To my other TR6 Pages

October 30, 2016

Accelerator Shaft

[Click the pics for a better view]

For

left hand drive (LHD) TR6 cars, which is the vast majority of them, the

accelerator pedal on the left side of the car has to operate the

carburettor throttle plates on the right side of the engine. This

is accomplished by a metal shaft running cross-wise directly behind the

engine. On the port end of the shaft is the accelerator pedal,

attached such that pushing the pedal rotates the shaft. The shaft

passes through the firewall in the driver's kickspace, across the

engine compartment where its starboard end is supported by a hole

into the passenger's footwell. Just before it leaves the engine

compartment, the shaft has a lever arm clamped to it. This is

where the corburettors' throttle linkage connects.

The shaft

and pedal were rusty and dirty, but in servicable condition. The lever

arm had an ovaled hole where the linkage attaches. The picture

doesn't show how bad the elongation was. The path from the

accelerator pedal to the carb throttles in a TR6 is a complex one with

an unreasonable number of joints and pivots, each contributing its

share of slop to the total, so to tighten the system up, every

intersection has to be made as good as it can be. For the lever

arm, I welded up the hole and redrilled it.

The

other thing about these shafts is the bushings that it rides in.

They are reportedly hard rubber or plastic, prone to wear, and a

bear to replace. I wouldn't know what they look like, because

they were not present in this car--probably wore through and fell out

during the Reagan administration.

This is an area that begs for

improvement, and there are many good solutions. For this car, I

made two of these little bushings out of nylon. They are a

sliding fit on the shaft and a firm fit in the tub holes. Nylon

is a reasonable choice due to its natural lubricity.

There

is also a spring that pulls the lever arm down, which rotates the pedal

up. The spring was pretty rusted, so I got a close-ish hardware

spring and modified to to be a close match.

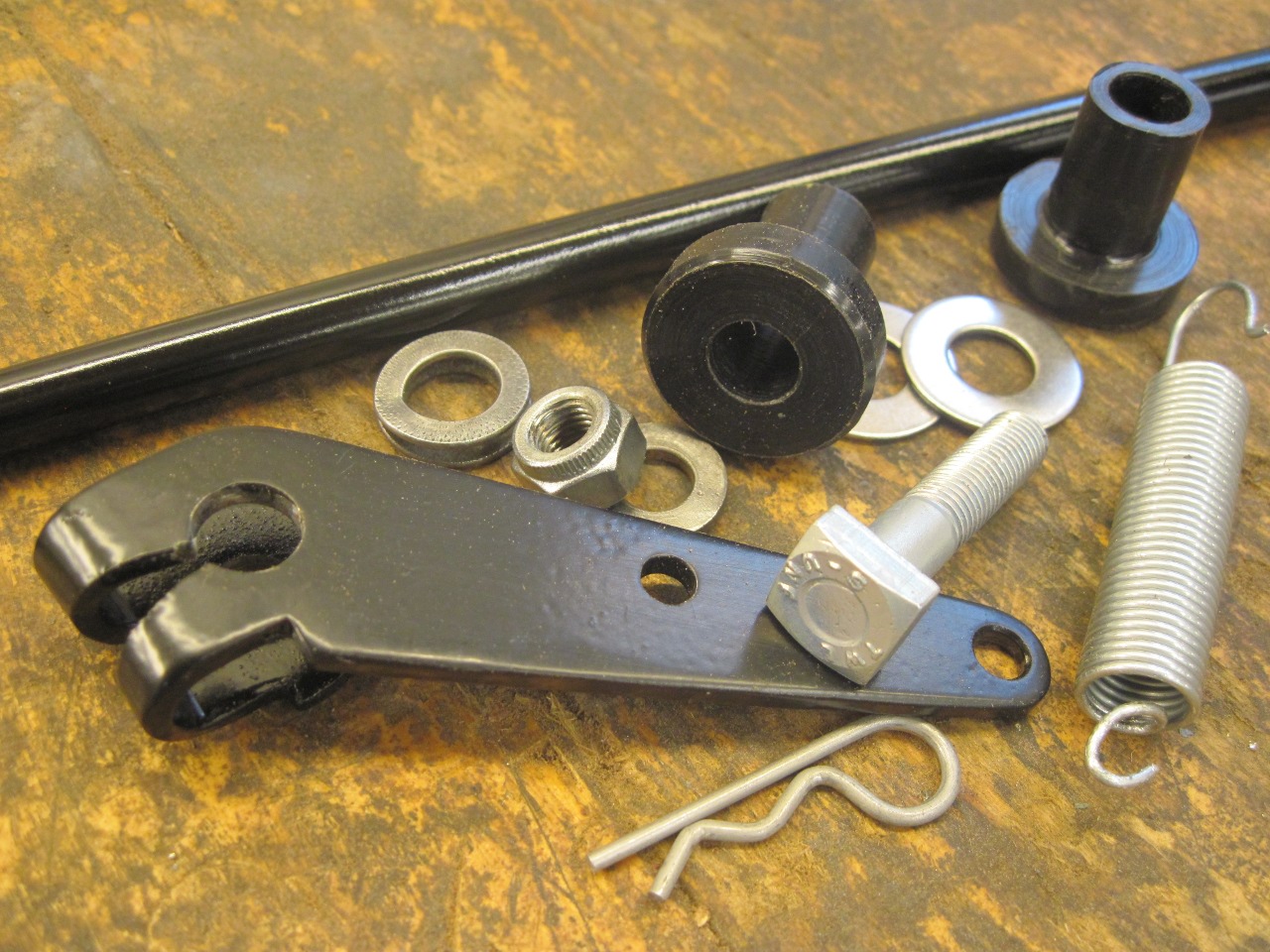

So

here are all the parts that will go into the new and improved

accelerator shaft assembly. The shaft is painted, the lever

powder coated, and the clamp screw replated.

There

is a difference of opinion on which way the lever arm goes on the

shaft. Most, if not all of the catalogs show the long arm on the

outboard side, while Bently shows it the other way. I assume

Bently is right, but since my new bushing moved the lever arm towards

the center of the car a little, putting the arm to the outside put it

in better alignment with the body tab that the extension spring

connects to.

At

the other bushing, a keeper pin goes in a drilled hole. The lever

arm is positioned such that putting the pin in the hole slightly

compresses the Thackery spring washer on the shaft next to the arm.

This takes up any back and forth play in the shaft so it can't

rattle.

Accelerator action is now tight and smooth.

This was a fun little project. It took a few hours, but the cost was almost nothing.

Comments to Ed at: elhollin1@yahoo.com

To my other TR6 Pages