To my other TR6 pages

May 29, 2016

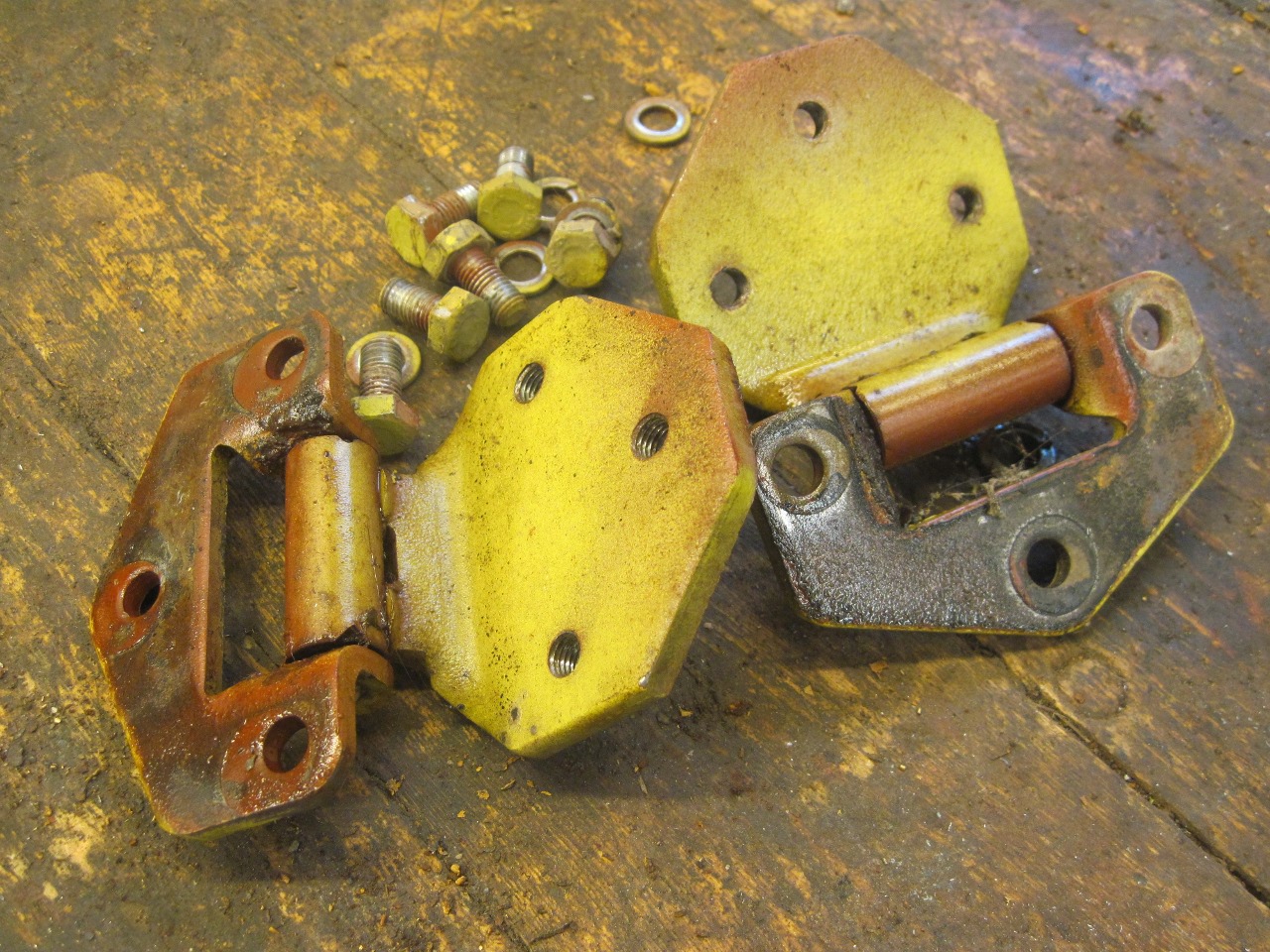

Door Hinges

[Click the pics for a larger view]

With

the tub freshly on the chassis, I wanted to check out whether the door

gaps were going to be a problem later. So I fetched the doors and

wings from the shed and set about hanging them on the tub. Ther

first snag I hit was that a couple of the door hinges were all but

seized, and another one was very loose and floppy. It seemed that

they would need some attention before I could mount the doors.

The

first thing I did was clean the hinges up for a better inspection.

In preparation for the door gap fitting, I made some of the fiber

pads that the catalogs show, though my car didn't have any when I took

it apart.

I

soaked the stuck hinges in penetrating oil, and when they finally

loosened up, I didn't really like how loose they were. I

decided I didn't want to use them in this condition. It looked

like a set of new hinges was going to set me back nearly $100, and

there is of course the crap-shoot concerning the quality of what you

get with after market parts.

The other option was to

rebuild the original parts. A hinge is pretty simple, and it

appeared there wasn't much of a downside to at least attempting to

repair the hinges I had.

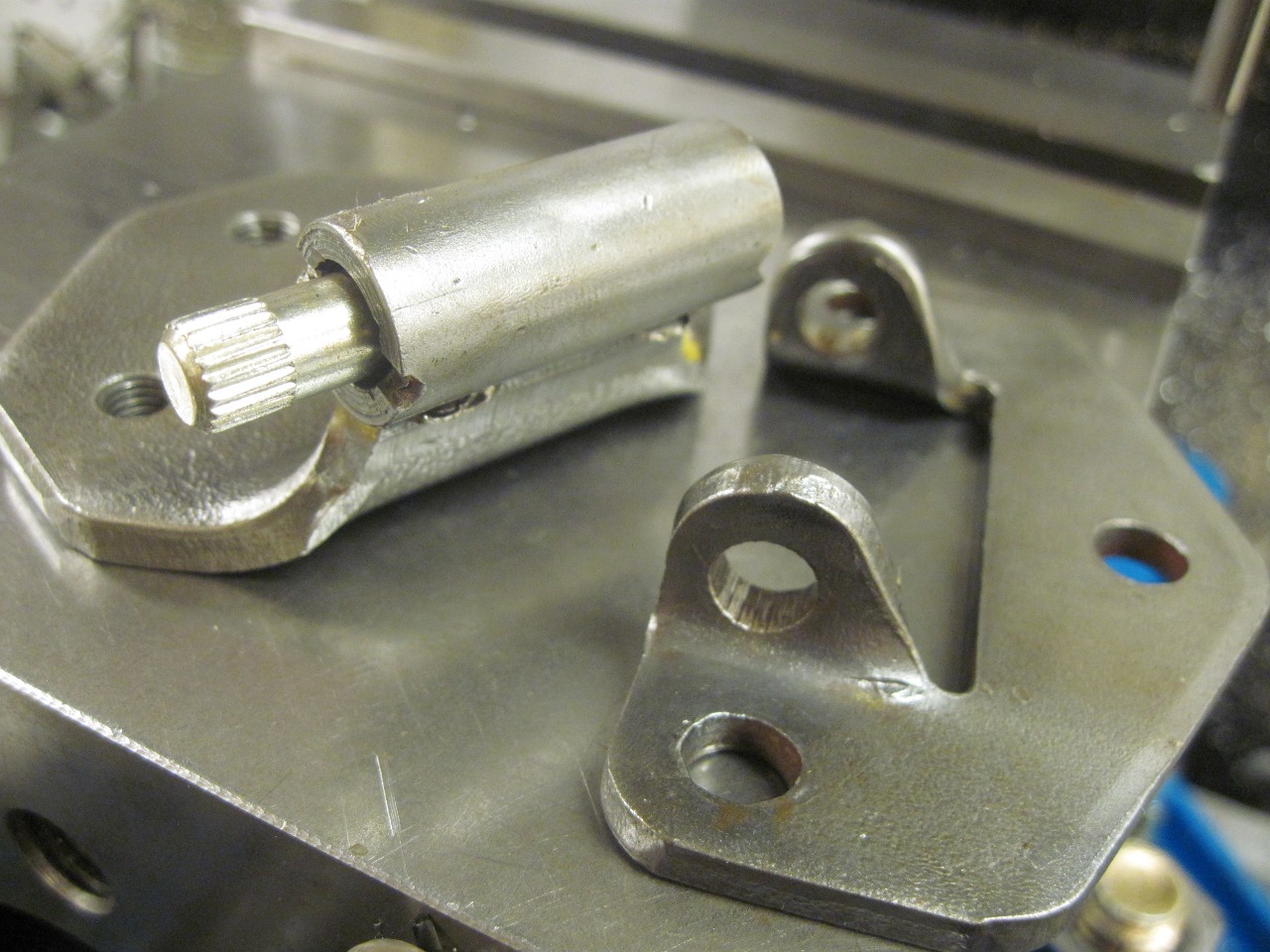

The hinge pins are held in the door

side of the hinge by a pressed in spline. They didn't come out

willingly, but only with generous amounts of heat and violence.

I

also discovered why one of the hinges was especially floppy. The

hinge pin was broken just below the splined section. I couldn't

drive it out because the larger part of the pin wouldn't stay aligned

with the broken part. I ended up welding a small bar to the top

of the splined part so I could extract it. The rest of the pin

then came out easily.

I

couldn't find any replacement hinge pins in the US, but they seem to be

readily available in the UK, so I ordered some from there. The

pins, being aftermarket items, had some issues. First, they were

slightly oversized. I don't think the description of the pins

said they were oversized, but this ended up working in my favor.

The original pins still measured very close to 0.3125",

which is probably what they were when new (5/16" pins). But now

they were a little loose in their worn bores. The pins were very

hard, which explains both their durability and their brittleness.

I was prepared to sleeve the hinges to restore the nominal

5/16" bore, but the oversized pins made that unecessary.

The

second issue with the new pins is that they varied a little in

diameter, between about 0.315" and 0.316", but none of them would slide

into the hinge bores. That meant I could just ream the hinges to

accommodate the new pins. I bought both a 0.316" and a 0.317"

reamer, and hand fitted the pins to the reamed holes with the minimum

clearance to give smooth operation.

I also noticed that the new

pins were hard, but not as hard as the originals. This might be a

good thing, too, considering the broken original pin.

I

was able to adjust the ears on the door half of the hinge to minimize

up and down play by just squeezing them together in a vice. I

then ran the reamer down through the two ears to make sure the holes

were still colinear. I then drilled a 1/8" hole in each hinge

barrel as an additional lubrication point, then powder coated the hinge

bodies. This will be primed and overcoated with body color later.

The original hardware was still in excellent shape.

A favorite lube for things like this is a mix of STP and a moly loaded lithium grease.

Then pressed in the pins, and these dudes are ready for prime time.

The

pins and reamers came to a little over half what new hinges would have

cost, so I didn't save a lot of money on this job, but it was sort of

fun, and it keeps the car that much more original.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages