February 13, 2011

Tires

[Click pictures for a better view]

This

bike was supplied new with Dunlop K70 series tires. I'd replaced

them many years ago with K81 tires, and though they didn't have many

miles on them, and they had plenty of tread left, they were at least 30

years old and were noticably harder than new tires. It seemed

that traction could be a problem, especially in wet conditions.

I

found to my happy surprize that Dunlop still supplies the K70 tires,

apparently mostly for vintage bikes. Another happy surprize was

that they didn't cost as much as I feared. It looks like the K70

tires are a little higher in profile than the K81s. Also, the

K81s had markings on the sidewall indicating the correct direction of

rotation. The K70s apparently have no preference regarding which

way to spin.

When I had the

tires off, I decided to also check the wheels for true running. I

made a temporary axle out of some threaded rod and some nuts with one

side turned to just fit in the inner race of the wheel bearings.

Also made a jig to hold the wheels while truing and balancing.

I was prepared to learn to lace the wheels, but both

wheels turned out to be pretty true--within 0.030 both in concentricity

and runout. I was a little disappointed, actually.

The

back rim was pretty clean inside, but the front one had some rust on

the tire contact areas. I wire brushed the rust off, and applied

two coats of a rust conversion coating.

Here

is all the stuff that needs to go into the rear wheel. There is the inner tube, a

rubber rim strip that covers the spoke nipples so they won't chafe

the tube, and two "security bolts", sometimes called rim locks. These bolts clamp

the tire to the wheel so that on hard acceleration, the tire can't move

in relation to the wheel, possibly causing the tube to shift,

which would stress the valve stem. The front wheel does not have the security bolts.

The yellow mark is put

on each tire by Dunlop to mark the lightest side. Since the only

known imbalance in the wheel is the valve stem, the yellow mark is

normally aligned with the stem.

This

was not the original rear wheel for this bike. The original was a

"QD" (Quick Detach, I think) type in which the sprocket and brake

drum was a single piece. I believe this was a difference between

the US models and the "UK and General Export" models. When I went

to replace the worn sprocket back

in the States in the late 70s, I couldn't find a QD part, so swapped my

rear wheel

for a used US style replacement. I was sad to find when I took

the tire off that some past genius mechanic had used security

bolts for a much narrower wheel. They not only didn't clamp

properly, but got deformed by the tire bead.

After

the wheels were cleaned up and checked for true, I started to assemble

them. It is common to rub talc on the inner tube so it will

inflate smoothly and not get twisted or bind. Some baby powder today is

actually corn starch. I don't know if it works as well on tubes,

but actual talc can still be found. There apparently exists

actual "tire talc".

First

put on the rim strips, aligning the hole with the valve stem hole in

the rim. On the back wheel, it's necessary to cut holes for the

rim locks.

I

won't detail the mechanics of convincing a stiff rubber tire with an

18-inch inner diameter to go over a rim with a 19-inch outer diameter,

but it can be done. A couple of tire irons, a little soapy

water, and a determined attitude is all it takes. Put one bead

on, stuff in the inner tube and the rim locks, then try to get the

other bead on without pinching (and thus puncturing) the inner tube.

The rear wheel went without a hitch, but I ruined the first tube

on the front.

With

the tires on and inflated, I statically balanced them on the same jig

used for checking true. Set the wheel slowly in motion and mark

the bottom of the rim when it comes to rest. Repeat this a dozen

or more times, and it will become obvious where the heavy side is.

A "false indication " can sometimes happen where the heavy side

actually stops at the top, since there is no torque arm to pull the

wheel around. Once located, the heavy side can be checked by

placing it at the nine o'clock or three o'clock position and

releasing. The marked point should consistently fall to the

bottom.

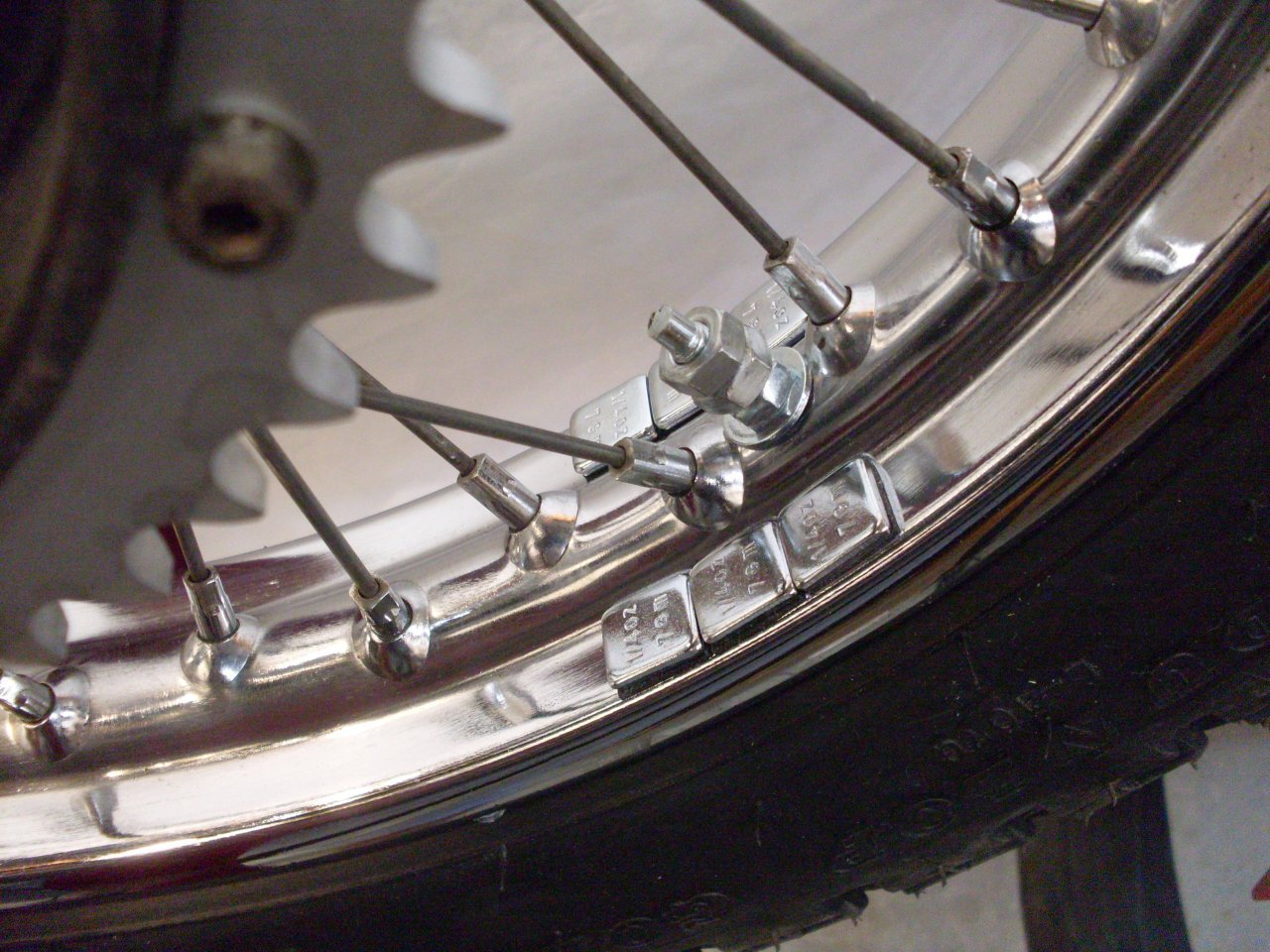

These

self-stick motorcycle wheel weights, are 1/4-ounce (about 7 grams)

each. I taped them on opposite the heavy side one at a

time at first just to see how many it would take. When

balanced, the wheel will stay in any position it is released, and show

no preference for any particular point being on the bottom. In

the case of my rear wheel, it took seven weights--almost two ounces.

On

my rear wheel, the light side happened to be right at one of the

rim lock bolts, so I was able to add some of the weight with extra nuts

on the bolt. This let me get the number of 1/4-ounce weights to

an even number . I split them up to both sides of the rim for

better symmetry. With any self-stick item, adhesion is improved

by cleaning the surface with alcohol first.

My

front wheel already had this balance weight that fits on a spoke

nipple. I had to add anpther 1/4 ounce to make it perfect.

That yellow spot will come off with soap and water.

[Click pictures for a better view]

To more pictures

Send comments to: elhollin1@yahoo.com