To my other TR6 pages

July 29, 2017

Shift Boot

There

is nothing too special about theTR6 shift boot. It's a pretty

standard vinyl cone-shaped thing that is primarily cosmetic. My

boot was original and was in deplorable shape. New vinyl or

leather boots are easy to get and not too expensive. On the other

hand, I had quite a bit of vinyl left over from recovering the crash

pads and dash support, so I figured why not just try to make a boot.

This

opened up a range of possibilities to tweak the design a little.

I've always liked the look of a finish ring around the base of

the boot, so I decided to add that feature. To me, it looks a

little more, well, "finished".

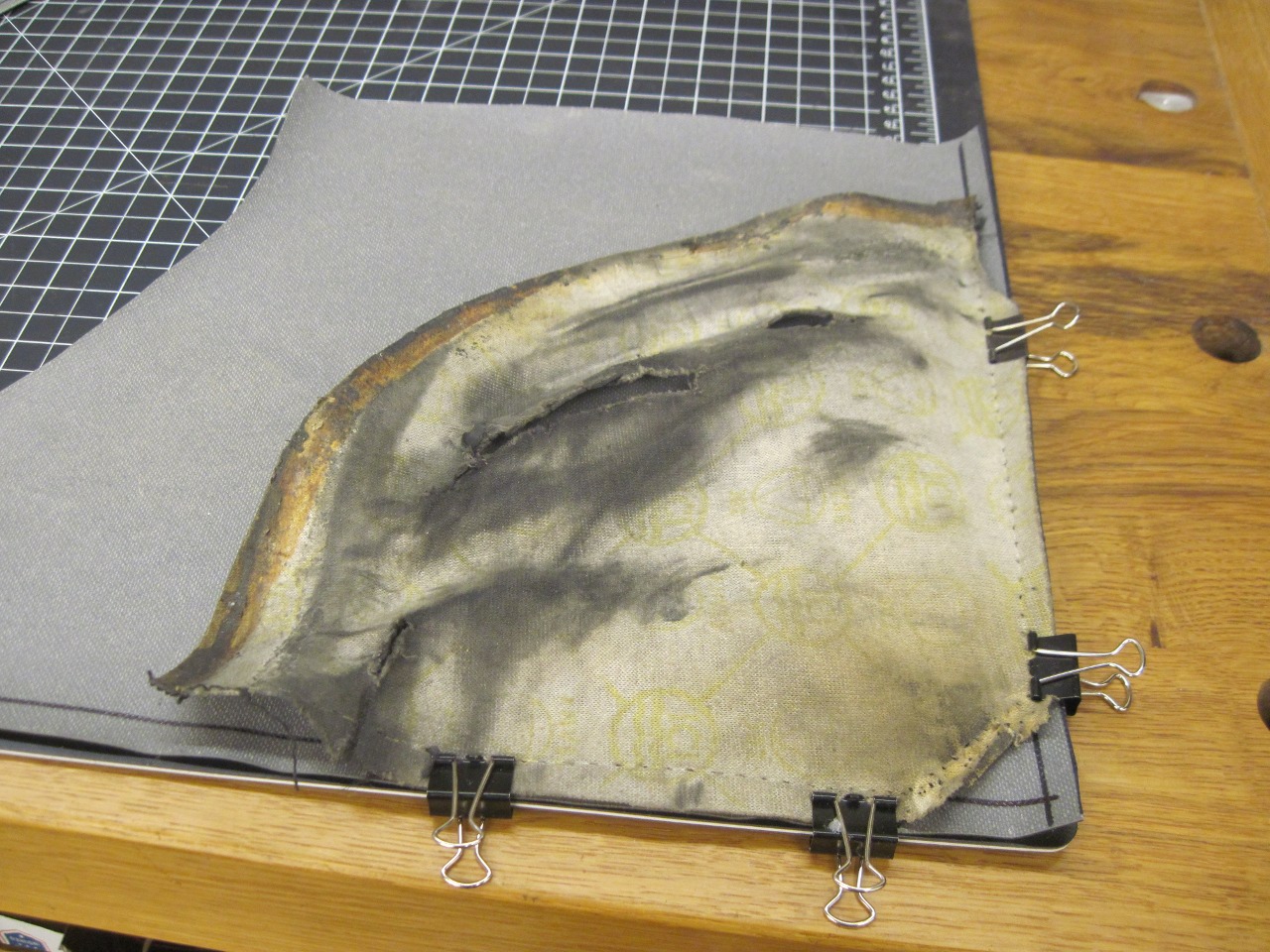

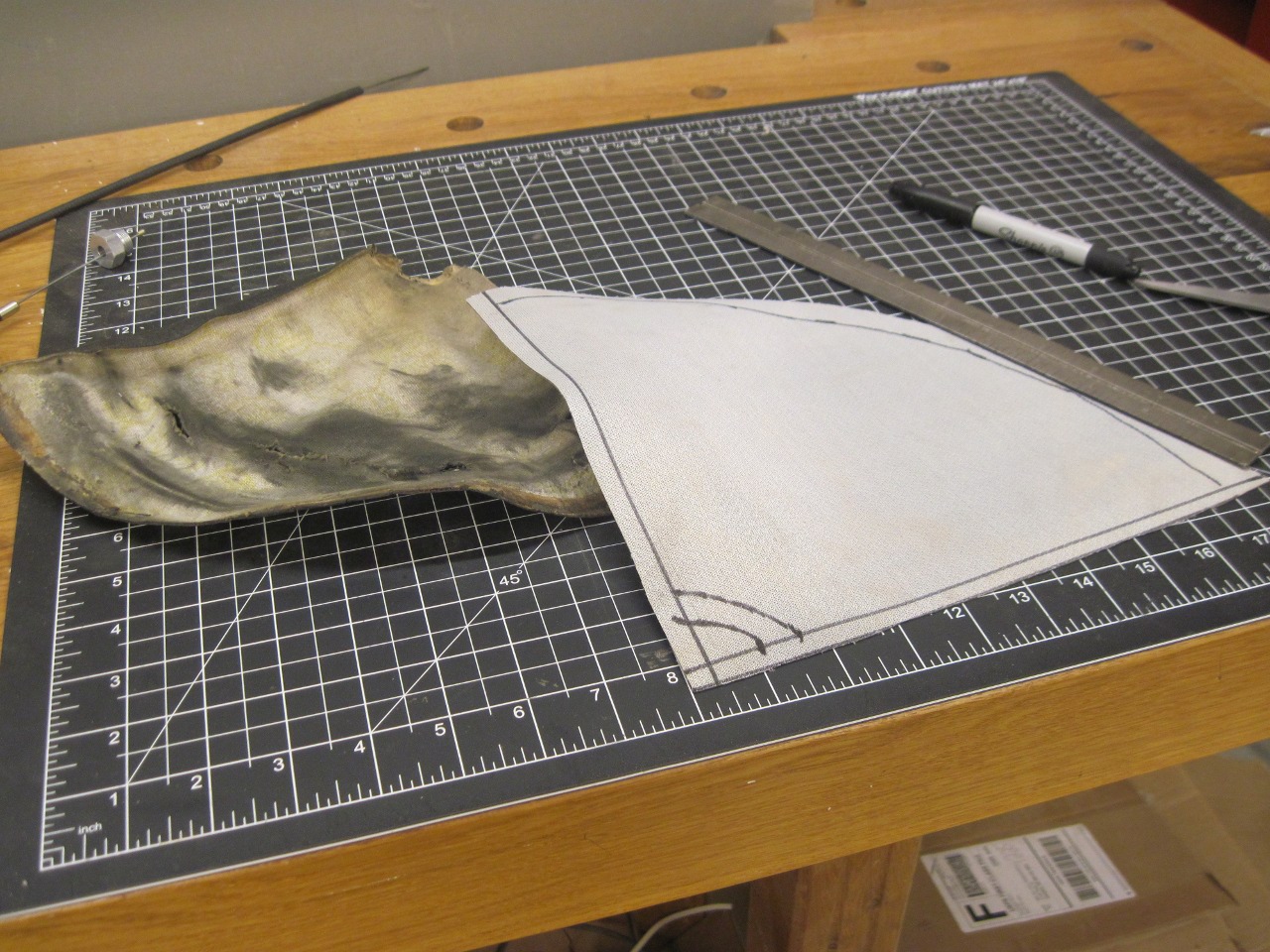

First, I unstitched the old boot to see how it was constructed, and to use it for a pattern.

Before

going too far, I decided to make the finish ring to make sure the new

boot would fit it. There are actually two rings, an aluminum one

to go on top of the shift surround, and a steel one to go on the

underside. The bottom ring will be tapped for the fixing screws

from the top ring. After drilling and tapping, the steel ring was

powder coated, and the top ring anodized black.

.

The bottom ring has two extra threaded holes to hold it in place until the upper ring is installed.

I

wanted to glue the boot to the underside of the top ring, so using the

old boot, I was able to determine that it would fit without any changes.

Then marked and cut the new boot from some black automotive vinyl.

Now

I don't have a sewing machine, and the love of my life wouldn't let me

use hers, so this was going to be a hand stitching job. I used

this sail-maker's stitching awl, which worked pretty well. I'm

certainly no seamstress, so my first attempt ended up with a pretty

crooked and ragged seam. On version 2.0, I made a couple of

plastic strips with guide notches that helped space the stiches and

keep them straight. This worked much better.

I

had machined a little lip on the underside of the aluminum ring to

account for the vinyl thickness. It also worked as a dam when

brushing on the contact cement.

Pressed on the rim of the boot, and then cut holes inthe vinyl to match those in the ring.

Making sure everything lines up. I used little nylon washers under the screw heads to protect the anodizing.

Getting

ready to try the new boot on the car. The real weather-seal boot

is a two piece rubber affair that attaches to the gearbox tunnel.

In my case, the lower boot was in fine shape. The upper one,

while looking pretty good, had some splits in the recesses of the

bellows.

I got a new upper boot, and despite my trepidation about replacement

part quality, especially rubber parts, this boot looked and felt pretty

darn good. New boot is on the right.

The

upper boot fits inside the lower one. I believe the original

factory construction was to glue the vinyl boot to the upper rubber

boot before inserting it into the lower boot.

Now

for the final fitting. Since the new vinyl boot mounts a bit

higher than the original position, I probably could have made it a

little shorter. I made a little ferrule to top it off.

So this is how it looks. I like it.

This

was a pretty simple, fun project, and it stretched my skill set.

It occurred to me that it might actually be an improvement over

the original design, since the boot can now be replaced without

removing the dash support. Total cost was probably less than the

cost of a ready-made boot.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages