February, 2015

Vacuum Pump

I

think I've now accumulated enough reasons to build a real vacuum

pump setup. First, I've done some synthetic rubber casting of

small parts, and while the parts came out totally usable, they would be

cosmetically better looking if I did a degassing step before pouring

the resin. Degassing is done by subjecting the freshly catalyzed

resin to a vacuum, and would eliminate the pin holes and rough surface

texture on some of the parts.

More recently, on my Triumph TR6

rebuild project, I want to apply a new veneer to the original wood

dashboard. One good way to ensure a smooth and well bonded veneer

is with a vacuum press, which requires a good vacuum pump.

I did

a little research into commercial systems and found that in addition to

the vacuum pump itself, they often include a vacuum reservoir and a

vacuum sensor that is able to cycle the pump to keep the reservoir

charged, like an air compressor. Also like an air

compressor, there is usually an "unloader" arrangement so that the pump

doesn't have to start against a vacuum, but rather is allowed to come

up to speed before the pumping load is applied.

One really wonderful source of information (and parts) for these devices is at http://www.veneersupplies.com/pages/DIY__Vacuum__Press.html. Though

my system differs from theirs in a couple of aspects the

principles are all the same, and they have pretty good prices on some

of the pieces.

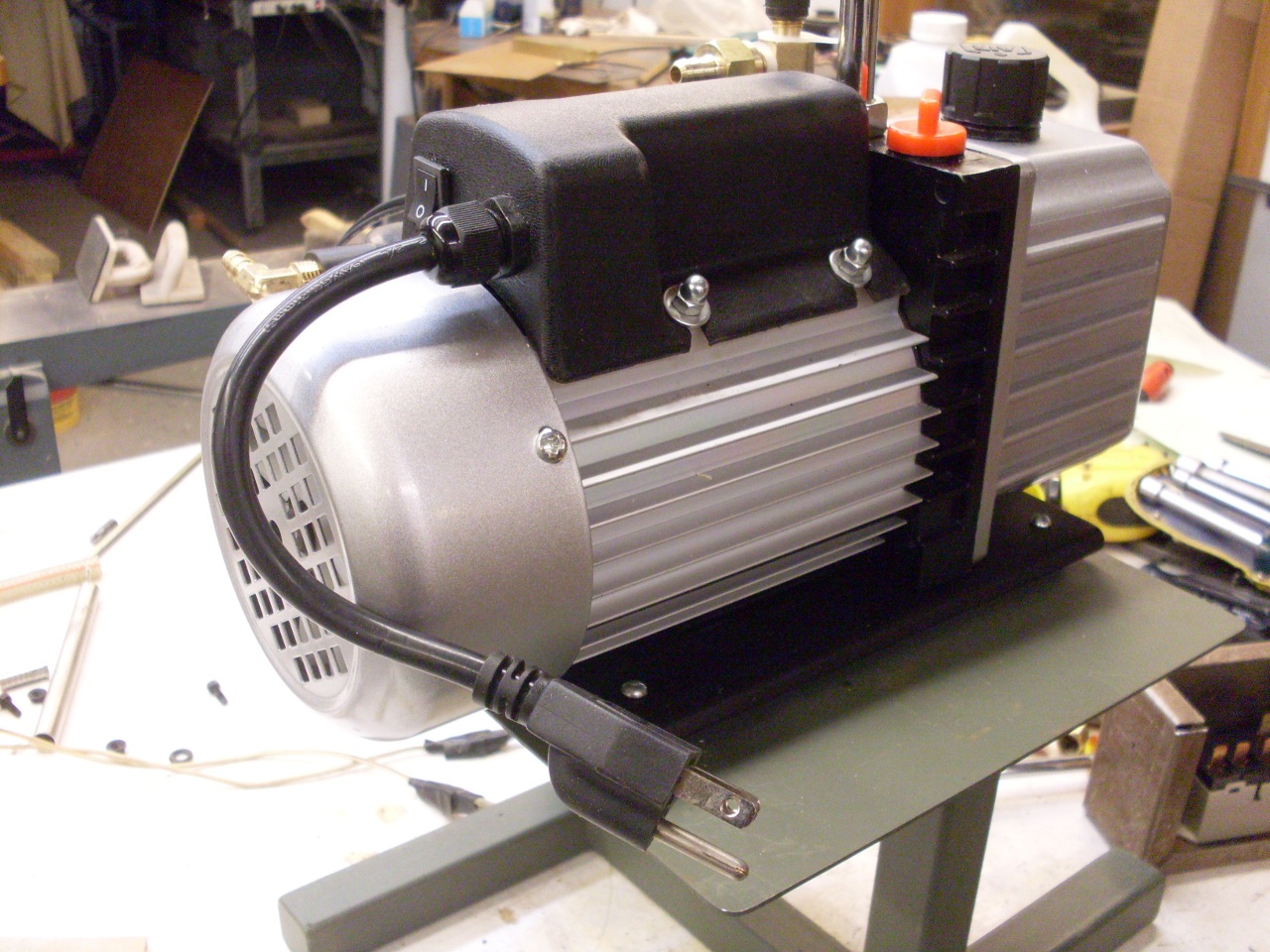

I started with a

3 CFM, two stage vacuum pump sold for evacuating AC systems. This

particular pump is fairly ubiquitous. I saw it sold under a

variety of brand names at prices that varied over a two-to-one range.

Right

off the bat, I hit a little snag with the pump. Since it was

designed for AC systems, it's two fittings were specific to that

application. The top inlet is a male flare, and the one on the

side is an 1/2" ACME, but what I wanted was a 5/16" hose barb. My

first thought was to just remove that brass fitting and replace it with

a barb fitting. That didn't work out since the fitting is also a

check valve. I found ways to make the transition with multiple

adaptors, but in the end, I just bought an ACME to flare adaptor, and

modified the flare part to a hose barb.

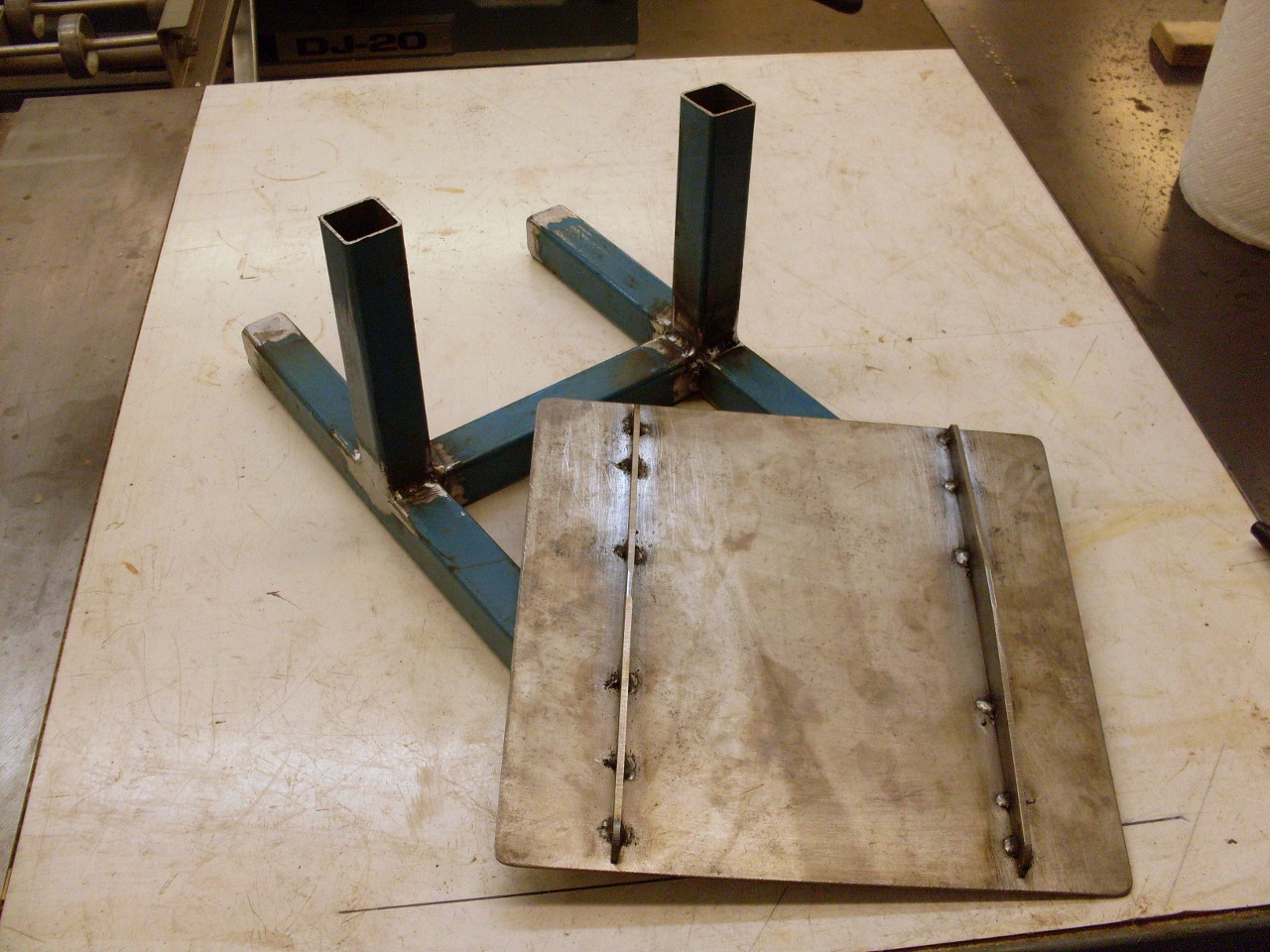

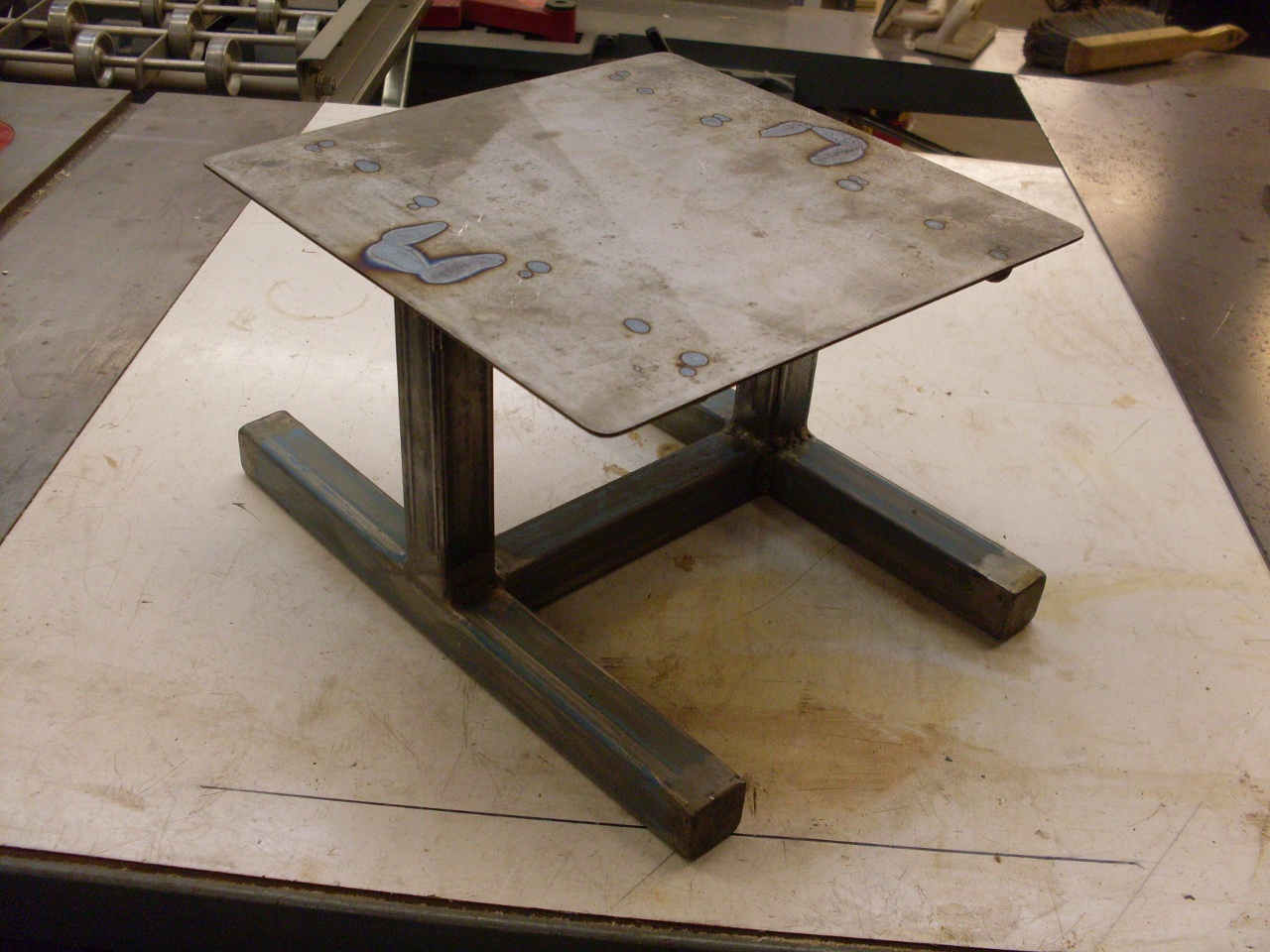

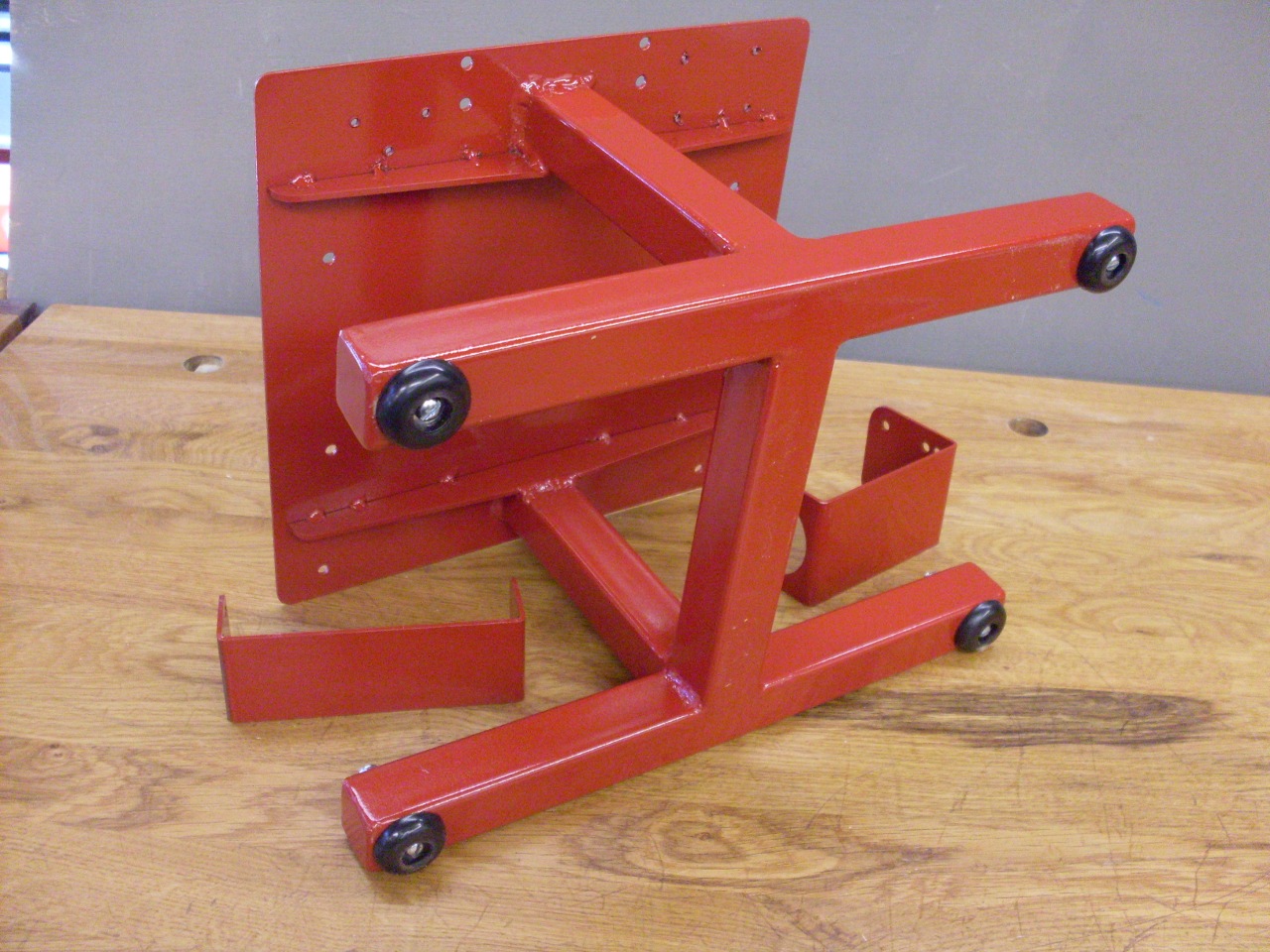

I

decided to build a frame with a platform that would hold the pump and

all the other parts of the system except for the reservoir, which would

be monted below the platform. This is a fairly common approach.

I found some 1 inch square tubing at a salvage yard, and I had a

chunk of 14 gauge sheet steel left over from something else.

Wellded it up, cleaned it, and primed it.

The

reservoir will be two pieces of 4 inch PVC plumbing pipe, each capped

on both ends. One thing I learned from this exercise is that I

had to drill a hole in one of the end caps for each tube. Without

the hole, the trapped air inside made seating the second cap

difficult.

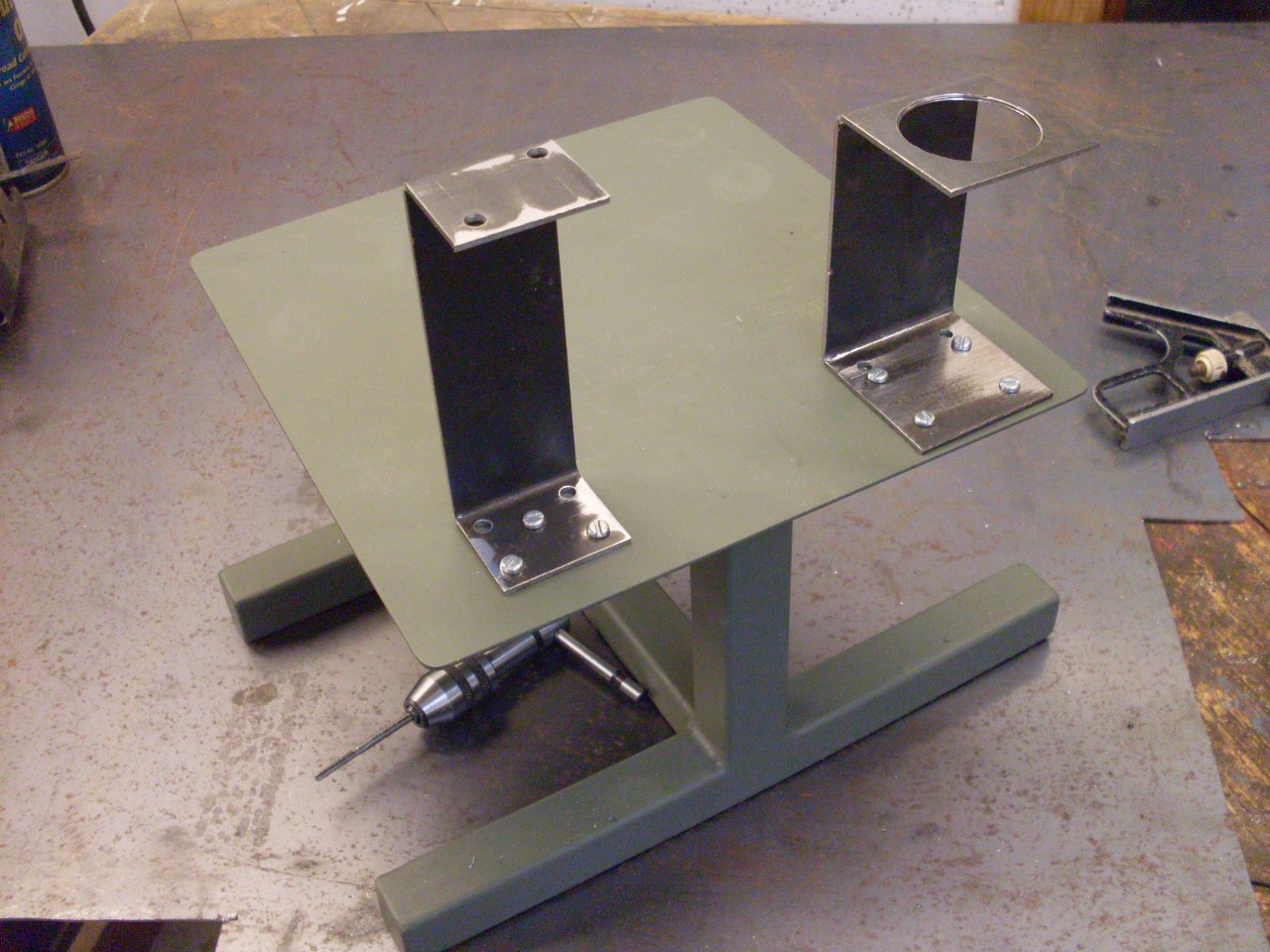

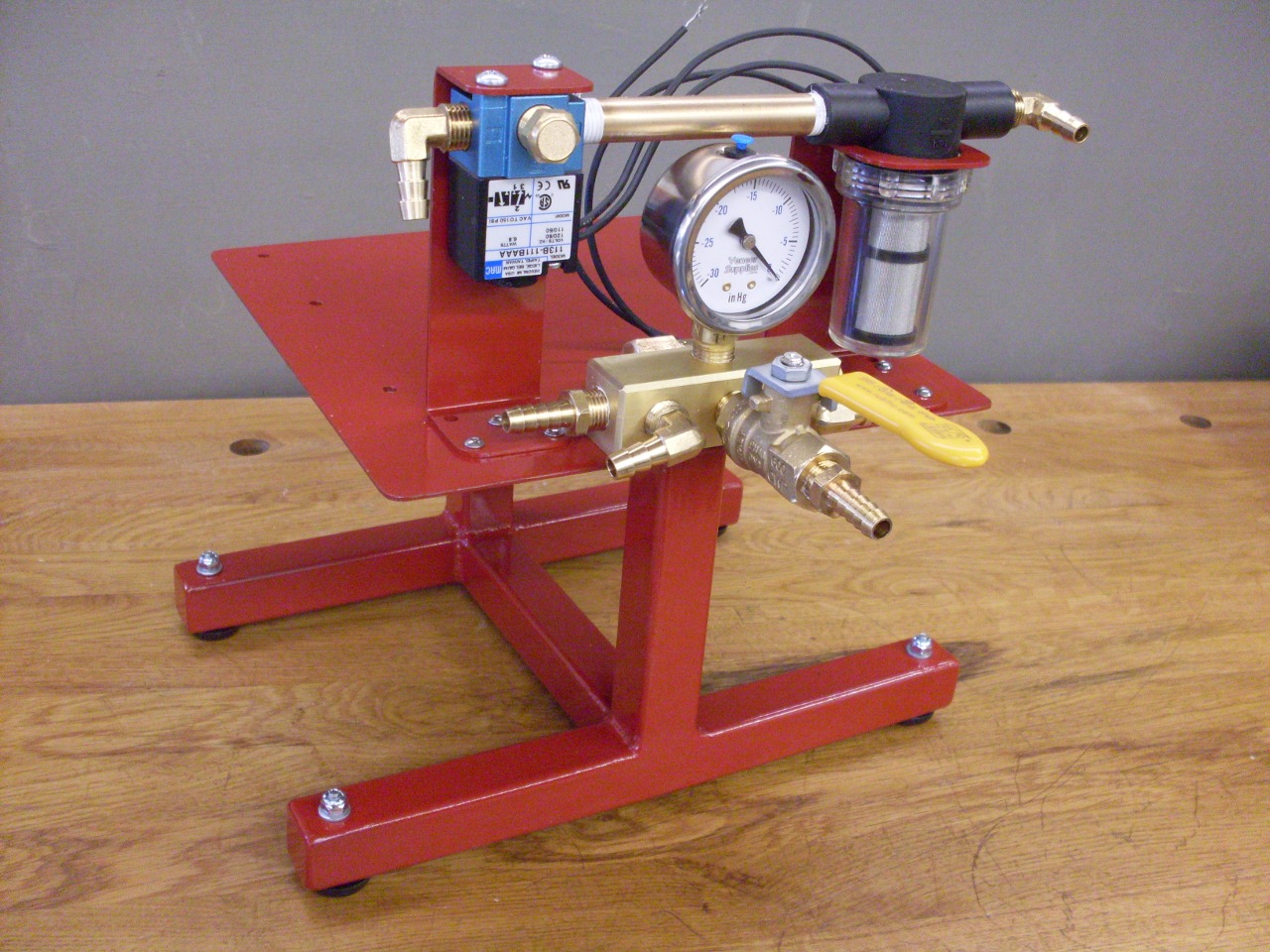

The

air plumbing goes on top of the platform. The air filter and the

unloader valve mount on brackets such that the connection between them

is a straight shot.

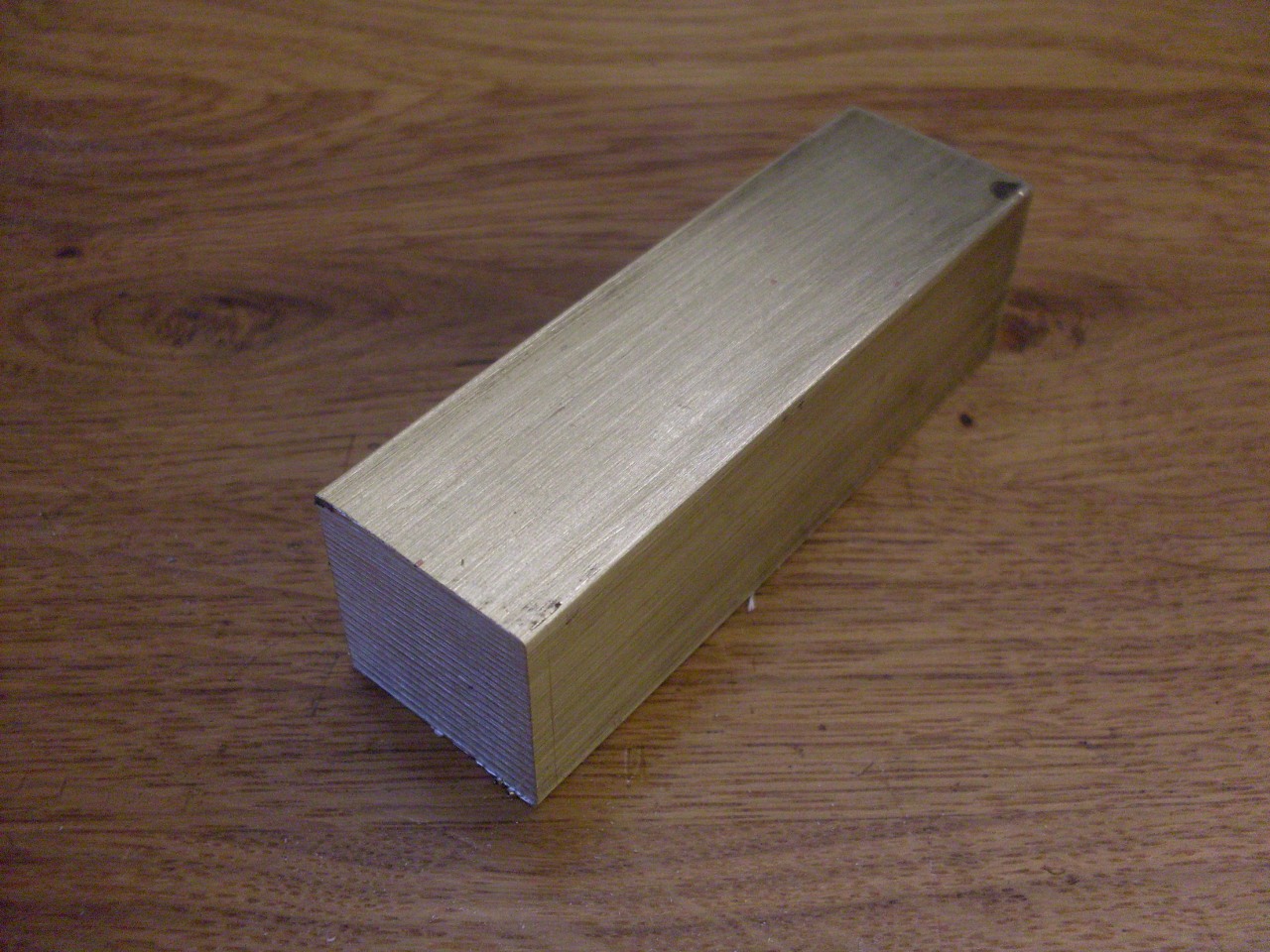

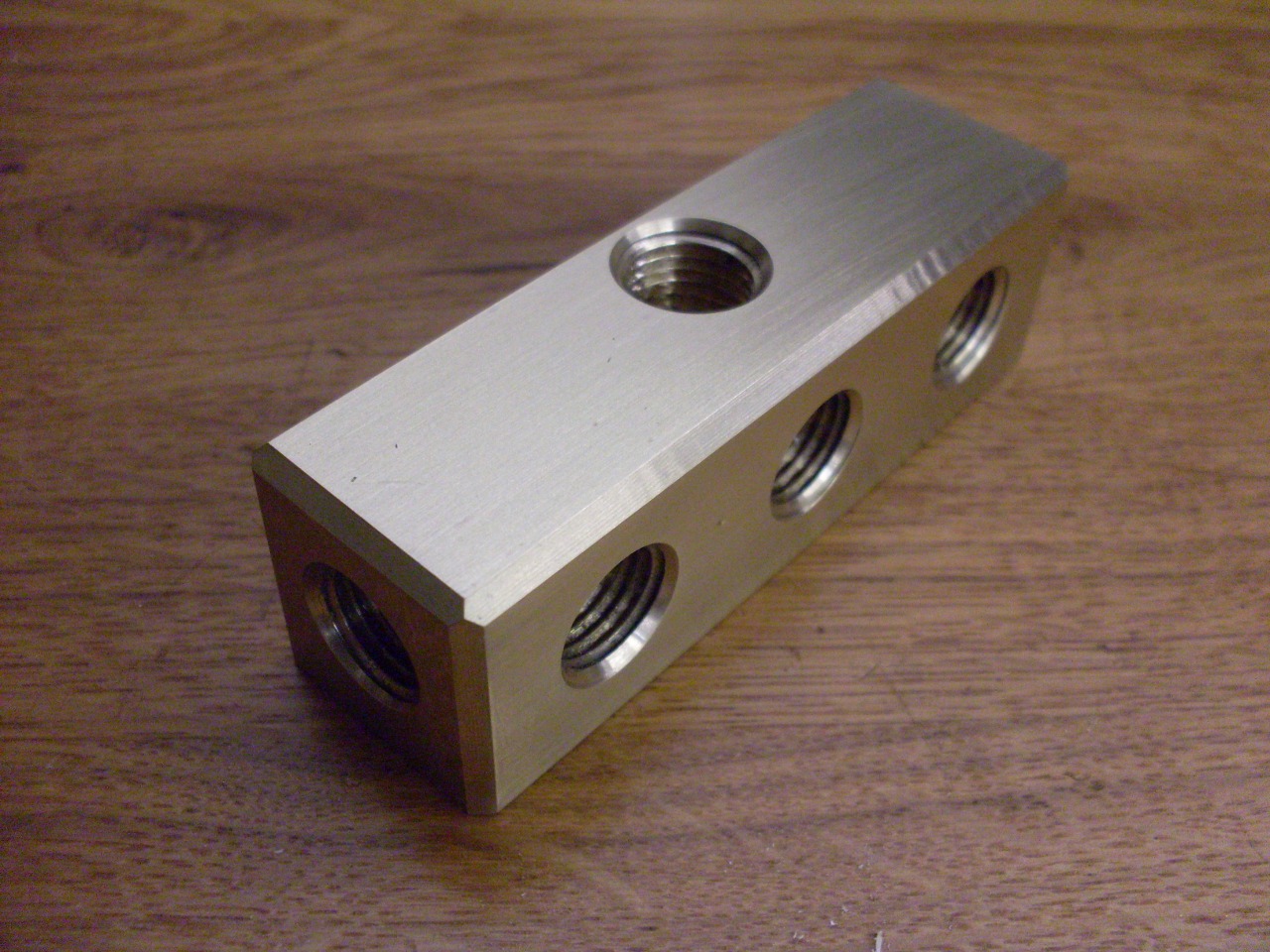

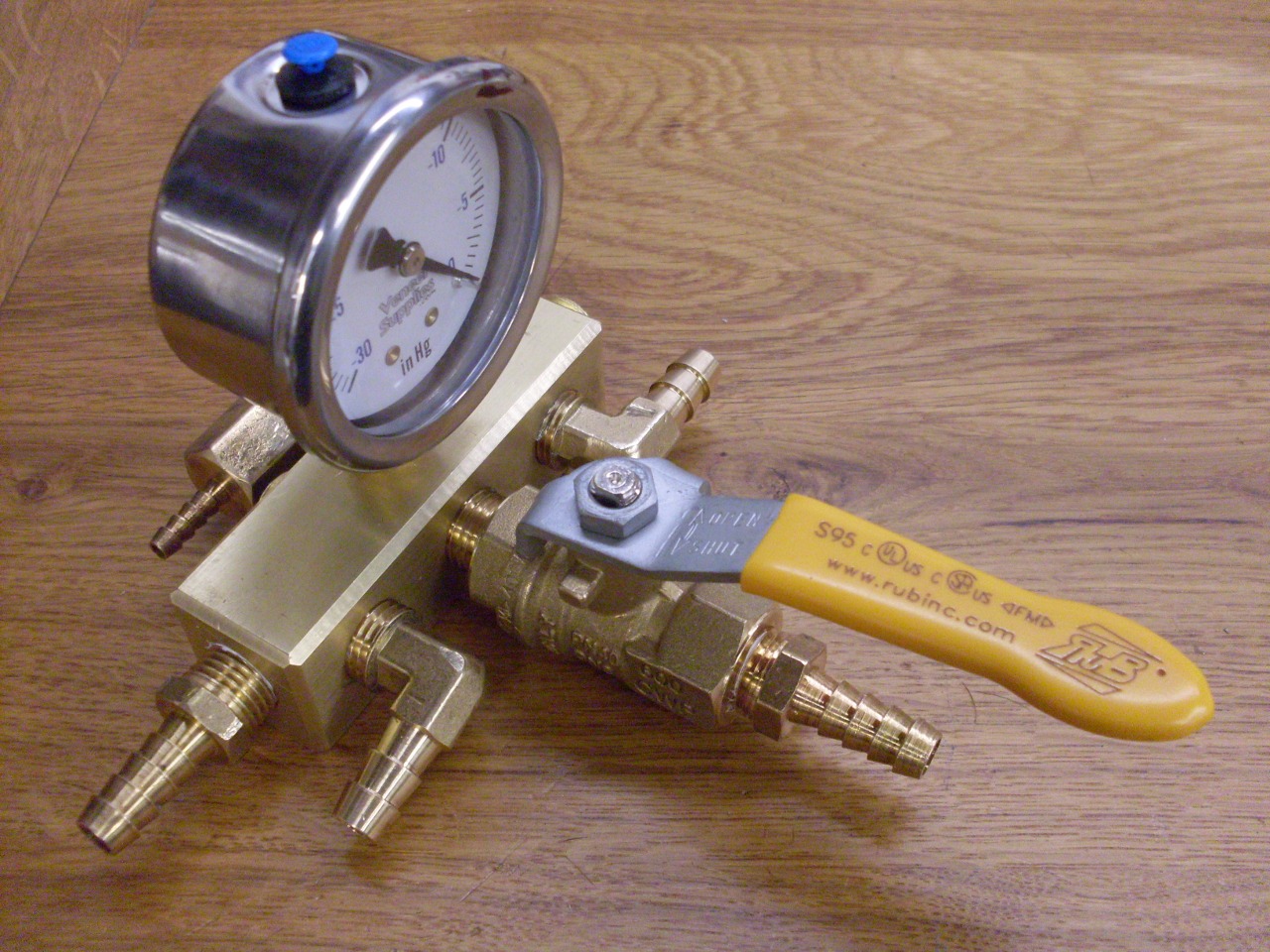

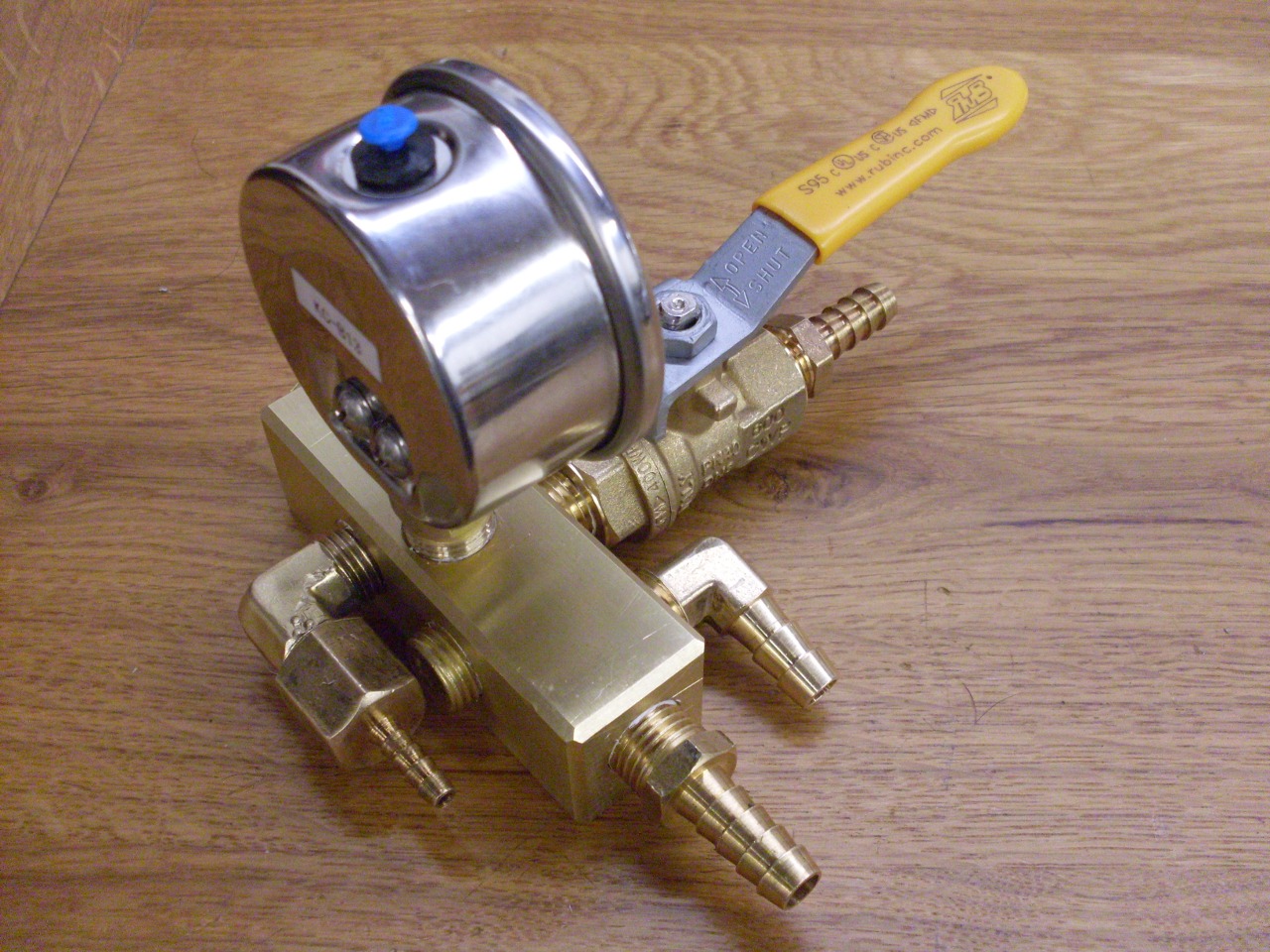

Rather

than having brass plumbing and fittings snaking everywhere, I made a

brass manifold for everything to connect to. It has eight 1/4

inch ports, including two that will be plugged. At this point, I

wasn't totally sure which ports were going to be used for what.

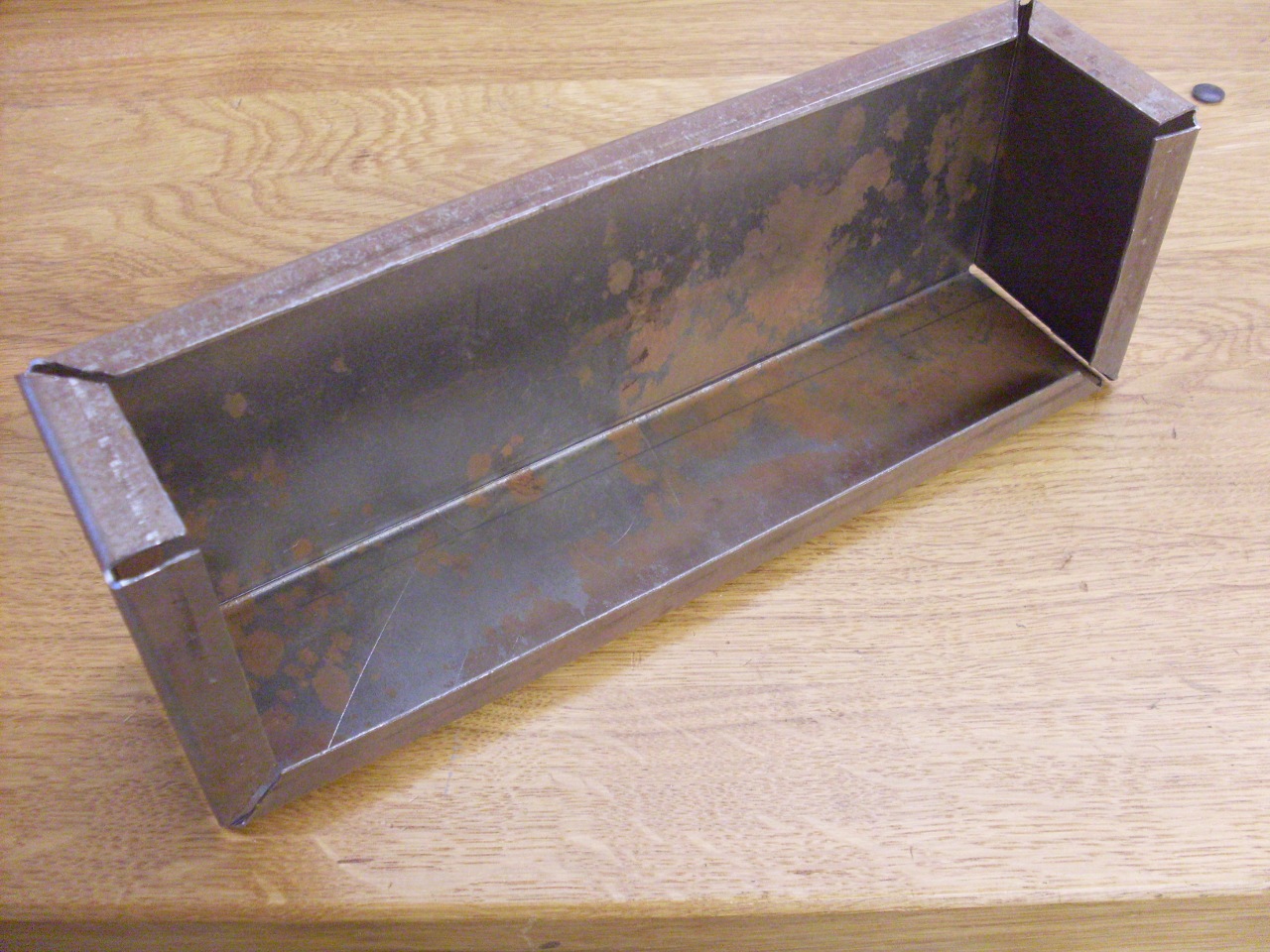

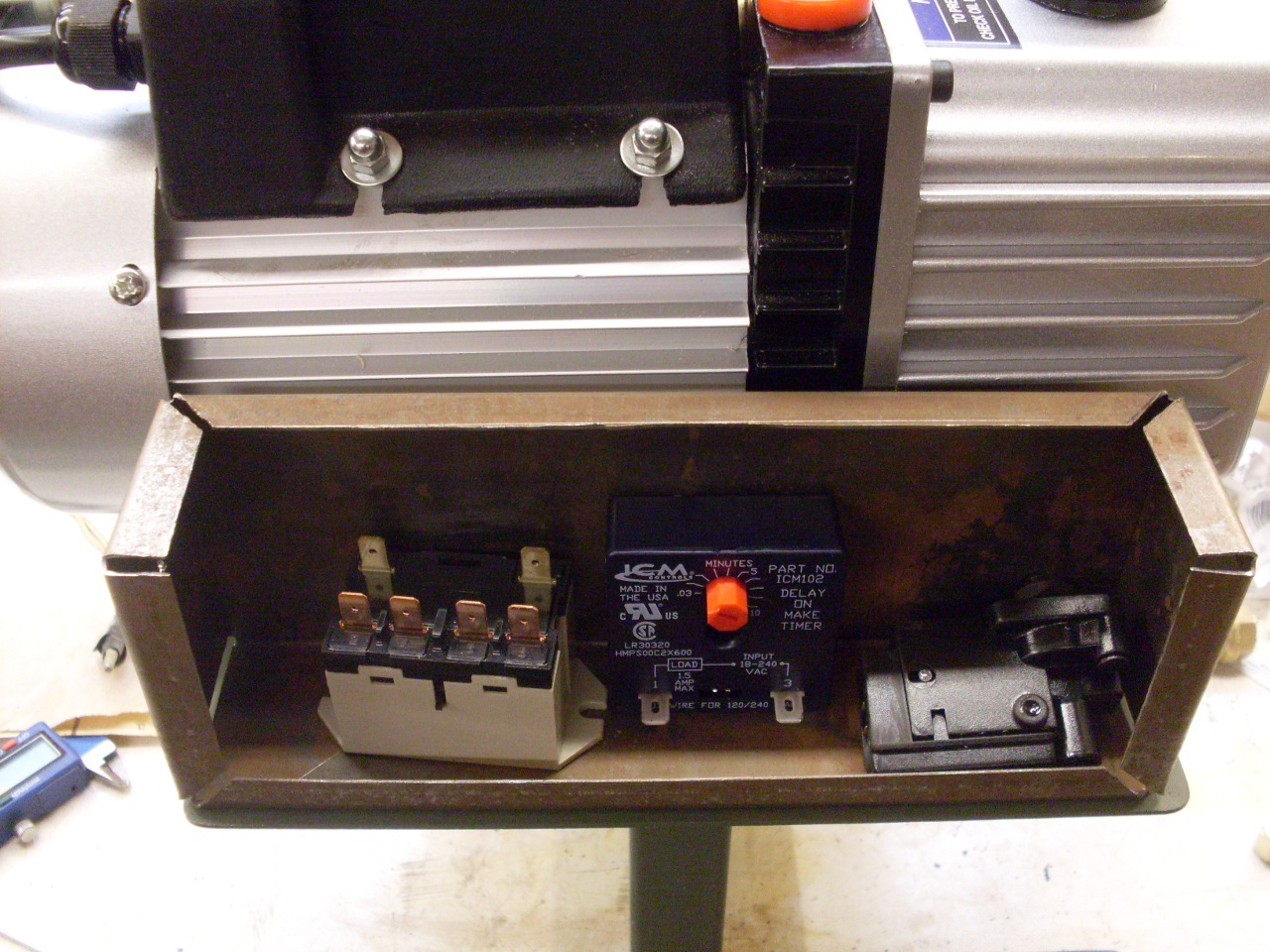

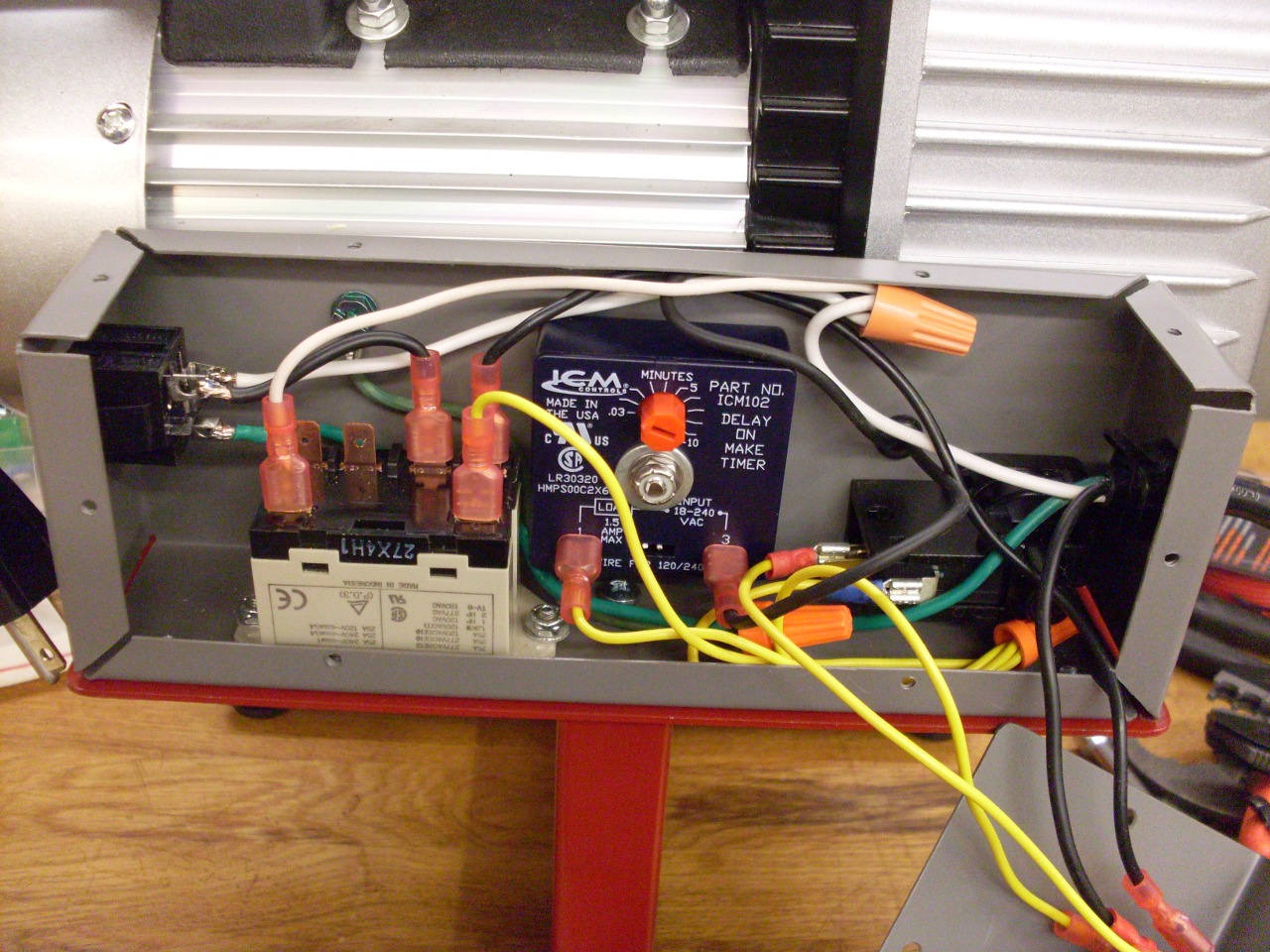

I

wanted to enclose the electrics both for safety and for a neater look.

I made up this box to fit on the platform next to the pump, and

began to trial fit the components. From left to right, there is a

power relay (since the vacuum switch doesn't have quite the capacity to

handle the pump), a delay module (to delay switching the pump over to

the load), and the vacuum switch.

This

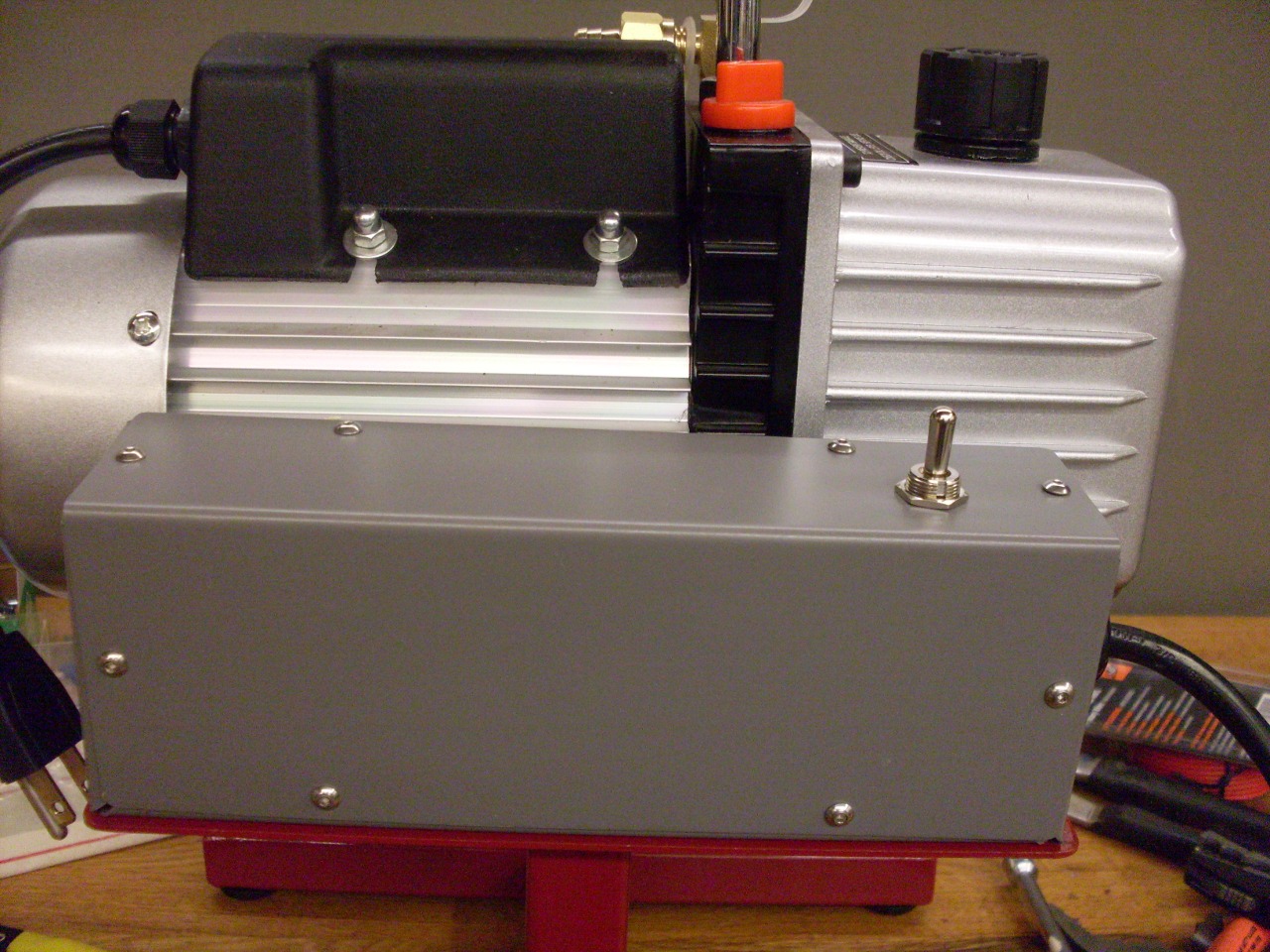

is the final layout. On the left end is an AC outlet for the pump

to plug into. I considered hardwiring the pump to tne box, but

finally decided that if I ever have to replace the pump, or want to

take it out for some reason, the plug would be handier. I did

shorten the pump's cord, though, so I wouldn't have six feet of cord to

find a place for.

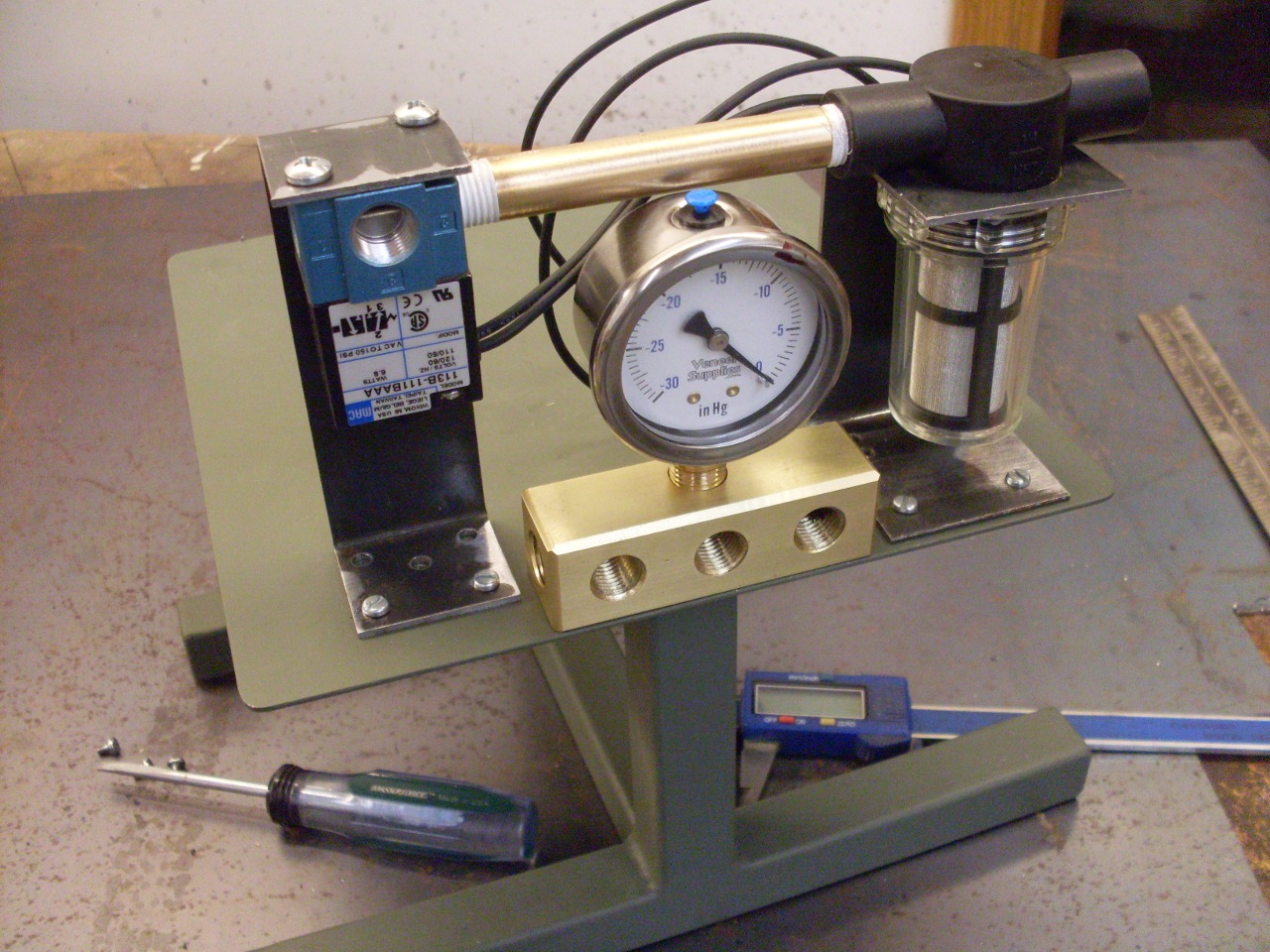

Here

is the final manifold setup. The vacuum outlet is in the middle

on the front. The reservoirs will connect to the right and left

of the outlet. the hose barb on the left goes to the pump, and

the barb on the back goes to the vacuum switch.

I painted the frame and brackets a nice cheery red, and added some soft feet.

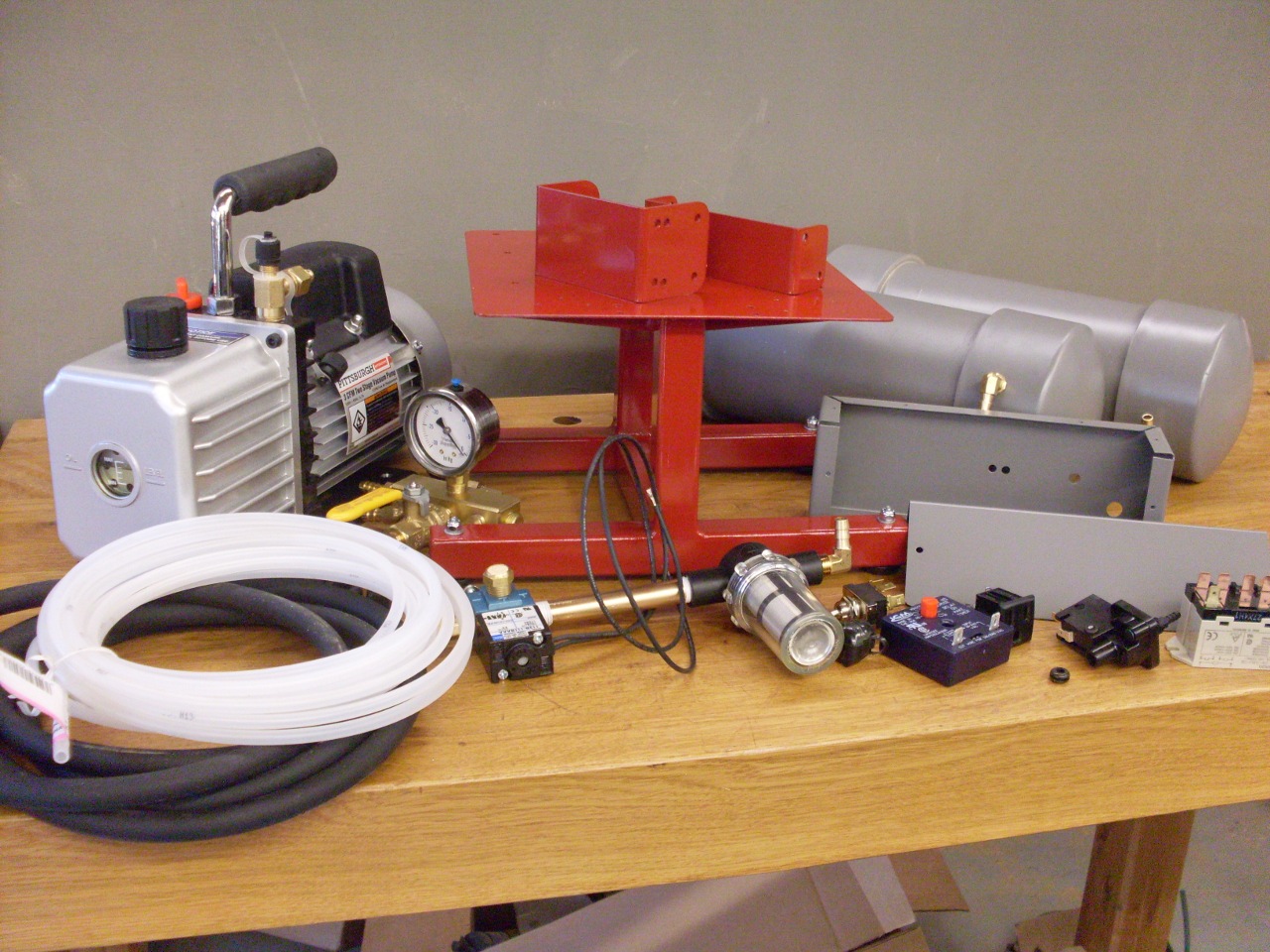

So here are all the parts that have to be screwed together to make a vacuum pump system.

Fist the brackets were mounted and the filter and unloader valve were added, followed by the manifold assembly.

Then I mounted the electrics in the box and fastened the box to the frame.

Then wired the box and mounted the pump itself. The Continuous/Off/Auto switch is on the box cover.

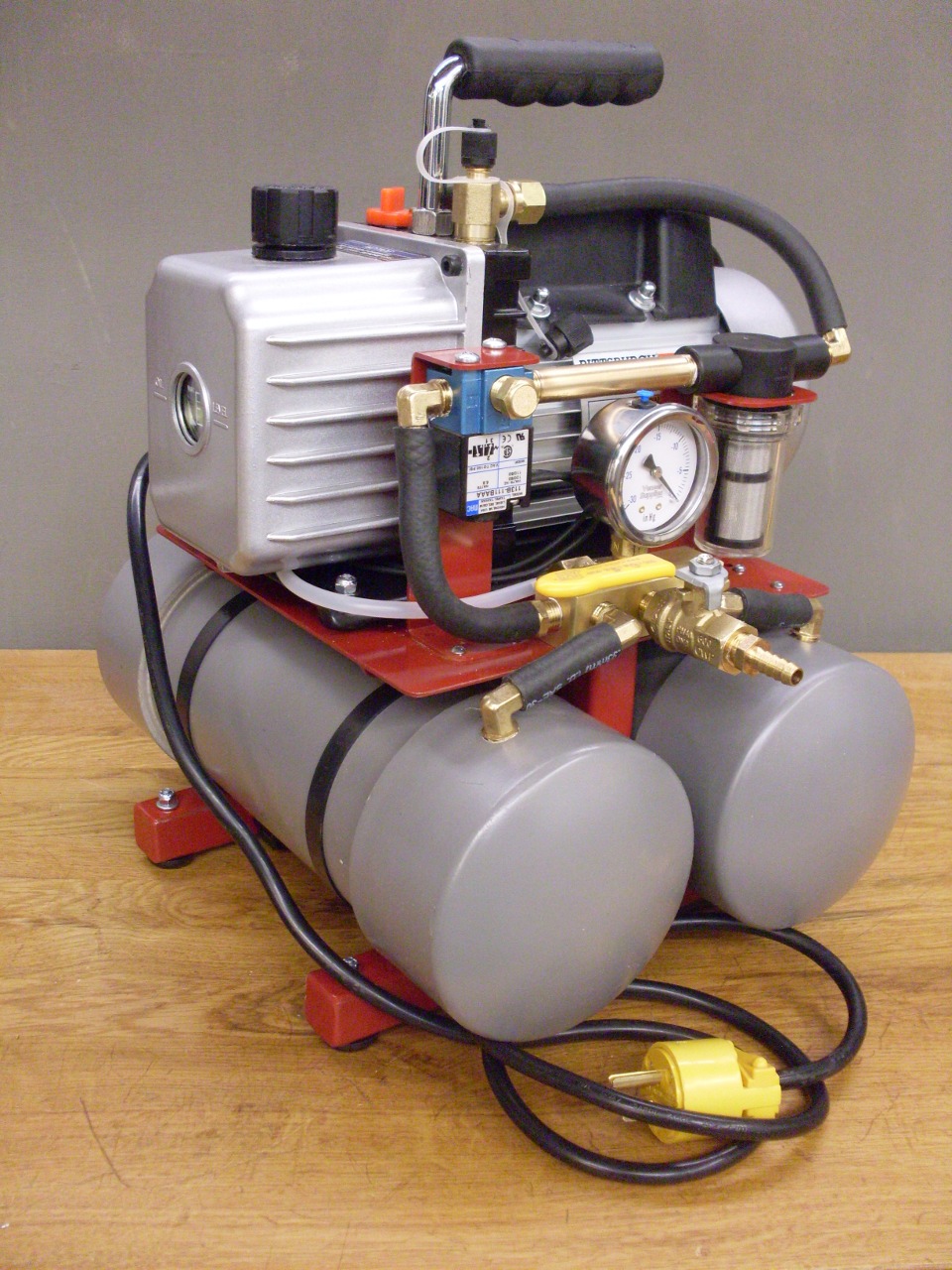

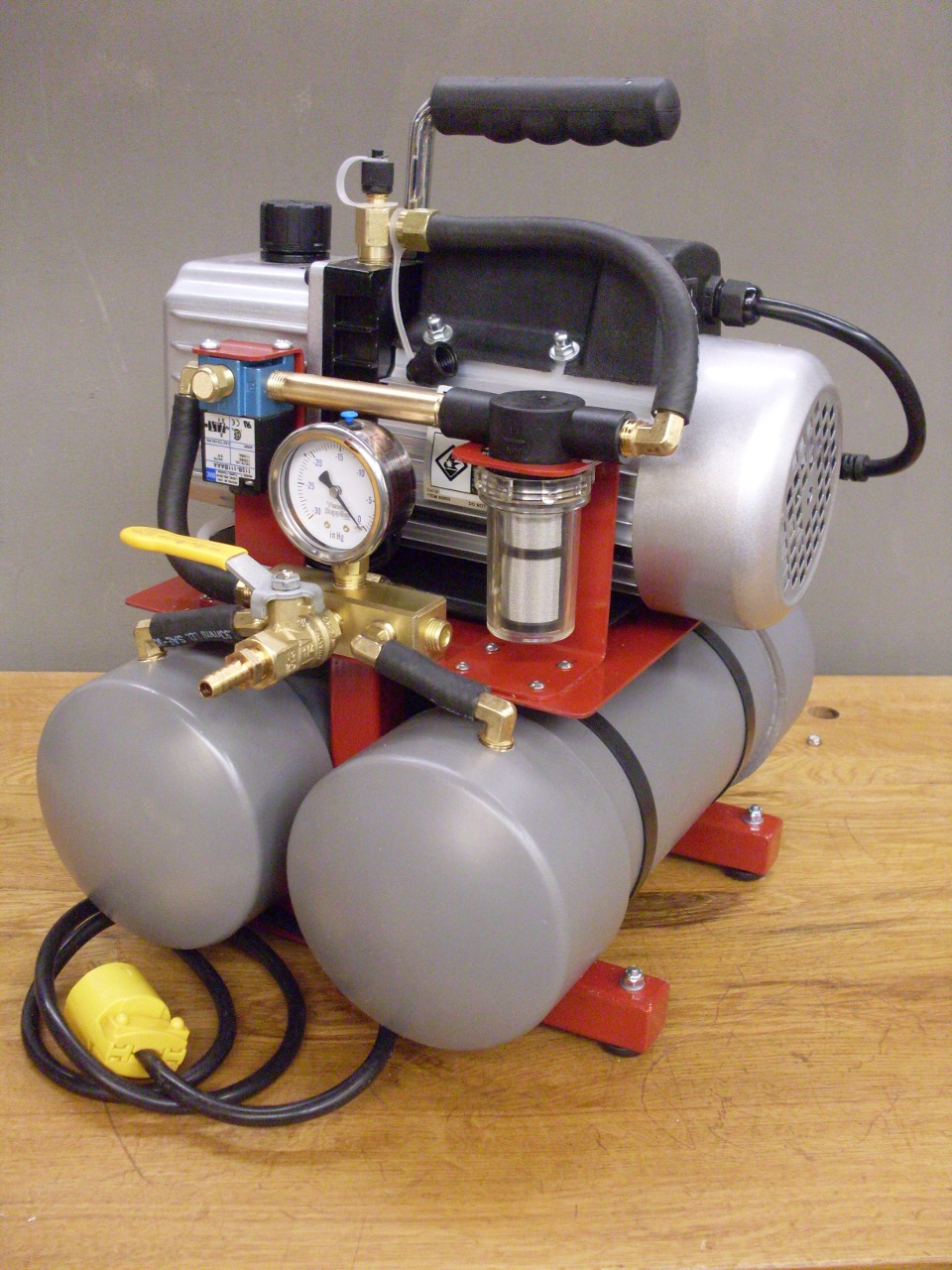

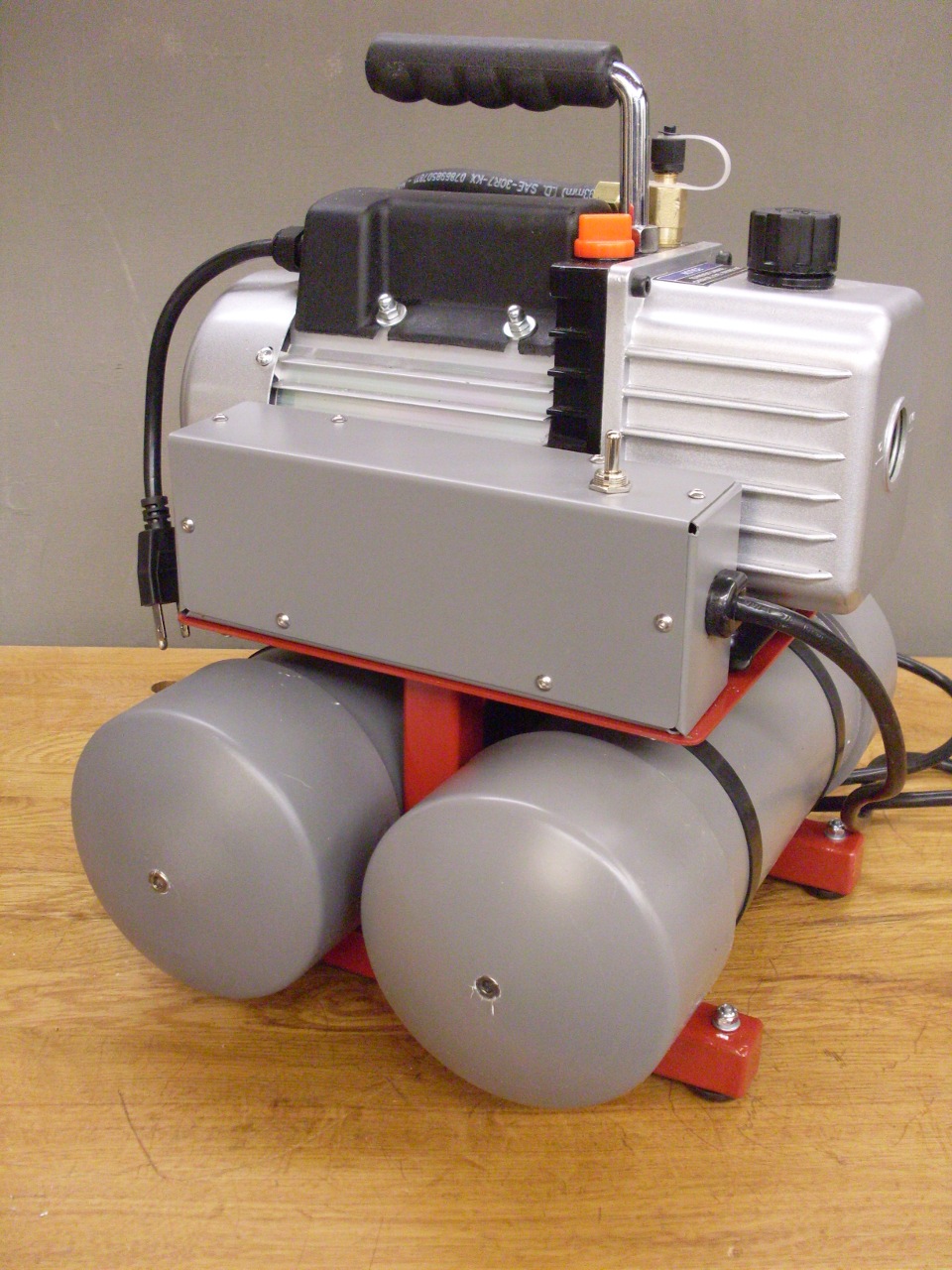

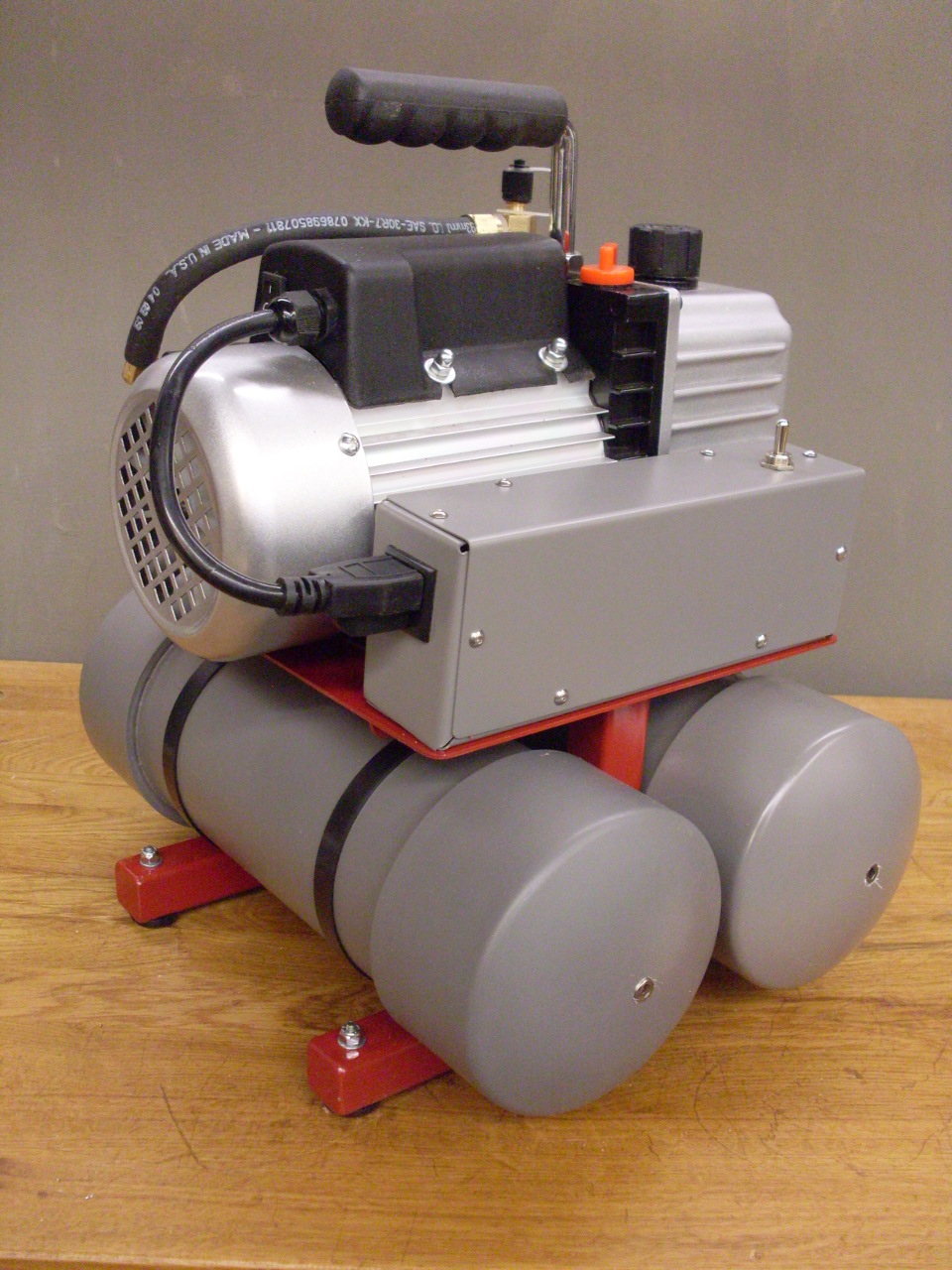

Mounted

the reservoirs with some serious duty cable ties, then finished the

plumbing with some vacuum rated 5/16" hose. Here's the final product:

After

moving one misplaced wiring connection, the pump ran great the second

time I tried it. The delay timer is set at about 2 seconds, which

seems to be plenty of time for the pump to get up to speed.

I'd really like to find a different timer since this one is

really more for the minute range, and I have to have it set almost at

its minimum.

I

did a quick 5-minute leakdown test, and saw no detectable drop in

vacuum, which means there are at least no gross leaks.

Now to see about making a vacuum veneering bag.

Comments to Ed at: elhollin1@yahoo.com