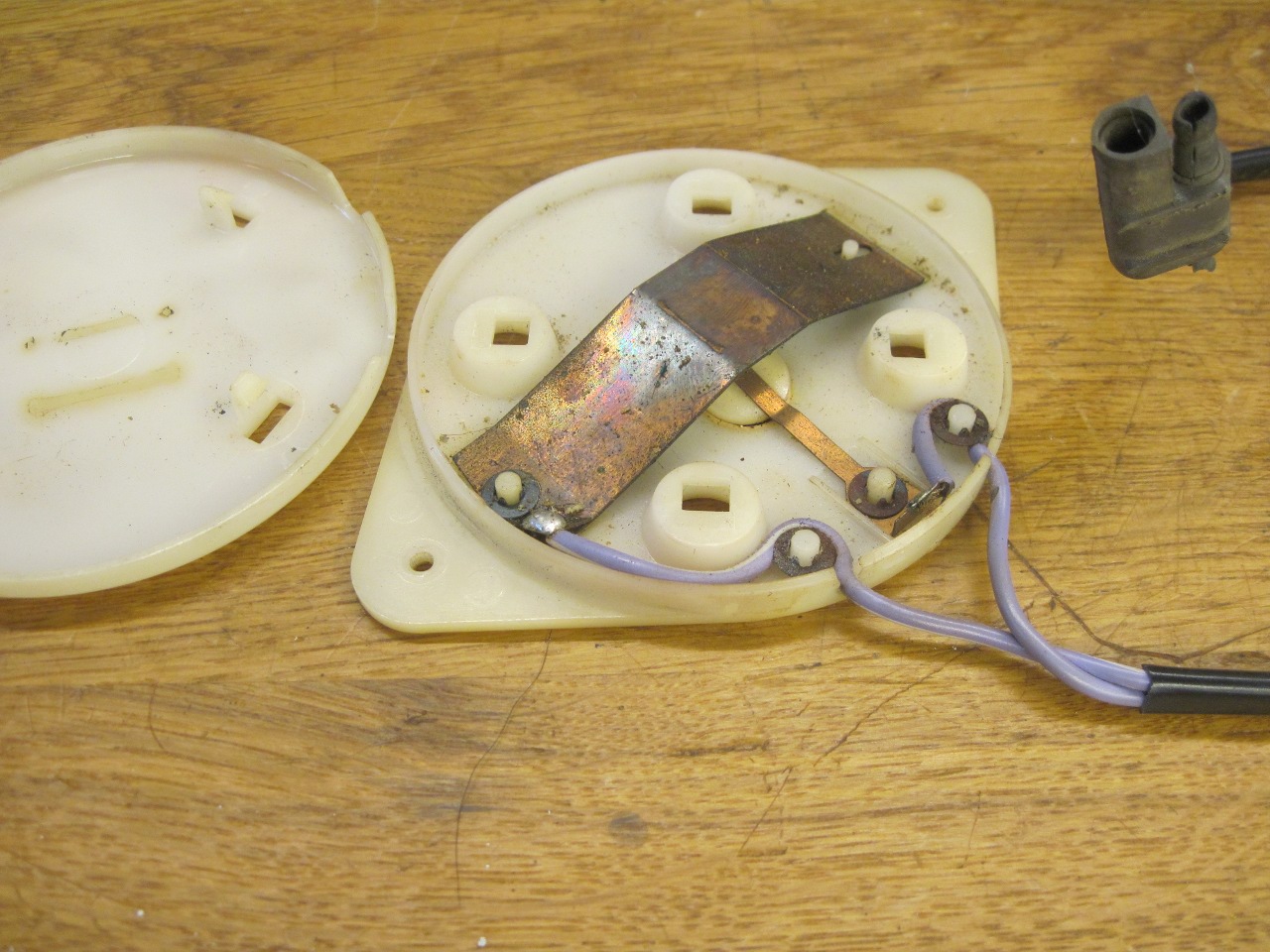

I

would have re-installed the seat pressure switch, just for old time's

sake, but the switch was inoperative. I took it apart and could

see the problem, but decided not to spend any more time on a device I

wasn't going to use anyway.

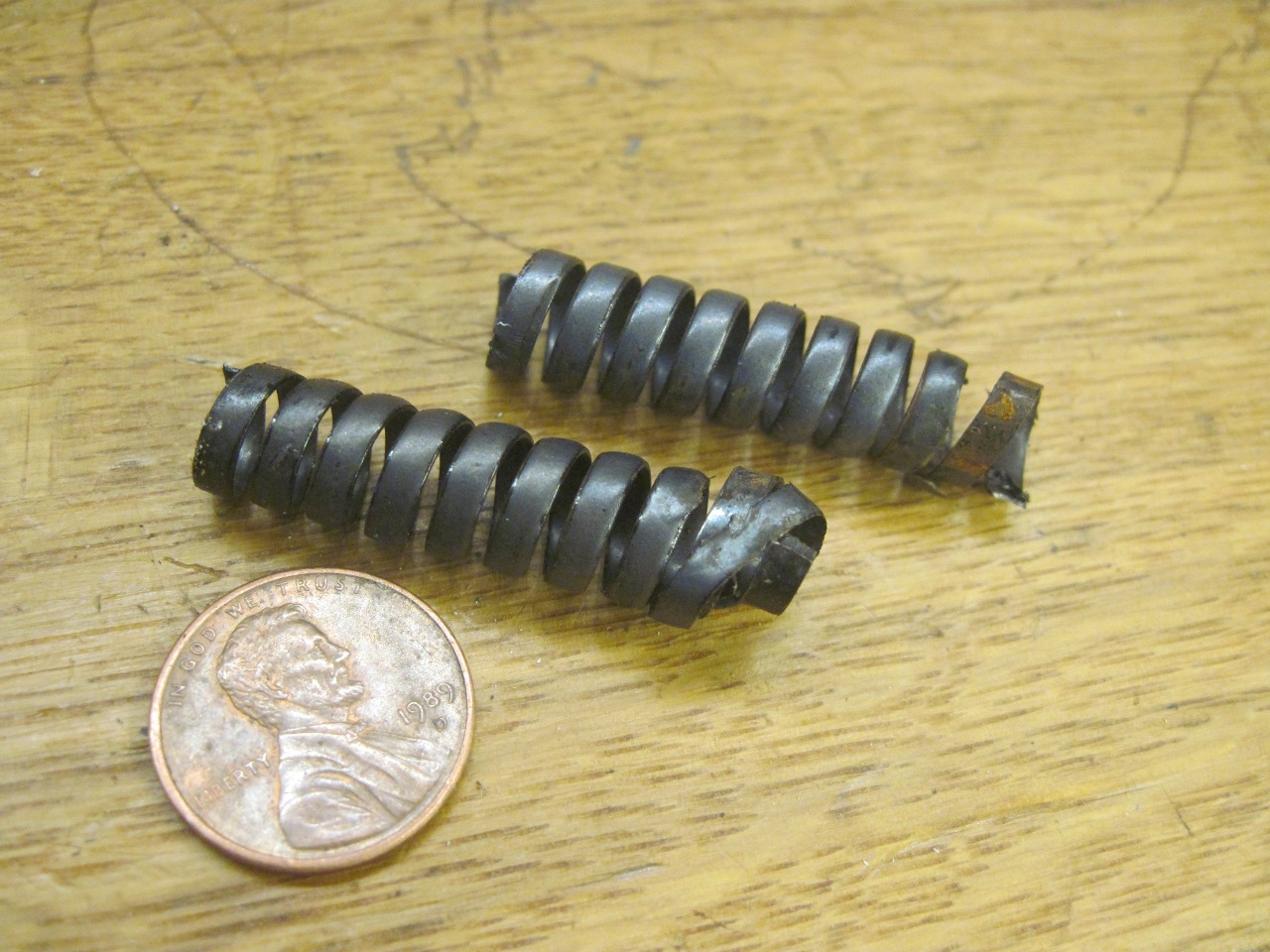

One

little quirky design on these seats is the headrest slide mechanism.

The headrest stalk slides into a channel in the seatback frame.

Across this channel, retained by a piece of tape, is a funny

looking spring-like piece. It appeared to have been broken in

two. It took me a while to figure out what was going on there.

The

spring is flat-wound, and has what looks like a plastic coating on it.

I believe the way it works is that the spring interferes with

headrest stalk, and the stalk pinches it into an oval shape, so that

the spring maintains constant pressure on the stalk. The coating

on the spring is to reduce friction so that the smooth chrome plated

stalk can still slide. The spring was broken in the middle,

probably just from wear.

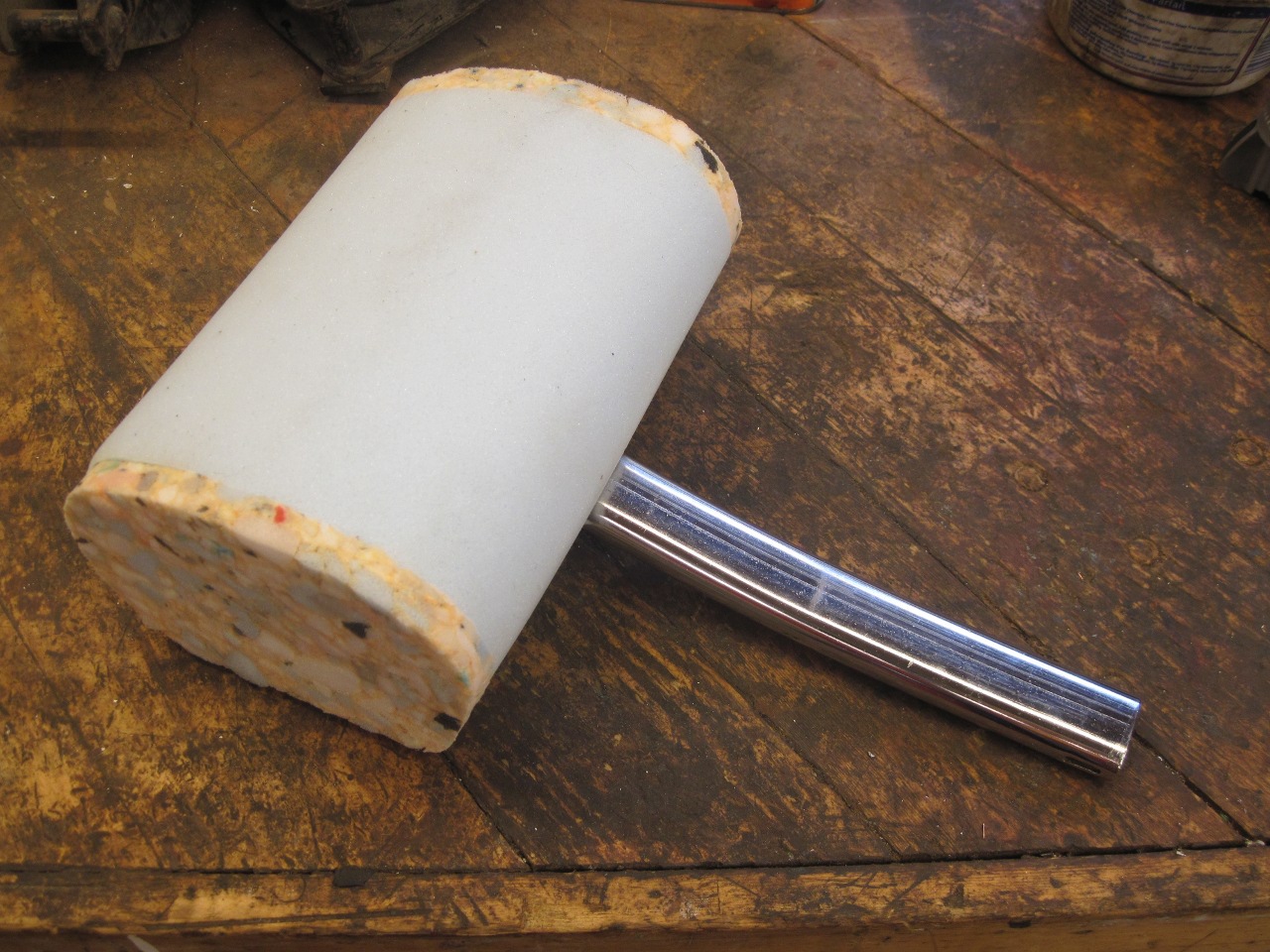

In

my research, I found that other people had replaced the original spring

with a standard one of appropriate size from the hardware store.

This was my first plan. I tried a few from my spring stash,

and even bought a few more. I could get it to work sort of OK,

but it still didn't seem right. In the end, I found a way to

re-use the remnants of the broken spring so that the function was the

same as it was originally. I took half a spring, squared the

ends, and put it on a short #10 threaded rod with two plastic spacers

to keep the spring centered. As far as the headrest stalk is

concerned, this is a stock setup. It works very well.

Then

came the upholstery. This is something I've never done before, so

I was a little apprehensive. It didn't help that neither the

expensive foam kits nor the expensive seat cover kits came with a

single word of instructions. Luckily, there are a few online

sources of guidance. Frankly, I would have been lost without them.

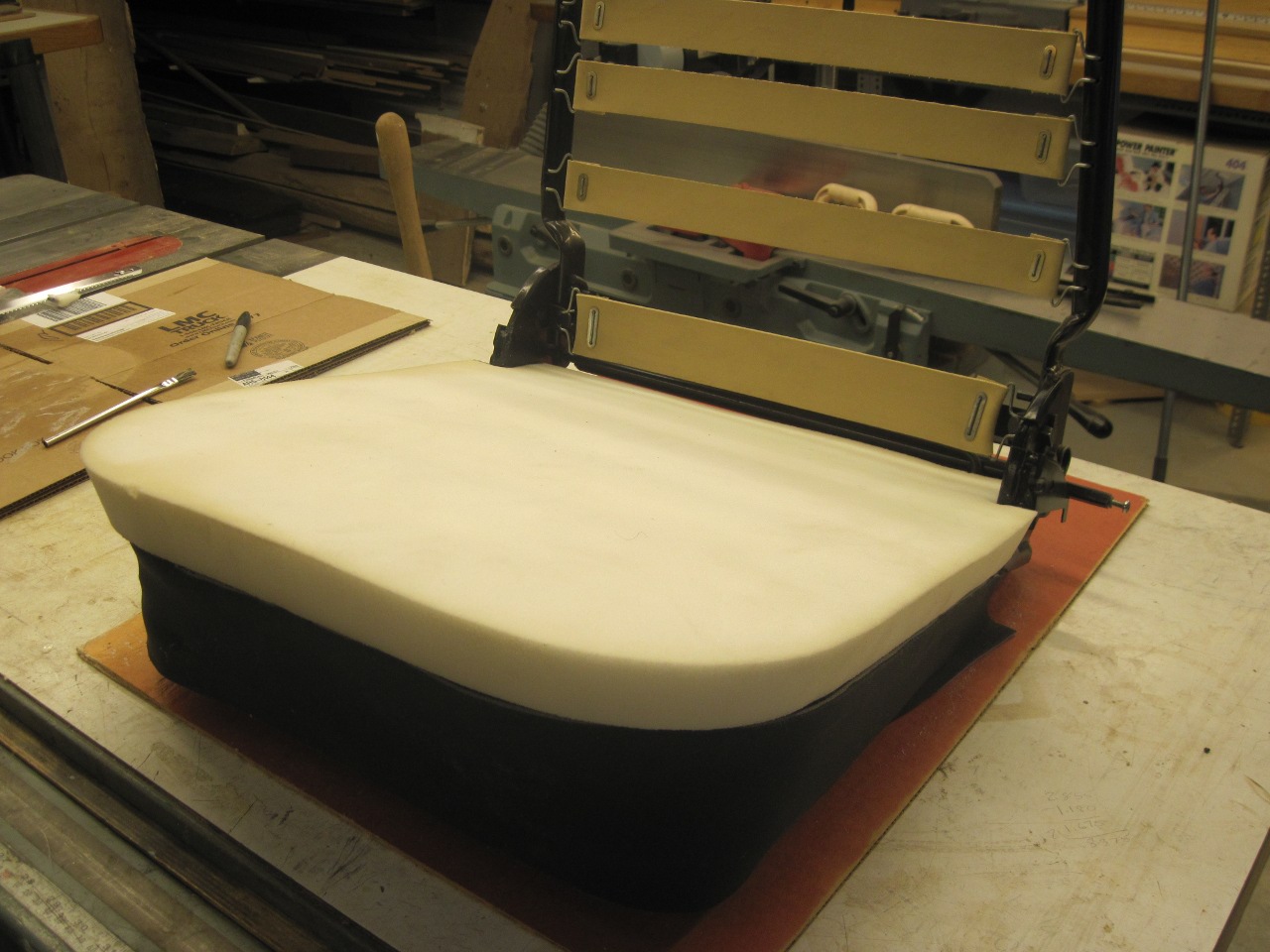

First, there is a foam skirt that is glued around the seat bottom frame, then a flat foam pad is glued down.

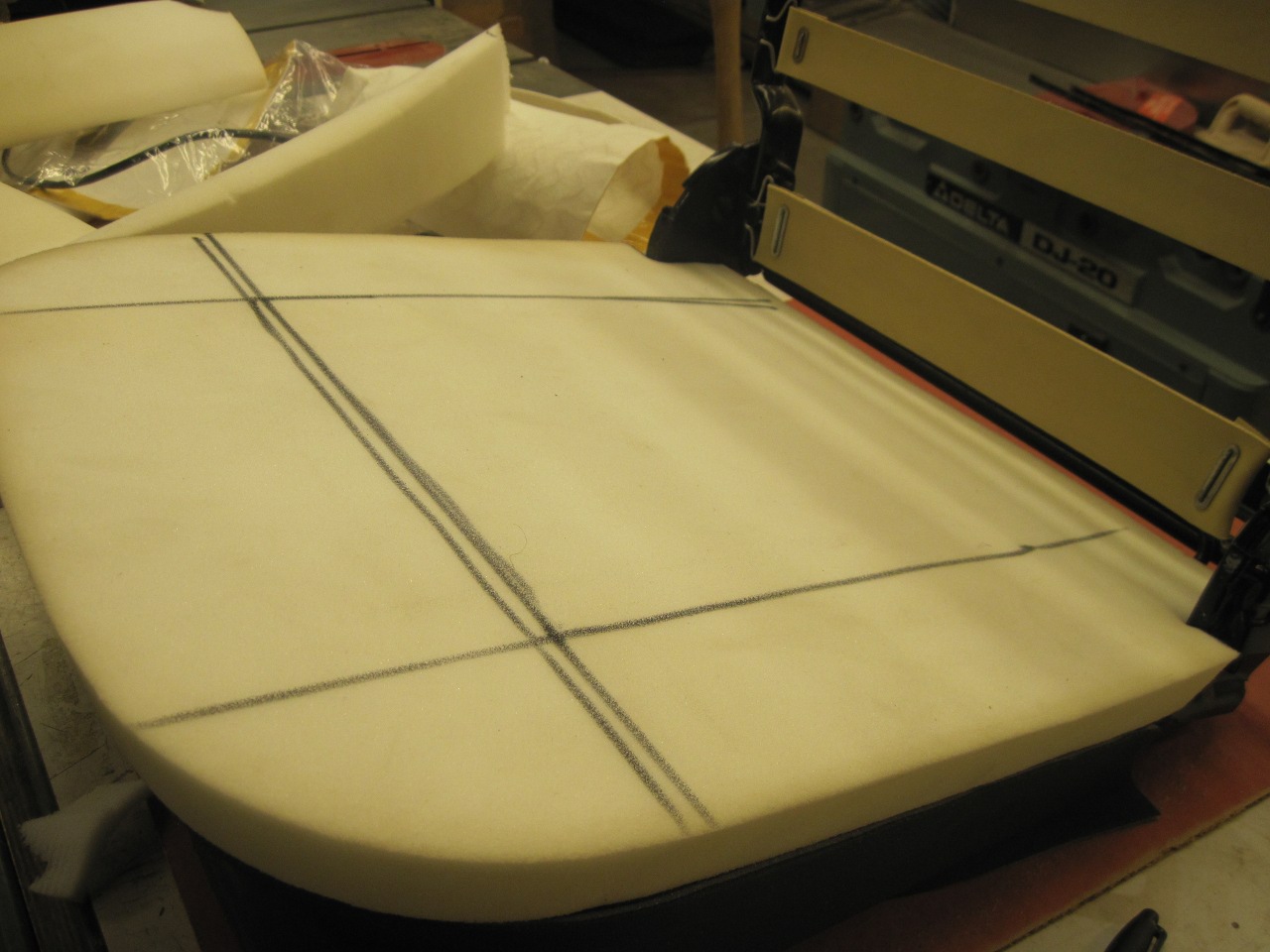

Then

it gets complicated. There is a glued-up foam piece that forms

the raised parts of the seat on the front and side edges. But

before it is applied, the seat bottom cover has some "tensioner" tabs

that have to be glued down. The tensioners keep the center

pleated part of the seat flat against the bottom foam pad. The

three-sided foam piece goes on top of the tensioners. So I held

in the three-sided foam piece and marked out where the seat cover seams

would go.

But

before gluing in the tensioners, I put in the bottom seat heater.

I did some research on after-market seat heaters. Though

there are a lot of places to buy these, there seem to be only two or

three different products available. Two of the three have only

so-so reviews at best, while the other has mostly good reviews.

It is also the most expensive. If a supplier doesn't show a

picture of the product, the price is usually the givaway as to

which kind they are selling. Since I suspected the usual

suppliers for these cars were selling the cheaper products, I opted to

go outside the network and buy from a general automotive supplier.

The risk, of course, would be that they wouldn't fit the TR seats.

These

are labled Dorman brand, which is a very large automotive parts

supplier. The heater was a pretty good fit for the seat bottom,

covering just about all of the pleated center section of the seat.

I passed the power wire down through a hole in the foam.

Then the seat cover tensioners were glued down.

After

a little setting time, the three-sided perimeter foam piece is added,

and the cover pulled down around it and clamped to the bottom frame.

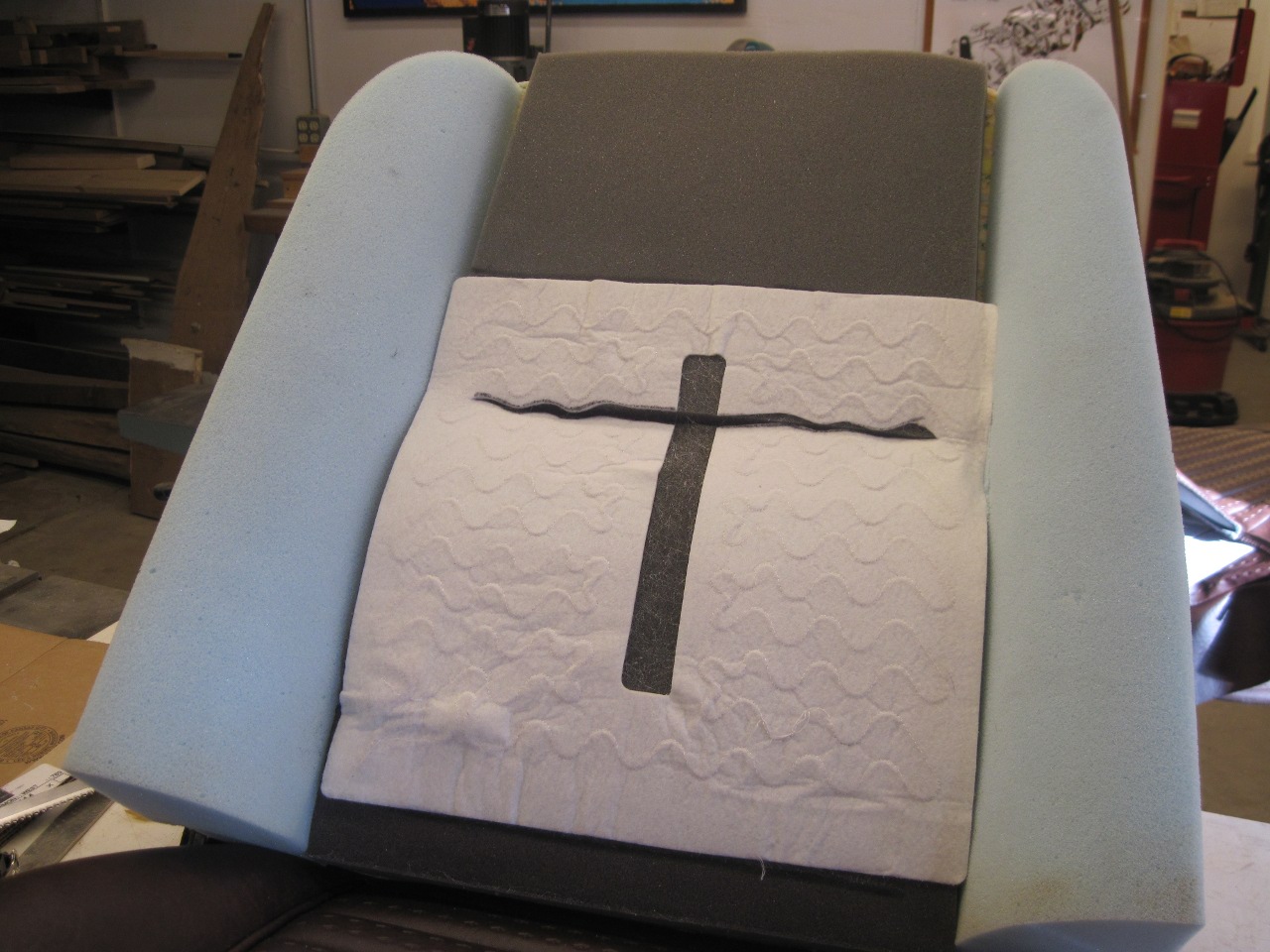

The seatback foam was a single piece. It was trimmed a little bit to clear the tilt mechanisms, and glued into place.

The heater

for the seatback presented a little bit of a problem. There is a

tensioner flap on the seat cover that has to pass through a wide slit

in the foam, and the heater pad covered the slit. There is an

opening in the heater pad, but it wasn't wide enough, and it was in the

wrong place. Though the instructions for the heater pads say

categorically not to cut or trim the pads, it is obvious that the pads

have a resistance wire sewn in a circuitous path, and it was easy to

see where it was. So cut the pad I did, being careful to choose a

cut path that didn't cross any of the wires. I ran the wire

through a hole and out the back of the foam. Where it got close

to metal parts, I slipped a piece of protective corrugated sleeve over

it.

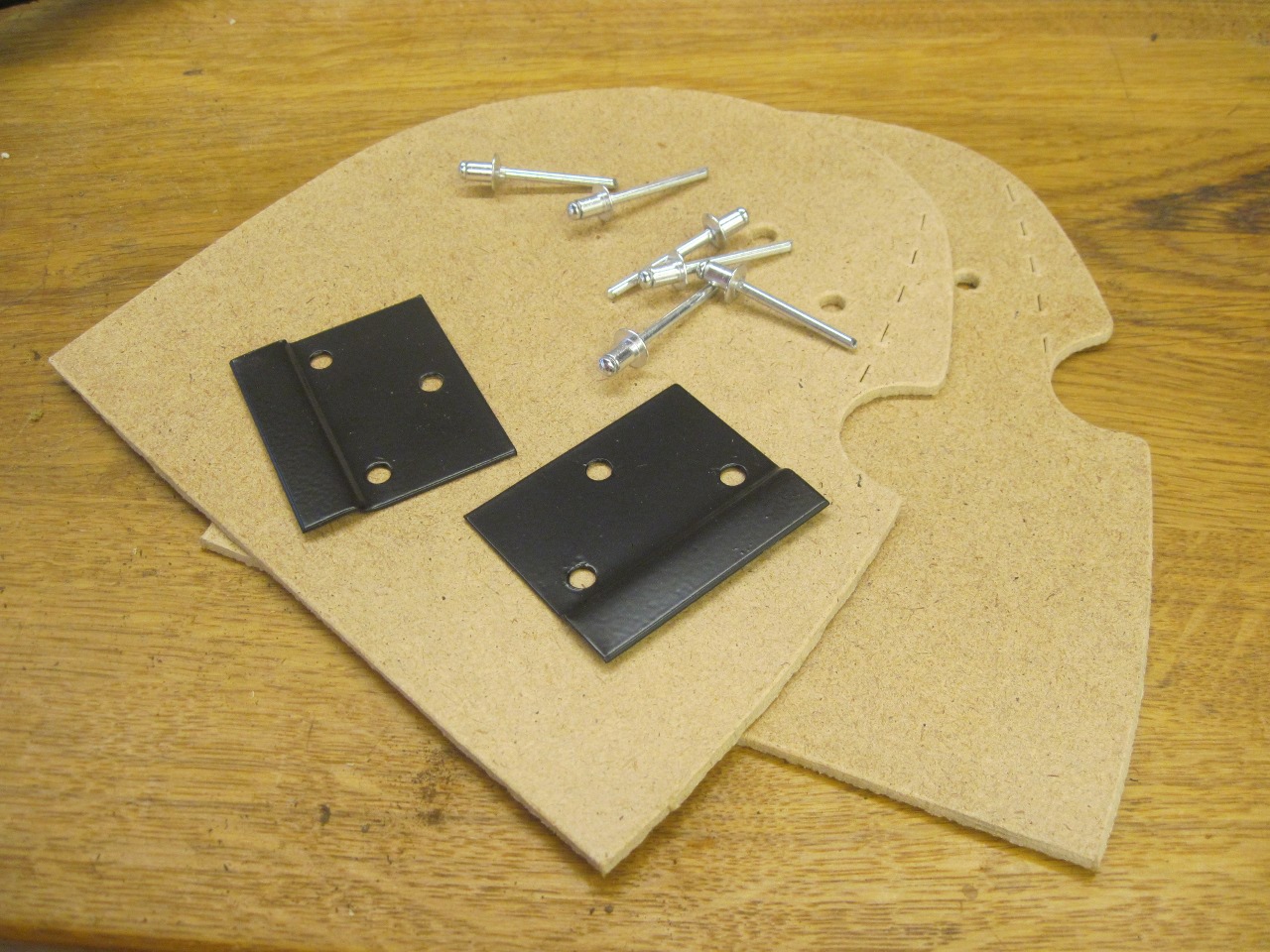

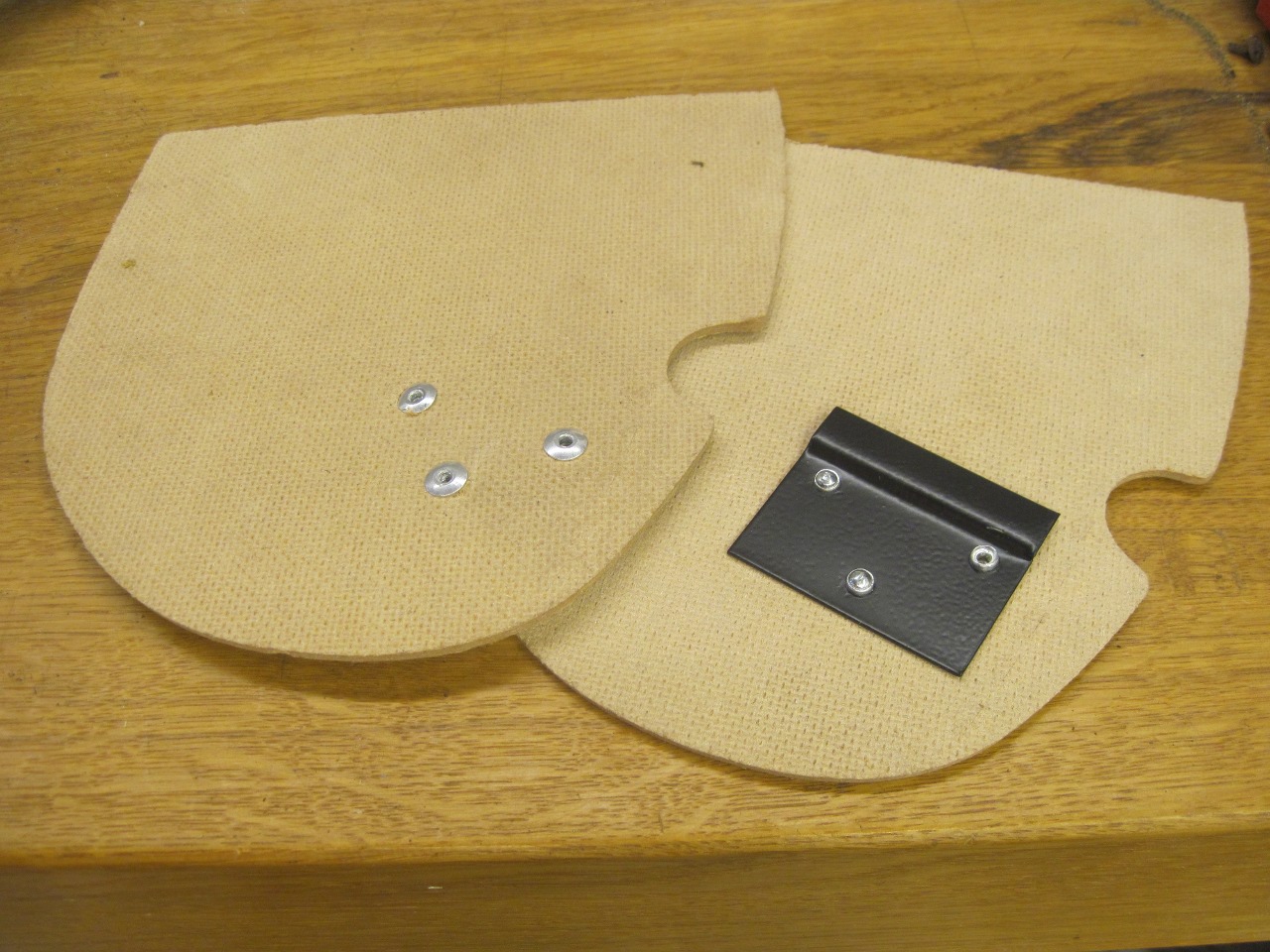

The

side panels of the seatback cover have pockets at the bottom that hold

some fiberboard pieces with metal hooks attached. The hooks grab

a bracket on the frame and keep the cover taut. The fiberboard

parts are included in the cover kit, but the metal hooks are not, and

have to be reused. The original attachment for the hooks is little

split rivets, which can be reclaimed and reused, but I opted for new

blind rivets instead.

It

was a challenge to stretch the back cover enough to engage the hooks to

the frame brackets, but warming the cover with a heat lamp and hair

dryer helped a lot.

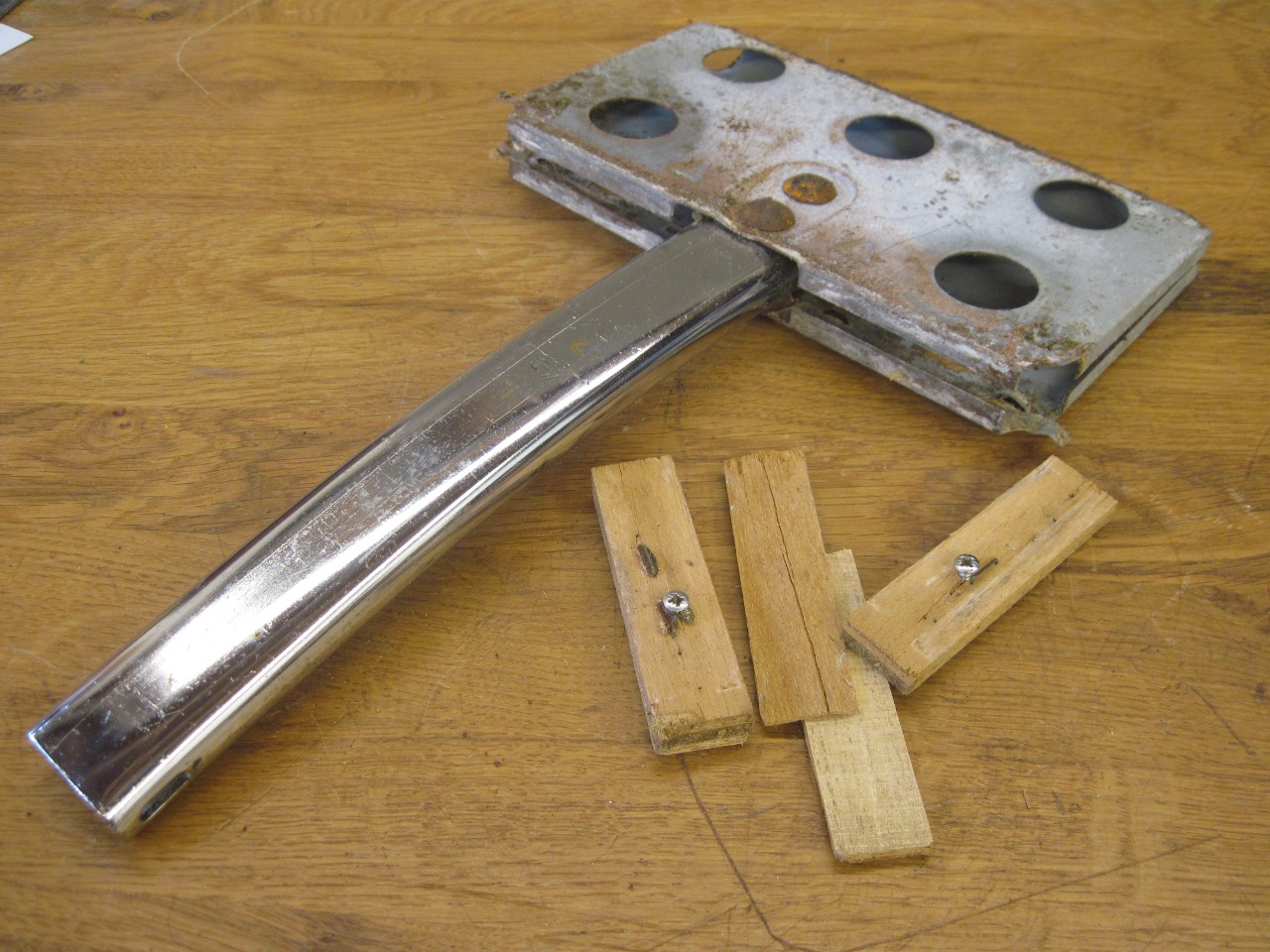

The old headrest seemed a little squishy, and I found out why.

The

internal headrest frame had some little plywood blocks captive along

the bottom edge so that the vinyl cover can be stapled to them, and to

hold the bottom cover plate screws. The blocks were falling apart.

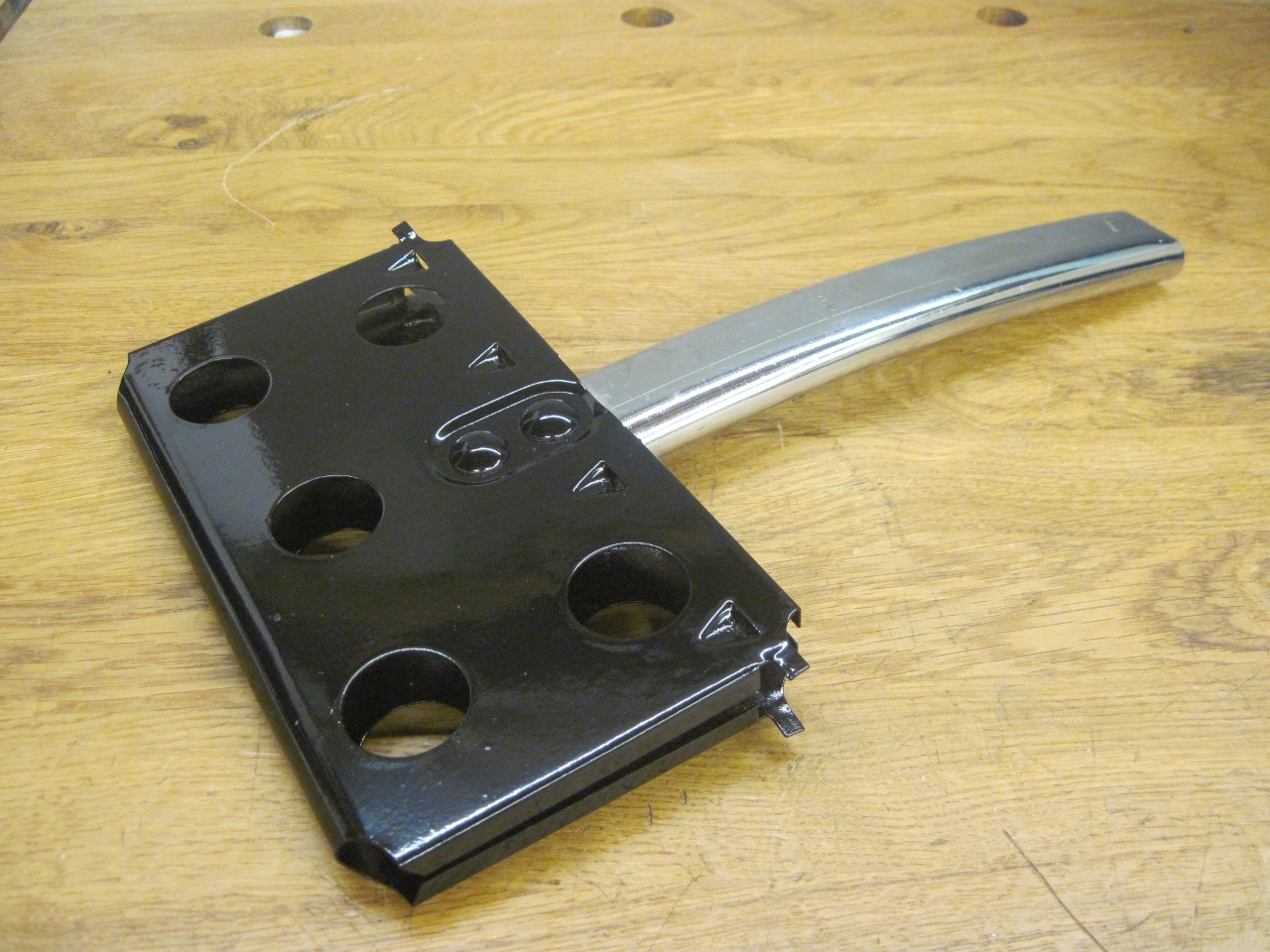

So

I cleaned up and powder coated the frame, and went rooting around in my

wood scrap bin for something to replace the plywood. The first

piece about the right size happened to be a scrap of African mahogany.

Now THAT's an upgrade!

It doesn't look like the headrest foam will fit in the cover, buit it will.

There

are a couple of rubber bumpers where the seat back rests on the tracks.

They were worn and distorted, so I got some new ones.

The

seat release latch mechanism was just cleaned up and powder coated.

One of the plastic knobs had gome AWOL, so I picked up on in an

Ebay auction for $7.

Screwed

the latch gizmo to the seat. The chrome recline levers were a

little pitted with age, but I found that most of the pitting was on the

top surface. Since the levers fit either side, I just flipped

them over and swapped them side for side.

I

give myself a B on the upholstery, and I have newfound respect for

someone who is good at it. There are still a few little lumps and

wrinkles, but they seem to be going away with time.

As

I mentioned, this was a difficult undertaking, and one of the most

expensive of the entire project. I'll have to think about whether

I'd do it again.

Comments to Ed at: elhollin1@yahoo.com

To my other TR6 pages