To my other TR6 Pages

August 5, 2017

Heater Plinth and Controls

Nestled

between the dashboard and the center dash support on a TR6 is a padded

plinth that holds the heater controls and the choke control. The

plinth is composed of a metal base that supports a molded foam shape

covered with textured black vinyl. My plinth was OK except for a

split in the vinyl above the choke control. This is a pretty

common place for vinyl damage since many people apparently brace their

thumb against the padding to pull out the choke.

I

didn't see a good way to repair the vinyl, so I peeled it all off,

exposing the foam. The foam was in good shape except for a few

little voids where it decided to go with the vinyl.

Based

on the good underlying structure, I decided to try to recover the

plinth with new vinyl. I gave it a valiant attempt, too. I

first filled the few voids and other minor inperfections with a pliable

filler.

My

first attempts to stretch new vinyl smootly over the plinth by hand

were utter failures. The curves were just too extreme.

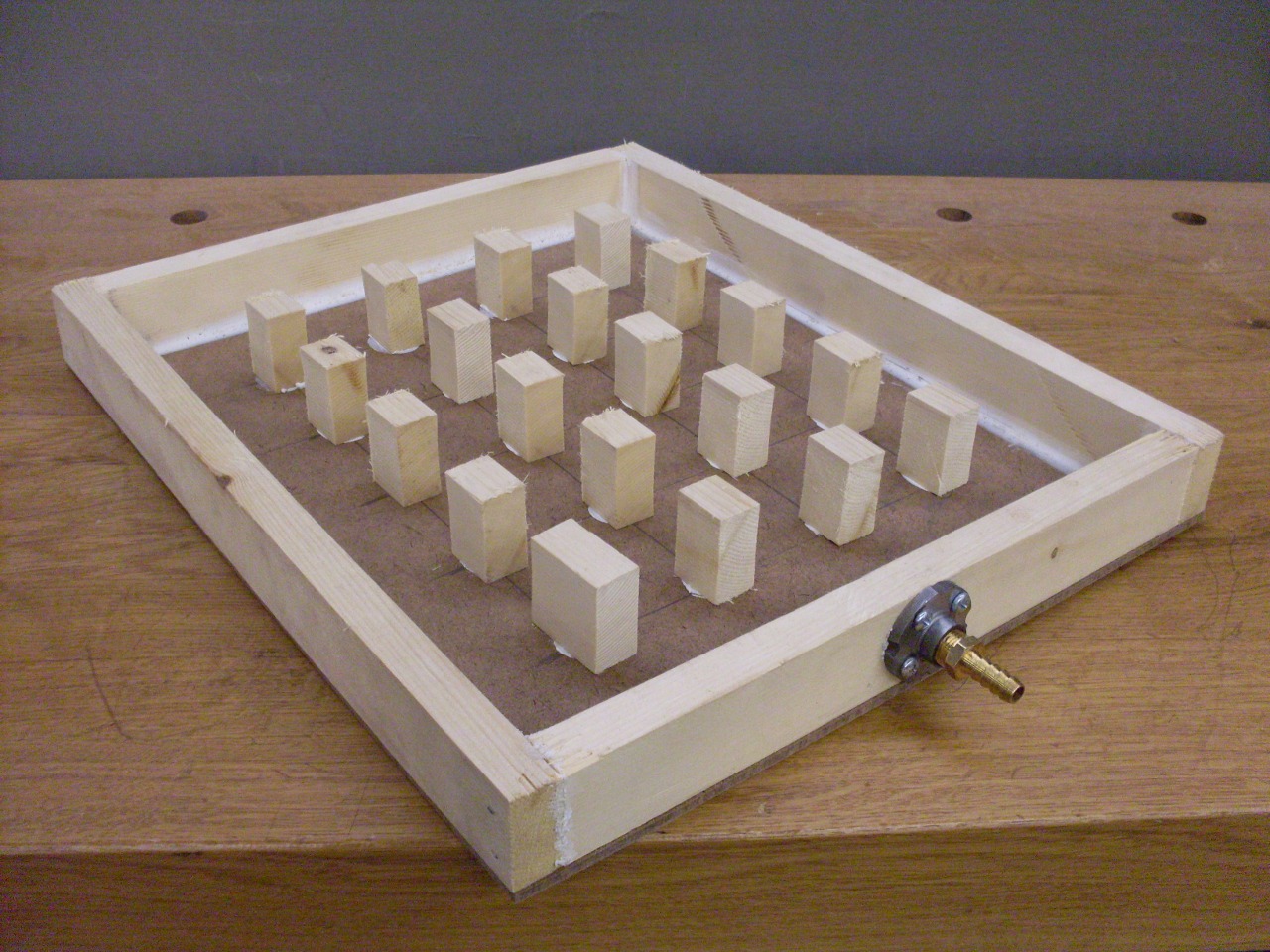

I

erven tried vacuum forming, using a vacuum box and a frame with heated

vinyl. This came closer, but I could never completely eliminate

the excess material at the corners.

In the end, despite heroic effort, I threw up my hands, admitted defeat, and grudgingly ordered a new plinth.

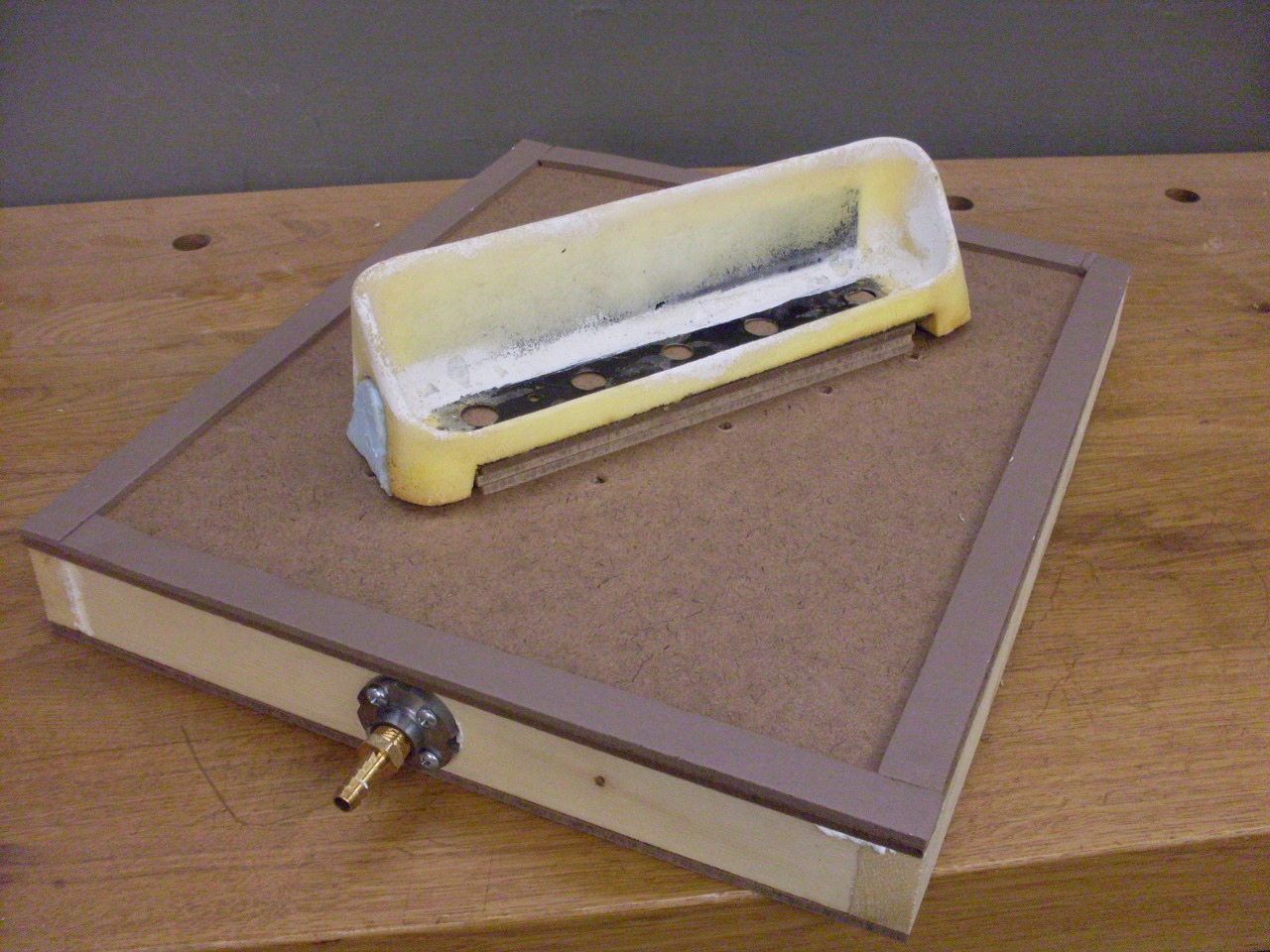

These

items are not cheap, but when I got it, the quality seemed OK. It

came with a lot of excess flash around the perimeter that has to be

removed. It would have been nice if the manufacturer had done

that step.

Also, the new plinth lacked the metal bracket on the right side rear of the part.

Though

the plinth seemed usable, I had a couple of mods planned for it.

First, I had decided to move the ignition switch from the awkard

and silly location under the steering column to the center of the

plinth, as in earlier TR cars. Second, I wanted to extend the

theme of the woodgrain dash and dash support to the plinth by including

a zebrawood insert.

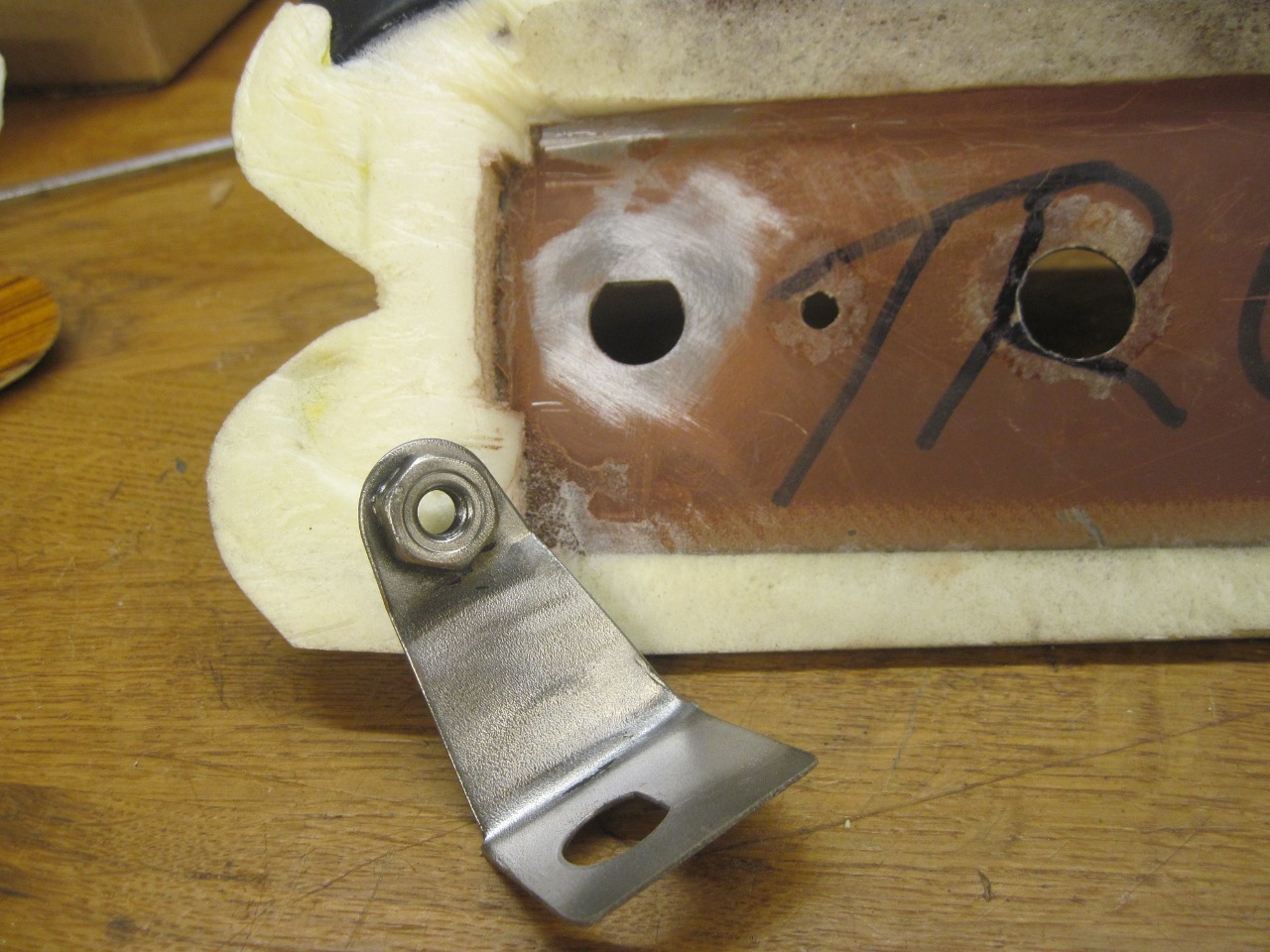

Before

I got to the mods, though, I wanted to see about adding the missing

bracket. I cut the bracket from the old plinth, including the

choke mounting hole. Keeping the hole would help align the

bracket on the new plinth.

I

cleaned paint and such from all the parts, and peeled back some of the

vinyl from around the choke controle mounting hole. This was

possible only because the wood insert will cover the area up.

Then clamped the bracket in place on the new plinth and fixed it

in palce with a few small spot welds.

Glued down the raised vinyl flaps, and painted the backside.

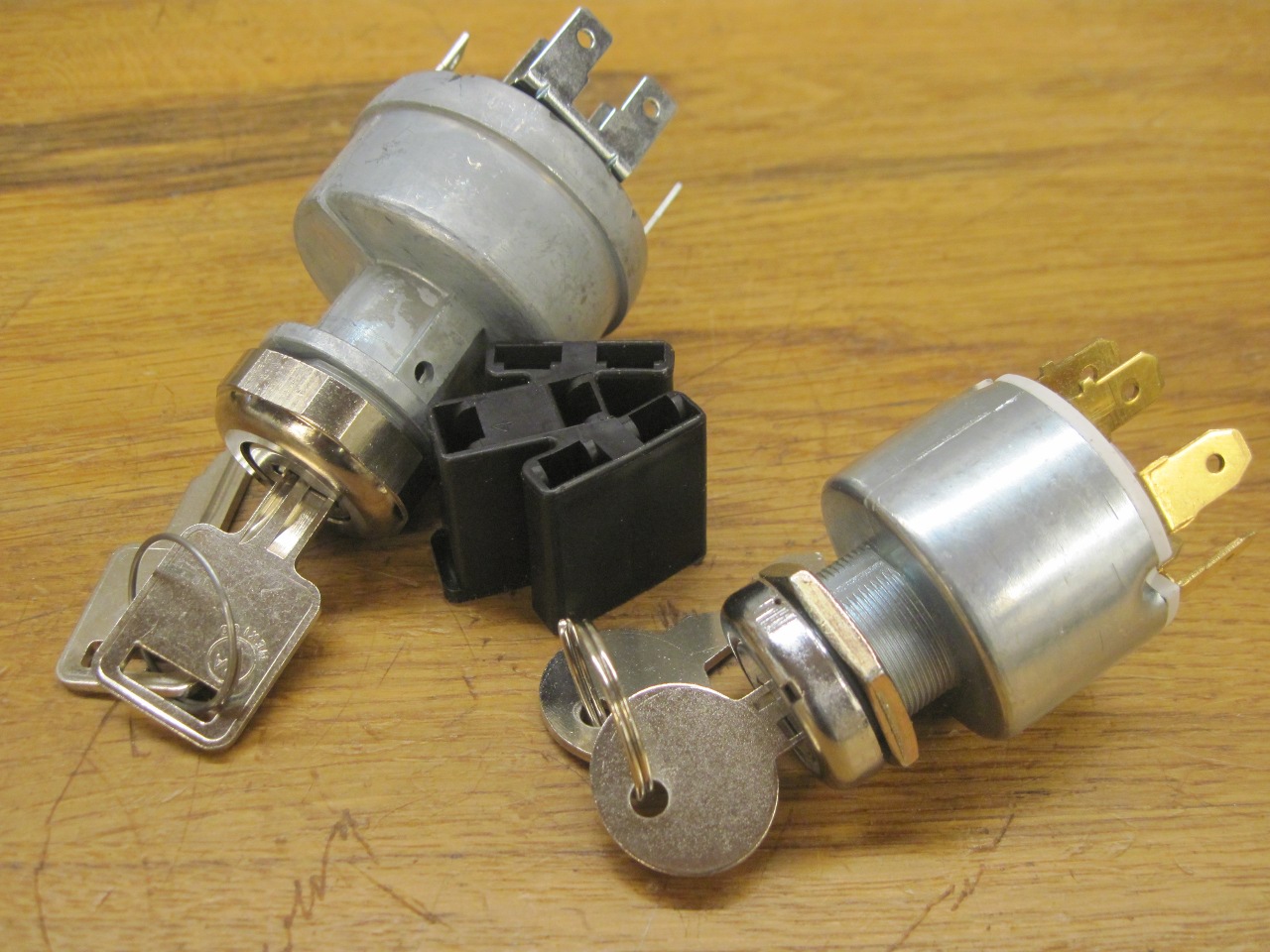

For

the ignition switch, I bought one apparently commonly used for this

application. It seemed a little cheesy, though. Even the

keys looked and felt cheap. I ordered another, more expensive

switch which felt more robust. The better one is on the left. I made the one-inch "D" hole necessary to mount it.

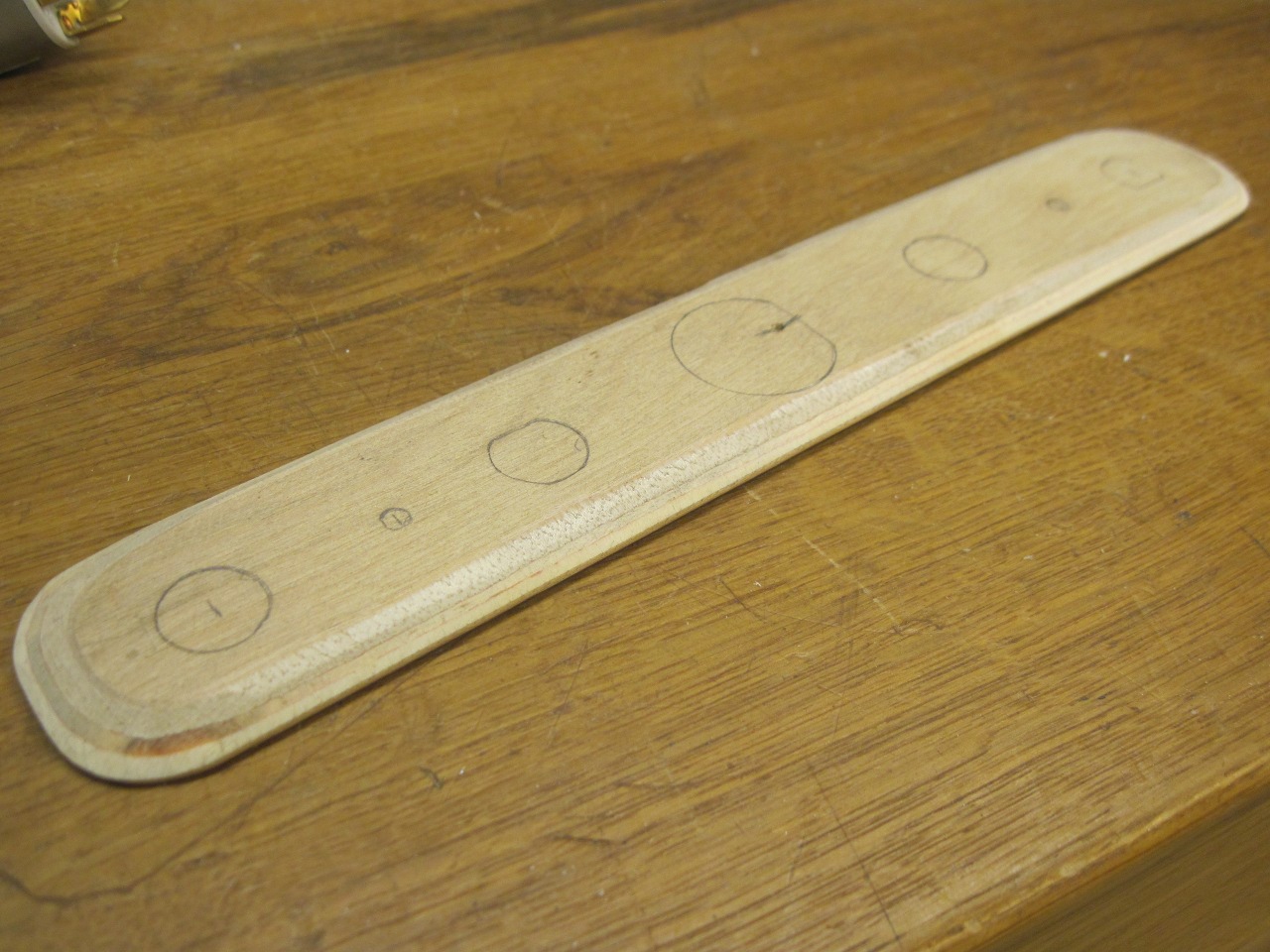

For

the woodgrain, I laminated some zebrawood veneer to some 1/8" plywood,

finished with seven or eight coats of varnish, and cut it to shape.

The backside had to be radiused to accommodate the generous

fillet around the bottom of the cavity in the plinth.

The

extra thickness of the wood insert posed an immediate problem.

The threaded snouts of the controls were now not long enough to

get the nuts on.

For

the ignition switch, I had to turn off the flange that normally would

be right against the backside of the mounting panel, and replace

it with a metal ring that rested on the body of the switch. This

allowed the threaded barrel to protrude enough for the fixing nut.

For

the other four controls, my solution was to open up the holes in

the wood insert and use these new custom fixing nuts. Each nut

has a short barrel below the hex that reaches down into the oversized

hole in the wood insert to bear against the metal base of the plinth.

This means that the hex of the nut doesn't actually touch the

finished wood, protecting the finish. I found an interesting

thing when making the nuts. Among the four controls, there are

three different threads. The blower switch is 9/16-28, the choke

is 1/2-26, and the other two controls are 9/16-24. Those Brits

sure do like their odd-ball threads. The nuts are aluminum, and I

anodized them black to match the black oxide hardware I'm using in

other places on and around the dash.

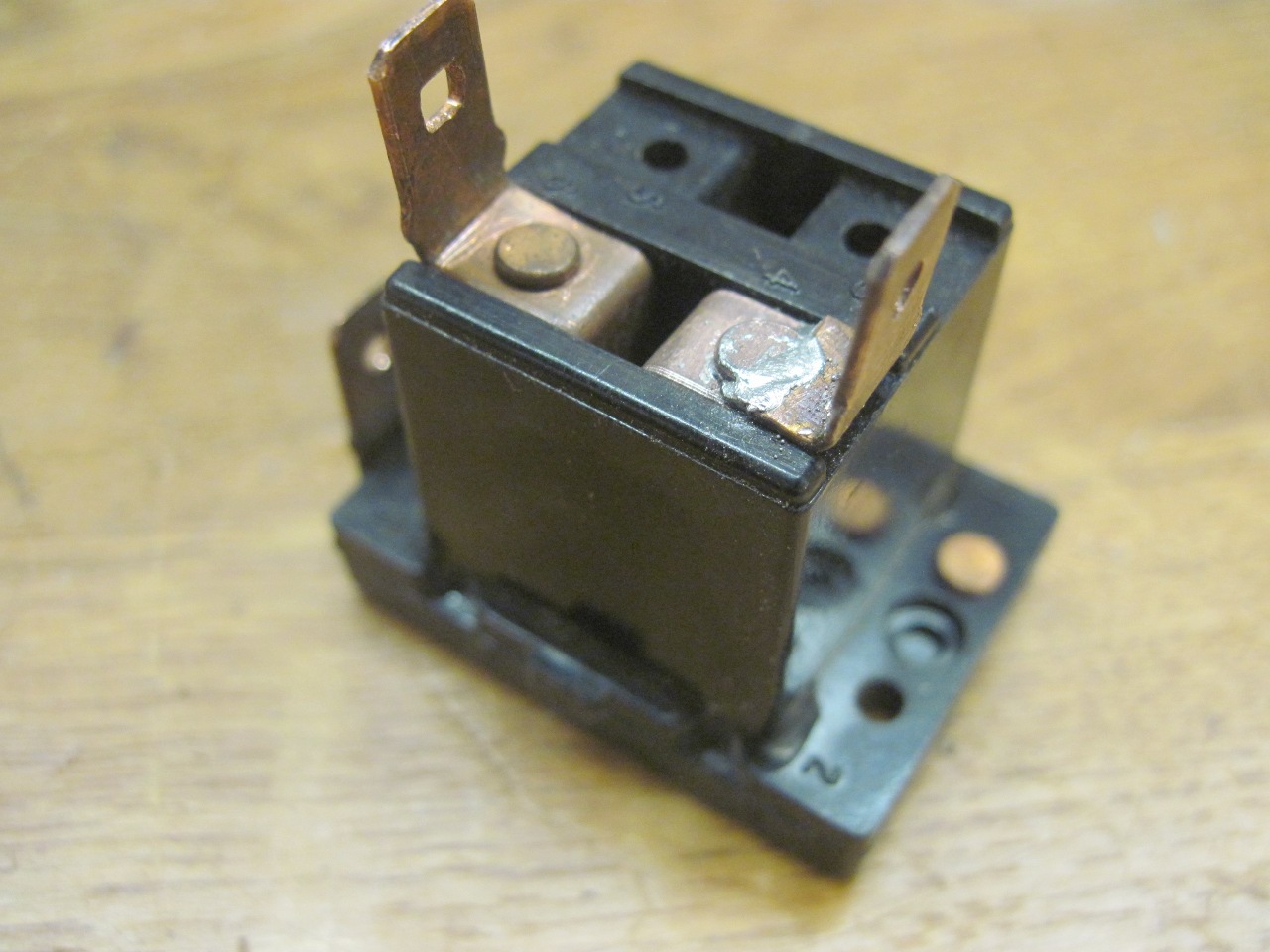

My

blower switch worked OK, but had one of its terminals broken off.

Fortunately, it has an unused terminal which I cut off and

soldered in the place of the broken one. I'll have to be careful

with it since it may not take as much stress as the other terminals,

but at least for now, I don't have to buy a new switch.

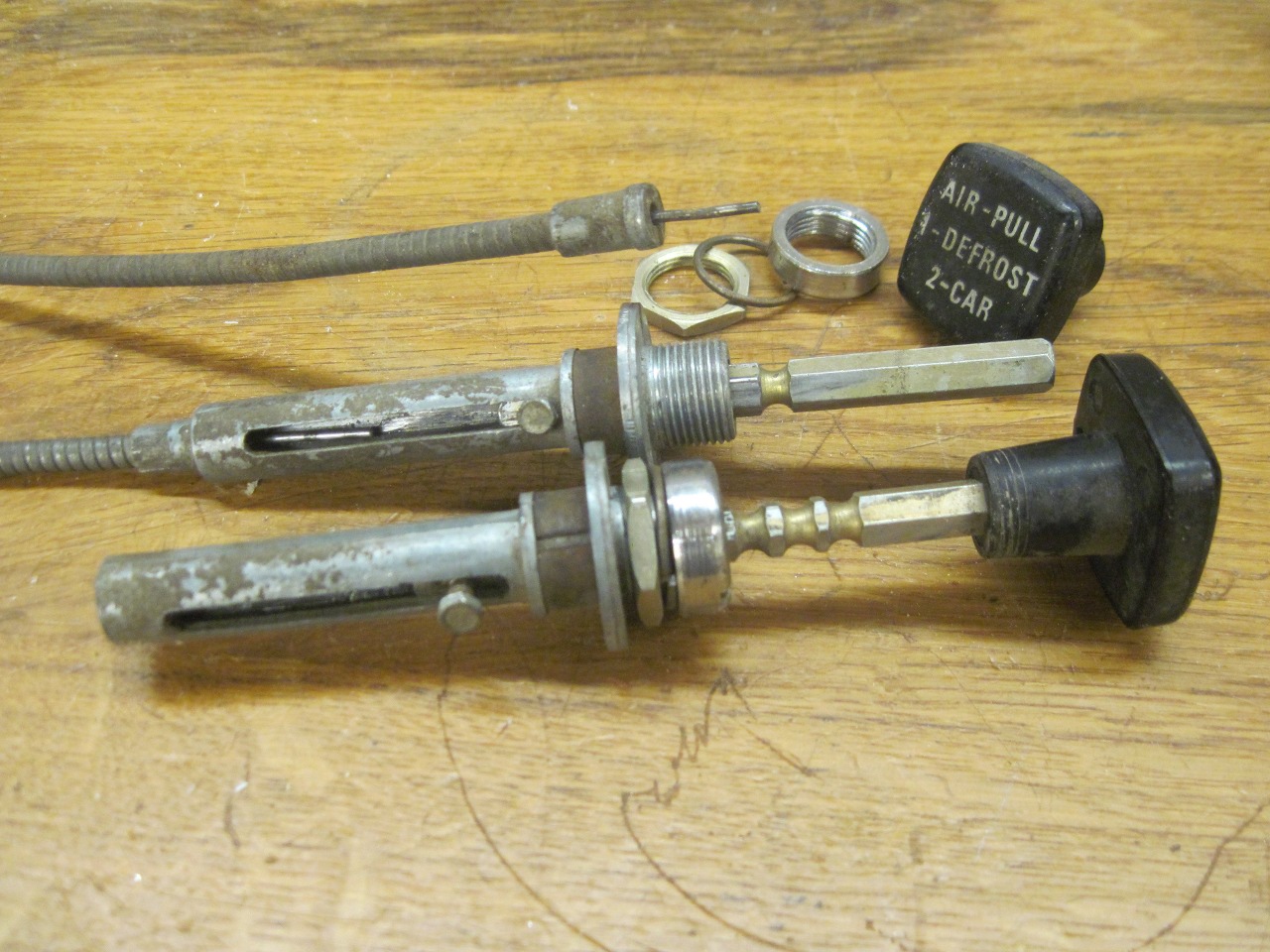

The

demister and the temperature controls are accomplished with Bowden

cables with solid wire at the core. Detented hex shafts at the

user end provide multiple positions for the controls. My controls

were dirty, but cleaned up well. One of the outer cable

housings had seperated from its control head, but this was easily fixed

by reinserting it and peening over some metal to retain it. I had

bought some new spring wire to replace the inner wires, but after I

straightened the original wires, they worked so well I didn't bother

replacing them. Heat shrink on the cables provides some extra

protection.

The

choke control on my TR6 was a dual cable with solid internal wire.

Solid wire allows both push and pull actions to be transmitted

from end to end. Earlier cars apparently had stranded

inernal wire. The stranded wire is so flexible that it can't

transmit any significant "push" force. In these cars, the choke

shafts on the carburettors had springs to make sure the chokes were

returned to the off position when the choke cable wass released.

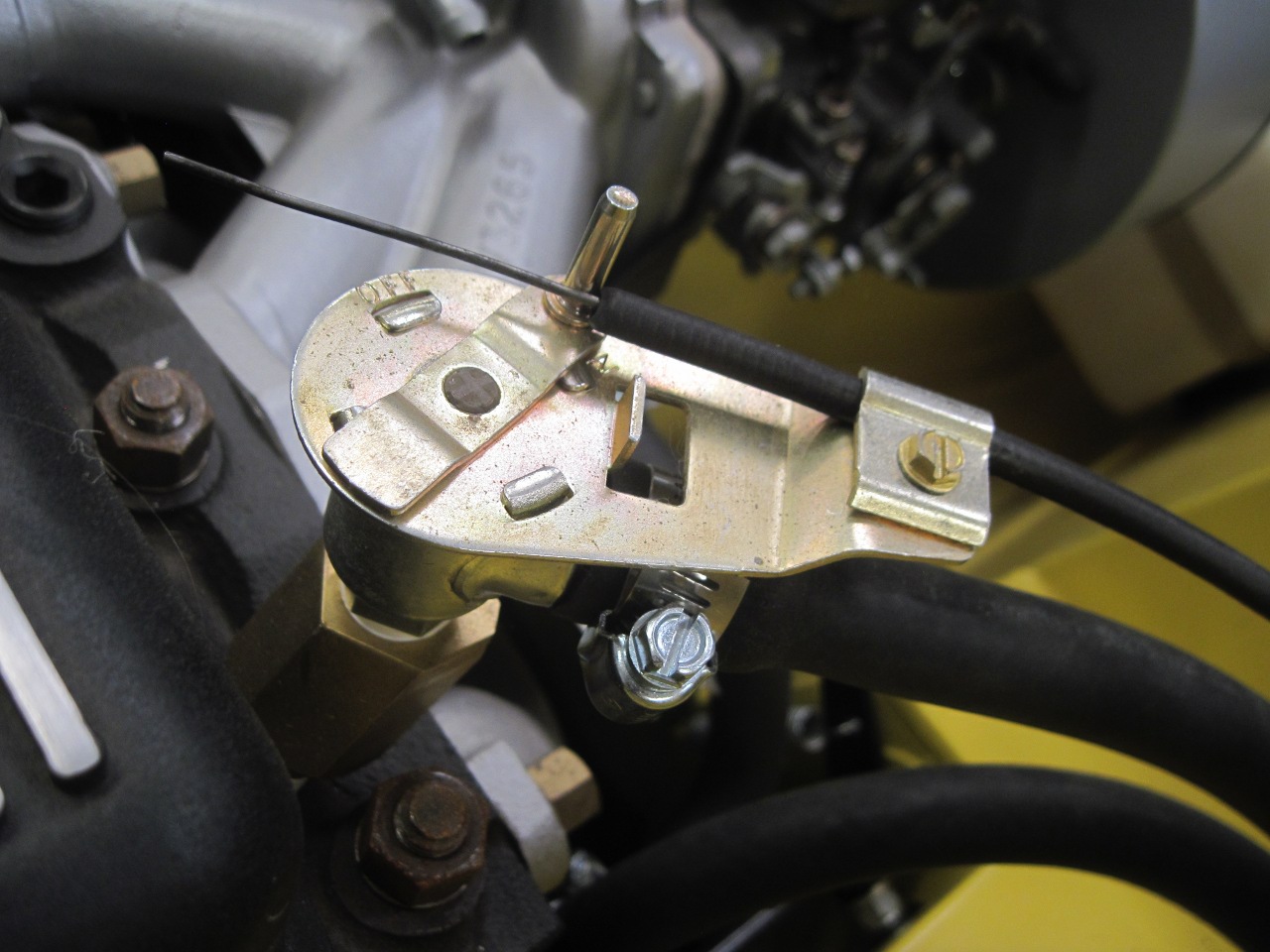

Since

the solid wire cables have a spotty track record as far as longevity

goes, I decided to revert my car back to the earlier design, and had

already installed the return springs on the carbs.

However,

since my solid-core cable was still working, and the cables are not

particularly cheap, I embarked on an ill-conceived effort to build a

hybrid cable. Though the cable worked fine, I deemed it

unnecessarily complex and finicky to set up, so I didn't use it.

Anyone really interested in seeing the complex and wonderful

cable, click here.

So,

I bought a choke cable. As with many replacement items I can't

avoid buying, this one required a little touch-up before I could use

it. I noticed right off that the knob wouldn't stay on. I

traced this to the spring that is supposed to press on a little brass

retaining pin. It wasn't even touching the pin.

Removing the spring and reshaping it slightly fixed that. I get tired of being our vendors' QC department.

I

bought new knobs, but the originals cleaned up well enough that I might

use them. The new knobs had the legends just painted on, while

the originals were heat stamped or embossed.

Stuck

knobs are a perennial problem of TR6 cars. They can be very

difficult to get off once they are on. I've been able to fix this

by doing two things: First, slightly file the corners of the hex

shaft, and file the flats near the spring loaded pin. The

staking operation that keeps the pin in place can distort the hex

a little. Second, broach the hex bore of the knob with a 1/4"

allen key that has had one end ground flat so the edges are sharp.

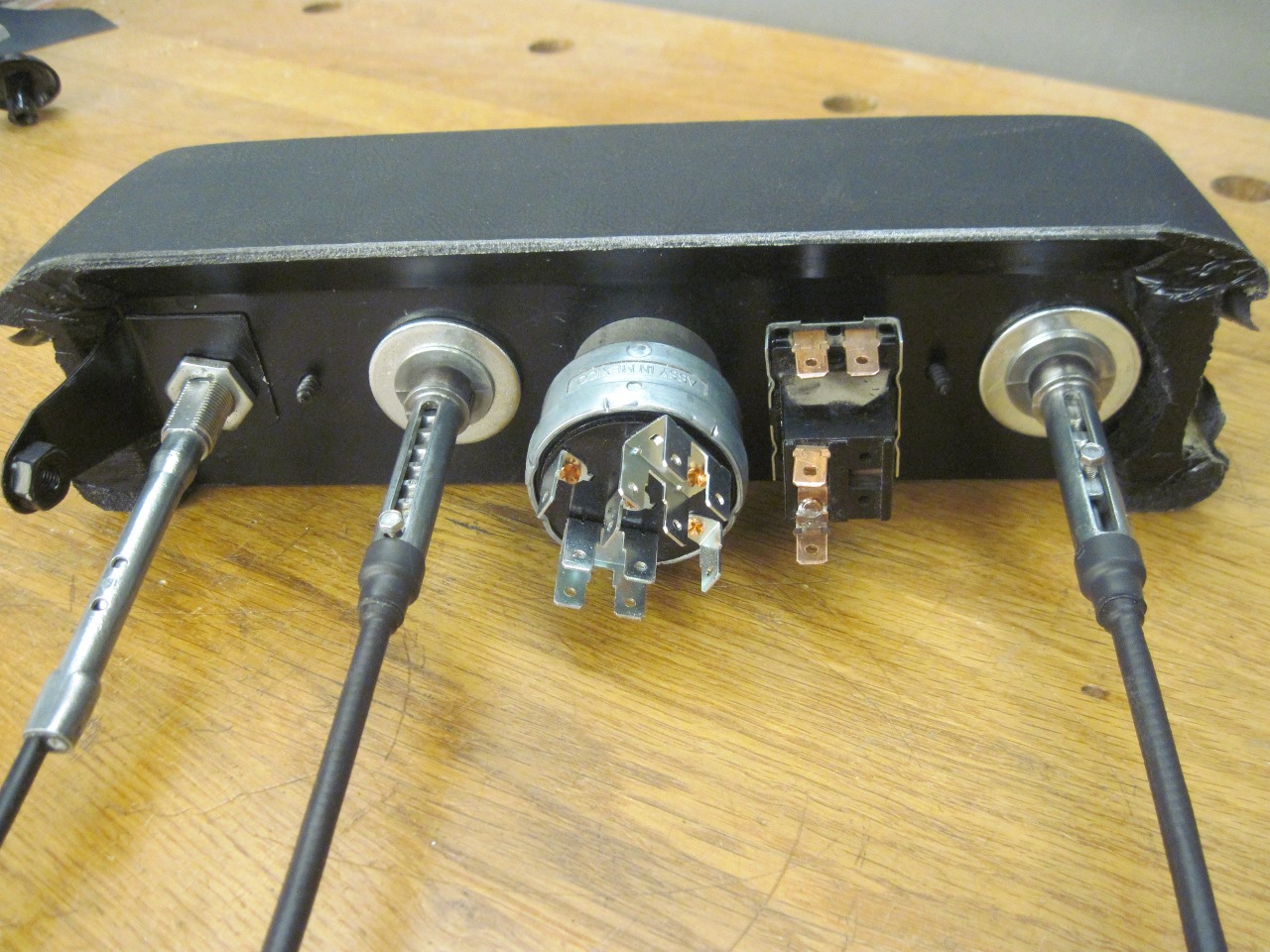

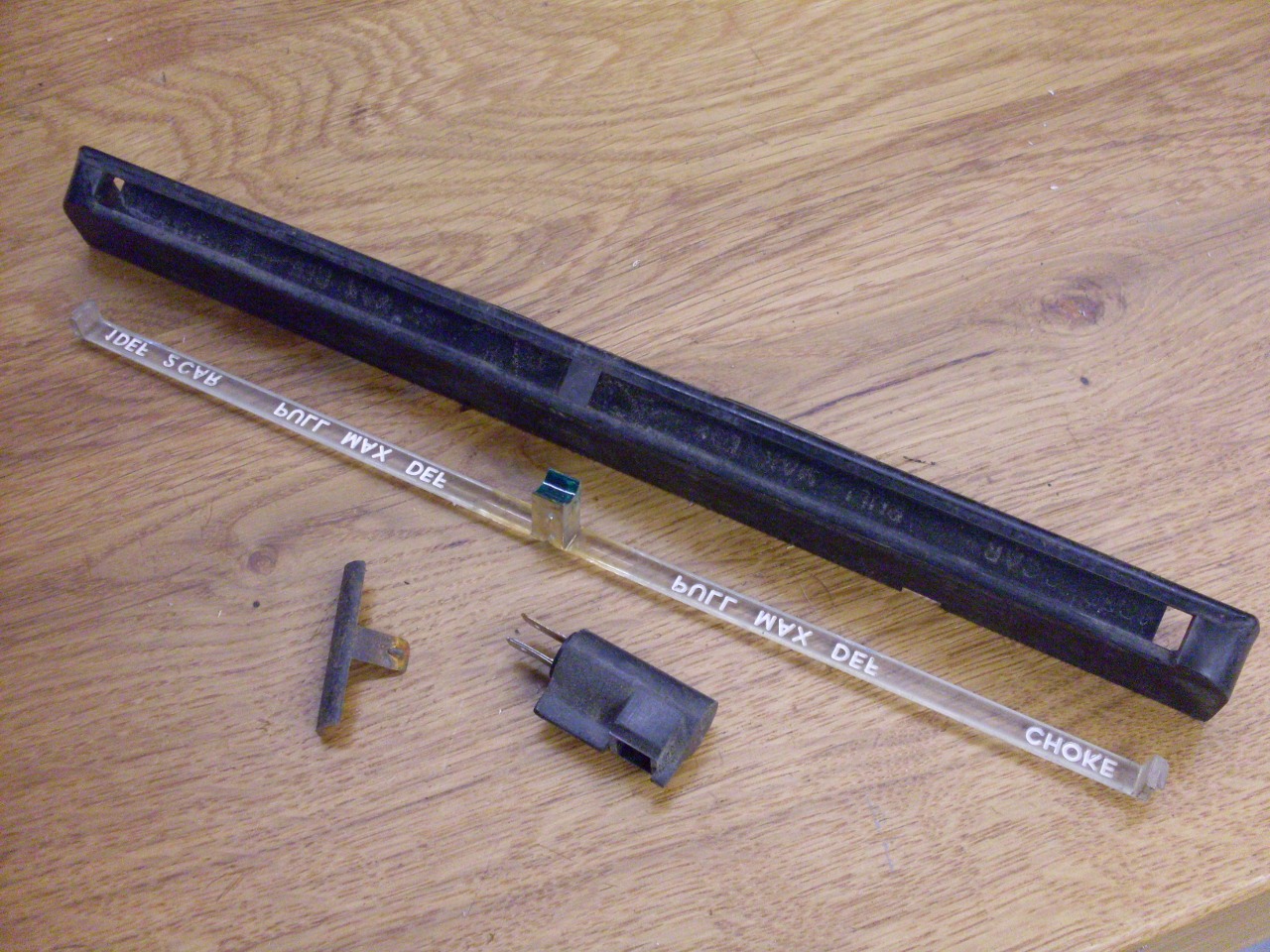

So here are all the controls that go into the plinth, except this was my experimental choke cable which I didn't use.

Test fit-up.

OK,

everything seemed to be ready to mount into the car. First, the

little lighted "Heater Control ID" bar was spruced up and installed.

Plinth goes home.

Then

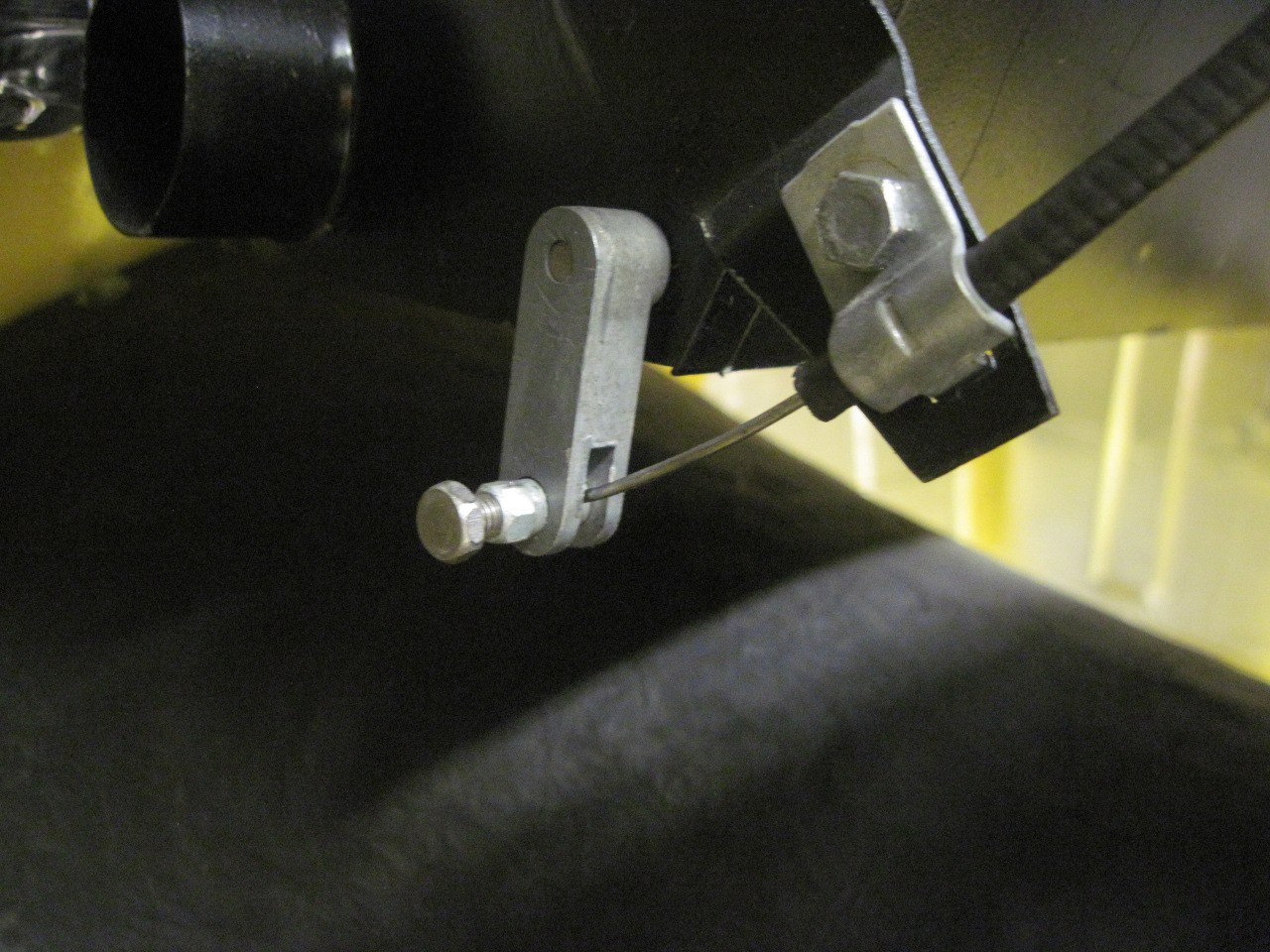

it's just hooking up the cables. My heater temp valve is an

aftermarket model, so I had to come up with a cable end that would mate

with the valve arm. Before that, I had to shorten the outer cable

sheath a little.

For

the demister control, I had somehow misplaced the cable end fitting.

To make one, I couldn't remember exactly what it looked like, but

it must have been something like this.

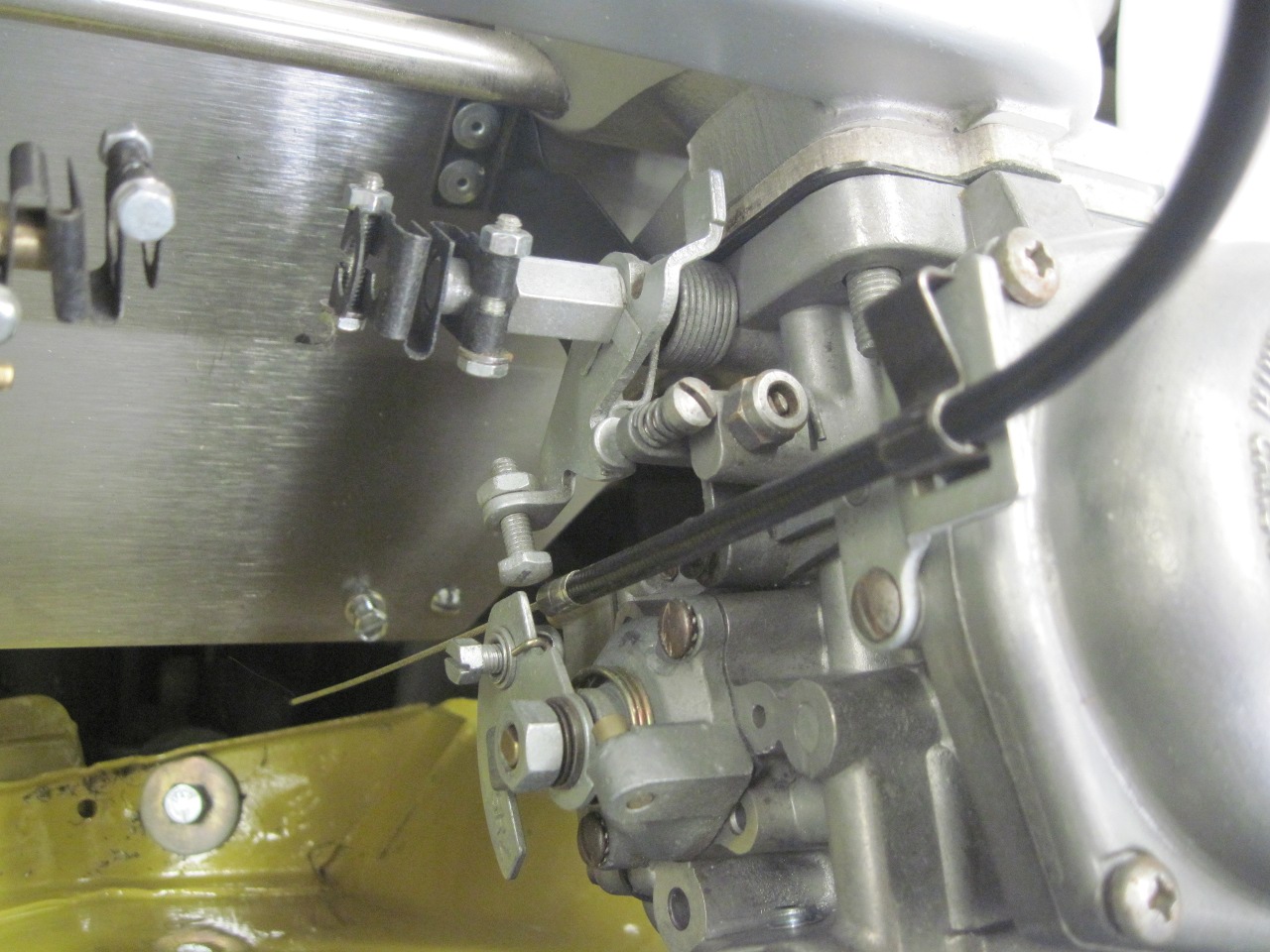

I

thought the choke cables were unnecessarily long, So I cut off a

few inches from each one. To do this, I had to pull the inner

wires back beyond the cut position. In turn, this means that the

little soldered brass keeper has to come off. I had some cable

housing ends to replace the crimped-on ones.

Ahhh, much better. Now they won't be wearing through the paint on the underside of the bonnet.

OK, going to have to find something else to do now.

This

project was a bit of a slog, even without the detour into exotic choke

cables. It was fun, though. About the only significant cost

was the choke cable and the plinth itself.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 Pages