To my other TR6 Pages

January 18, 2017

Power Module

I

consider the factory electrical system to be one of the weakest parts

of TR6 cars. TR6s weren't alone in this. Many British cars

of the era had similar systems. Beside the fragile switches and

underpowered electric motors, the design made minimal use of

relays, and ran everything on only three fuses. Add to this the

dirt simple lamp holders and unreliable body grounds, and it's easy to

see why Lucas is the butt of so many jokes. If there is one

system on this car that cries out for an upgrade, it's the electrics.

There

are, of course, vendors who know this, and who offer a range of

aftermarket products to enhance the reliability of the electrical

system. One popular upgrade is to add a central power management

device. There are at least two of these products available, and

they both add relays to key functions, and split out more individual

circuits to their own fuses. I've looked pretty closely at both

of these products, and though they differ in philosophy in some areas,

they both appear to be well thought out and well made. I'd

consider either one of these devices a worthwhile modernization of the

TR6 electrical system.

However,

designing electronic circuits like this is something I did as a

job once upon a time. I thought it might be fun to dredge up some

old skills and have a go at making such a device of my own. This

would allow some customization, and implementation of a few things that

I think are important.

I

decided to make the device, which I call the Power Module, PCB (Printed

Circuit Board) based. This is a little problematic right off the

bat, since there are some fairly high currents that need to be handled

by the relays, and high currents require wide copper traces on the PCB.

This would make any attempt at miniaturization a challenge.

This is one reason I decided to mount the Module on the small

deck above the windshield washer bottle on the passenger side of the

engine compartment. There is plenty of room there, access to

relays and fuses would be very good, and cable routing shouldn't

be a problem. A relatively large PCB would allow spreading the

relays and fuses out, with plenty of room for legends.

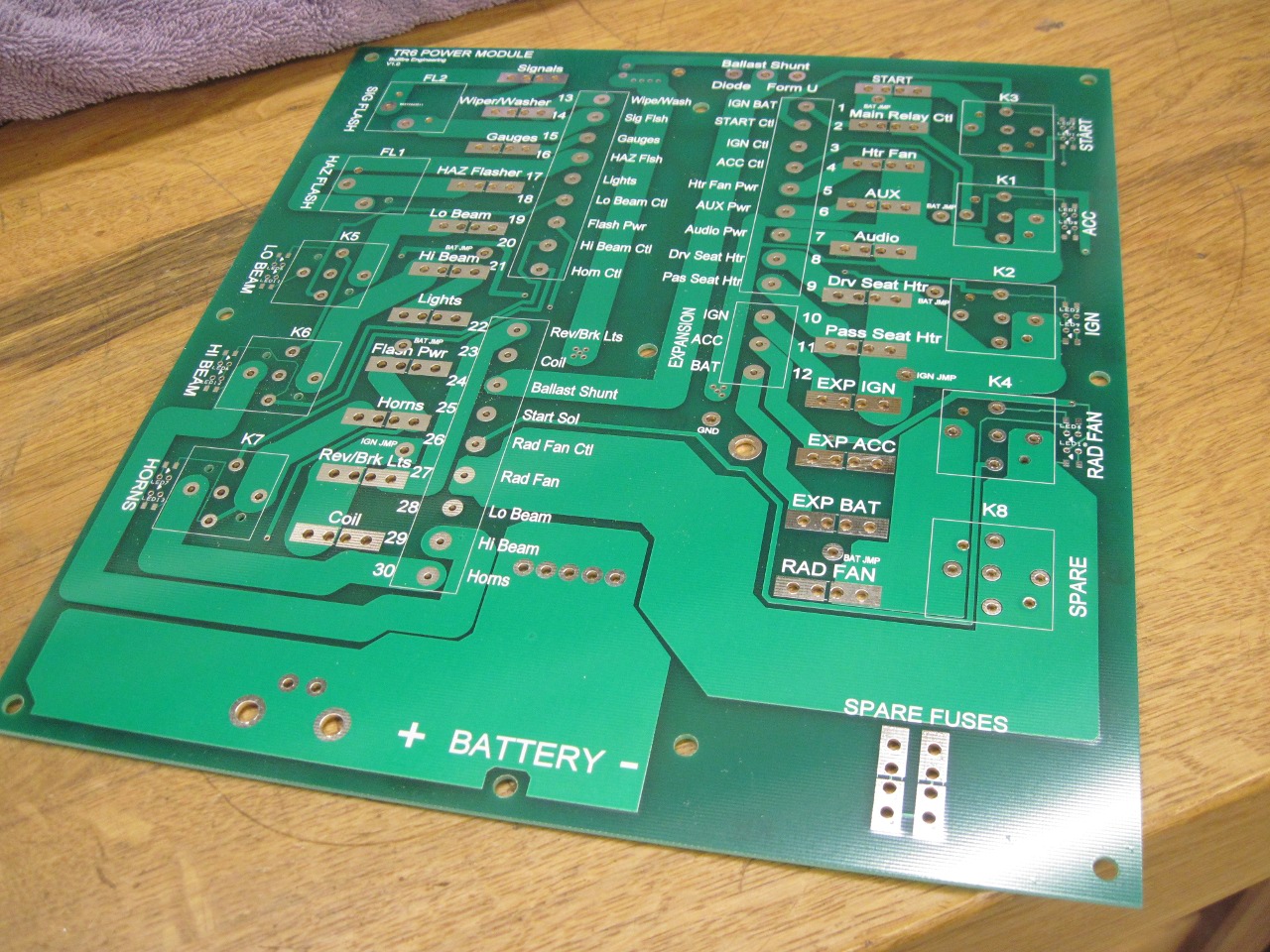

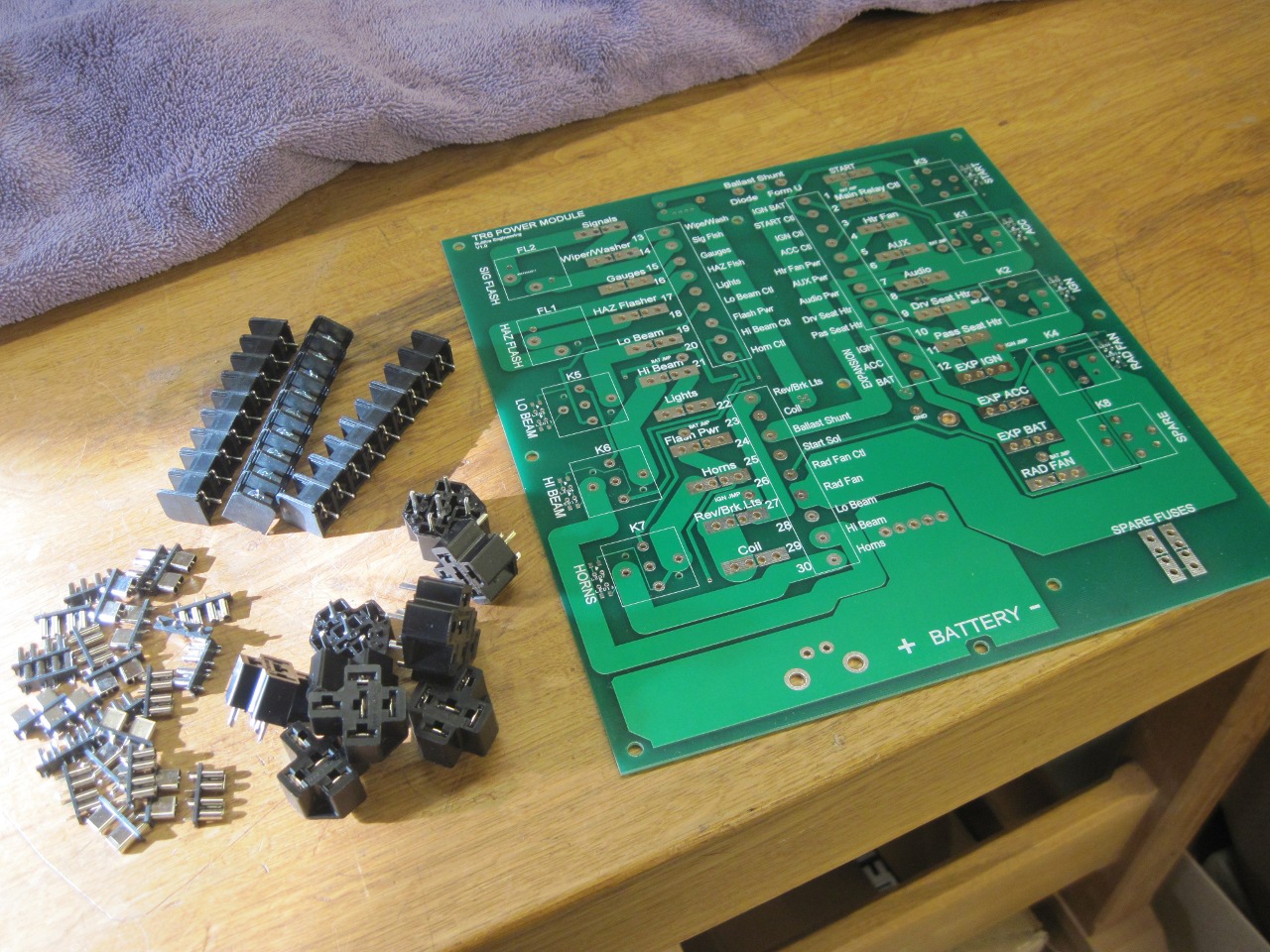

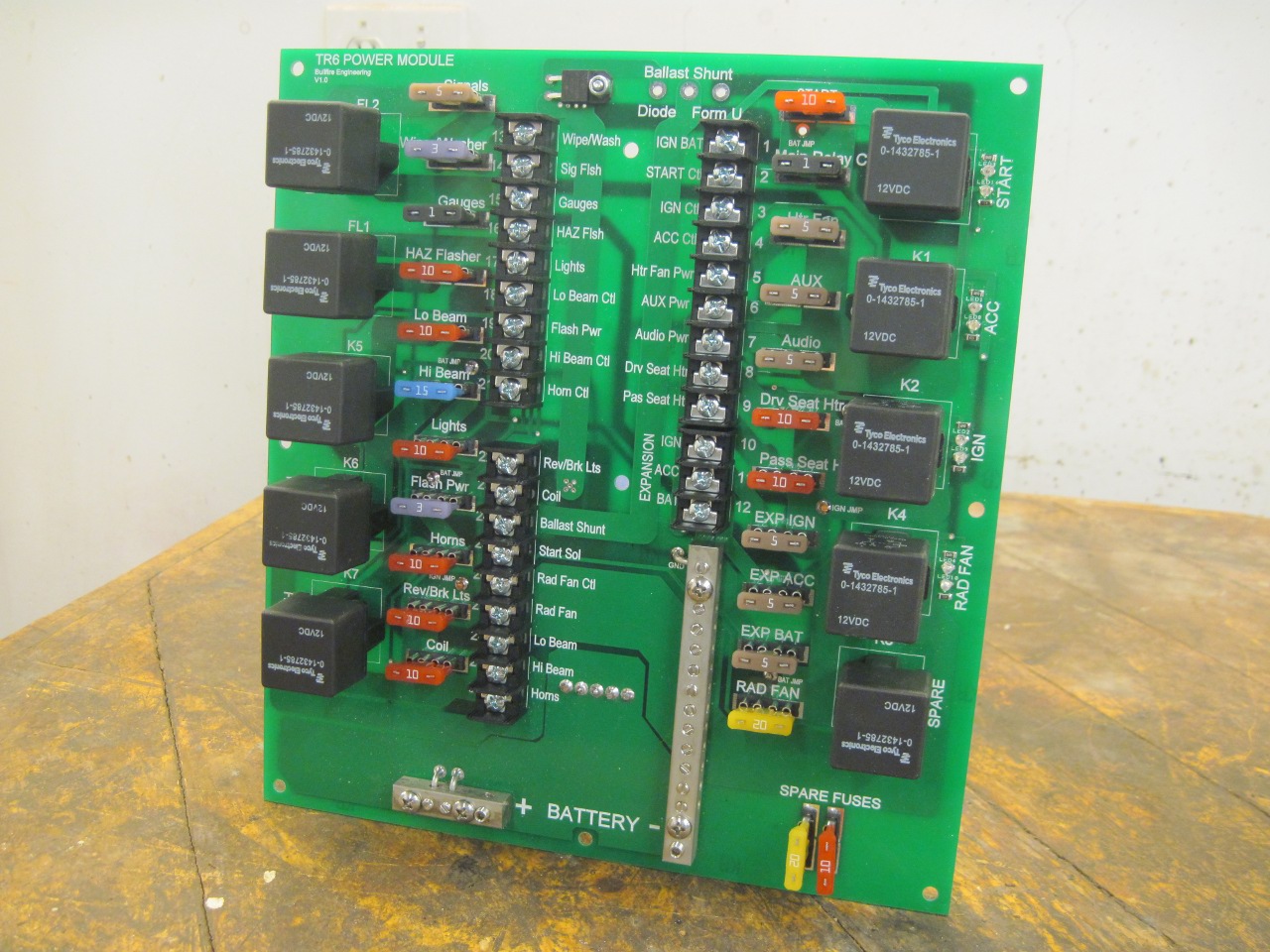

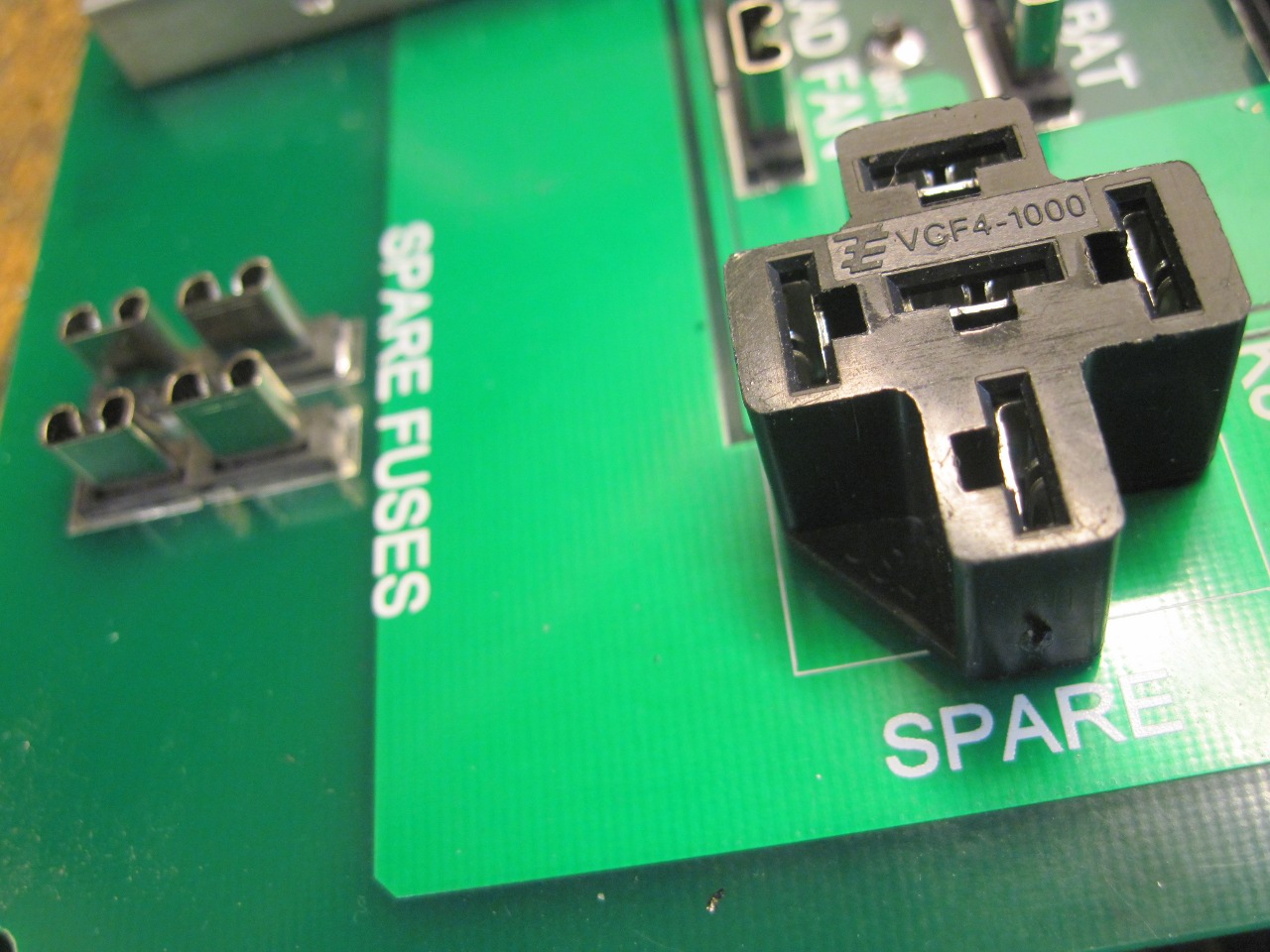

Here

is the bare PCB. It's about 9" x 10". The second picture

shows the standard relay and fuse sockets, and the barrier strips that

will populate the board.

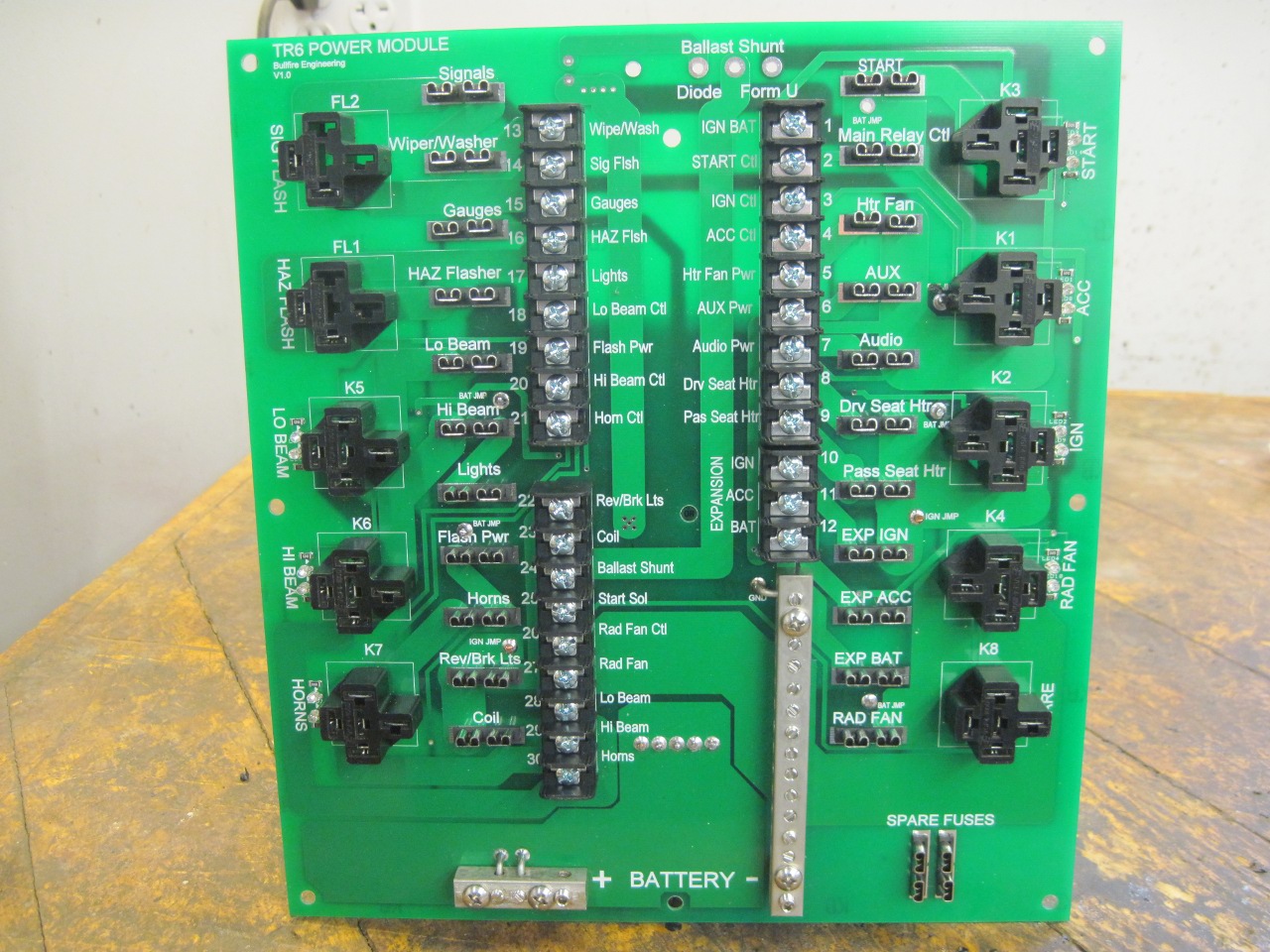

Here

are all the sockets and strips mounted. The long vertical bar

near the bottom is the return (ground) bus. Return circuits from

all over the car, including some that used to use the car itself, will

terminate there.

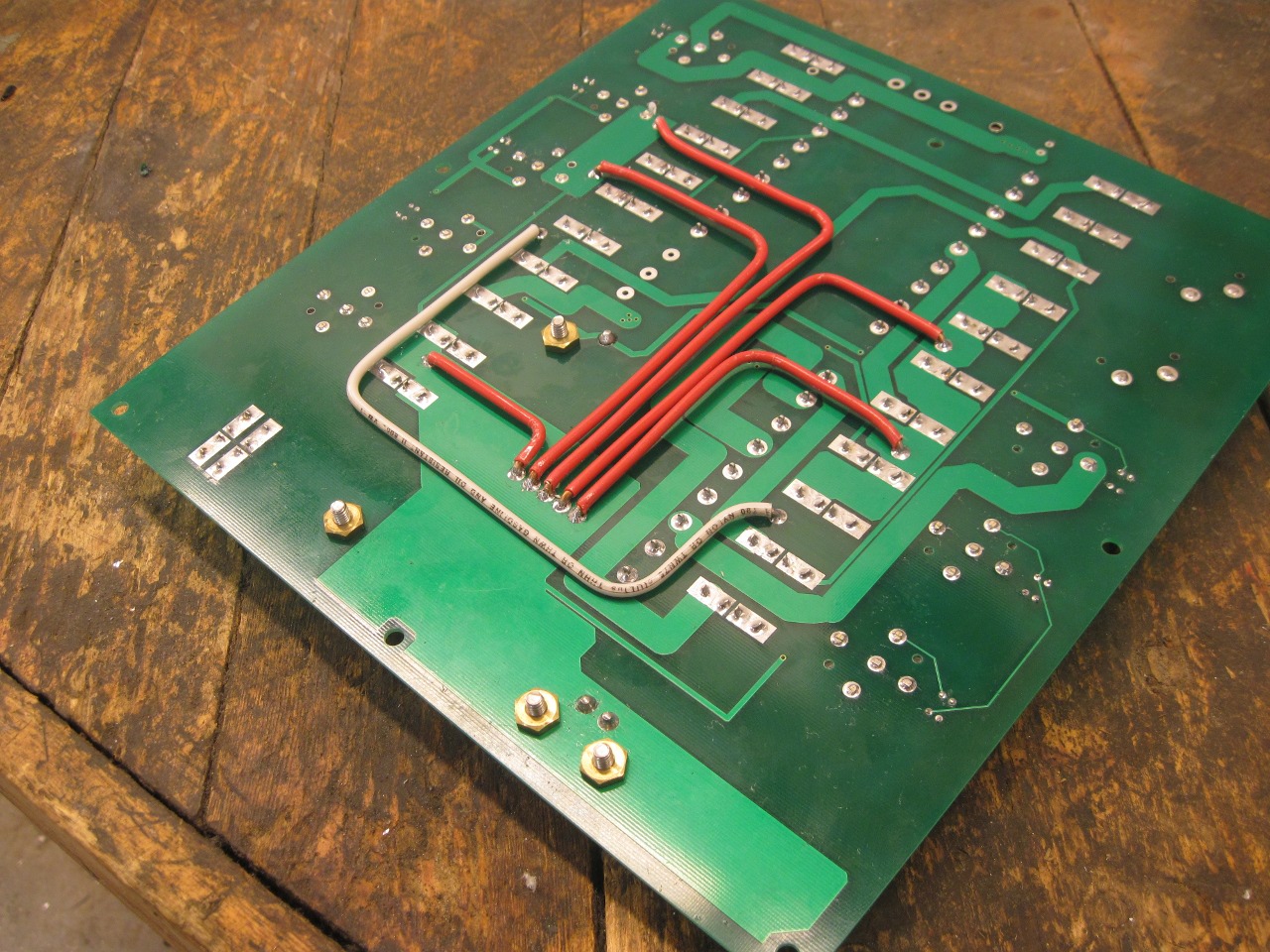

Even

with some traces as wide as I could make them, I wanted a little more

safety margin, so for a few higher current traces, I added

supplemental 12 gauge copper jumpers on the back of the board.

Here

is the board fully populated with relays and fuses. Instead of

bringing wiring to connectors on the perimeter of the board,

wires will come up the center of the board, and fan out th their proper

connection point. With a cover on the Module, this should give a

neat appearance with all wires entering in a single bundle.

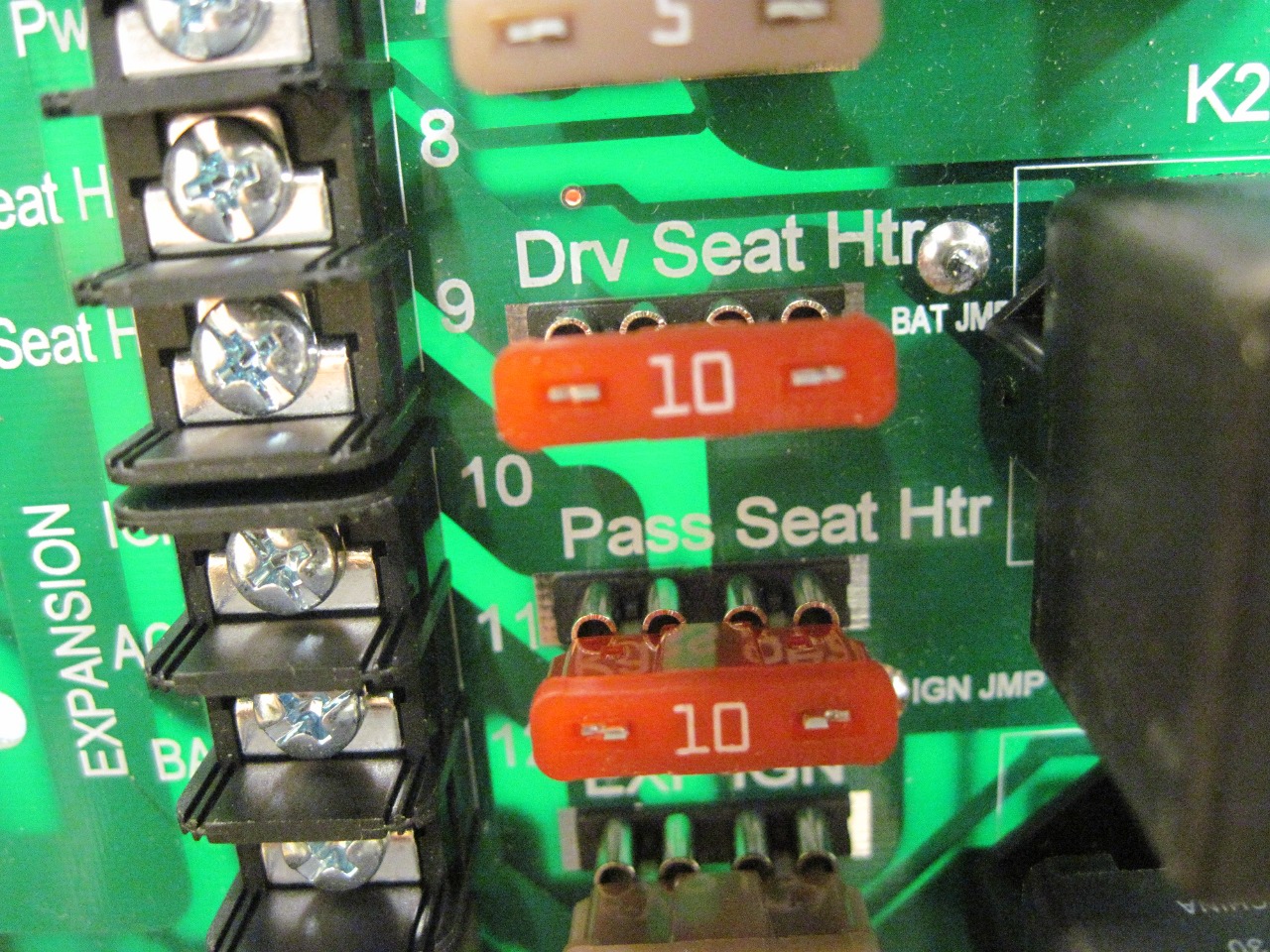

My seat heater kits came with inline fuses, but I'd rather have them with all the others.

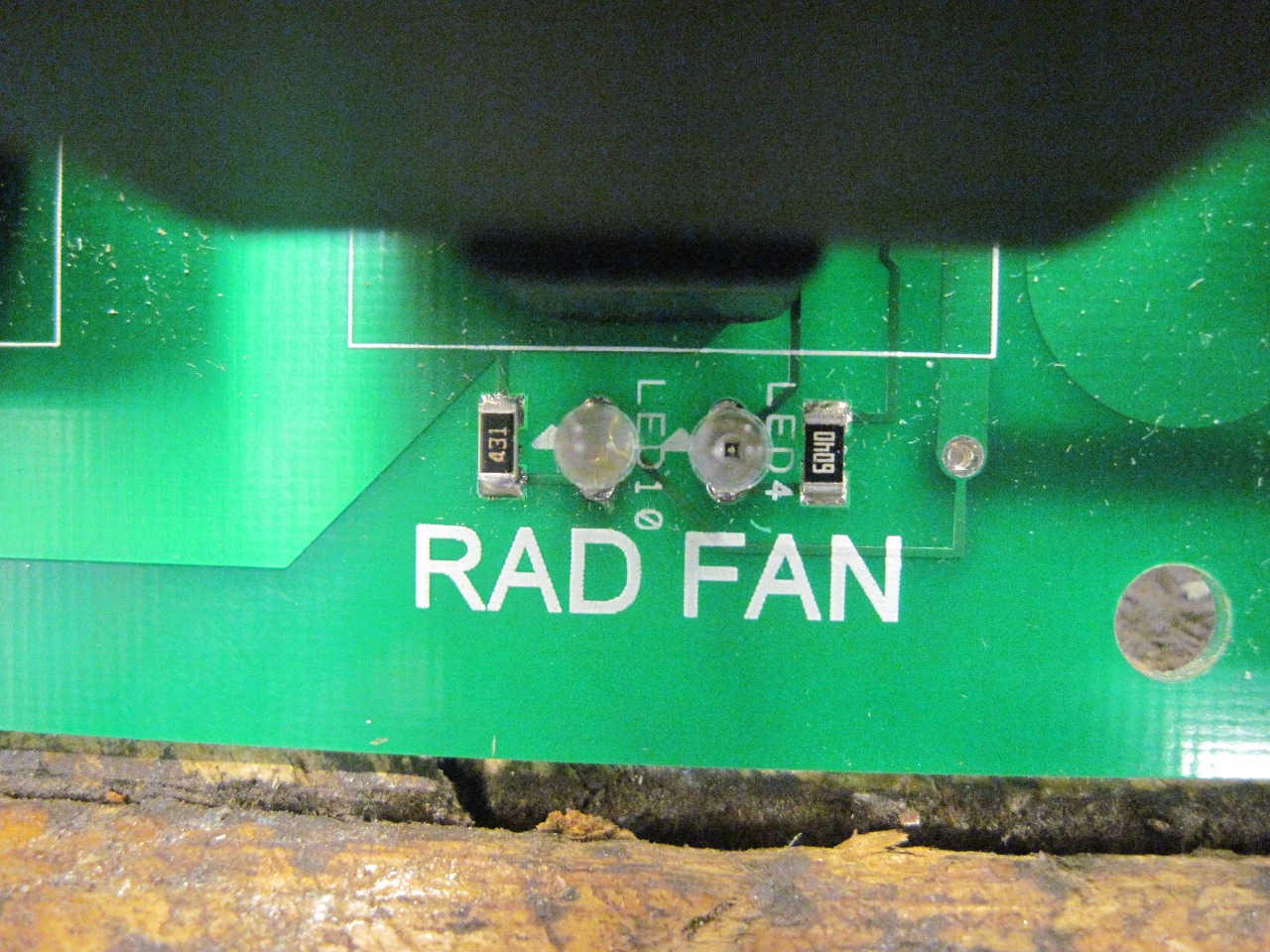

Other

features included in the design include diagnostic LEDs on each relay's

coil and power contact. With power to the coil, the right yellow

LED will light. With power on the switched contact of the relay,

the left green one comes on. So in all cases, both the yellow and

green LEDs should light when the relay is activated. Yellow and

no green would suggest a bad relay or possibly a blown fuse.

There

is a provision, through the use of jumpers, to use either of two

methods to accommodate ballasted ignition systems. A ballasted

system uses a coil designed to run at a primary voltage well below

battery voltage. The voltage drop is provided by a ballast

resistor (which may actually be a piece of resistance wire) in series

with the coil primary. To help with starting, the ballast is

bypassed (shunted) during cranking. The shunting can be done with

a special "Form U" relay in place of the START relay, or with a diode

to prevent backfeeding through the shunt connection. Some

TR6 cars, including mine, used a Form U start relay. (The Form U

relay is one that uses a dual SPST arrangement rather than the normal

Form C SPDT.) For an unballasted system, neither jumper is

installed.

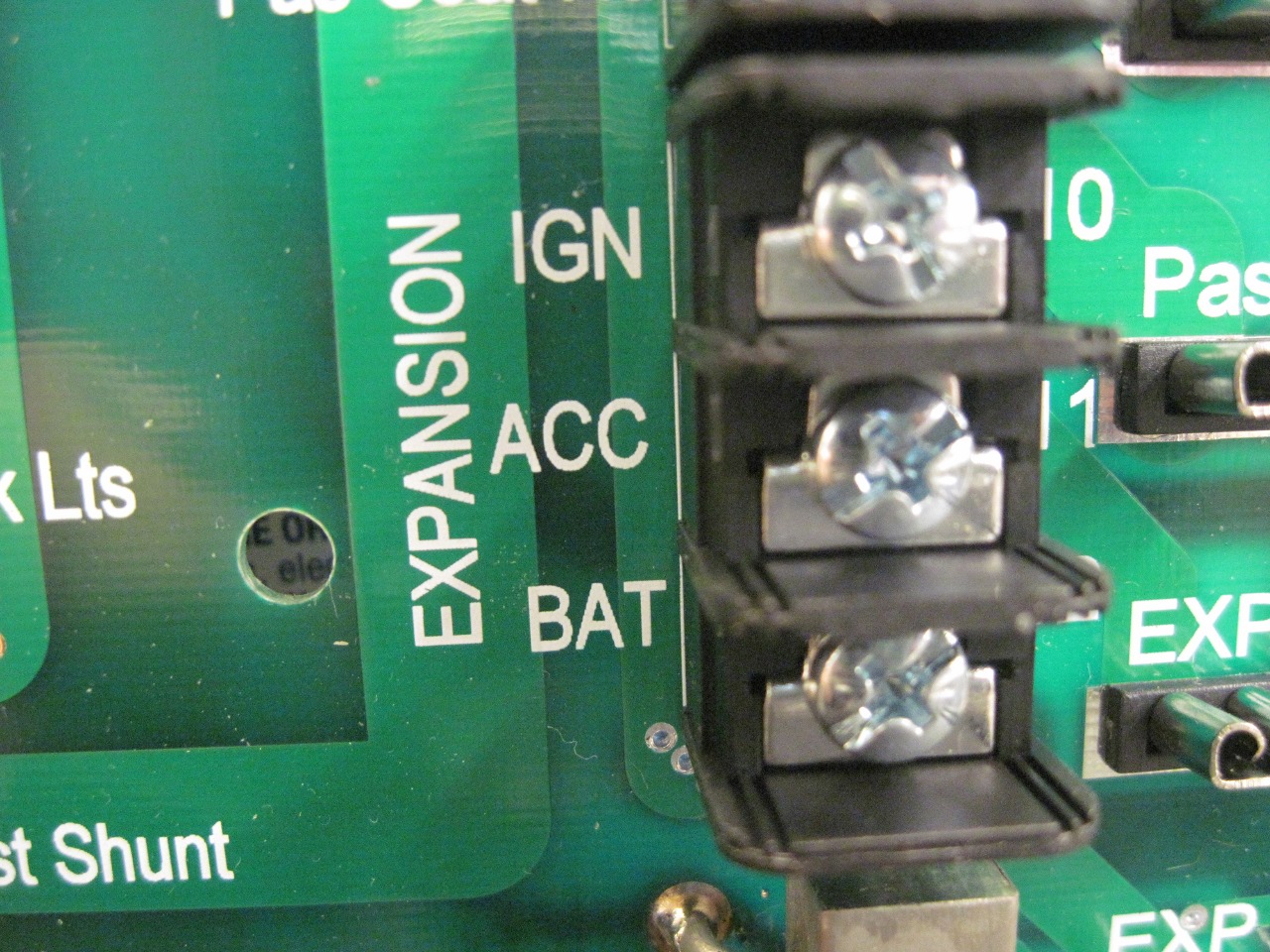

To

allow for unanticipated future needs, I included three undedicated

fused circuits, one each on the BAT (always hot), IGN (ignition switch

in the run position) and ACC (ignition switch in run or accessory

position) circuits.

I had a little extra room on the board, so I included some dummy sockets to hold a spare relay and a couple of fuses.

As

tasks go on this project, the Power Module is one of the most

time-intensive. Actually putting it together was trivial by

comparison. As far as cost, I probably could have bought a

commercial unit a little cheaper, but it certainly would not have the

level of customization. Though the Power Module itself tested out

fine for functionality, I'm a little concerned about rubustness.

I used a very standard PCB material and thickness, and while I

think it should be adequate, it probably wouldn't take much rough

handling. Stronger, thicker board material was quite a bit more

expensive, and I wasn't ready to say this is the final design of the

Module.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 Pages