To my other TR6 pages

August 32, 2016

Horns

[Click the pics for a larger view]

The

Lucas 9H "Windtone" horns on the TR6 were apparently fairly ubiquitous

from the early sixties through at least the seventies.

They were even used on some European motorcycles. The TR6

used two 9H units--one "High Note", and one "Low Note", the "notes"

being roughly a major third apart.

My

horns were weatherbeaten and dirty, and neither of them worked when I

connected them to a power supply. I could get a sort of a grunt

out of one of them, but the other was totally inert. As a first

diagnostic step, I measured the resistance between the terminals on

each horn. The totally dead one read as an open circuit until I

rapped it on the bench a few times. It finally showed about 12

ohms, but still wouldn't produce any sound. The other horn

measured about 0.5 ohms--pretty close to factory spec, and was trying,

but couldn't manage a proper honk.

Now,

generic replacement horns, or even reproduction Windtone horns are not

all that expensive these days, and that would have been a

perffectly reasonable way to go. However, I had in front of

me on the bench two original horns that I believed had a very good

chance of being revived, given a few hours and a little tenderness.

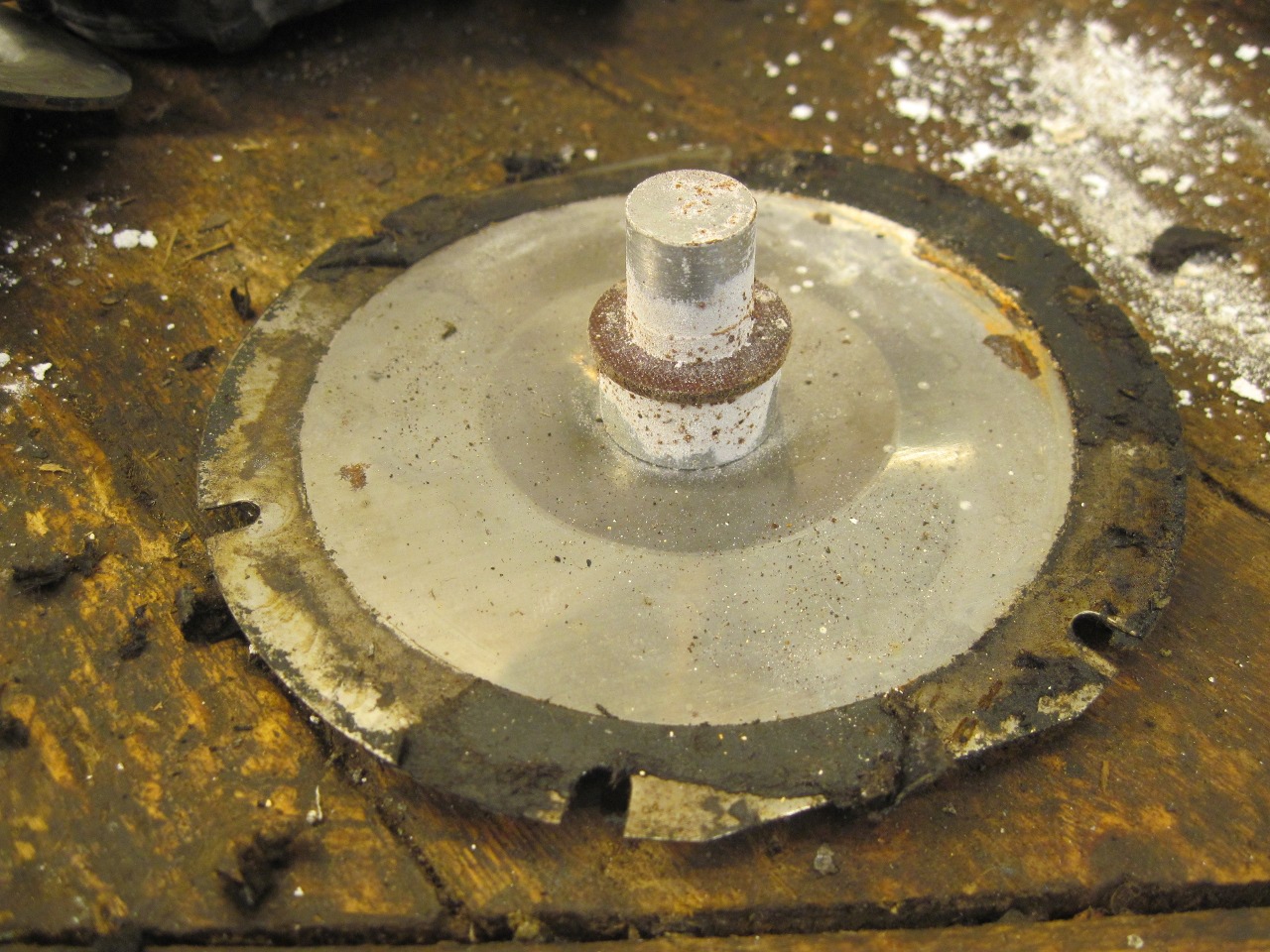

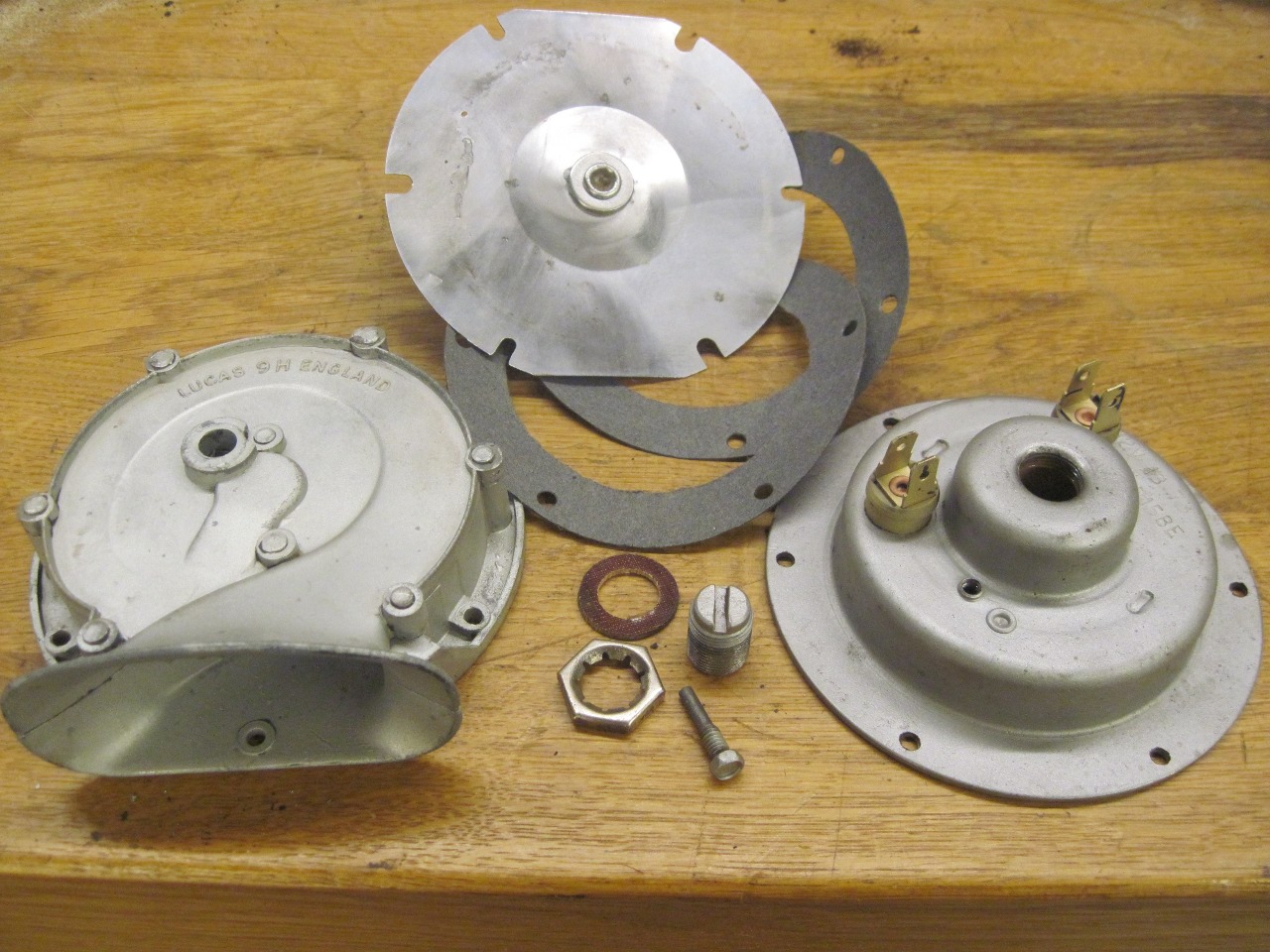

These

horns weren't meant to be disassembled, but are just held together with

six aluminum rivets, which doesn't present much of a deterent.

Undoing the rivets revealed three major parts--a pot metal

casting that forms a coiled horn, a metal diaphragm, and an assembly

that includes a coil of wire and a set of electrical contacts. It

also revealed a lot of white powder--probably a corrosion product of

the pot metal and moisture. The diaphragm is attached to an iron

slug at its center. This slug extends into the core of the coil.

When power is conected to the horn terminals, current flows

through the contacts, and through the coil. The resulting

magnetic field pulls the slug further into the core against the

springiness of the diaphragm. At a certain point in its motion, a

fiber ring on the slug hits a finger on the contacts, and separates

them, breaking the current path. The magnetic field collapses,

and the slug and diaphragm spring back, which allows the contacts to

touch again. This cycle happens hundreds of times per second, at

a rate determined by the mass and springiness of the moving parts.

There

are two adjustments on the horns. First, there is a threaded plug

that can limit how far the diaphragm slug can move. There is also

a small screw (left-handed, oddly) that can move the fixed side of the

contacts a little. Lucas suggests that this is to account for

wear. I measured the positions of the plugs and screws so they

could be put back in their original positions.

On

the unit with high resistance, the problem was simply dirty contacts.

Pulling a little strip of 400 grit abrasive paper through them

fixed that right up. The other horn just had corrosion crud on

the slug, binding it up. I cleaned the insides, blasted the

outsides, and made some new gaskets.

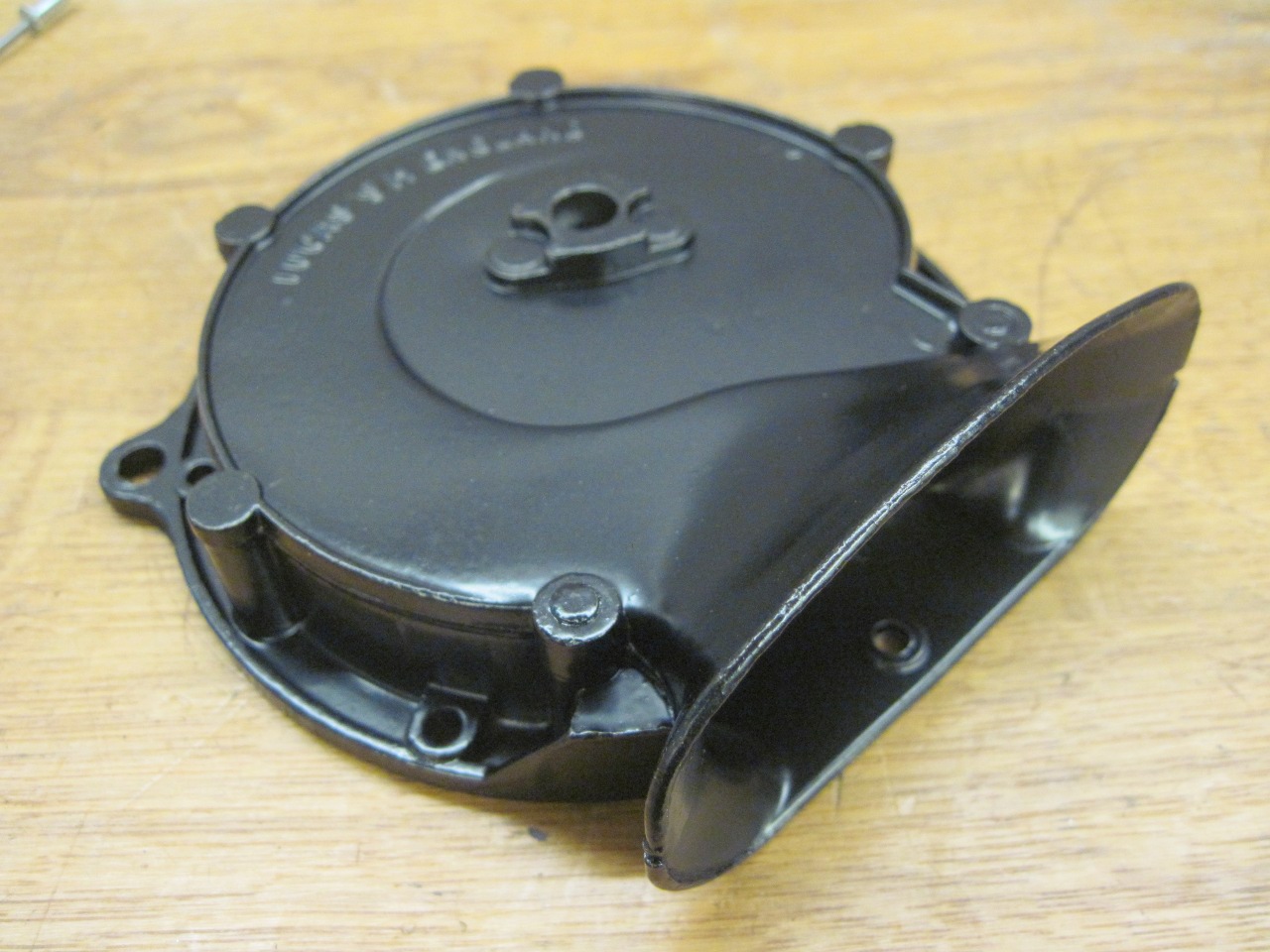

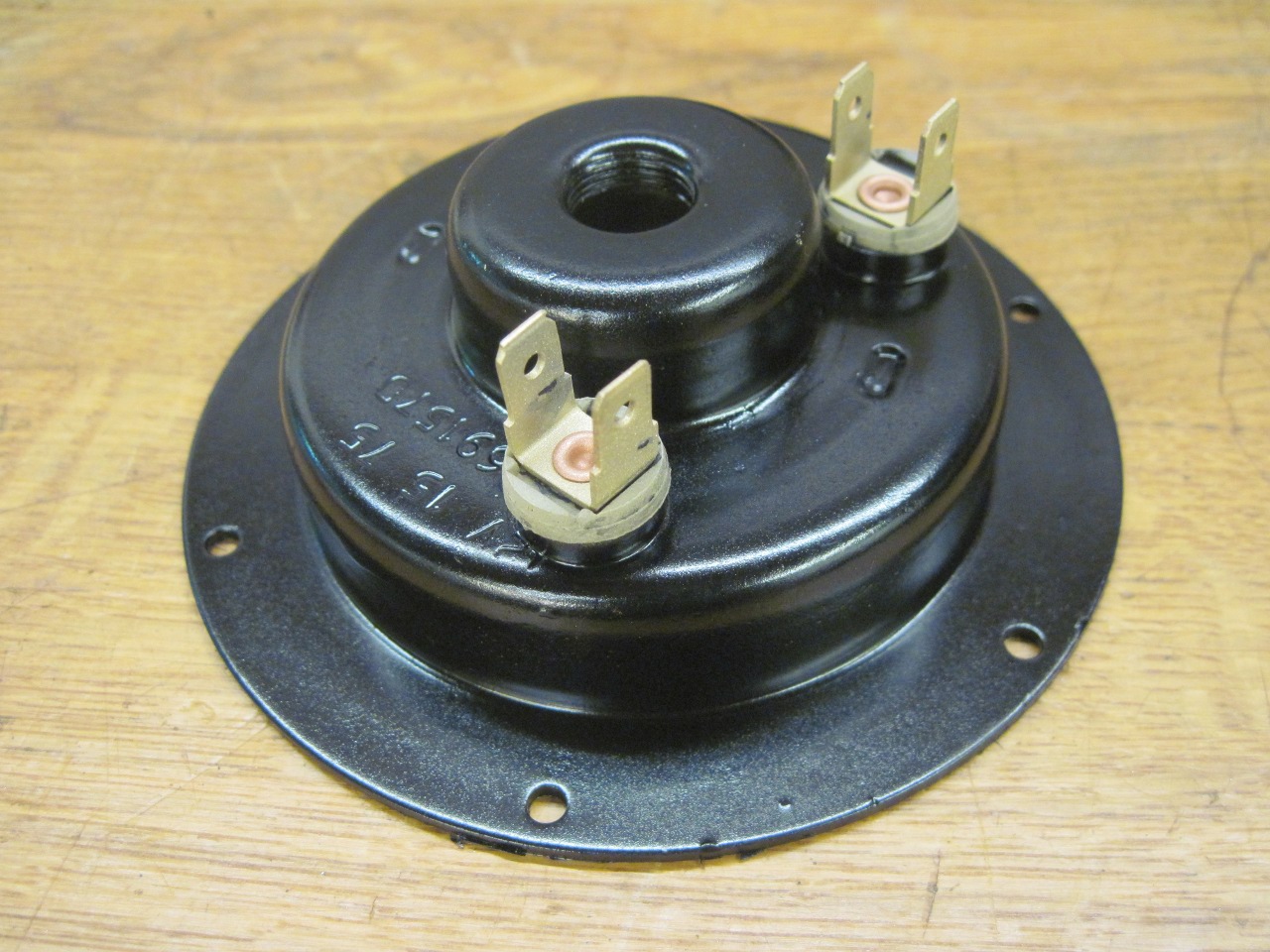

Then

powder coated the casting, and since I fretted a little about high

temps on the coil wire insulation, just primed and painted the other

half. This is when I realized that one of the horns was not

original to the car. Its date code was in 1975, so it must have

been an early replacement for the 1974 car.

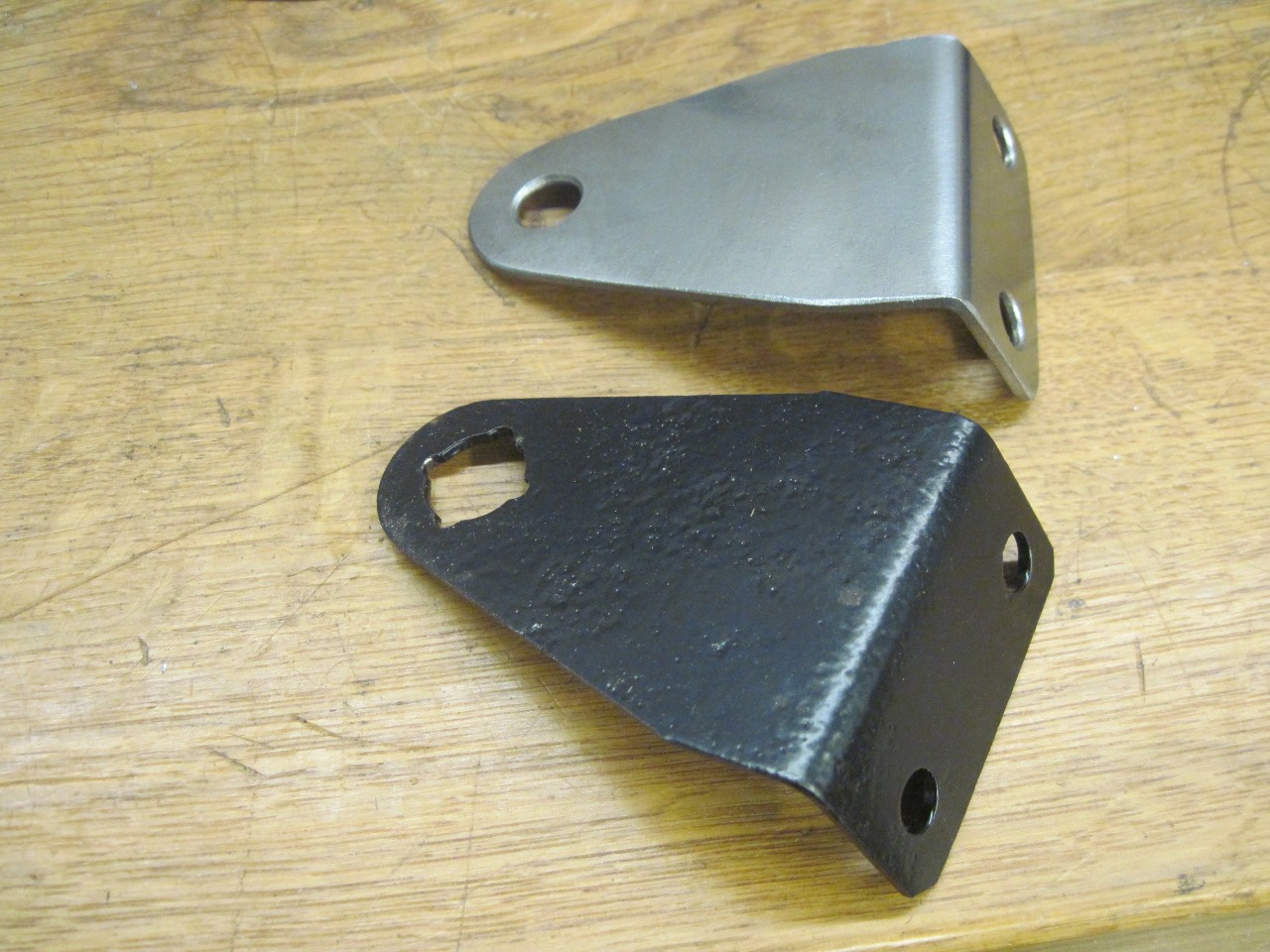

The

replacement horn might also explain the incorrect mounting bracket.

One of the brackets had a squarish hole for mounting the horn,

probably for a square boss on some other kind of horn. The lock

washer actually fell right into the larger hole. The solution was

to just make a correct backet. On the topic of lock washers, the

originals were external star washers--the kind often found on

electrical parts that use the car body as a ground. The

points of the star washer penetrate the paint for a good electrical

path. It is a strange choice for these horns since they don't

rely on the body for ground. In fact, the body of the horns are

totally isolated from the electrical path.

With

everything put back in its proper place, I tested the horns. They

both worked. I fooled with the adjustments a little, but where I

had them turned out to be about the best.

On the shelf with these dudes.

As

a side bar, when I was researching horns, I found many claims that

multi-tone auto horns were normally in the key of F. Apparently

Lucas didn't get that memo. Out of curiosity, I compared the

notes to a keyboard, and found that the low note was approximately G4

and the high note was close to B4, making it most of a G major chord.

The factory spec for the notes are 390-400 Hz and 490-500

Hz, respectively. None of the adjustments on the horns change the

note appreciably.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages