To other pages

August 8, 201

Contact Breaker

[Click on pictures to see a bigger version]

After

getting most of the wiring squared away, I turned to the contact

breakers today. Though going to some kind of breakerless

electronic ignition is a very popular mod to these bikes, I've decided

to stay with the stock points at least for now. I have nothing

against solid state ignition systems, but I also don't see a huge

advantage, either. If a problem develops in the ignition system,

a roadside fix is a lot more likely with a conventional point system

than with an electronic one.

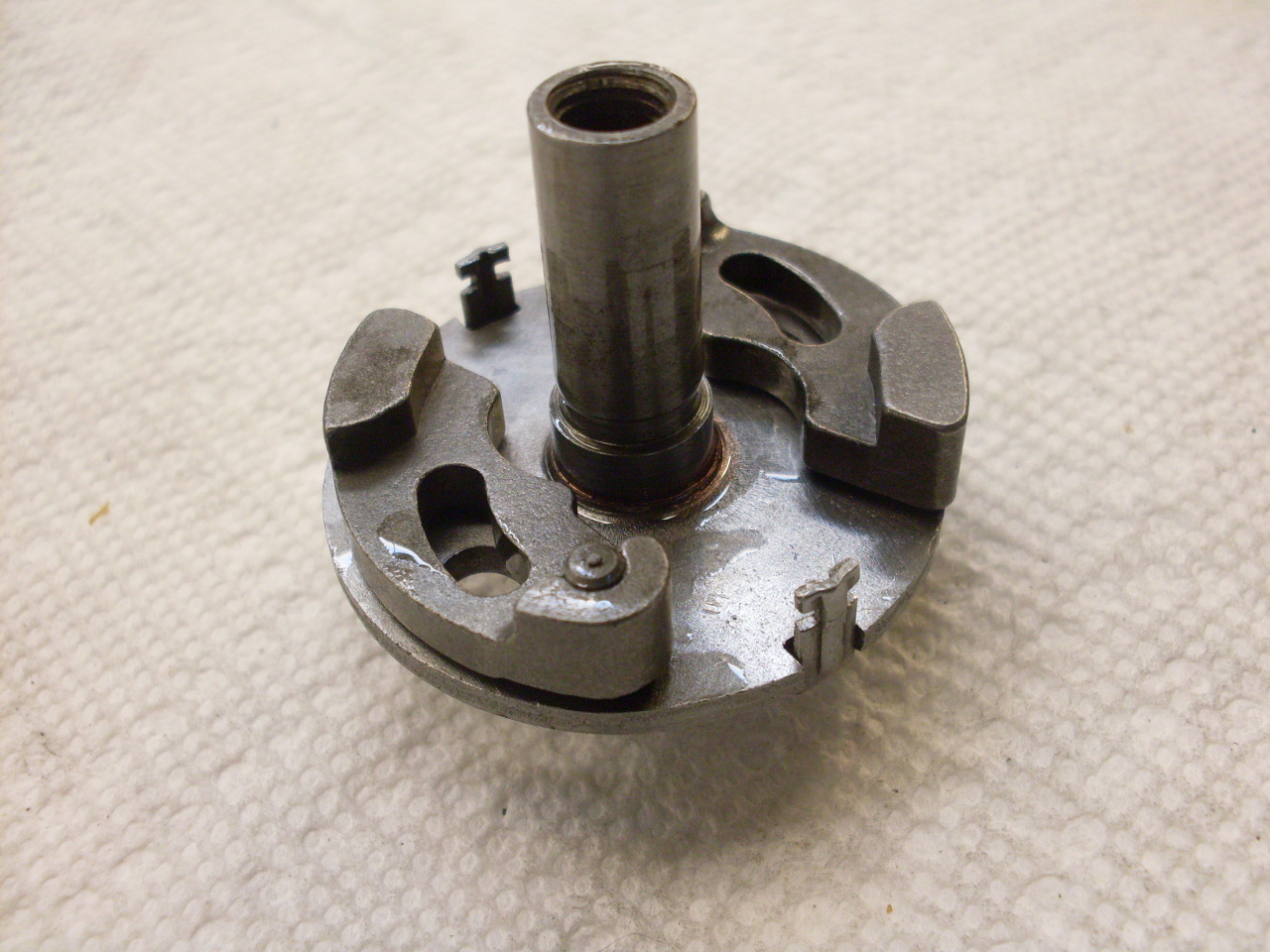

Thre breaker system on this bike

has two major subassemblies--the centrifugal spark advance system and

the breaker points themselves. The Auto Advance Unit (AAU)

is pretty sturdy and basic. The parts cleaned up easily.

There is a spindle that is driven by a short keyed taper from the end

of the exhaust cam shaft. On the spindle is a plate that carries two

weighted arms that can pivot outward against a pair of springs. Over

the spindle is the breaker cam with two arms that fit into arced slots

in the weighted arms. As the arms move outward with increasing RPM of

the engine, the breaker cam is rotated relative to the spinning

spindle. The AAU can advance the breaker cam up to 12 degrees, and the

advance curve (vs RPM) is determined by the weight of the arms and the

rate of the springs.

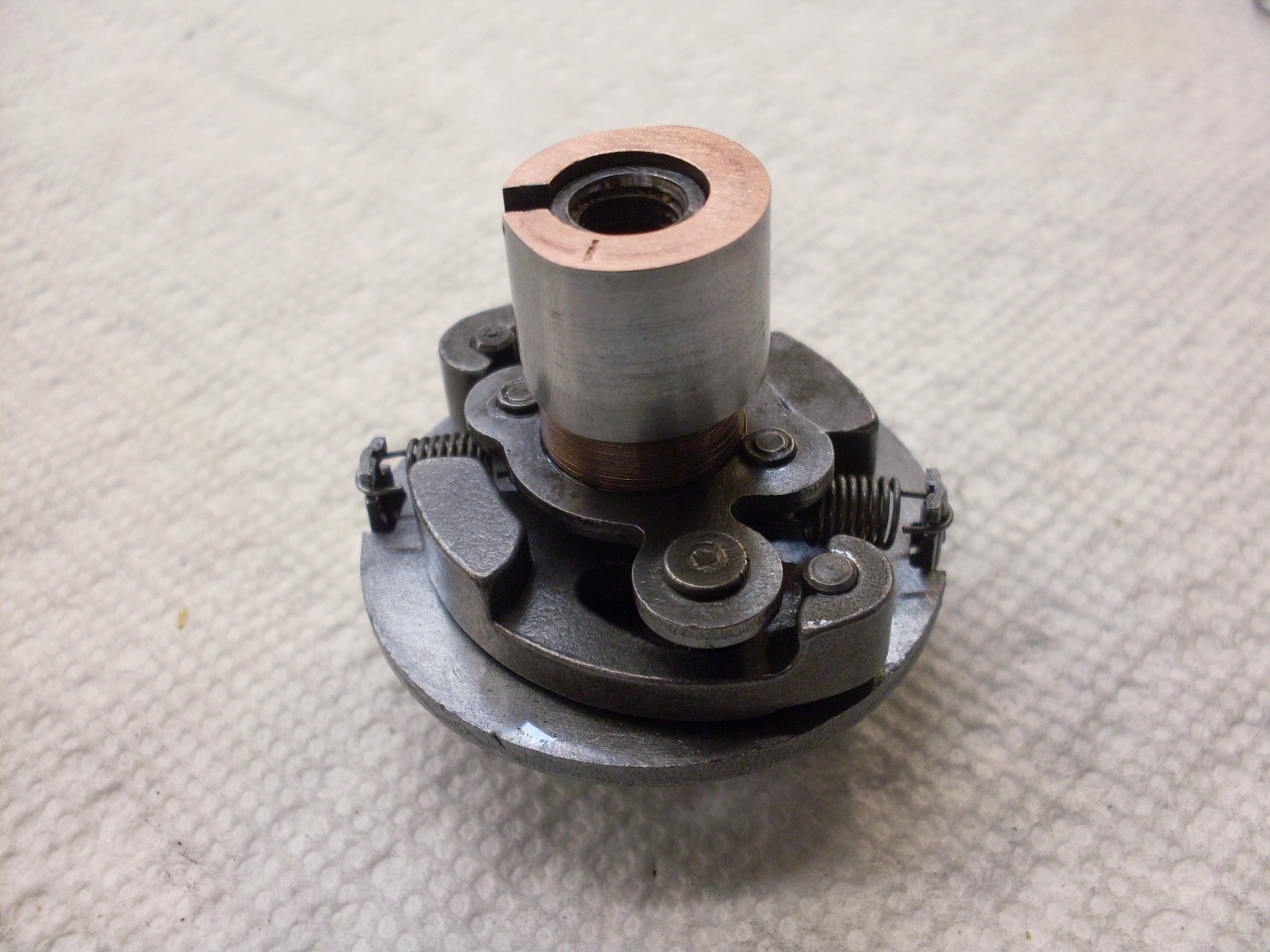

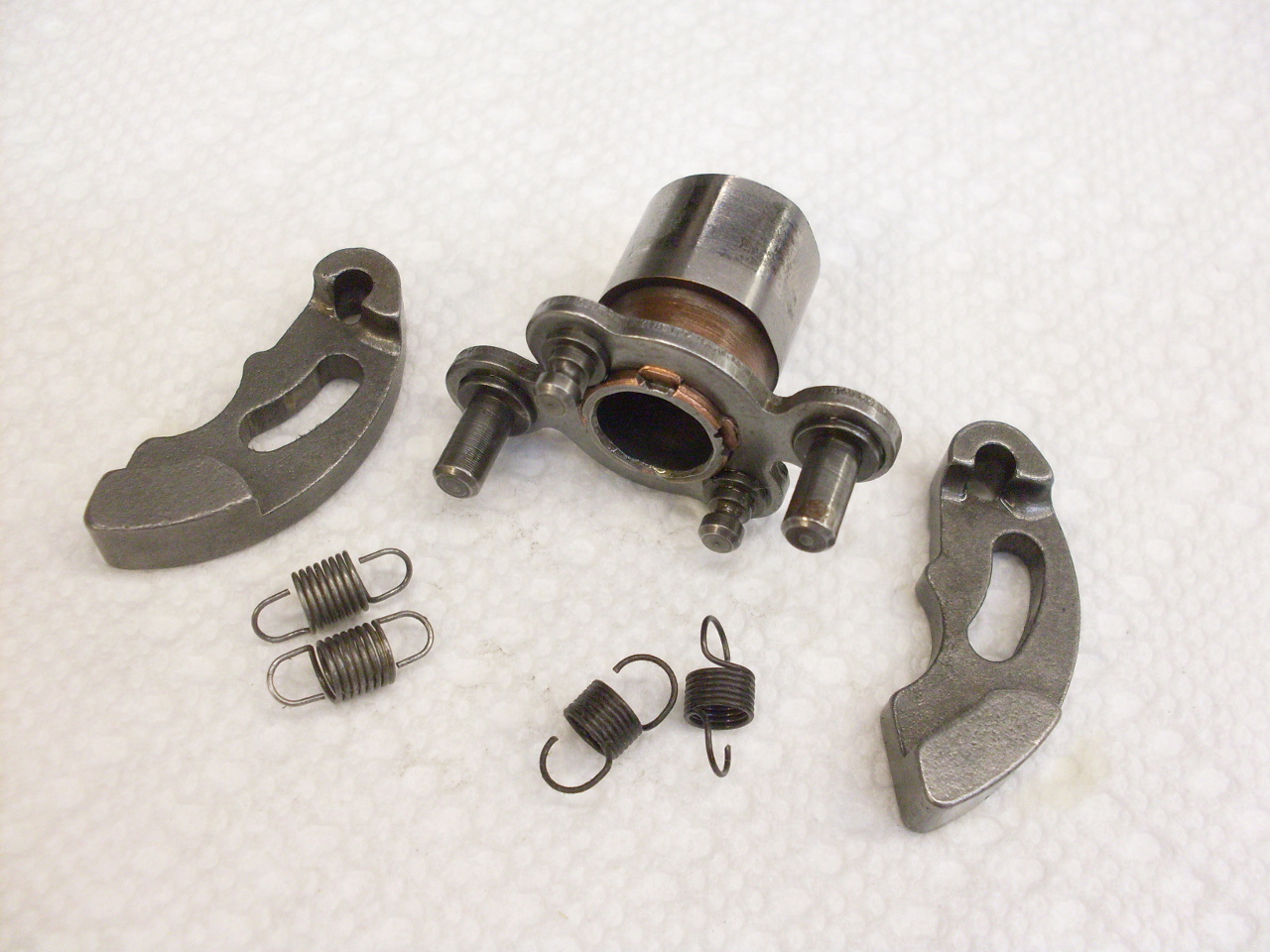

Though

I had no specific reason to suspect they were bad, I ordered a new set

of AAU springs to replace the 40-year old ones. New springs are

on the right. They do look a little tighter than the originals.

The AAU assembly slides in, finds it's key slot, and seats in the taper. It is held in place with the re-plated hex screw.

The

breaker assembly was in there somewhere. Actually much of the

crud was sawdust from sitting on a shelf near my table saw for a year.

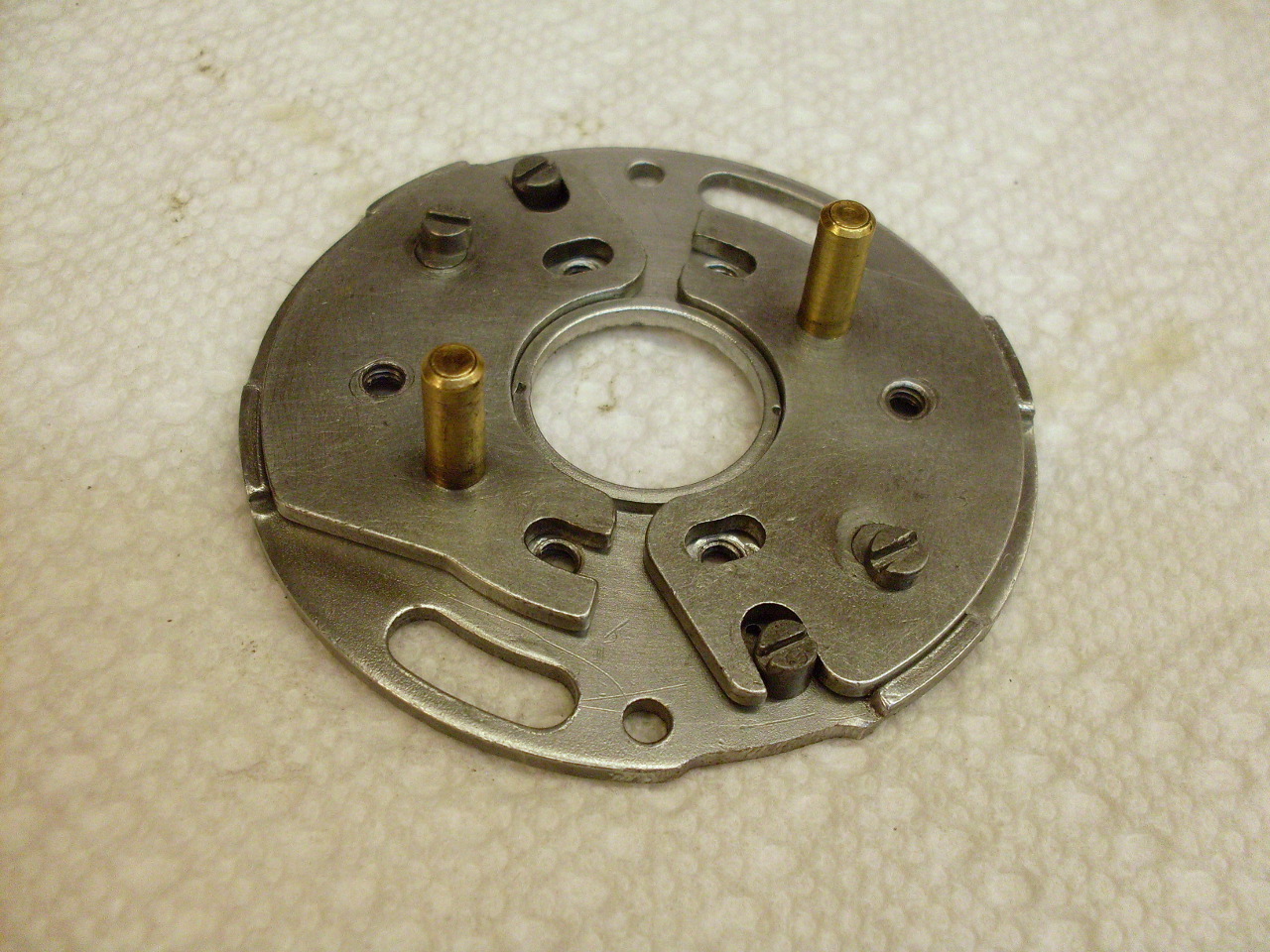

This

is the bare breaker plate. It shows a small edge cutout at the

lower right that I added to relieve the very tight squeeze for the

ignition wires. The picture also shows new little eccentruc pins

that are always bunged up on these old machines.

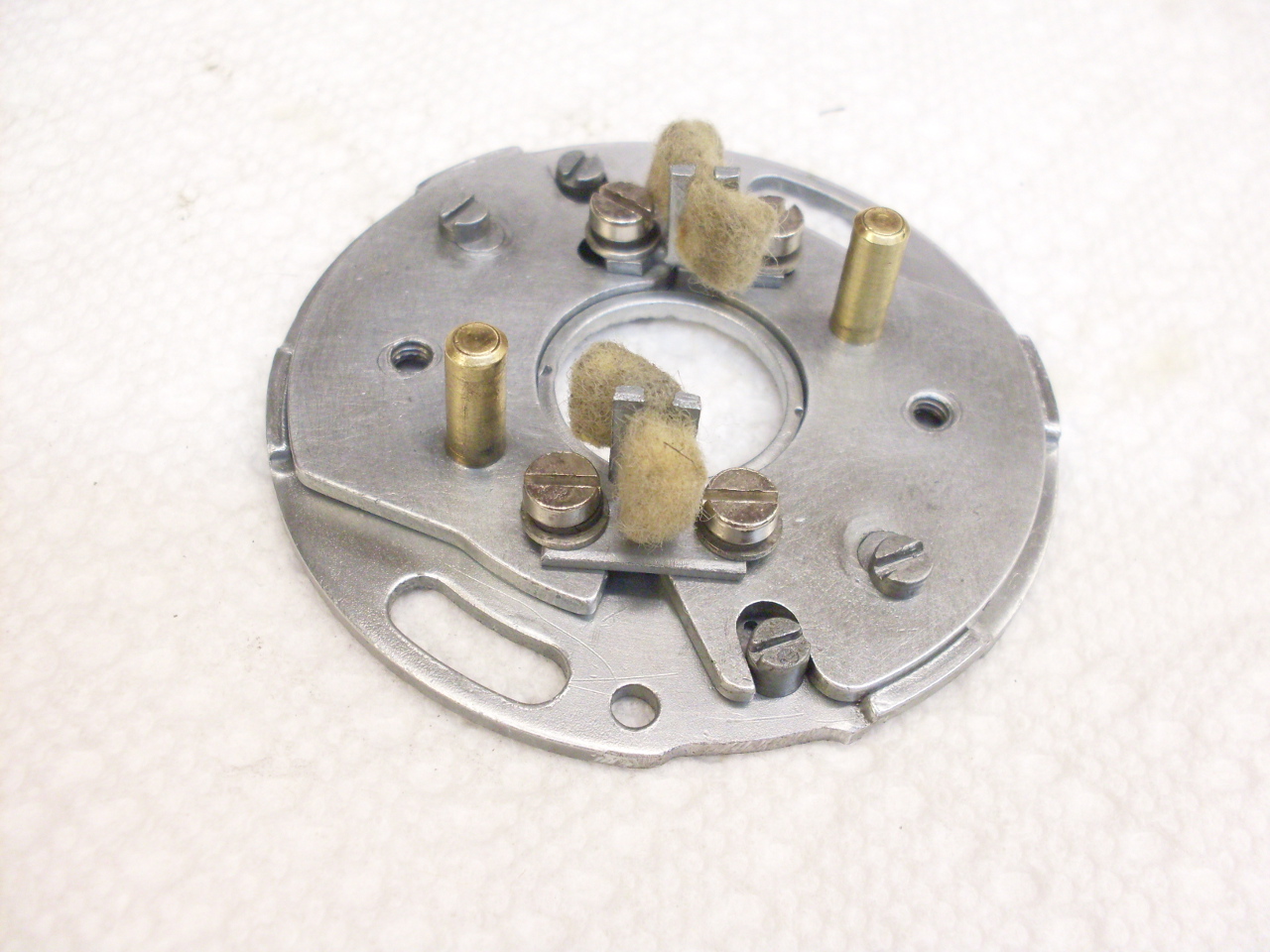

To

the breaker plate are mouned a carrier plate for each set of points.

The eccentrics on the breaker plate can move the carrier plates

in short arcs around the center of the breaker plate. This allows

independent timing adjustment for each cylinder, something that wasn't

possible on some earlier models.

The

carrier plates are fixed in position by little brackets that also carry

the felt wicks that lubricate the breaker cam. My shop manual

says that these felts were "...impregnated with Shell Retinax A

grease." It doesn't appear that Shell Retinax A is available any

more, but I believe it was just a #2 lithium grease. To

rejuvenate the felts, I just soaked them in solvent a few times,

then soaked them in a bath of modern lithium grease considerably

thinned with mineral spirits. The felts soaked up a surprising

amout of the grease.

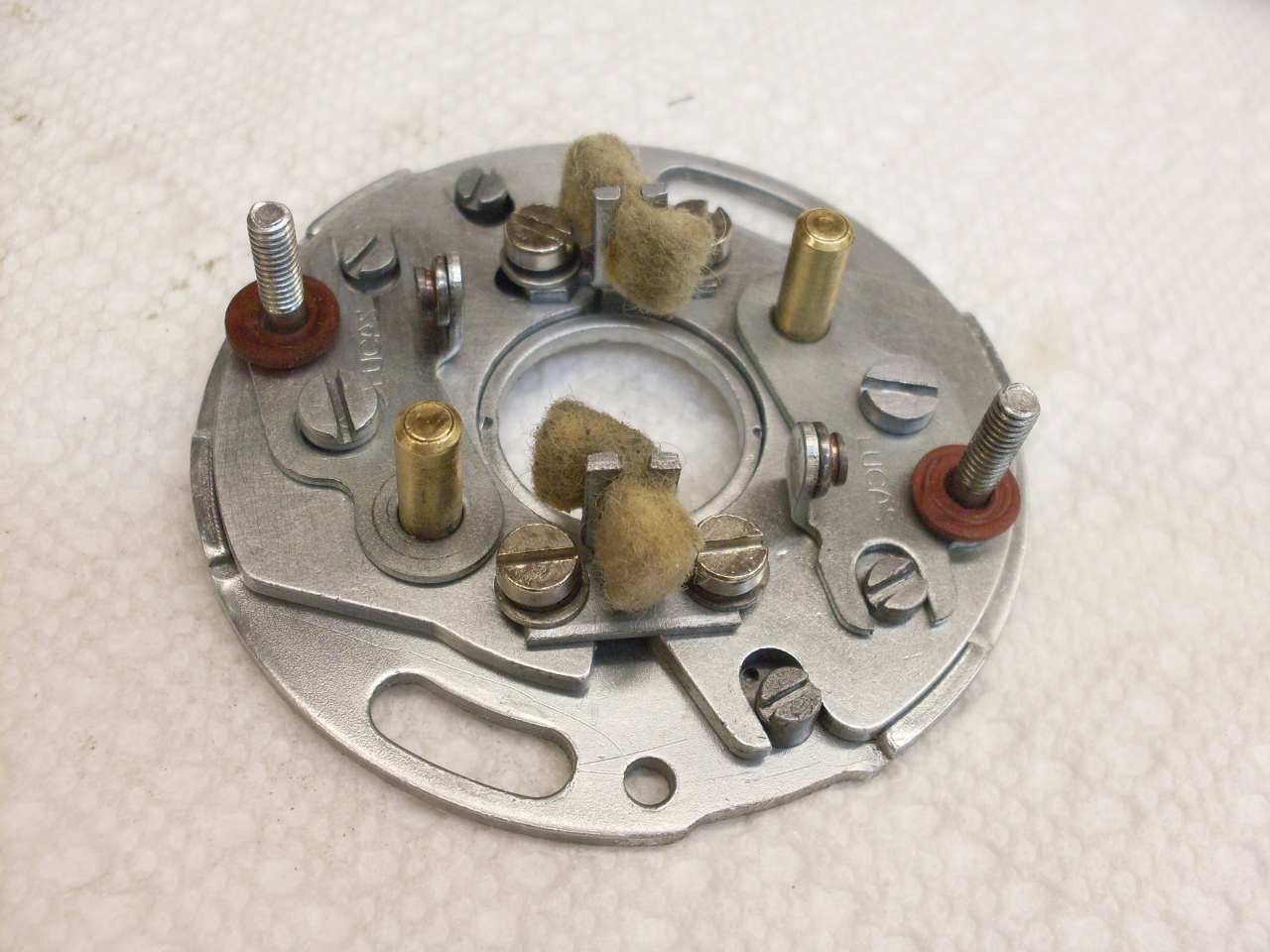

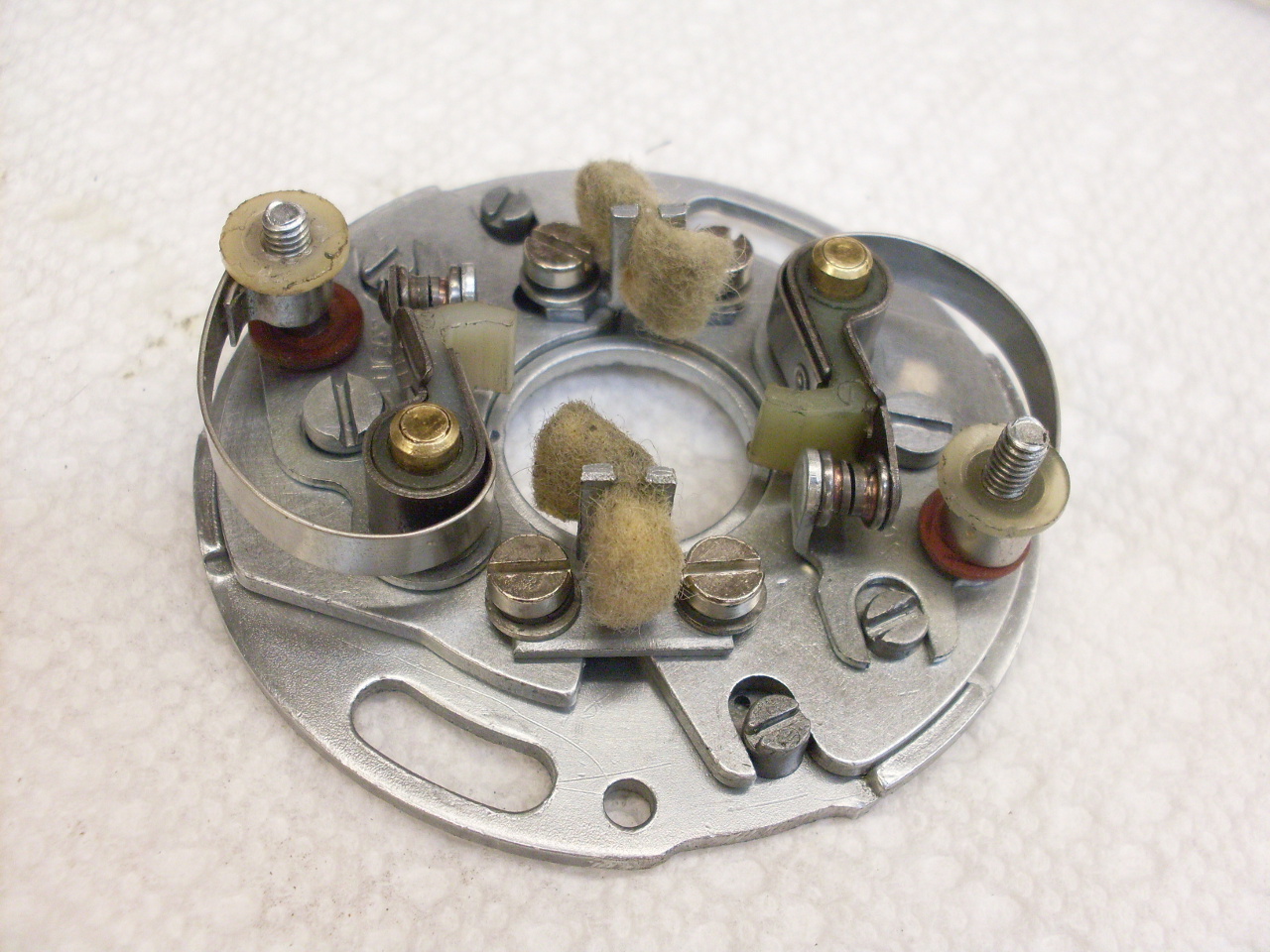

Then

the fixed and the moving parts of the points themselves are added.

I re-used the Lucas points. They are probably not original,

but certainly date from the 70s. Pitting was minor and cleaned up

easily with a diamond file and silicon carbide paper.

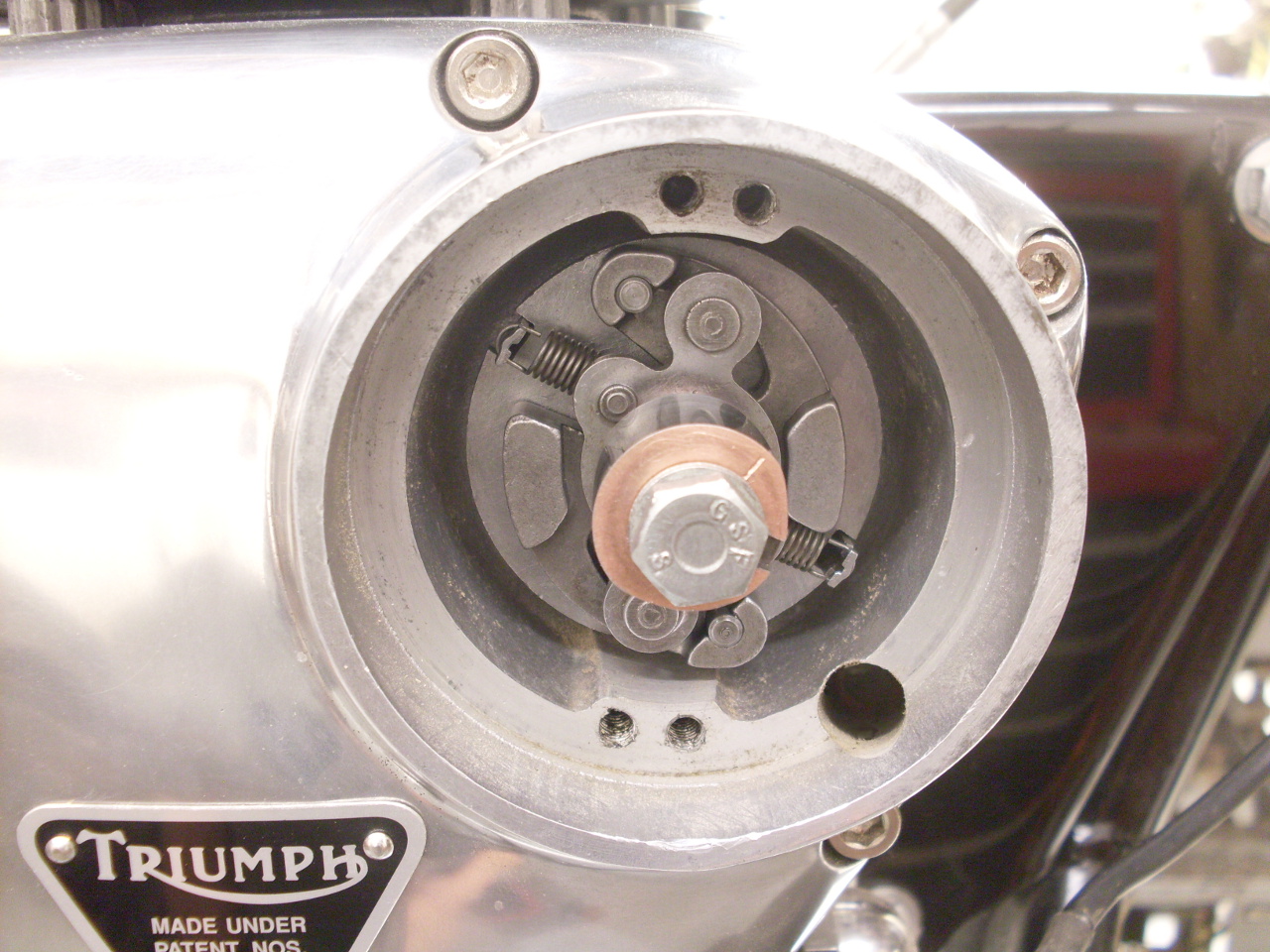

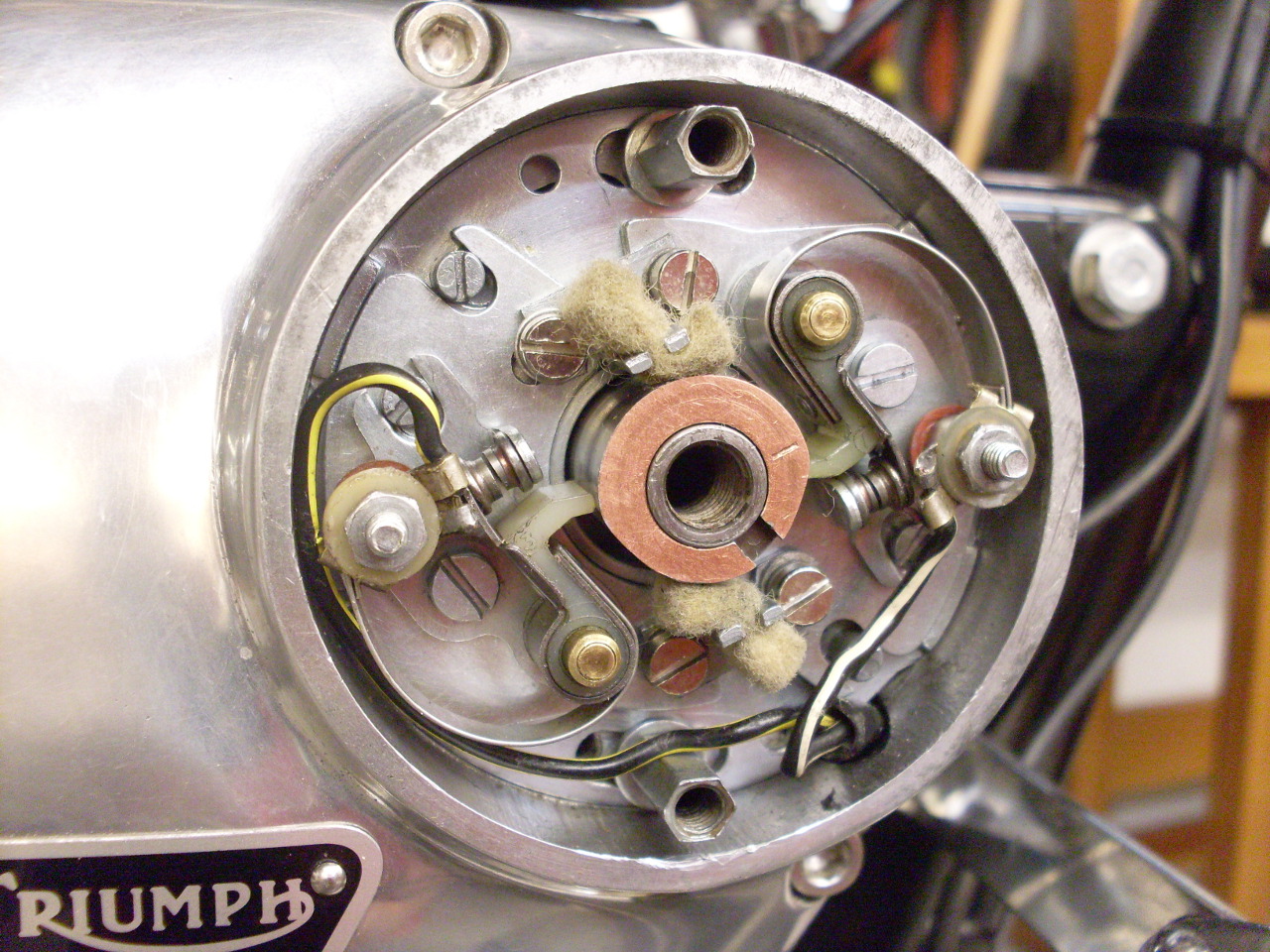

Mounted

the breaker plate in the timing cover after runining the breaker wires

through the hole to the outside world. The rubber grommet is a

pain to get in place, but being tight means it will do a good job of

keeping crud out of the engine.

Next time I take this cover off will be to time the engine.

Comments to: elhollin1@yahoo.com

To other pages